Movement mechanism of waxen image carving machine

A technology of motion mechanism and engraving machine, which is applied in decorative art, processing models, etc., can solve the problem of not being able to process full-dimensional statues, etc., and achieve the effect of reducing manufacturing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

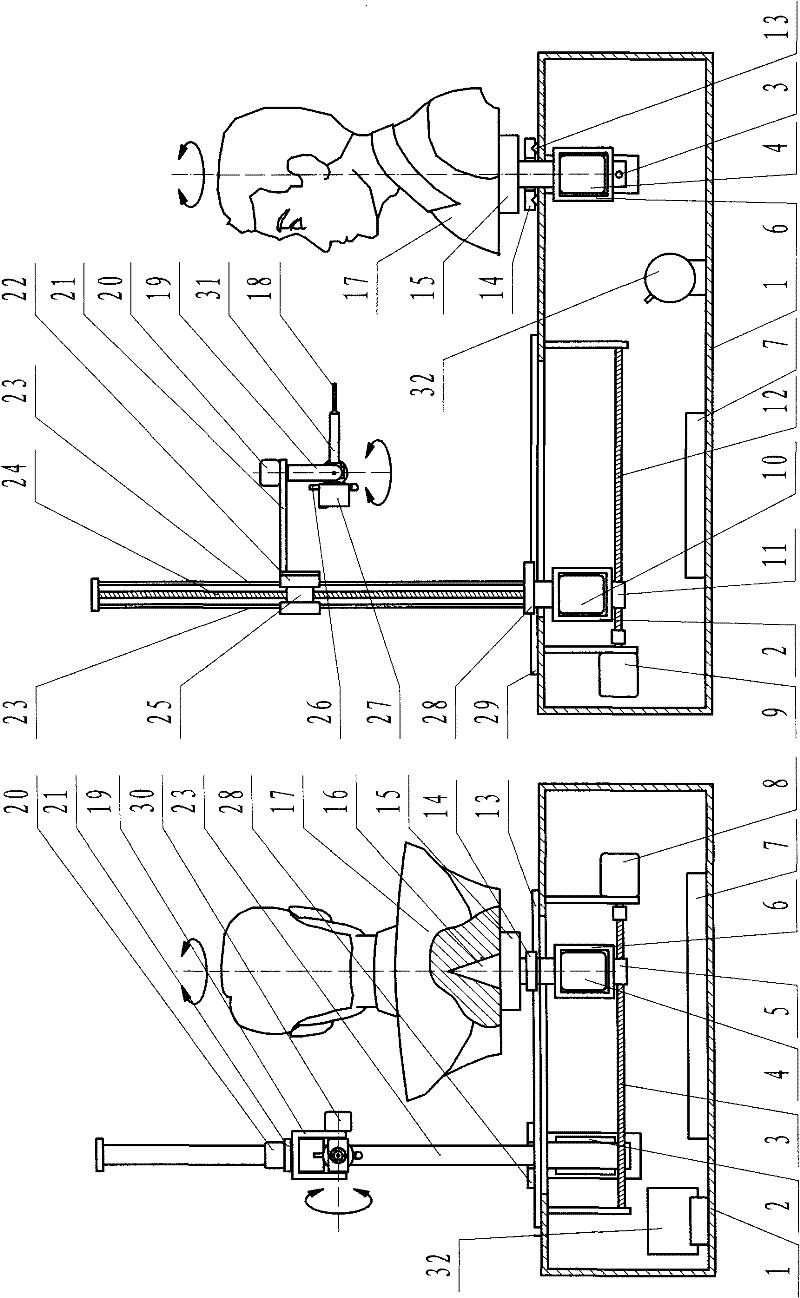

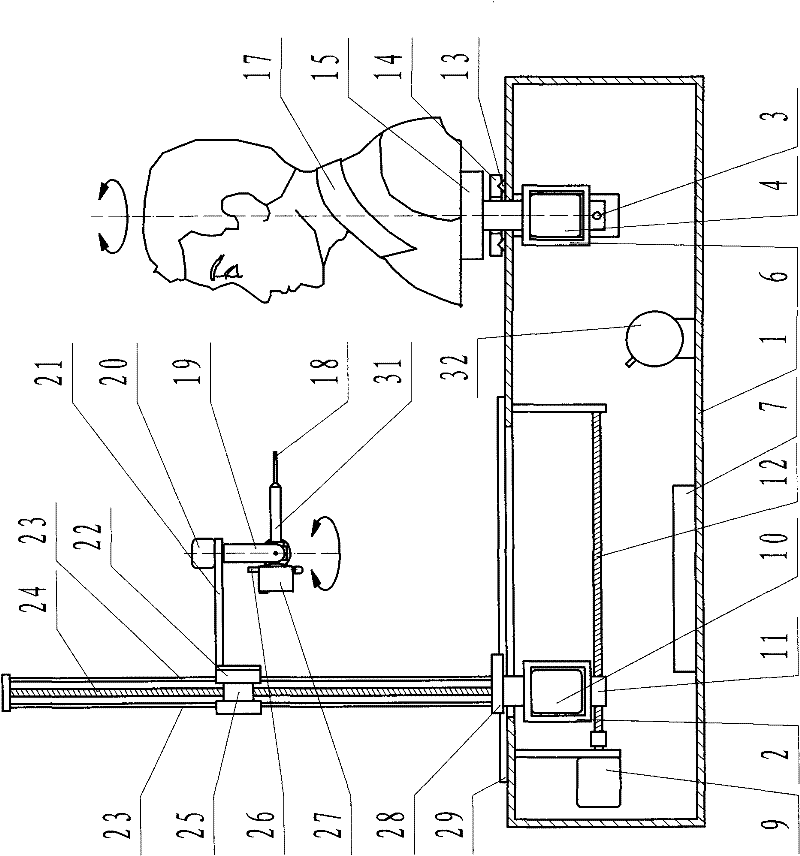

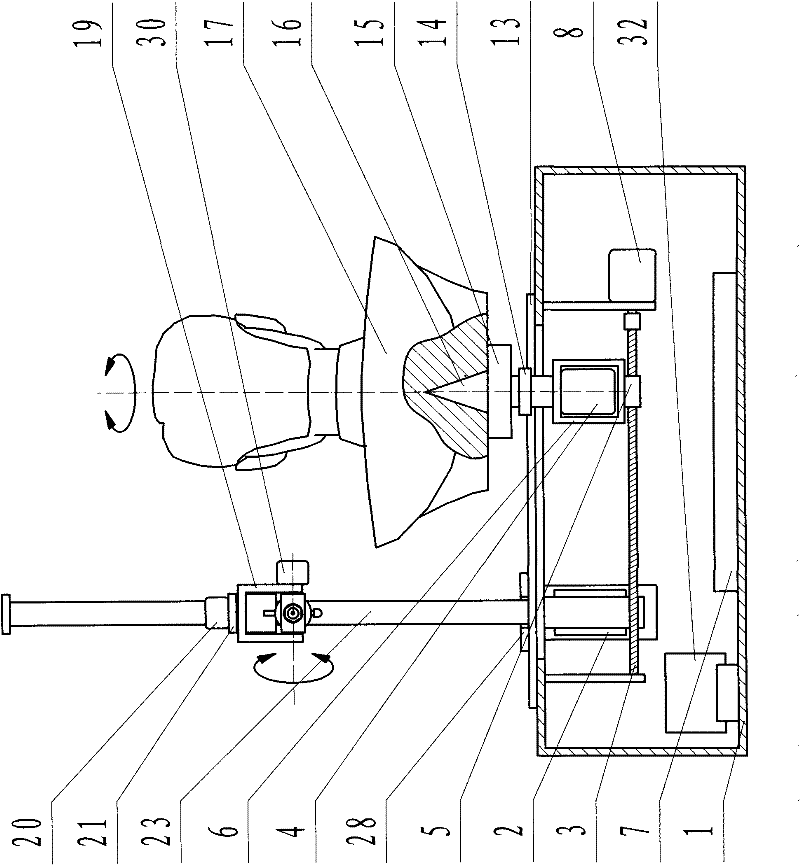

[0020] Below in conjunction with accompanying drawing and embodiment this patent is described further.

[0021] 5.1 Structure

[0022] Tool rest Y direction driving motor (9) is housed in the casing (1), and its axis links to each other with Y direction driving leading screw (12), and this leading screw (12) is with Y direction driving screw nut (11). Fix Z direction driving motor seat (2) on this screw nut (11), install Z direction driving motor (10) in the seat, this seat (2) is also fixed with Y direction slide block (28), Y direction slide block ( 28) form the Y direction guide rail slider pair with the Y direction guide rail (29).

[0023] The axis of the Z-direction drive motor (10) links to each other with the Z-direction drive screw (24), which is covered with a Z-direction drive screw nut (25). On the Y direction slide block (28), a Z direction guide rail (23) is also equipped with in parallel with the Z direction drive screw (24), and this guide rail (23) forms a Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com