A mold laser engraving machine

A laser engraving machine and mold technology, applied in the field of laser engraving machines, can solve the problems of large volume and weight, low work efficiency, increased cost, etc., and achieve the effect of small size, saving cost and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

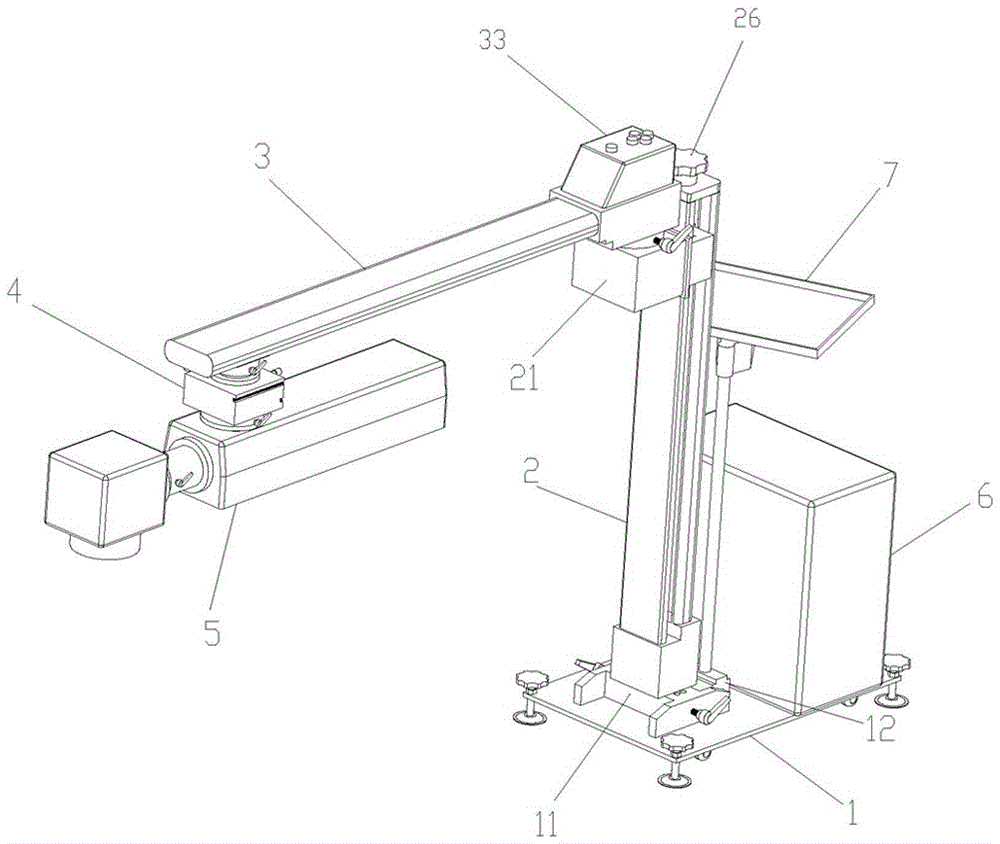

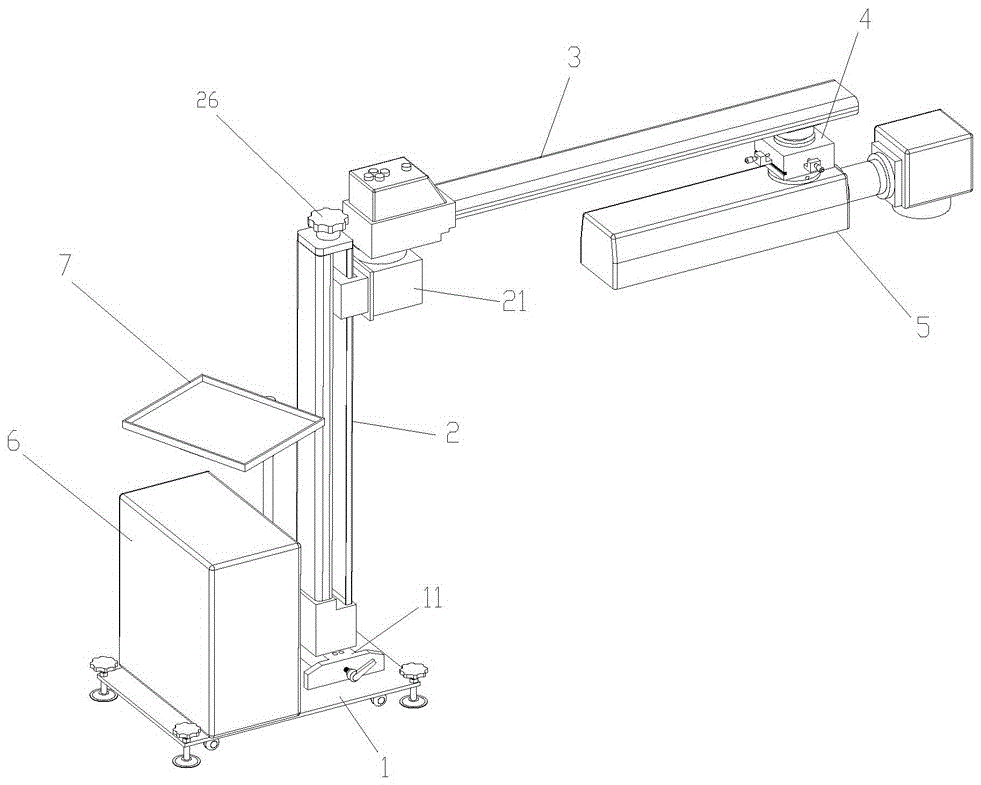

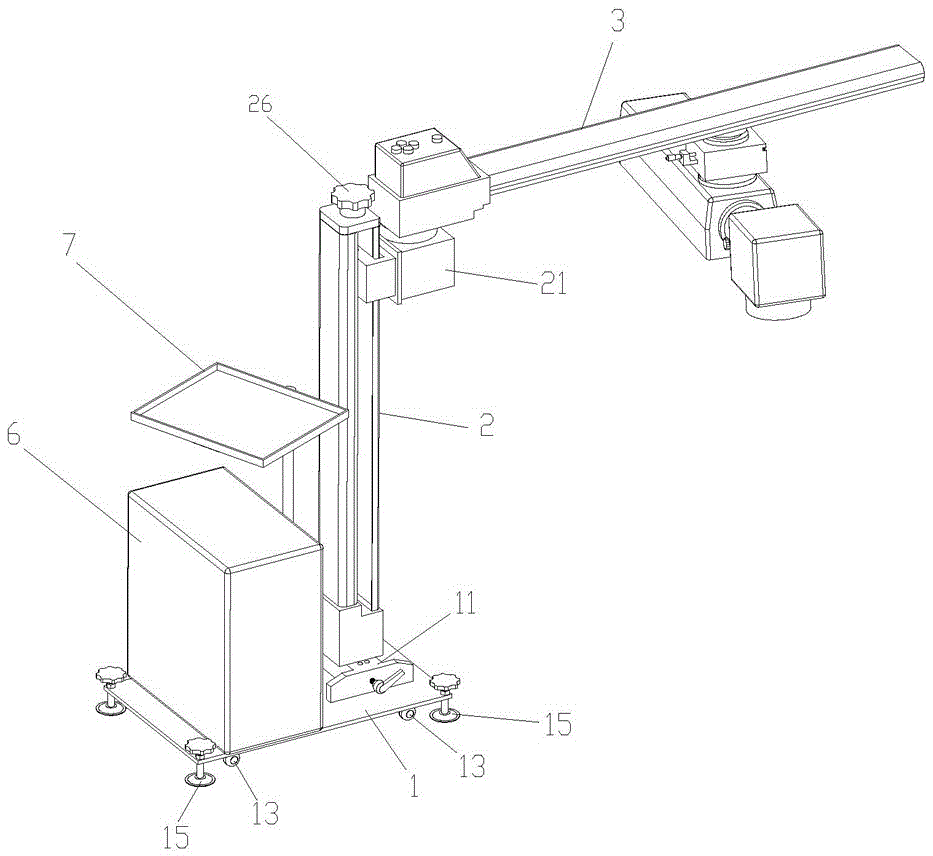

[0025] Such as Figure 1-9 As shown, a mold laser engraving machine includes a base 1, a longitudinal drive mechanism 2, a transverse drive mechanism 3, a fine-tuning connection block 4, a laser head 5 and a main box 6, and several universal wheels are arranged at the bottom of the base 1 13 and a horizontal adjustment support 15, the main chassis 6 is placed on the base 1, and a longitudinal connection seat 2 is arranged on the base 1, and the bottom of the longitudinal drive mechanism 2 is inserted on the longitudinal connection seat 11, and the horizontal drive mechanism 3 The end of the laser head 5 is connected to the horizontal slide block 31 of the horizontal drive mechanism 3 through the fine-tuning connection block 4, and the laser head 5 is connected to the longitudinal slider 21 of the longitudinal drive mechanism 2 through the rotating shaft 32 and the bearing. The main chassis 6 are also connected through cables and optical fibers.

[0026] A computer platform 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com