Device and method for optimizing power plant condensate polishing operation control

A condensate fine treatment and operation control technology, which is applied in water treatment parameter control, natural water body treatment, water/sewage treatment, etc., can solve the problems of increasing the work intensity of operating personnel, heavy operating burden of the fine treatment system, and accelerated resin performance degradation, etc. problems, to achieve the effect of reducing wastewater discharge, improving water quality in power plants, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings and specific implementation process.

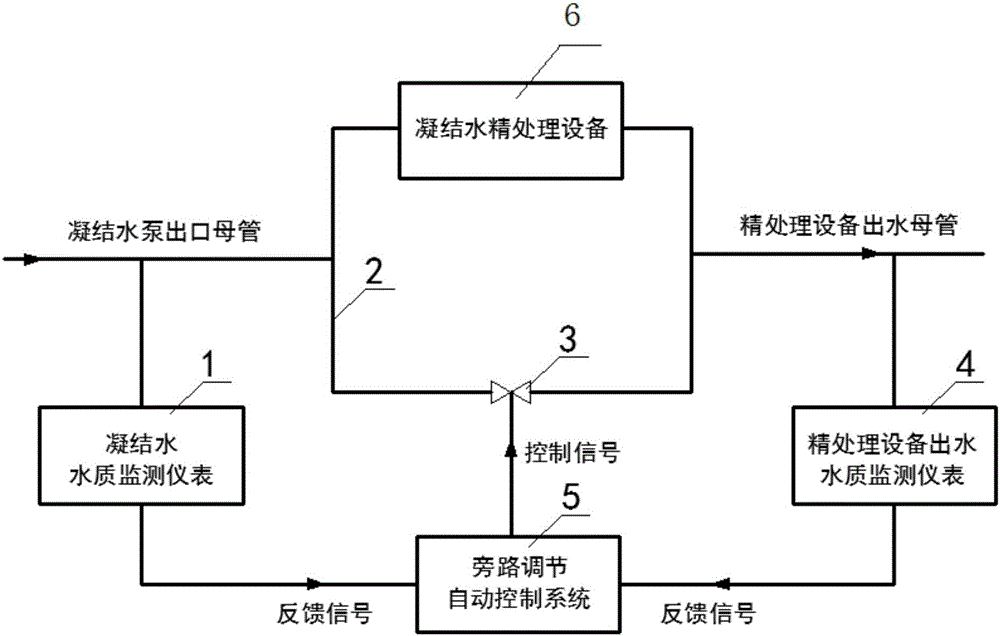

[0019] The device of the present invention includes a condensate water quality monitoring instrument 1 connected to the outlet main pipe of the condensate pump in a power plant and a condensate polishing equipment 6, and a bypass pipeline 2 with a control valve 3 is connected in parallel to the condensate polishing equipment 6 , the outlet jelly pipe of the condensate fine treatment equipment 6 is equipped with a fine treatment equipment effluent water quality monitoring instrument 4, the feedback signal of the condensate water quality monitoring instrument 1 and the effluent water quality monitoring instrument 4 of the fine treatment equipment is sent to the bypass adjustment automatic control system 5 , the control output of the bypass regulation automatic control system 5 is connected with the control valve 3 .

[0020] The condensed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com