Preparation method of tough alumina ceramic membrane

A technology of alumina ceramic membrane and toughness, which is applied in the field of preparation of tough alumina ceramic membrane, can solve the problems of low membrane toughness, small processing area and complicated process of alumina ceramic membrane, and achieves high toughness, uniform structure, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

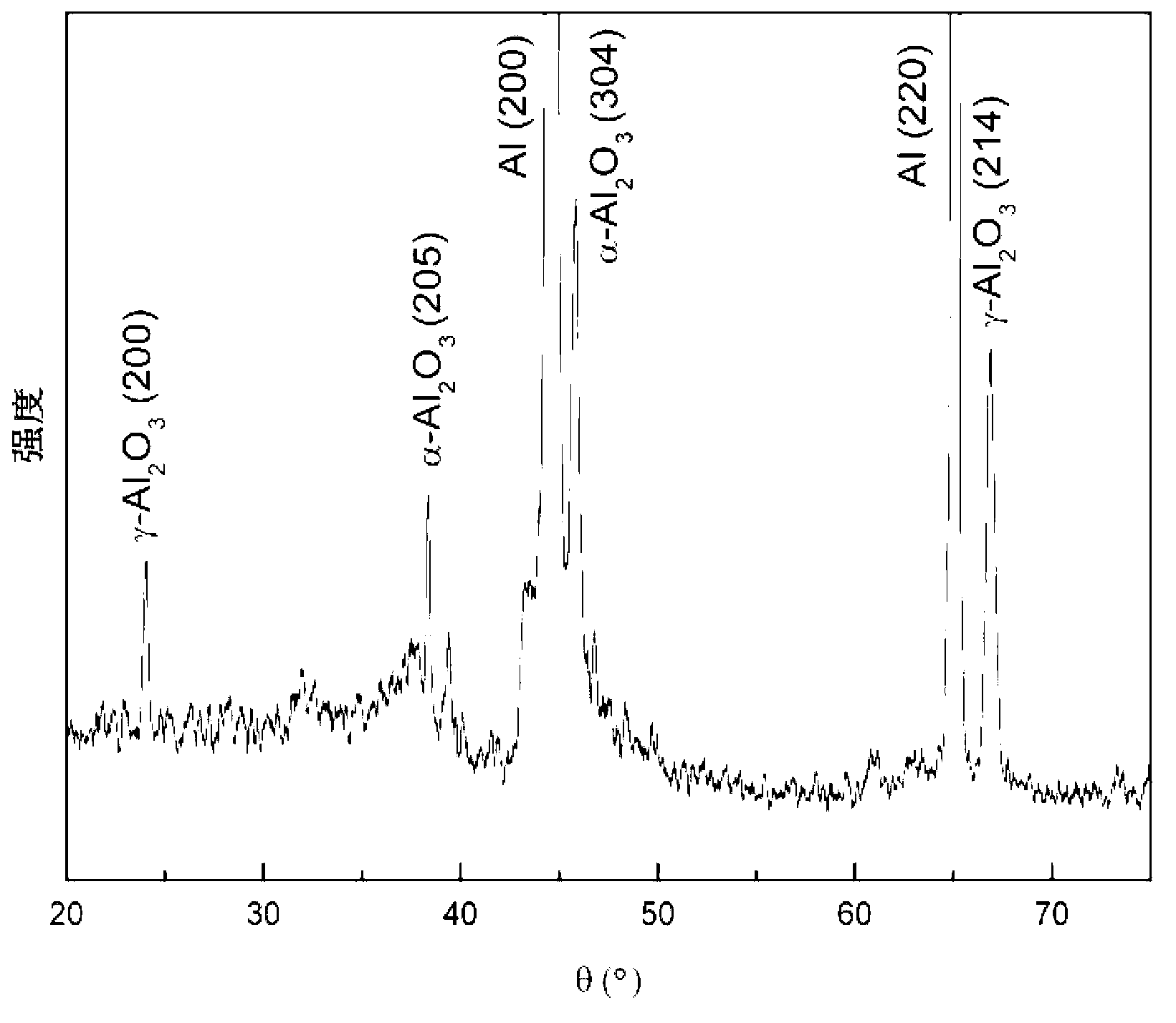

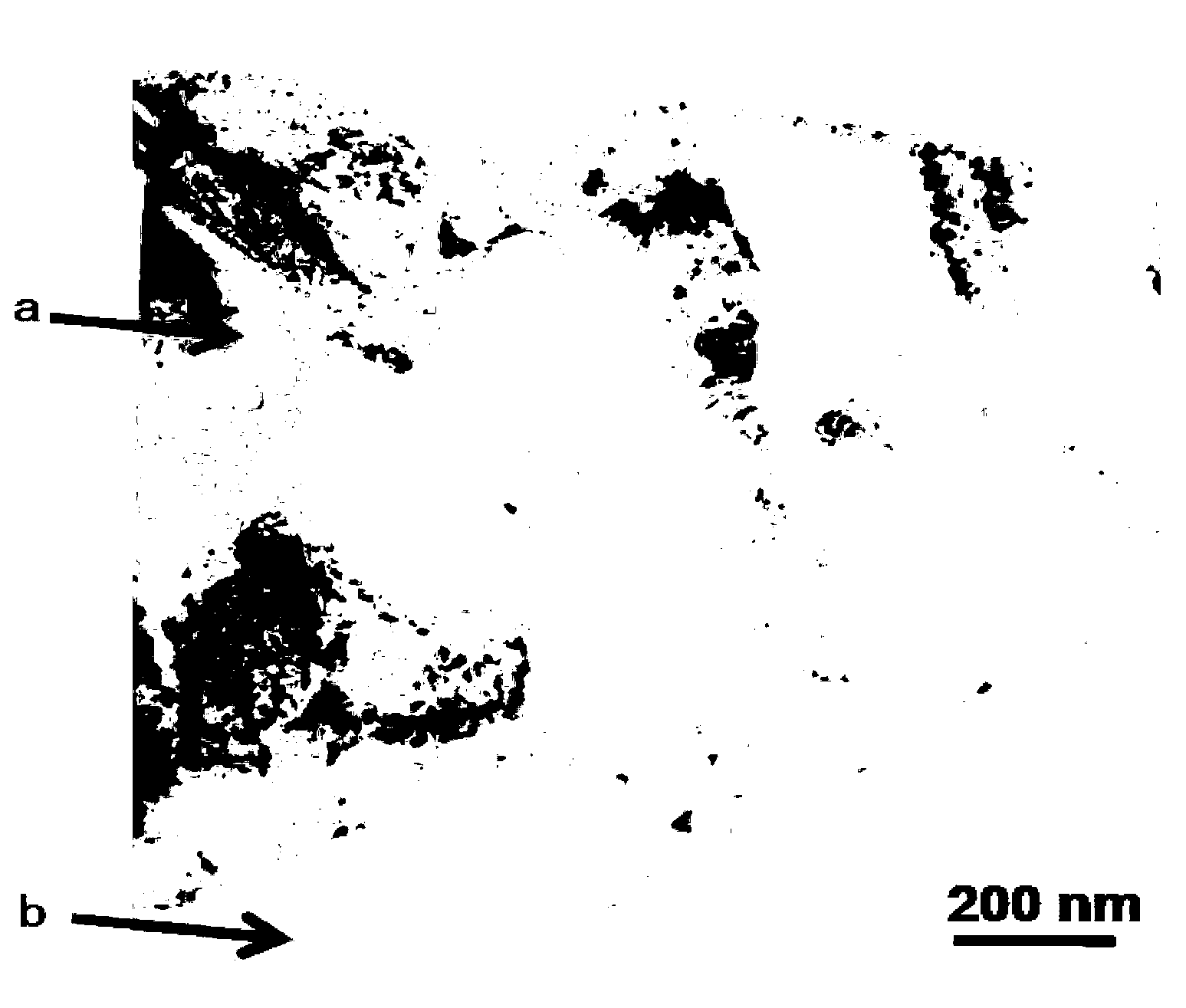

Image

Examples

specific Embodiment approach 1

[0011] Specific embodiment one: the preparation method of a kind of ductile aluminum oxide ceramic film of this embodiment is to carry out through the following steps: 1, prepare weakly alkaline electrolyte, weakly alkaline electrolyte is made up of alkaline regulator and spark regulator 2. Aluminum alloy is placed in the tank body filled with the weakly alkaline electrolyte prepared by step 1, wherein the anode is aluminum alloy, and the negative electrode is stainless steel or graphite material, then the power supply is oxidized with liquid phase plasma, at current density Oxidation for 1-12 minutes under the condition of 0.02-0.14A / cm2; 3. Rinse and dry the aluminum alloy treated in step 3 to obtain a tough alumina ceramic film; wherein the spark control agent in step 1 is rare earth Salt; the final concentration of the alkaline regulator in the weak alkaline electrolyte is 1-30g / L, and the final concentration of the spark regulator is 1-20g / L.

[0012] In this embodiment, ...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the alkaline regulator in step 1 is a mixture of one or more of metaaluminate, sodium hydroxide or phosphate in any ratio . Other steps and parameters are the same as in the specific embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the rare earth salt is cerium nitrate, lanthanum nitrate, ytterbium nitrate or yttrium nitrate. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com