Seal ring with streamline groove end face and mechanical seal device

A sealing ring, streamlined technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of large fluid film stiffness and opening force, cannot be obtained, cannot be active, etc., to achieve large opening force and stiffness and load capacity , Good end surface hydrodynamic pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

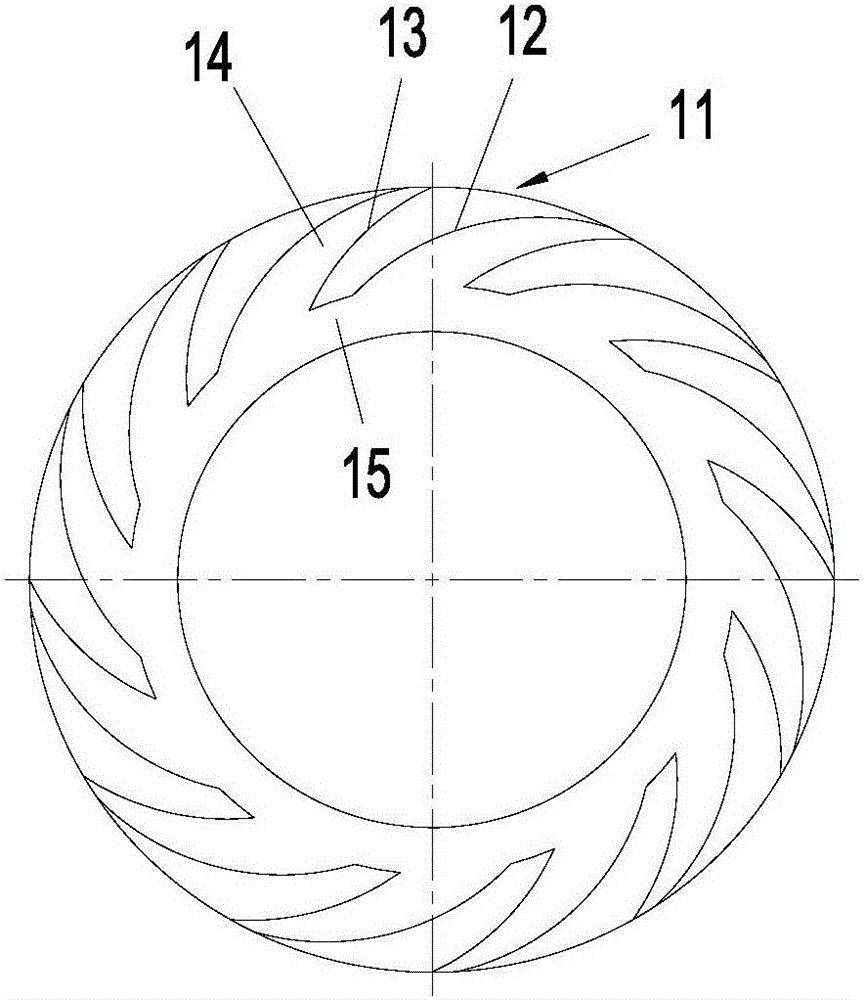

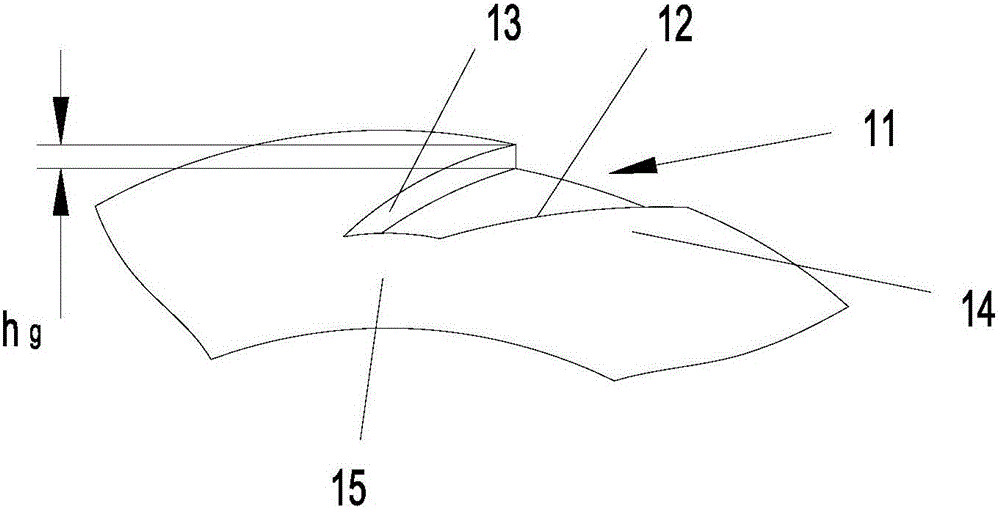

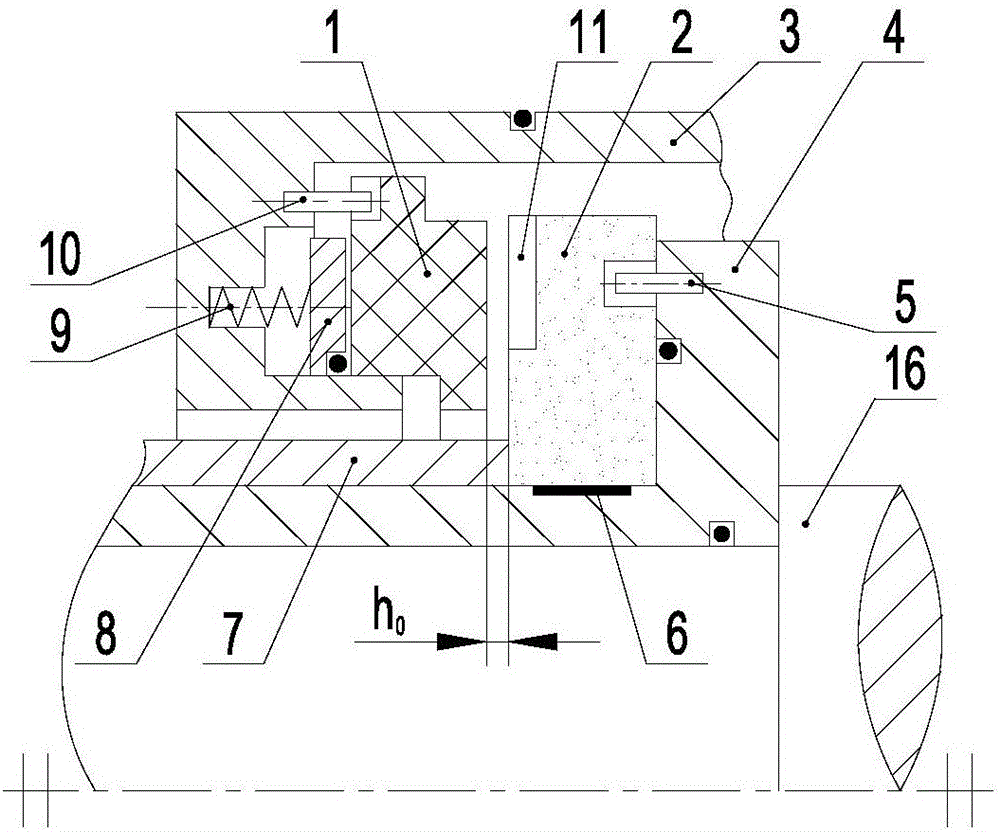

[0021] Such as figure 1 and figure 2 Shown is a structure of the sealing ring with a streamlined groove end face of the present invention, and 8 to 18 isolation parts 14 (ie weir areas) of the same form with the height of the end plane are separated into a uniform arrangement on the sealing end face. The groove 11. The centerline of the groove 11 is arranged along the streamline track where the particles of the sealing fluid flow inward from the periphery of the sealing ring, and the opening of the groove 11 can be located on the pressure upstream side or the pressure downstream side of the fluid film on the sealing end surface. When the opening of the groove 11 is located on the upstream side of the pressure of the fluid film, the bearing capacity of the fluid film on the sealing end surface can be increased, and it is widely used. When the opening of the groove 11 is located on the downstream side of the pressure of the fluid film, the pressure of the sealing end surface c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com