Heating curing closing mold for glue joint of middle wing of unmanned aerial vehicle and middle wing assembling method

A heating and curing, unmanned aerial vehicle technology, applied in the field of unmanned aerial vehicle aviation, can solve problems such as affecting production efficiency, increasing process conversion, and difficulty in moving, so as to improve product yield and product quality, reduce investment costs, and simplify workflow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

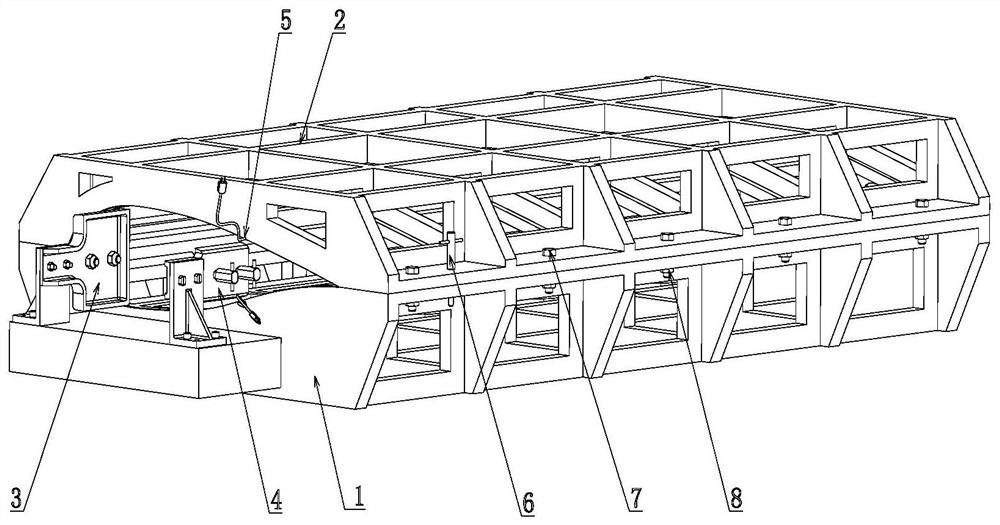

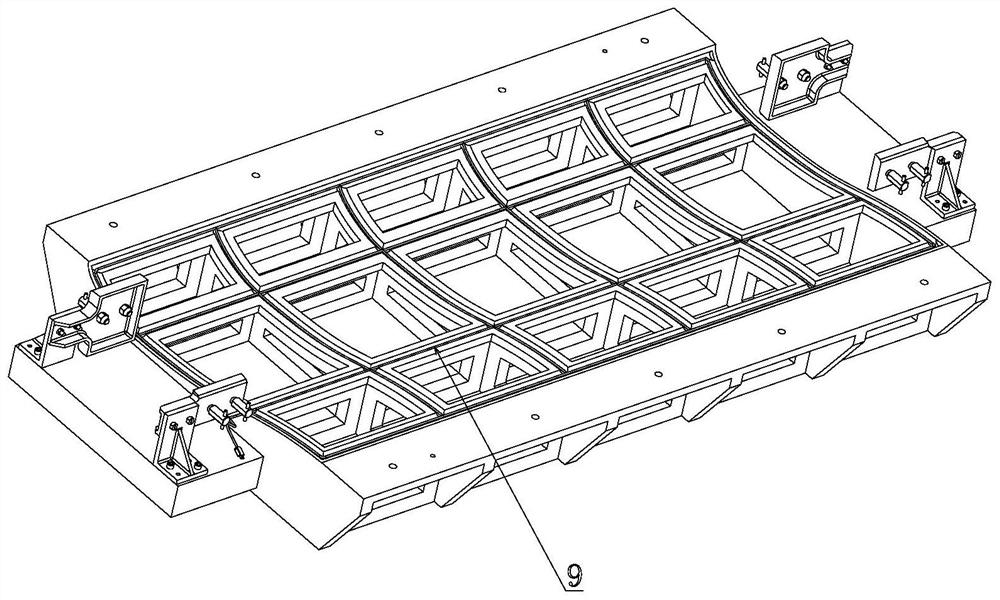

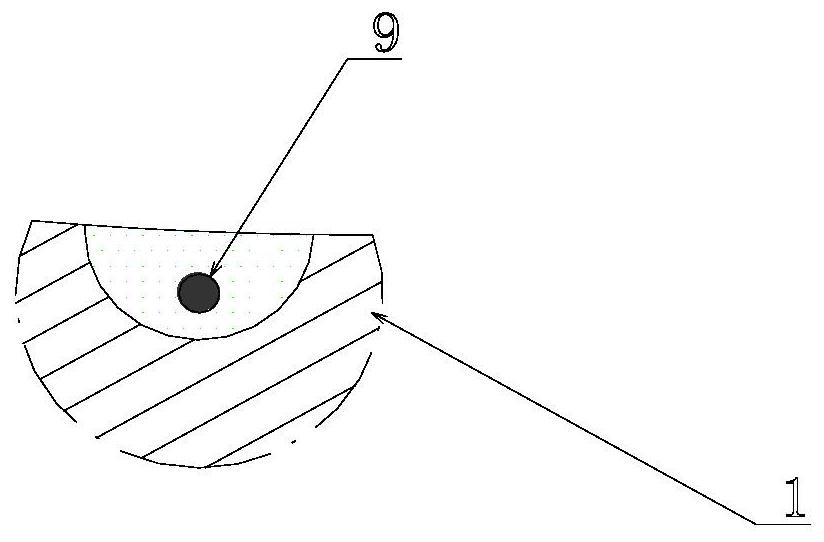

[0038] This embodiment integrates positioning, pressurization, and heating into one, and the heating and curing closing mold for the glued assembly of the middle wing includes the base of the middle wing closing mold 1, the middle wing closing molding frame 2, the center wing front beam positioner assembly 3, the middle wing Rear beam locator assembly 4, heating system (silicone carbon fiber heating wire plug-in power connector 5, silicone carbon fiber heating wire 9), positioning pin 6, hexagon head bolt (M20X80) 7, nut 8. It is characterized in that the base of the center wing folding mold is used to support the lower plate of the center wing, and the shape and precision of the base are consistent with the profile and precision of the airfoil of the lower plate, which can effectively ensure the accuracy of the airfoil of the center wing.

[0039] The folding mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com