Fatigue resistant rubber additive

A fatigue-resistant rubber and additive technology, applied in the field of rubber materials, can solve the problems of reduced mechanical properties, cracks, and fractures of materials, and achieve the effects of reducing the degree of agglomeration, improving compatibility, and improving heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

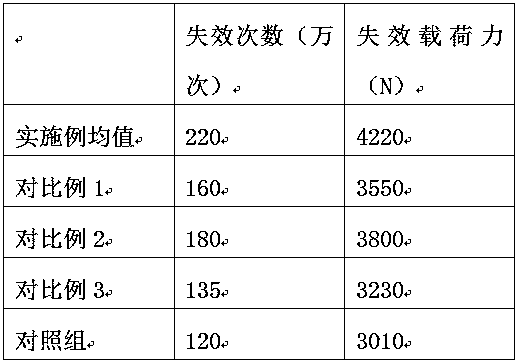

Examples

Embodiment 1

[0018] A fatigue-resistant rubber additive is obtained by modifying a mixture of nanocellulose and graphene with polycyclic amines, and the nanocellulose and graphene are mixed in a mass ratio of 10:1.3.

[0019] Further, the preparation method of polycyclic amine modified nano-cellulose and graphene mixture comprises the following steps:

[0020] (1) Uniformly disperse the nanocellulose in deionized water to obtain a nanocellulose dispersion, adjust the pH of the nanocellulose dispersion to 10.2, heat it in a water bath to 85°C, keep it warm for 30 minutes, and then perform rotary evaporation and drying to obtain a pretreated nanocellulose cellulose;

[0021] (2) Disperse graphene evenly in deionized water to obtain a graphene dispersion, add 0.1% of its mass oxidant to the graphene dispersion, heat it in a water bath to 75 ° C, keep it for 40 minutes, and then perform rotary evaporation and drying to obtain the pre- processing graphene;

[0022] (3) Dissolve polycyclic ami...

Embodiment 2

[0030] A fatigue-resistant rubber additive is obtained by modifying a mixture of nanocellulose and graphene with polycyclic amines, and the nanocellulose and graphene are mixed in a mass ratio of 10:1.5.

[0031] Further, the preparation method of polycyclic amine modified nano-cellulose and graphene mixture comprises the following steps:

[0032] (1) Uniformly disperse the nanocellulose in deionized water to obtain a nanocellulose dispersion, adjust the pH of the nanocellulose dispersion to 10.2, heat it in a water bath to 85°C, keep it warm for 30 minutes, and then perform rotary evaporation and drying to obtain a pretreated nanocellulose cellulose;

[0033] (2) Disperse graphene evenly in deionized water to obtain a graphene dispersion, add 0.1% of its mass oxidant to the graphene dispersion, heat it in a water bath to 75 ° C, keep it for 40 minutes, and then perform rotary evaporation and drying to obtain the pre- processing graphene;

[0034] (3) Dissolve polycyclic ami...

Embodiment 3

[0042] A fatigue-resistant rubber additive is obtained by modifying a mixture of nanocellulose and graphene with polycyclic amines, and the nanocellulose and graphene are mixed in a mass ratio of 10:1.4.

[0043] Further, the preparation method of polycyclic amine modified nano-cellulose and graphene mixture comprises the following steps:

[0044] (1) Uniformly disperse the nanocellulose in deionized water to obtain a nanocellulose dispersion, adjust the pH of the nanocellulose dispersion to 10.2, heat it in a water bath to 85°C, keep it warm for 30 minutes, and then perform rotary evaporation and drying to obtain a pretreated nanocellulose cellulose;

[0045] (2) Disperse graphene evenly in deionized water to obtain a graphene dispersion, add 0.1% of its mass oxidant to the graphene dispersion, heat it in a water bath to 75 ° C, keep it for 40 minutes, and then perform rotary evaporation and drying to obtain the pre- processing graphene;

[0046] (3) Dissolve polycyclic ami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com