Hydrodynamic-hydrostatic pressure combined face seal device

An end-face sealing and combined technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., to reduce starting resistance, reducing starting power and friction and wear, and reducing end face deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

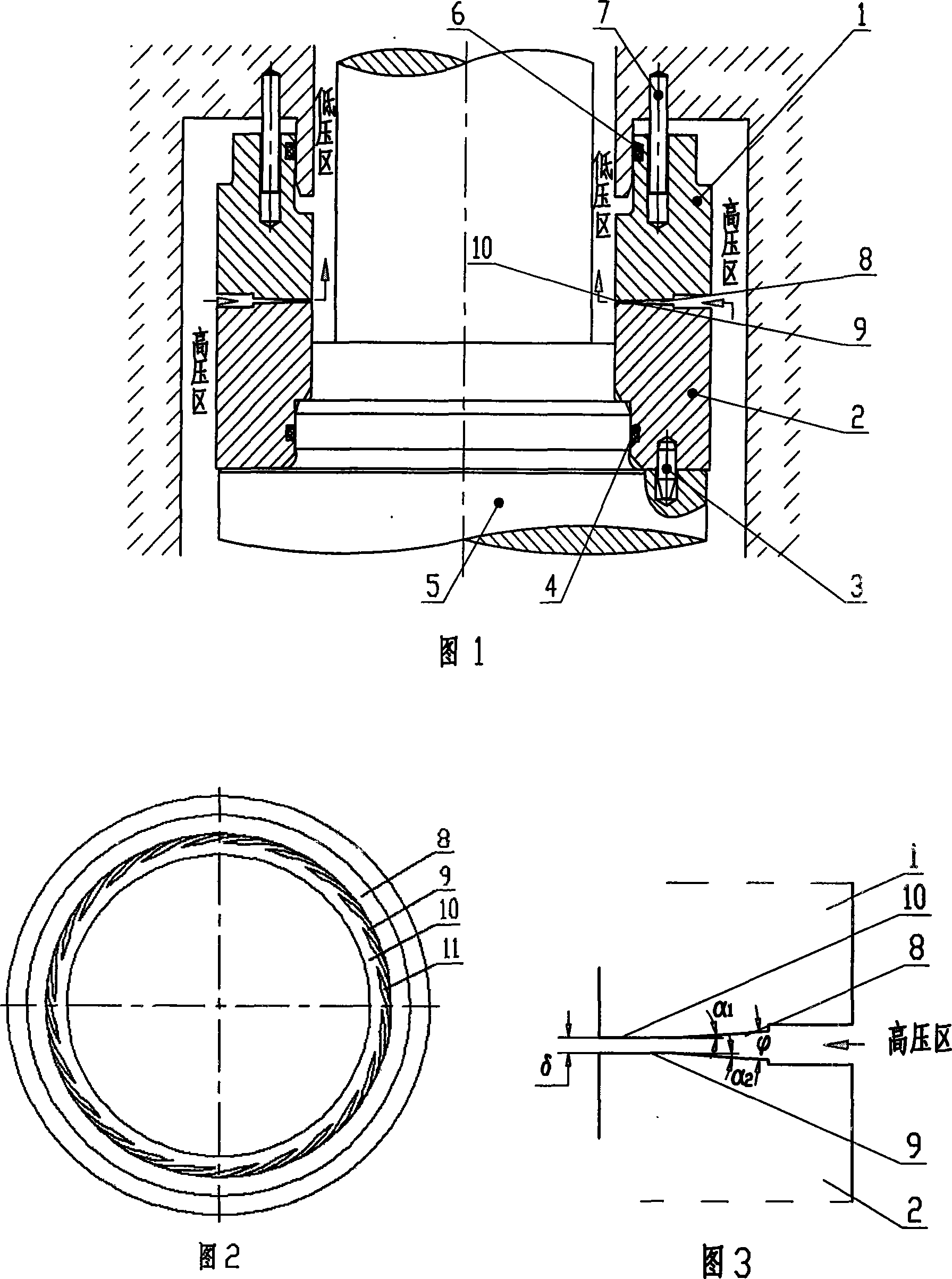

[0017] As shown in Figures 1 and 3, the structure of the dynamic and static pressure combined end face seal device of the present invention includes a static ring 1 fixedly connected to the static part of the sealing part through the anti-rotation pin 7, and a static ring 1 connected to the rotating shaft or shaft through the transmission pin 3. The rotating body unit 5 such as the sleeve is connected to the moving ring 2 that can rotate therewith. On the opposite sealing end faces of the static ring 1 and the moving ring 2, three concentric ring-shaped end face sealing areas are respectively arranged in a corresponding manner from the outside to the inside: the radial outer side is adjacent to the high pressure area The area in the middle part is a convergent gap static pressure sealing ring area 8 that can open outwards between the corresponding areas on both sides of the dynamic and static rings; The dynamic pressure sealing ring area 9; the innermost area in the radial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com