Polymeric composite material and preparation method thereof

A composite material and polymer technology, which is applied in the field of polymer composite materials and its preparation, can solve problems such as waste and filler agglomeration, and achieve the effects of simple and easy operation, good monodispersity and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a polymer composite material, realized by the following scheme: Accurately weigh 0.004g of graphene, add acetone and ultrasonically disperse it in 39.996g of epoxy resin, and obtain epoxy resin-graphene matrix by ultrasonic for 2 hours material. Weigh 0.1g-7g of the masterbatch, ultrasonically disperse it in 39.9g-30g of epoxy resin to obtain a mixed solution, put the mixed solution together with zirconia balls into a PTFE ball mill tank with a volume of 100ml, each Among them, the mass ratio of zirconia grinding balls to the mixed liquid is 6.25:1, and the diameter of the balls is 1 mm to 4 mm. Put the polytetrafluoroethylene ball mill tank filled with the mixed liquid symmetrically into the planetary ball mill for ball milling at a speed of 300 rpm After 24 hours, a graphene-epoxy resin composite material (filler content obtained: 0.25-17.5 ppm) was obtained.

Embodiment 2

[0039]A method for preparing a polymer composite material, realized by the following scheme: Accurately weigh 0.004g of graphene, add acetone and ultrasonically disperse it in 39.996g of epoxy resin, and pack the mixed solution with zirconia balls after ultrasonication for 30min Put it into a polytetrafluoroethylene ball mill tank with a volume of 100ml. In each portion, the mass ratio of zirconia balls to the mixed solution is 6.25:1, and the diameter of the ball is 1mm to 4mm. The jars were symmetrically put into a planetary ball mill and ball-milled at a speed of 300 rpm for 24 hours to obtain an epoxy resin-graphene masterbatch. Weigh 0.1g-7g of the masterbatch, ultrasonically disperse it in 39.9g-30g of epoxy resin to obtain a mixed solution, put the mixed solution together with zirconia balls into a PTFE ball mill tank with a volume of 100ml, each Among them, the mass ratio of zirconia grinding balls to the mixed liquid is 6.25:1, and the diameter of the balls is 1 mm to...

Embodiment 3

[0043] A method for preparing a polymer composite material is realized through the following scheme: accurately weigh 0.004 g of graphene, disperse it in 39.06 g of unsaturated resin, and obtain an unsaturated resin-graphene masterbatch by ultrasonication for 2 hours. Weigh 0.1g-7g of masterbatch, ultrasonically disperse in 39.9g-30g of unsaturated resin to obtain a mixed solution, put the mixed solution together with zirconia balls into a PTFE ball mill tank with a volume of 100ml, each Among them, the mass ratio of zirconia grinding balls to the mixed liquid is 6.25:1, and the diameter of the balls is 1 mm to 4 mm. Put the polytetrafluoroethylene ball mill tank filled with the mixed liquid symmetrically into the planetary ball mill for ball milling at a speed of 300 rpm After 24 hours, a graphene-unsaturated resin composite material was obtained. (The obtained filler content is: 0.25~17.5ppm).

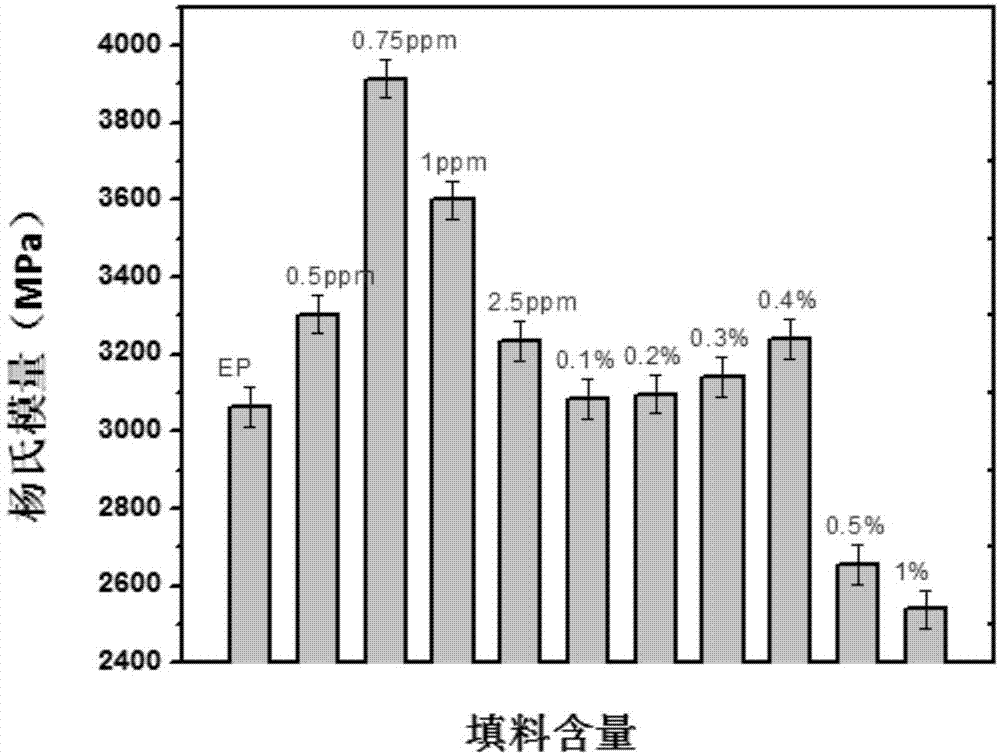

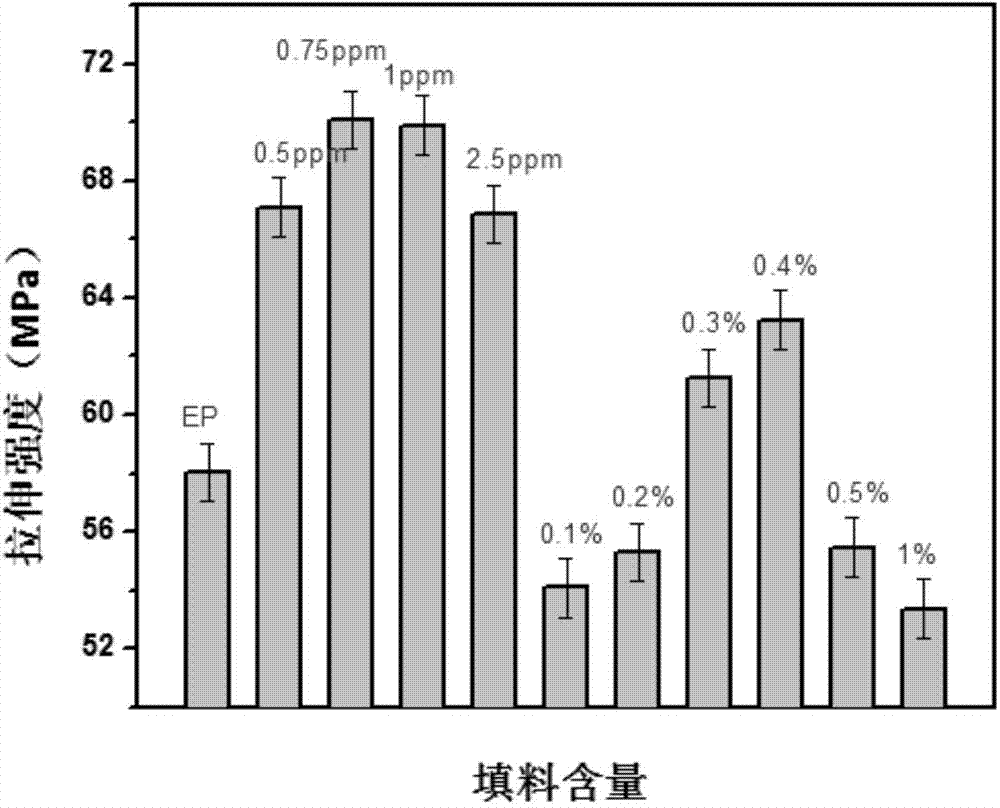

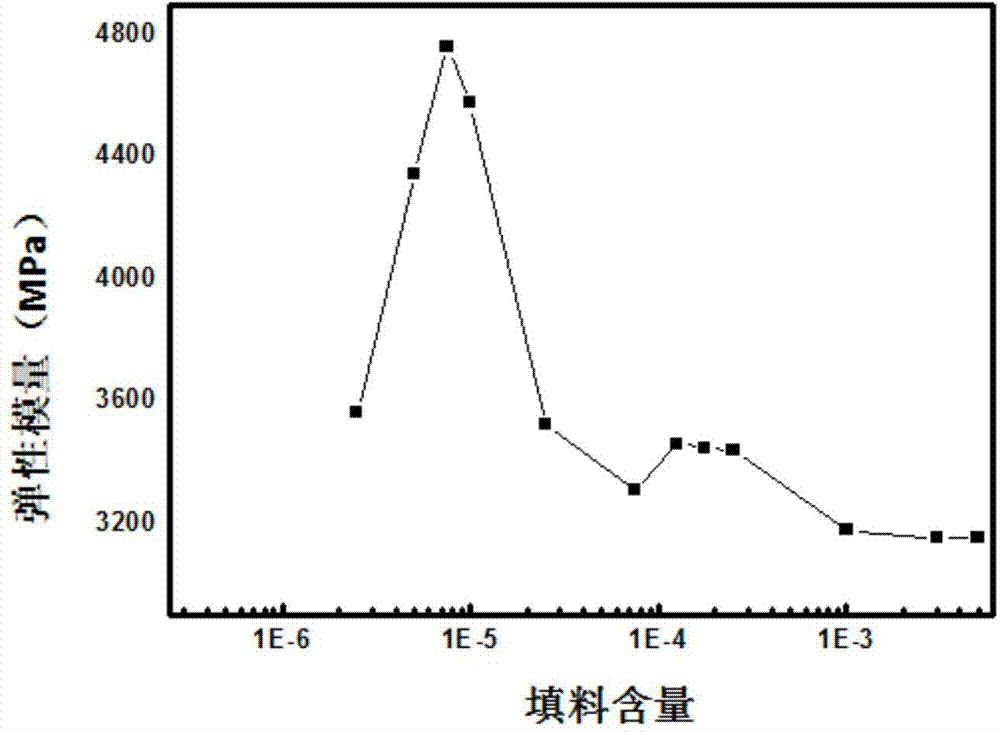

[0044] The following table 1 is the elastic modulus and tensile properties tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com