Miniature high-pressure electromagnetic valve

A high-pressure solenoid valve and miniature technology, which is applied in the field of solenoid valves, can solve the problems of complex structure, short service life, and small magnetic field force of solenoid valves, and achieve the effects of increasing strength, controlling high temperature, and increasing suction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

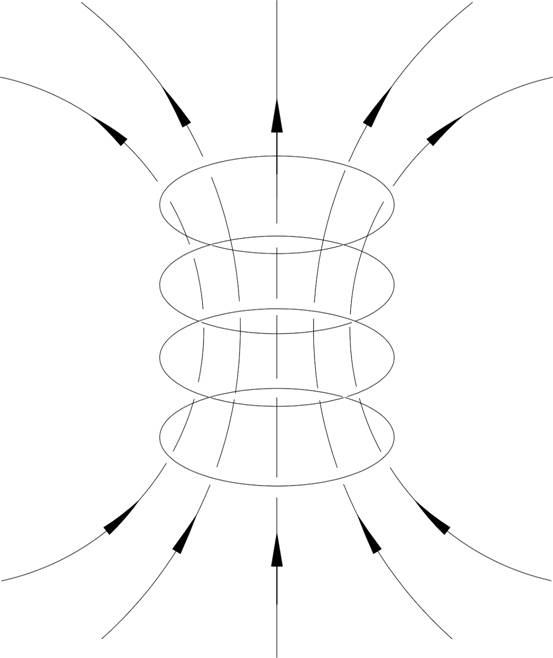

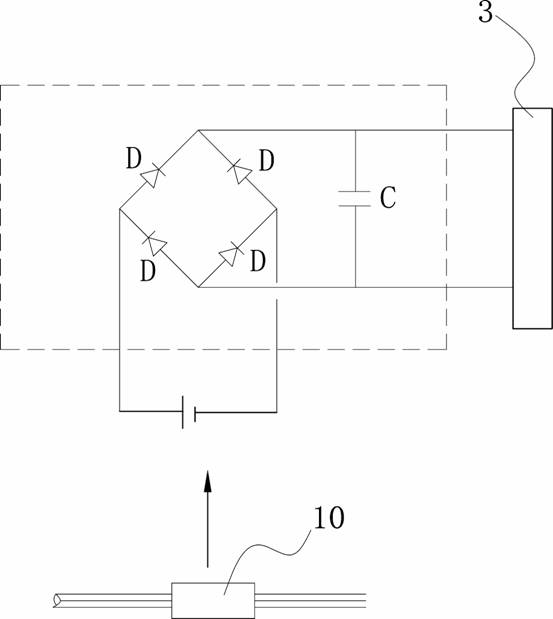

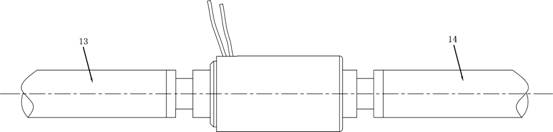

[0038] refer to Figure 1 to Figure 9 , The present invention provides a miniature high-voltage solenoid valve, which includes a coil bobbin 1 made of metal, a fixed iron core 2 fixed at one end of the coil bobbin 1 and a coil winding 3 installed on the coil bobbin 1 .

[0039] refer to figure 1 with Figure 4 One end of the fixed iron core 2 facing the bobbin 1 is provided with a threaded portion 201 , and the threaded portion 201 extends into the bobbin 1 and is screwed to the bobbin 1 . The fixed iron core 2 is threadedly connected with the coil frame 1, and the screw threads are used for positioning and fixing. The strength of the steel connection between the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com