Five-axis linkage carving machine for processing redwood furniture

A five-axis linkage, mahogany furniture technology, applied in the direction of engraving, processing models, decorative arts, etc., can solve the problems of increased manufacturing costs, waste of resources, huge rack structure, etc., to improve efficiency and accuracy, improve processing accuracy, optimize The effect of the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

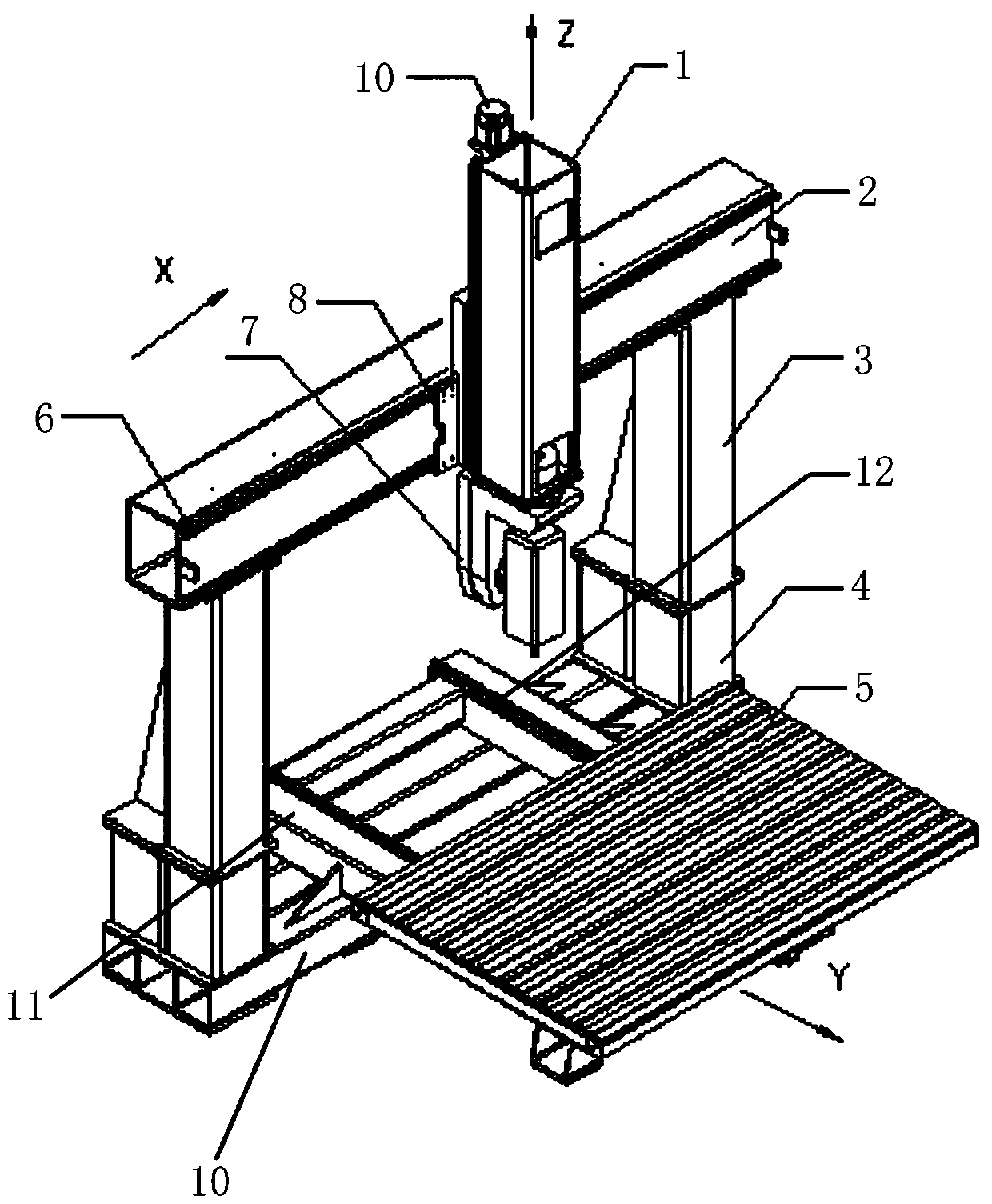

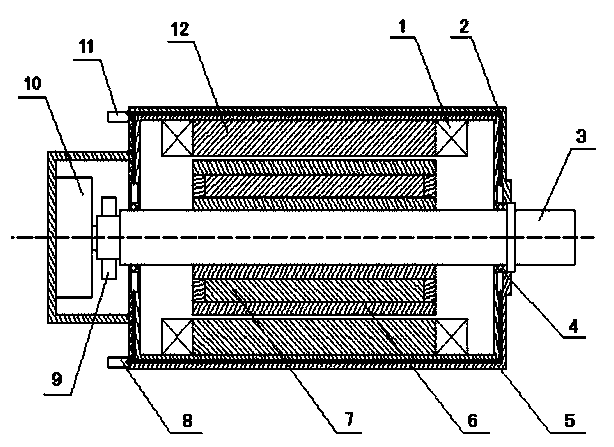

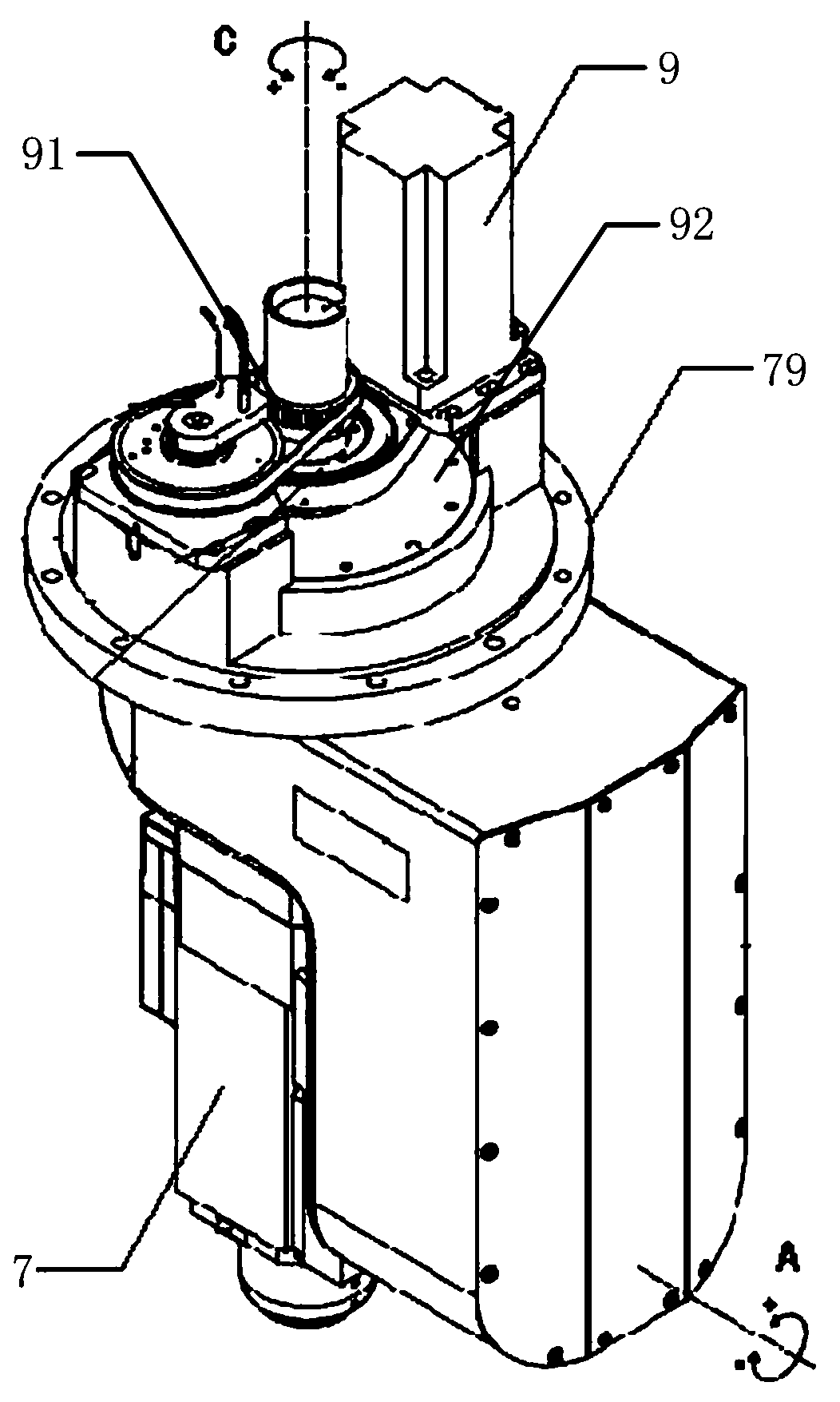

[0028] The embodiment of the five-axis linkage engraving machine in the present invention will be further described with reference to the accompanying drawings.

[0029] As shown in the drawings, this embodiment is a five-axis linkage engraving machine used for mahogany furniture processing, including a gantry chassis 10 formed by overlapping multiple stainless steel square tubes, above the gantry chassis Two square guide bars 11 are fixed by triangular reinforcing steel bars, and the two guide bars are arranged parallel to each other. A workbench 5 is set up above the two guide bars, and the guide bars are fixed on the gantry chassis by welding. After welding, a secondary tempering treatment is required to remove the stress, and then the workers use milling cutters to finish the welding position to improve the structural rigidity of the woodworking engraving machine frame. The sliding connection between the workbench and the guide bar is realized by a ball screw 12, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com