Novel vertical numerical-control engraving machine

A CNC engraving machine and vertical technology, applied in the field of engraving machines, can solve the problems of inconvenient disassembly and assembly, large amount of feed, low work efficiency, etc., and achieve the effects of reducing labor intensity, reducing processing errors, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

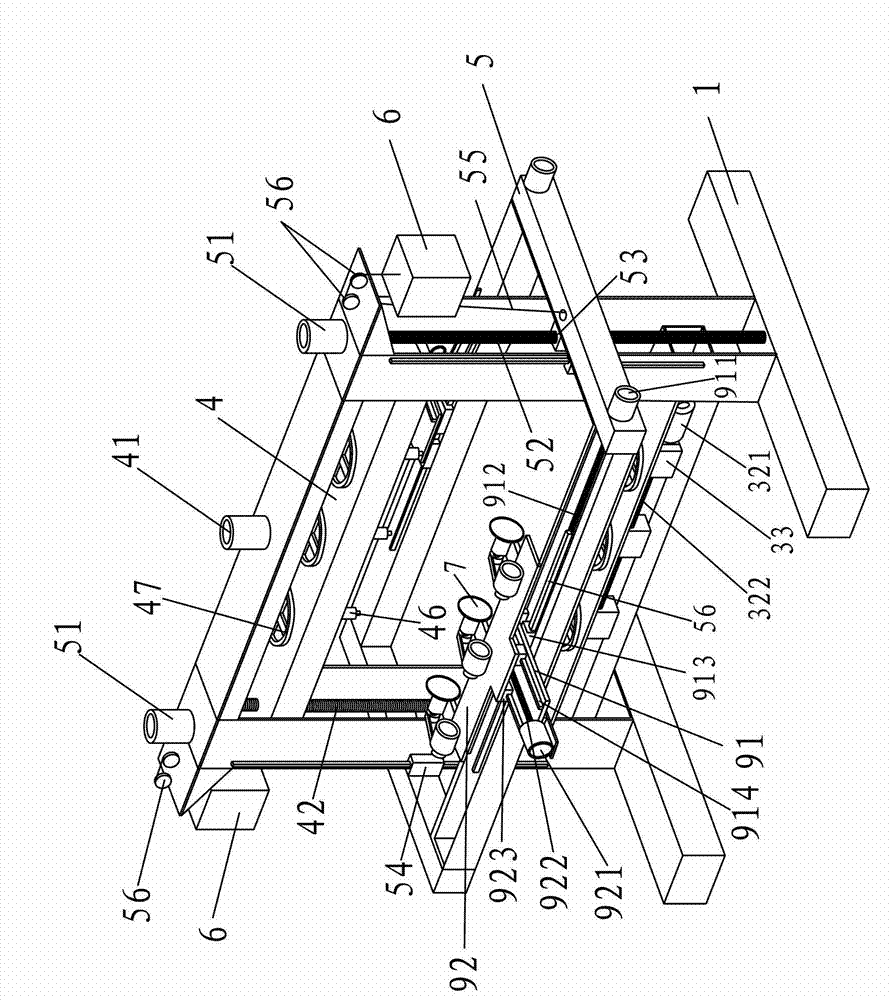

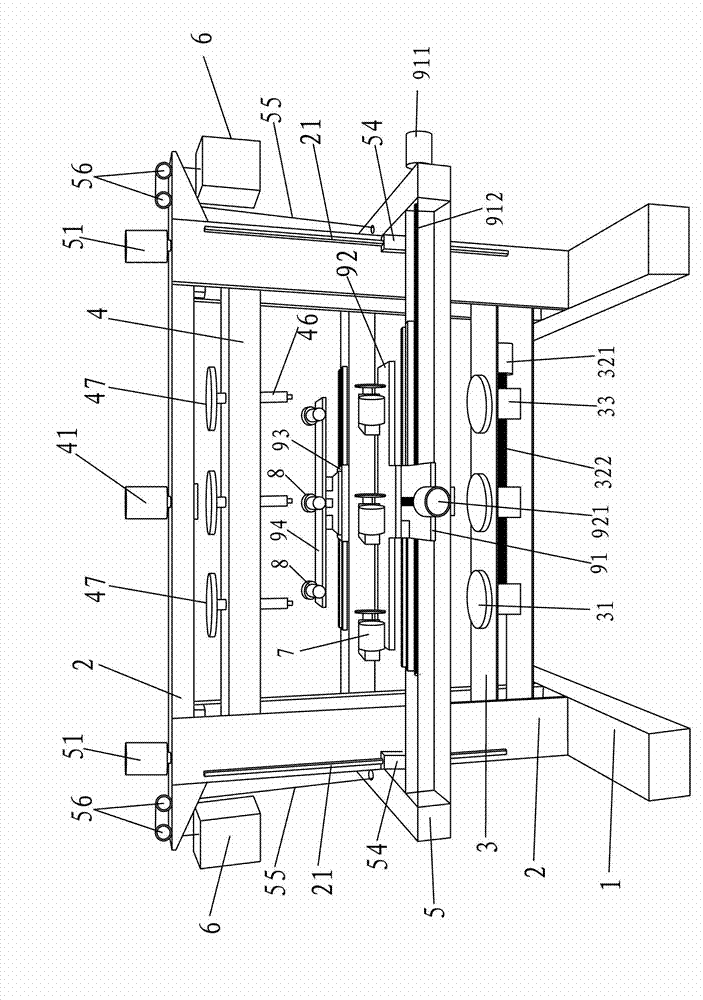

[0025] A kind of novel vertical numerical control engraving machine of the present invention, as figure 1 , 2 As shown, it includes a base 1, a gantry frame 2, a workpiece clamping bottom frame 3, a workpiece clamping top frame 4, and a processing tool rest 5, and the gantry frame 2 is fixed on the base 1.

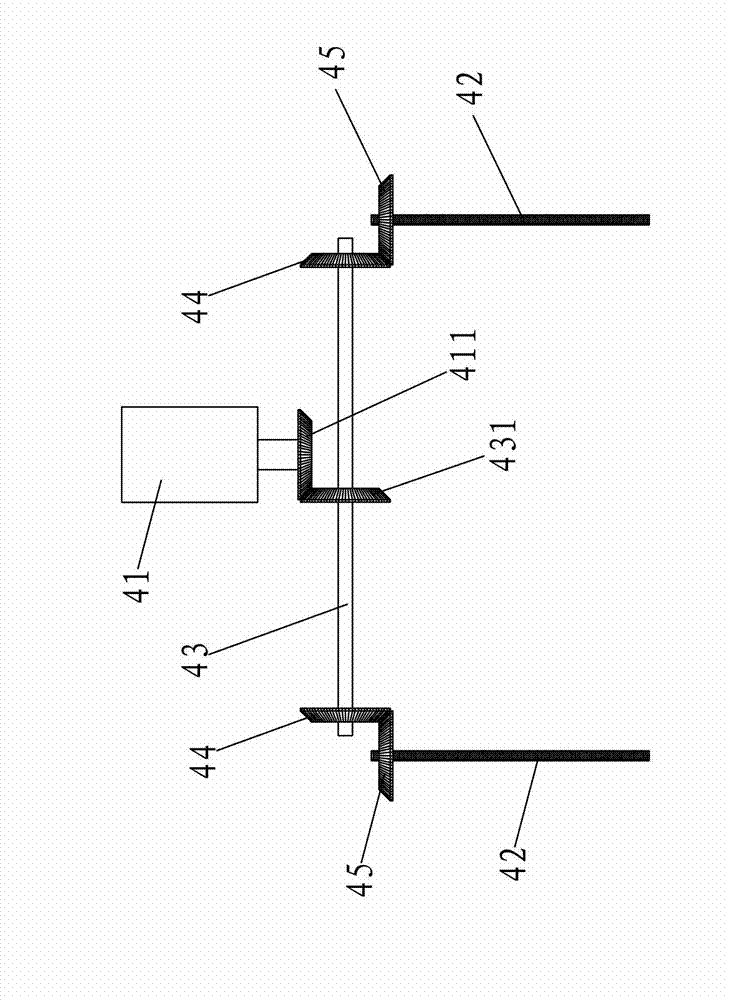

[0026] The workpiece clamping chassis 3 is a square frame, which is horizontally placed in the bottom of the gantry 2 and fixedly connected with the gantry 2. The upper surface of the workpiece clamping chassis 3 is stacked with Placement tray 31 for placing workpieces to be engraved. The placement tray 31 is a disc. There are at least three placement trays 31. The square frame is provided with a rotation control mechanism that drives the rotation of the placement tray 31. The rotation control mechanism incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com