Patents

Literature

37results about How to "Accurate engraving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

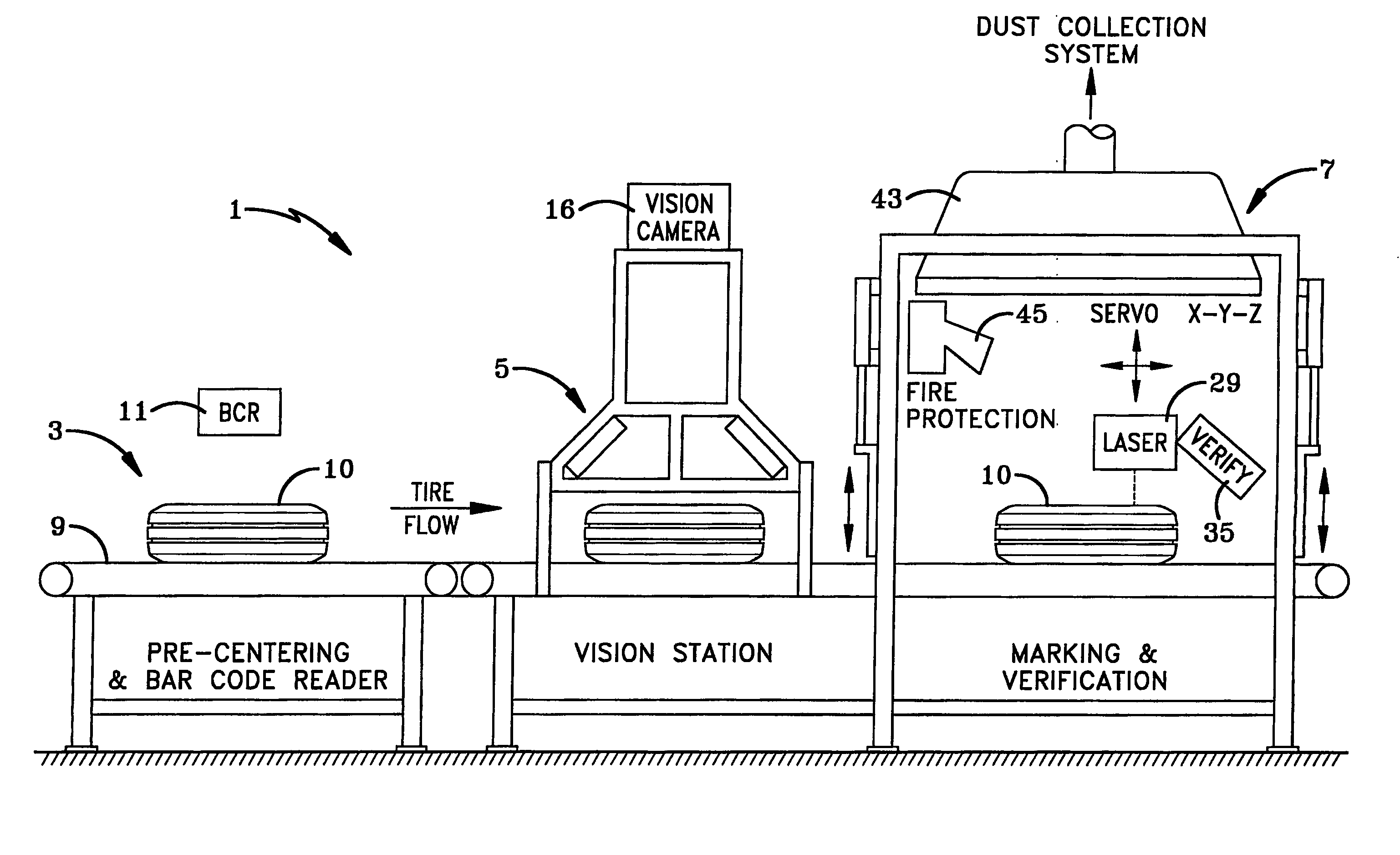

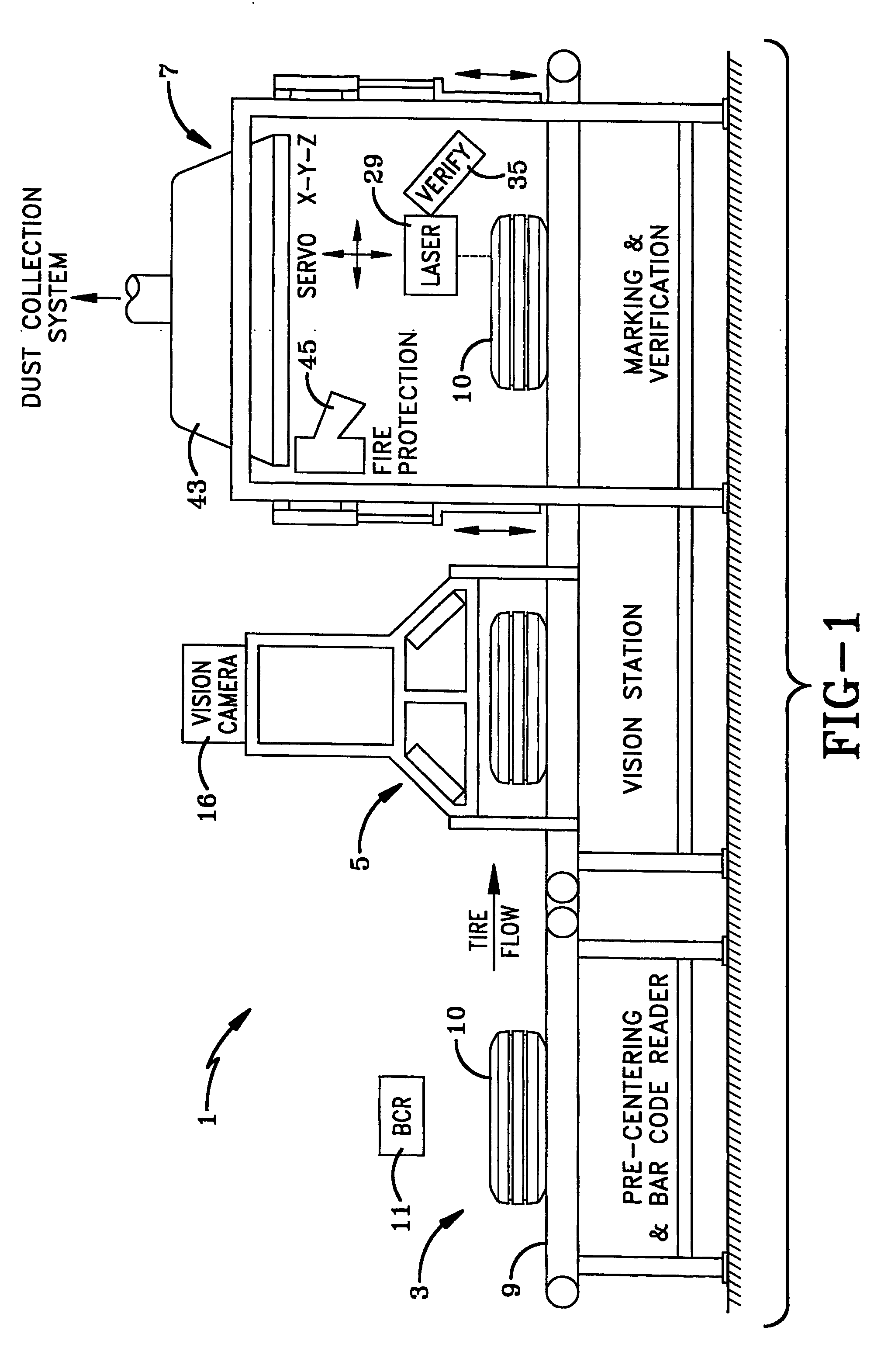

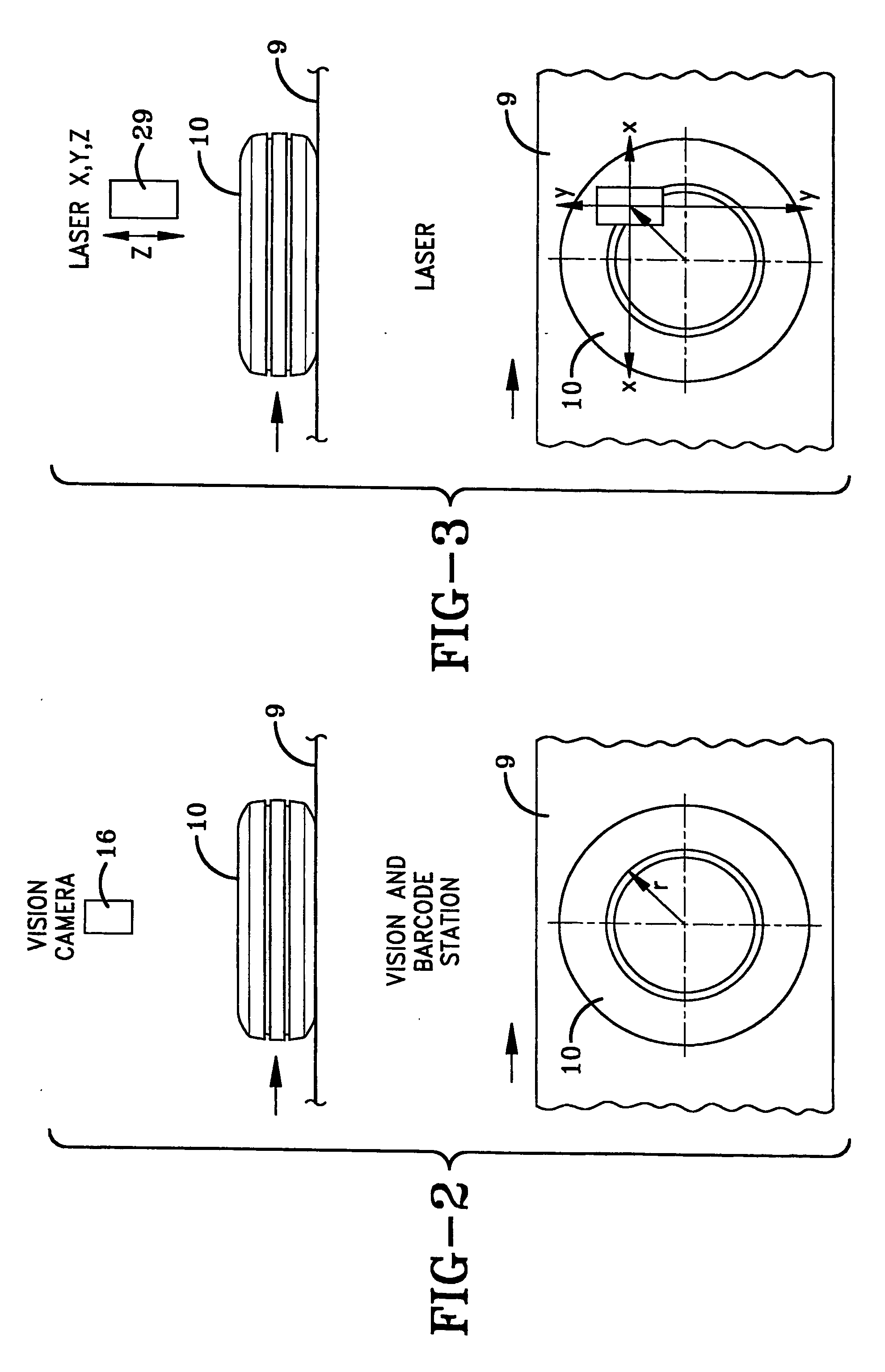

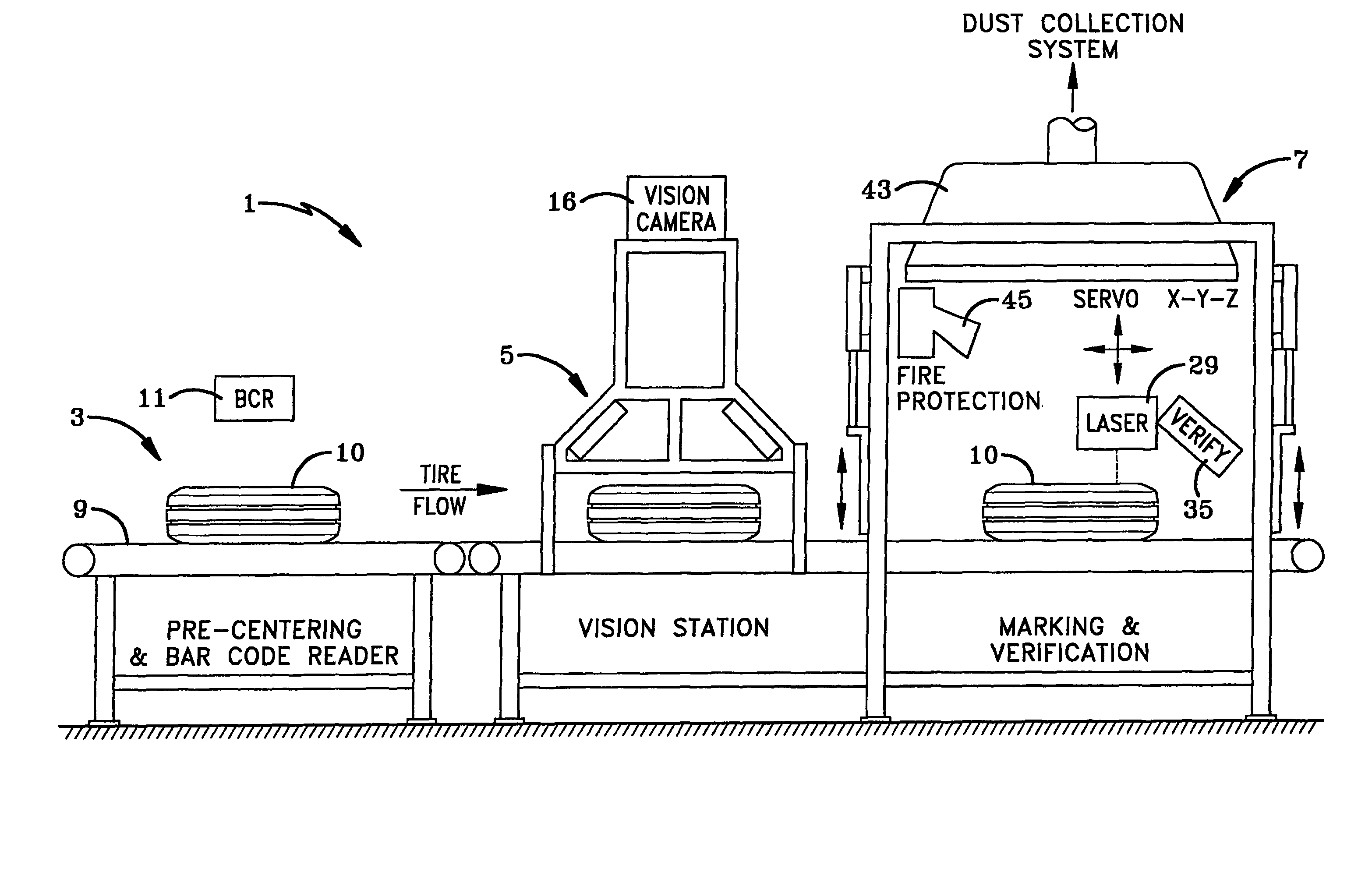

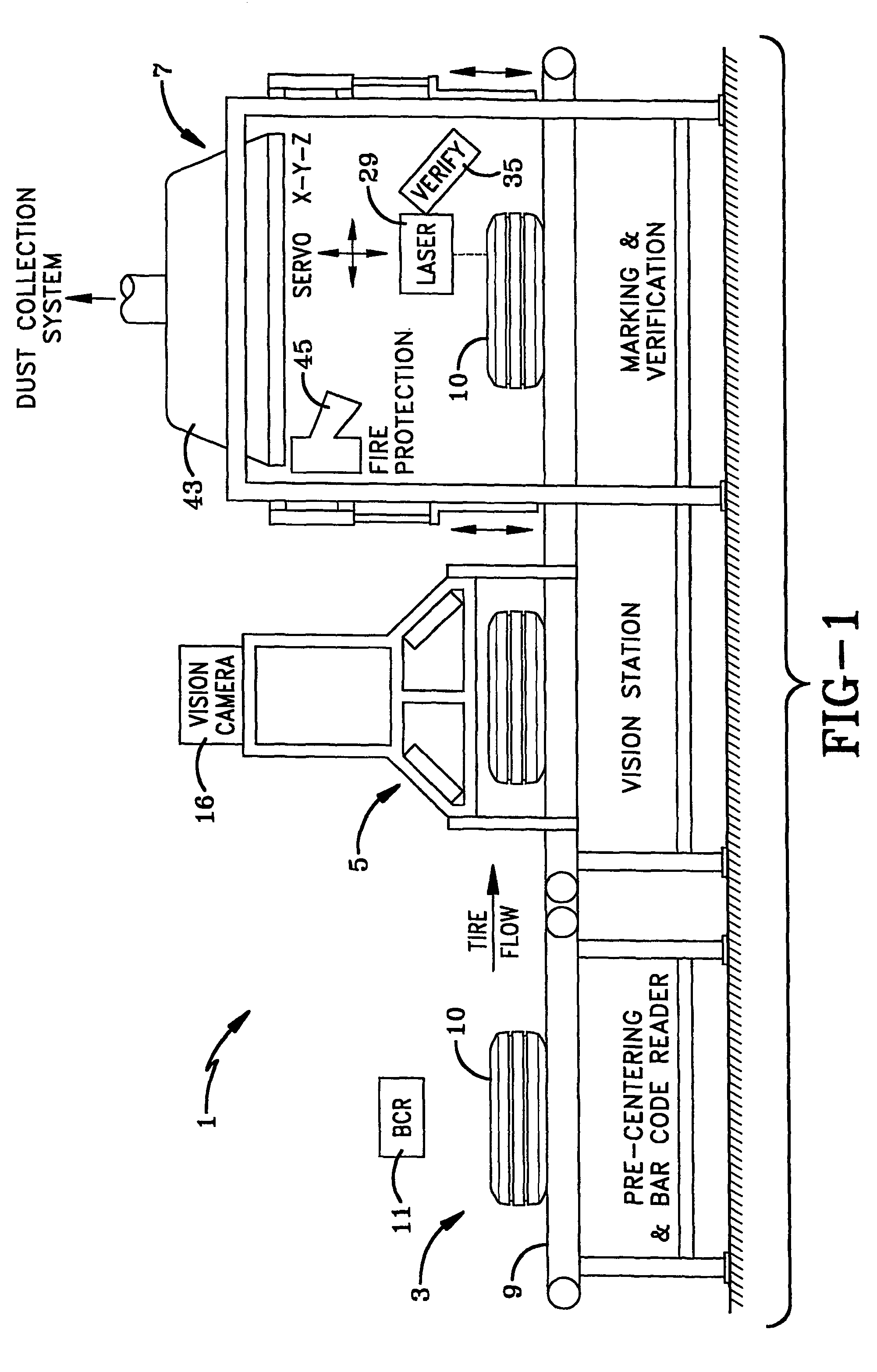

Method and system for marking tires

A system and associated method of marking a molded vehicle tire with laser engraved information to provide both human visible and machine readable data concerning the tire. Information contained in a barcode on the tire is read at a first station and supplied to a control unit. The physical location of human visible information previously molded into the tire is read from the tire at a second station and supplied to the control unit which uses this information to position a laser located at a third station for engaging additional human visible information pertaining to the manufacture of the tire adjacent the existing visible information to satisfy the Department of Transportation (DOT) tire marking requirements. The additional information also can be laser engraved into the tire in a machine readable encoded format, such as 2D symbols, for subsequent control and verification throughout the life of the tire.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

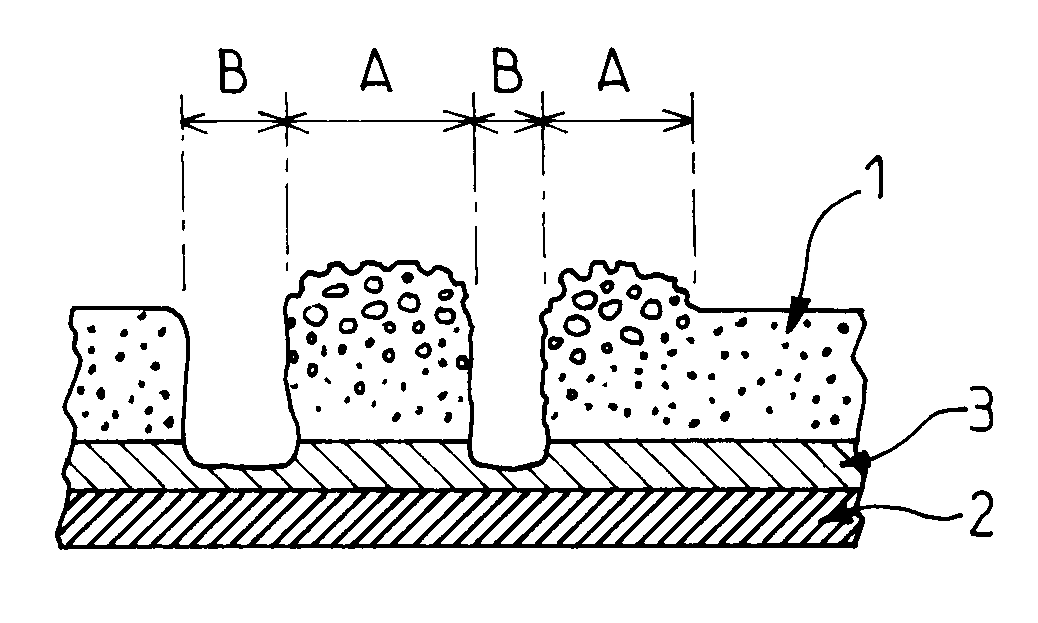

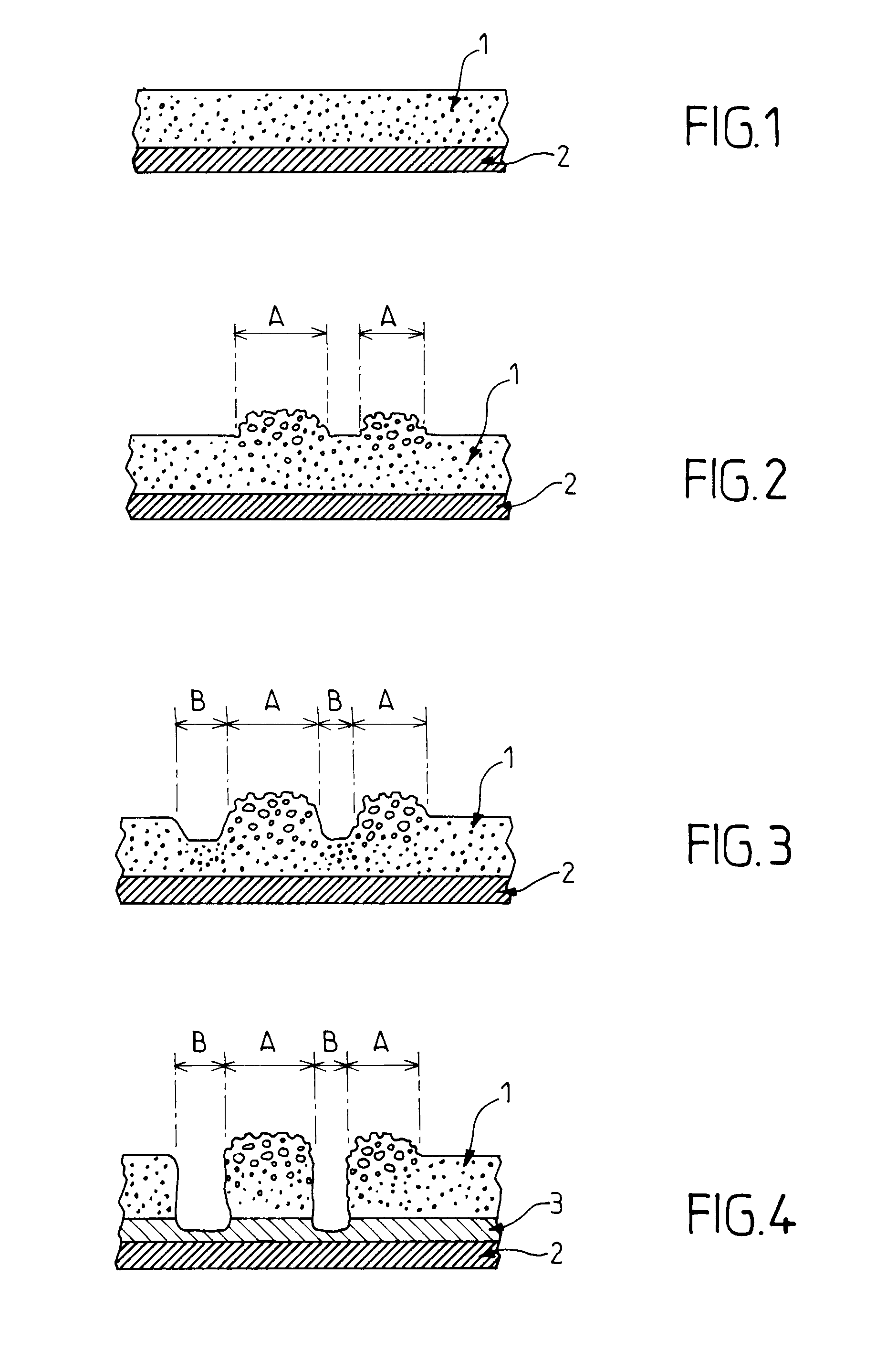

Resin-coated material and process for manufacturing same

InactiveUS20120015162A1Pleasant feelAccurate engravingRadiation applicationsPretreated surfacesPolymer resinPolyresin

A coated material includes a support covered with at least one layer of polymer resin, characterized in that the resin includes heat-expandable microspheres. A process for manufacturing the novel material, and also the use thereof in the binding and packaging fields and an article including the coated material are also described.

Owner:SOC DENDUCTION & DE FLOCKAGE

Manufacturing technique of stereoscopic underglaze multicolor ceramic

The invention relates to a manufacturing technique of stereoscopic underglaze multicolor ceramic, which comprises the following steps: carrying out ball milling on a selected ceramic raw material, screening, slurrying, carrying out injection forming on a mold to obtain a required shape, preparing a blank, and carrying out bisque firing to obtain a biscuit; carving out a stereoscopic multilayer plain color picture on the biscuit with a carving tool; dipping a drawing tool into underglaze multicolor pigments, and drawing and decorating on the stereoscopic picture of the biscuit to obtain a colored biscuit; carrying out color depth gradation treatment on the picture of the colored biscuit by using a special brush; and covering a glaze layer on the surface of the colored biscuit subjected to color treatment; and firing the glaze-covered colored biscuit in a kiln again to obtain the finished product. The technique adopts the two modes of biscuit carving and mold carving. The ceramic article prepared by the technique has the advantages of strong stereoscopic effect, abundant colors, high color layering effect and glossy and bright glaze.

Owner:HUNAN NEW CENTURY CERAMICS

Method and system for marking tires

A system and associated method of marking a molded vehicle tire with laser engraved information to provide both human visible and machine readable data concerning the tire. Information contained in a barcode on the tire is read at a first station and supplied to a control unit. The physical location of human visible information previously molded into the tire is read from the tire at a second station and supplied to the control unit which uses this information to position a laser located at a third station for engaging additional human visible information pertaining to the manufacture of the tire adjacent the existing visible information to satisfy the Department of Transportation (DOT) tire marking requirements. The additional information also can be laser engraved into the tire in a machine readable encoded format, such as 2D symbols, for subsequent control and verification throughout the life of the tire.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

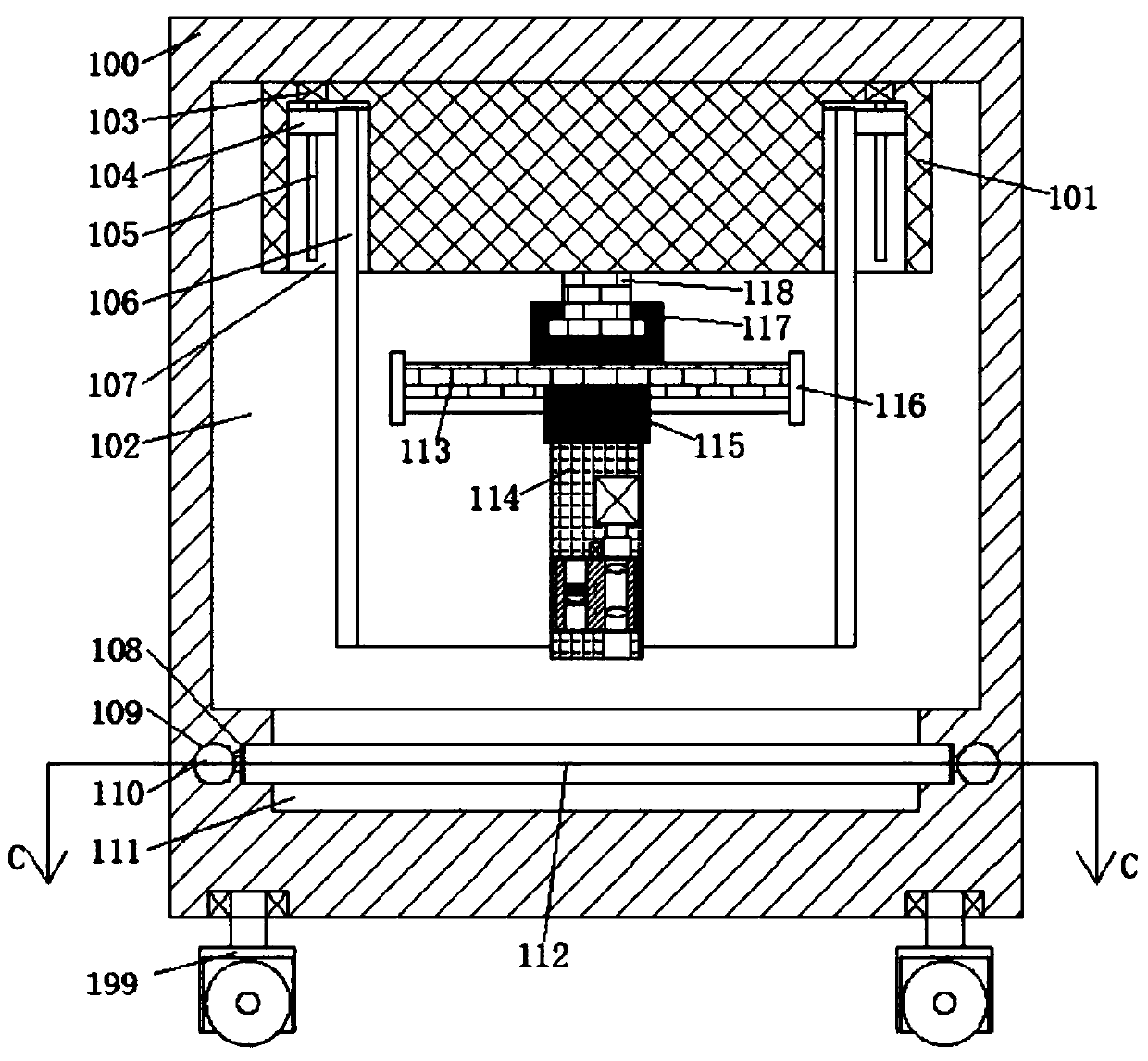

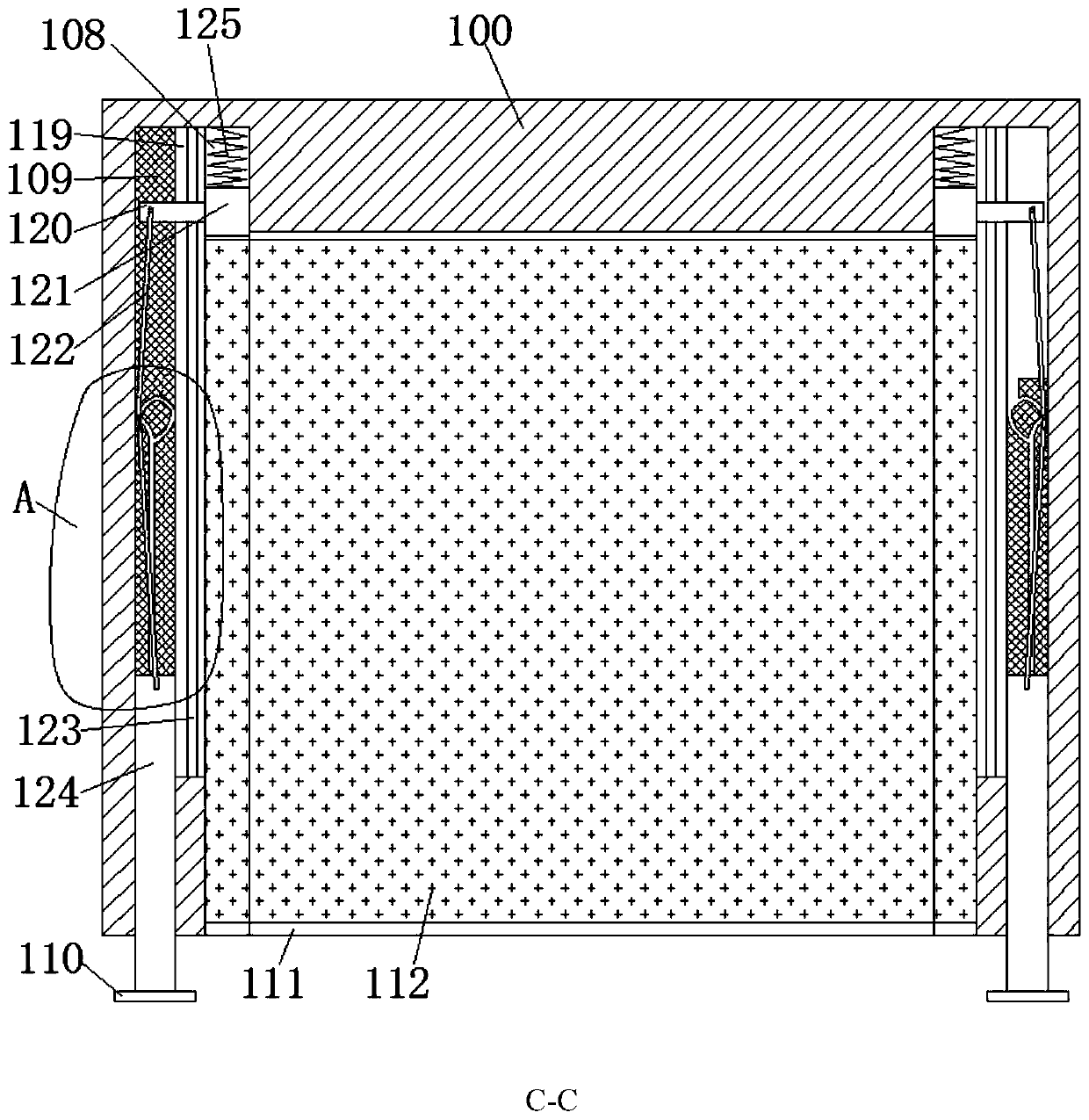

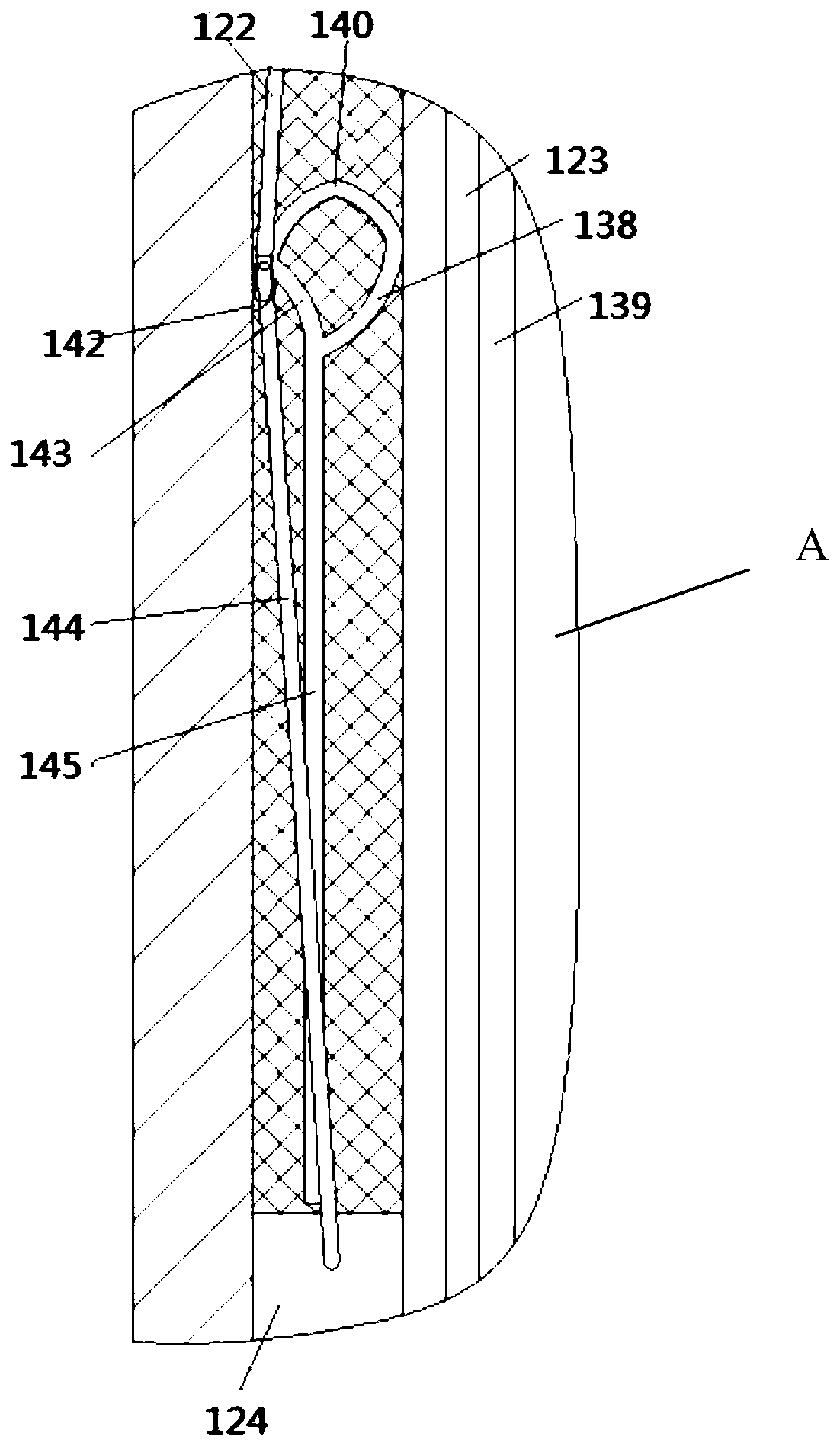

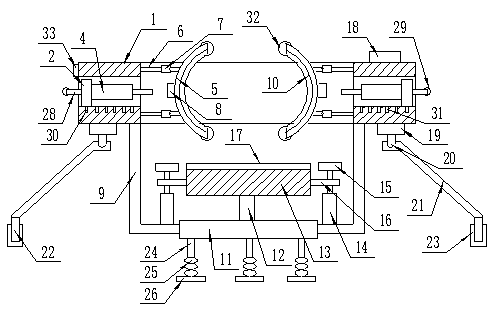

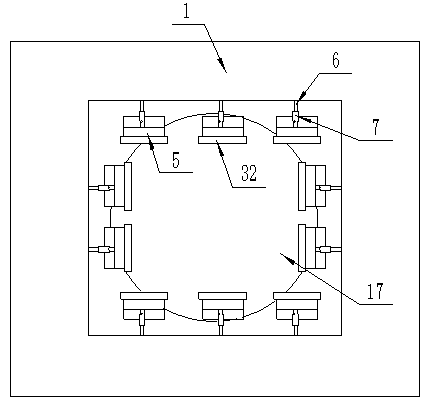

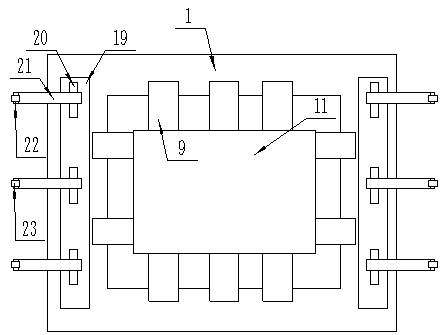

Carving machine used for industrial equipment

ActiveCN105818592AAccurate engravingReduce consumptionModel makingEngravingIndustrial equipmentCarving

The invention discloses a carving machine used for industrial equipment. The carving machine comprises a base, wherein a carving table is firmly connected to the top of the base; a supporting table is disposed on one side of the carving table; a slideway is formed in one side face of the supporting table; a first slide block is movably connected inside the slideway; a drill bit is firmly connected to one side face of the first slide block; a first carving rod and a second carving rod are disposed on the bottom of the drill bit; one end of the first carving rod passes through the drill bit and extends into the drill bit; one end of the second carving rod is firmly connected to the bottom of the drill bit; one side face of the drill bit is firmly connected to a supporting plate; a water tank is disposed on the top of the supporting plate; a water hose is disposed on the bottom of the water tank; and one end of the water hose communicates with a through hole in the bottom of the water tank. The carving machine used for the industrial equipment has the advantages that accurate carving of a small model is implemented as a whole; consumption of energy sources is reduced; effective processing of chippings is implemented; overall carving precision is increased; and working efficiency is increased.

Owner:建湖县高新投资发展有限公司

Wooden furniture polishing and carving machine

InactiveCN108747665AEfficient collectionEasy to clean and maintainProfiling/shaping machinesBark-zones/chip/dust/waste removalPulp and paper industryCarving

The invention discloses a wooden furniture polishing and carving machine. The wooden furniture polishing and carving machine structurally comprises a polishing and carving machine body, a slide rail,a control panel, dust collectors, a polishing roller and a cutting hole, wherein the slide rail is arranged on the top of the polishing and carving machine body; rolling crawler belts are arranged atthe two ends of the slide rail; the bottom of a control device is connected with a laser carving device; the two sides of the laser carving device are both provided with locating and monitoring devices; the dust collectors are arranged on the two sides of the polishing and carving machine body; the cutting hole is formed in the middle of the bottom of the polishing and carving machine body; a cutting knife is arranged at the bottom of the cutting hole; the front and rear sides of the bottom of the polishing and carving machine body are both provided with connecting plates; the polishing rolleris connected to the top of a first connecting rack. The wooden furniture polishing and carving machine drives fans to conduct high-efficiency dust suction through motors, is more accurate in carvingand processing, high in automatic performance, capable of rising and dropping to conduct cutting, more convenient to use and reasonable in design and facilitates polishing front and back during transportation.

Owner:黄文才

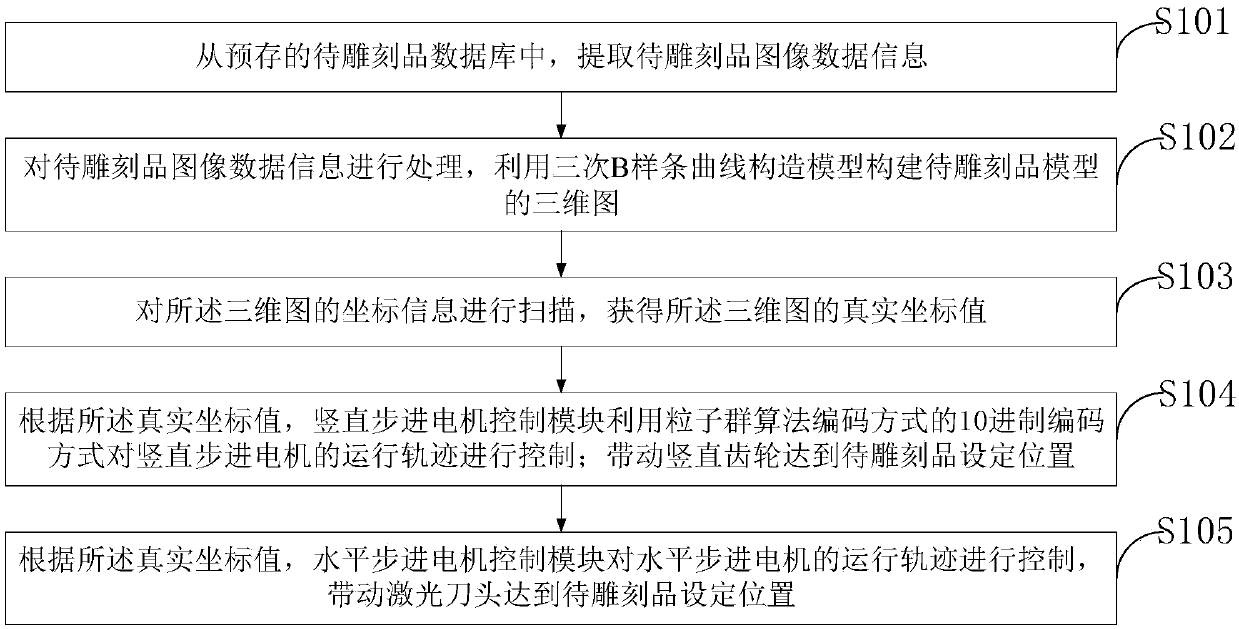

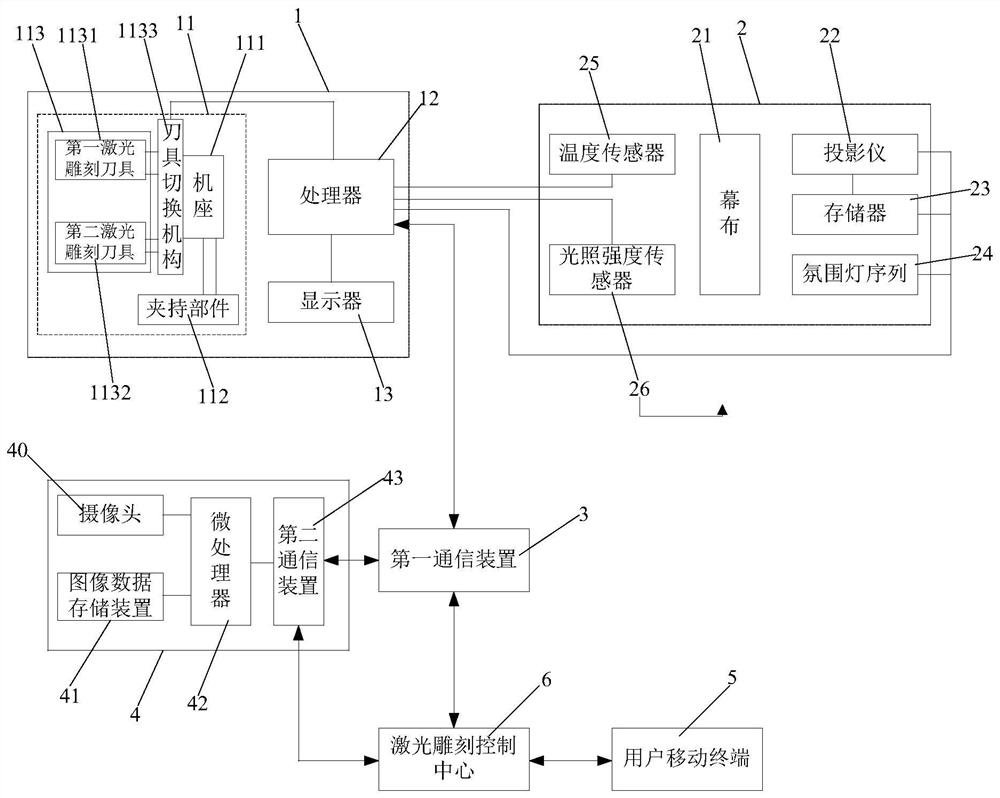

Laser engraving machine, control system and control method

InactiveCN108490882AFree and easy to moveAccurate engravingProgramme controlComputer controlThree-dimensional graphData information

The invention belongs to the laser engraving processing technology field and discloses a laser engraving machine, a control system and a control method. The method is characterized by extracting the image data information of a product to be engraved from the pre-stored database of the products to be engraved; processing the image data information of the product to be engraved, and using the cubicB-spline curve construction model to construct the three-dimensional graph of the model of the product to be engraved; scanning the coordinate information of the three-dimensional graph and acquiringthe real coordinate value of the three-dimensional graph; according to the real coordinate value, using the decimal coding mode of a particle swarm algorithm coding mode to control the operation pathof a vertical stepping motor by a vertical stepping motor control module; driving a vertical gear to reach the setting position of the product to be engraved; and according to the real coordinate value, regulating and controlling a laser cutter head to reach the setting position of the product to be engraved by a horizontal stepping motor control module. In the invention, the design is reasonable,engraving of substances with different heights and thicknesses and different shapes and sizes can be satisfied, the engraving is accurate and work efficiency is greatly increased.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

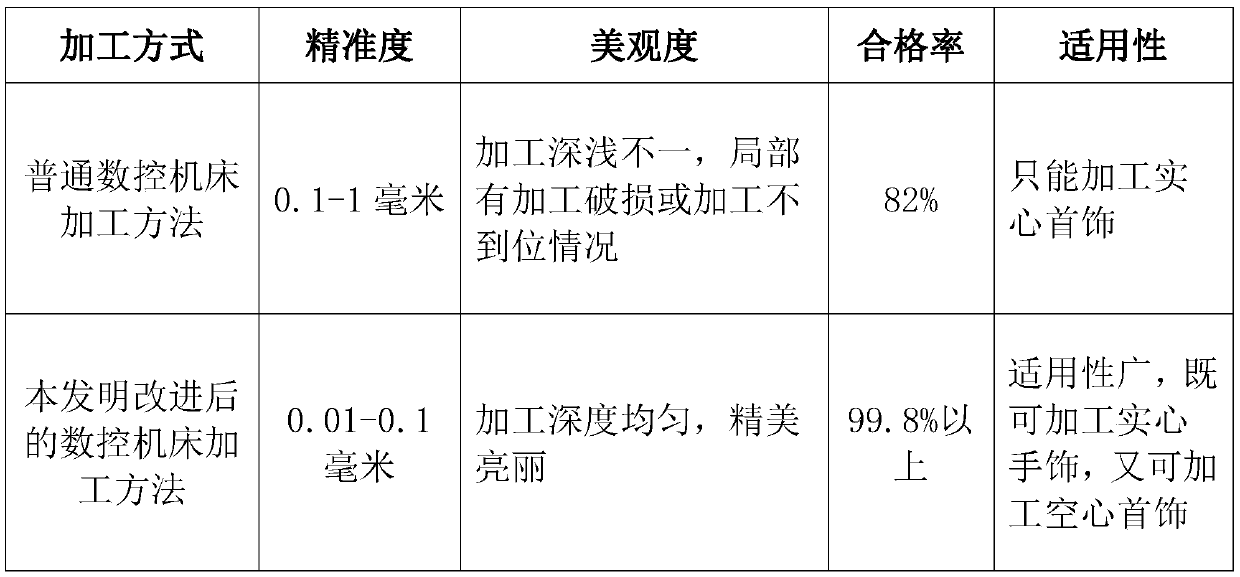

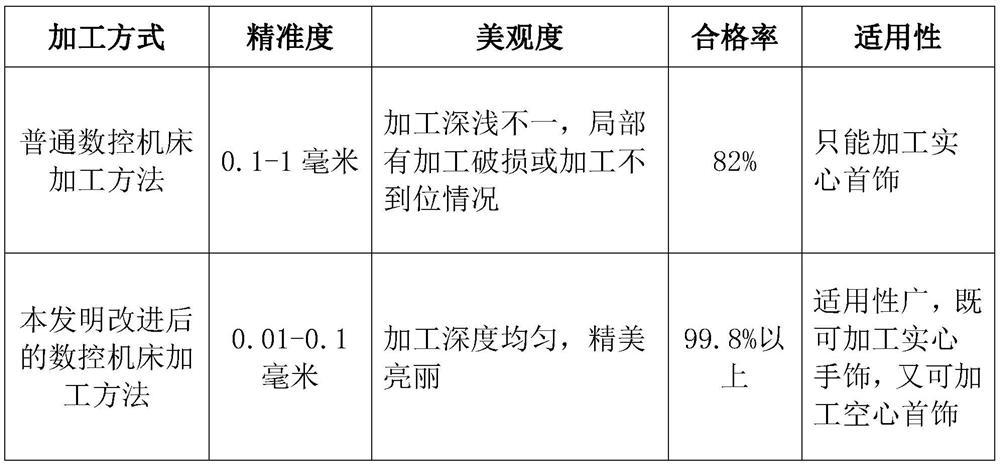

Machining control method for follow-up measurement and application thereof in jewelry processing field

ActiveCN111300212AAchieve precision machiningRealize industrialized environmental protection productionGrinding feed controlUsing optical meansNumerical controlTool bit

The invention discloses a machining control method for follow-up measurement and application thereof in jewelry machining field. The method comprises the following steps of S1, pre-programming a coordinate program for automatic machining of a numerical control machine tool according to the boundary dimension of a standard jewelry blank; S2, controlling a probe of a machining tool to detect the jewelry blank point by point automatically in a follow-up manner to obtain a spatial coordinate position of a shape surface needed to be machined for the jewelry blank and feeding the position back to acomputer of the numerical control machine tool; S3, comparing and calculating the spatial coordinate position of the shape surface of the detected jewelry blank and the shape spatial coordinate of thestandard jewelry blank to obtain machining calibration data, and compensating the machining calibration data to a coordinate parameter of automatic machining in advance automatically to obtain the actual machining parameter of the numerical control machine tool; and S4, starting a tool bit of the numerical control machine tool to machine to obtain the standard jewelry blank. Each piece of jewelrycan be measured dynamically in a follow-up manner, and deviation is calibrated and compensated automatically and precisely, so that the machining precision of the numerical control machine tool is improved greatly, and therefore, the machining percent of pass of jewelry of various types reaches over 99.8%, and the rejection rate is reduced obviously.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV

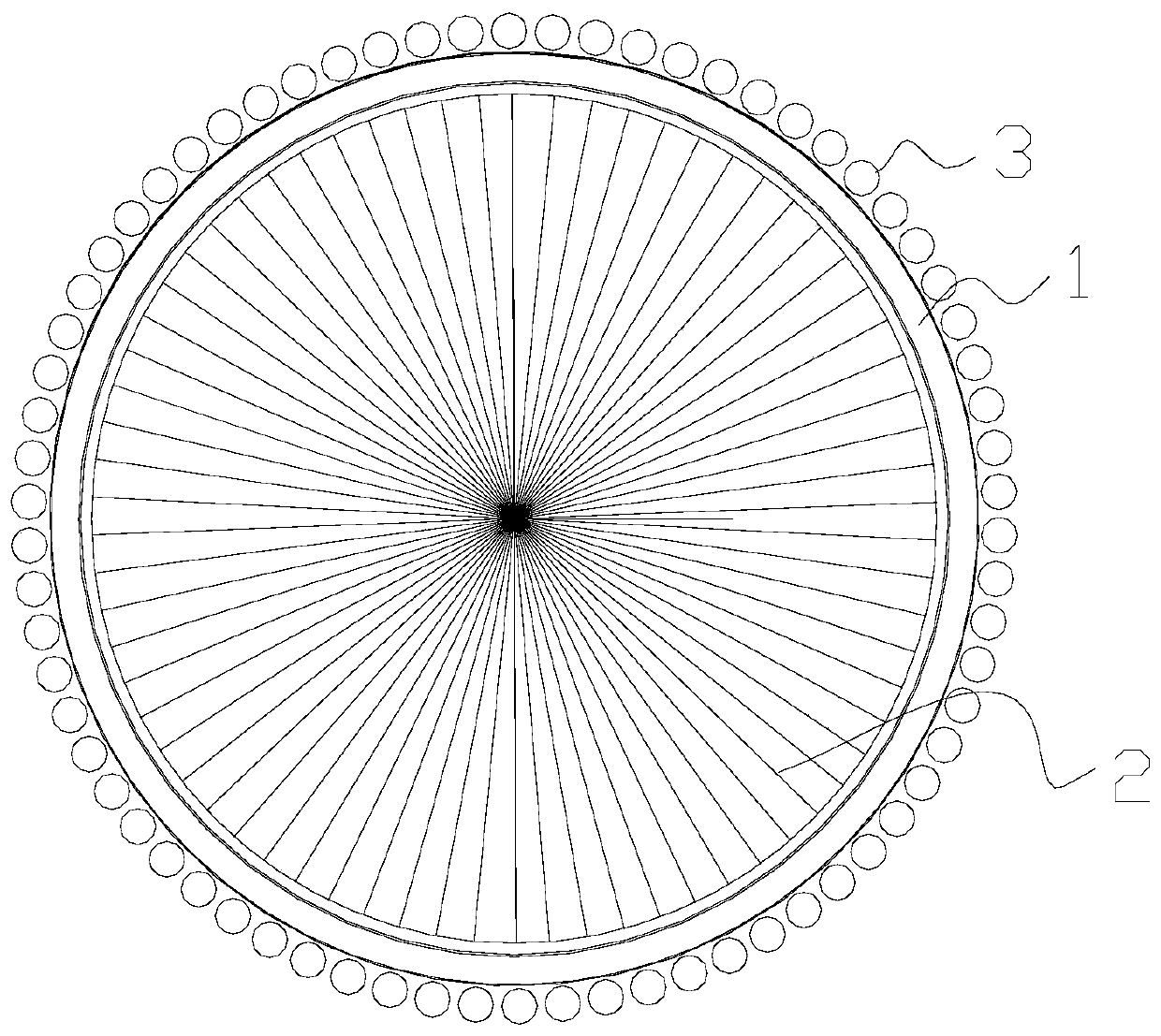

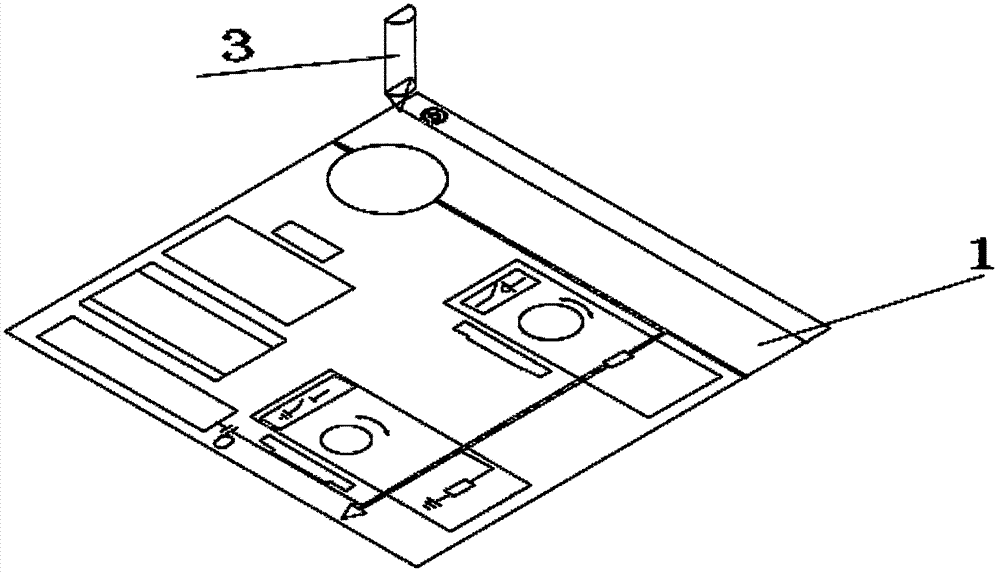

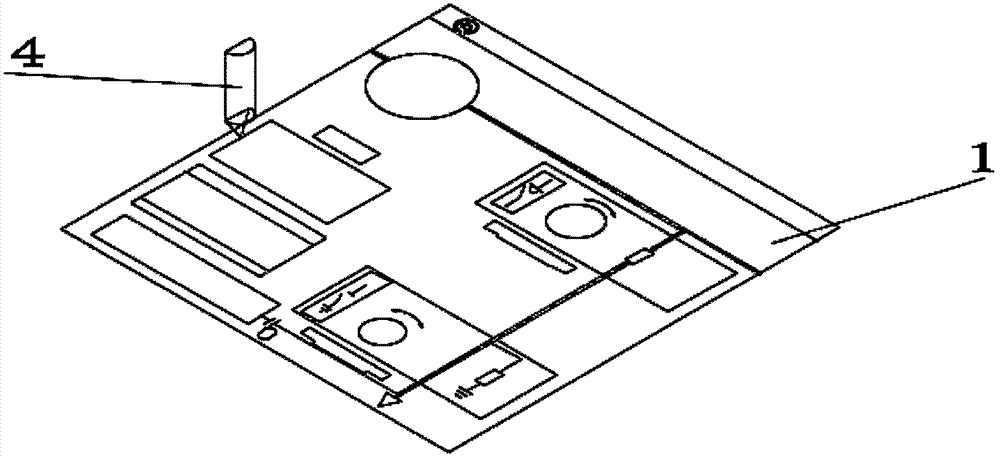

Convertible internal and external engraving laser equipment

The invention relates to convertible internal and external engraving laser equipment. According to the equipment of the invention, double linear motors are adopted; laser emitters are arranged at thebottoms of the double linear motors; the double linear motors are intelligently controlled by a controller; and therefore, the laser emitters move according to tracks set by a program, accurate engraving in a whole plane is realized; a laser transmitter is arranged in a laser transmitting machine body; light emitted by the laser transmitter is refracted by a main light hole to form lasers with different purposes; a switching device is arranged on the main light hole to drive a lens body bearing body in butt joint with the switching device; and a common laser refractor assembly is arranged in the lens body bearing body and is used for the external engraving and internal engraving of a laser optical lens set. A laser optical lens produced based on the equipment provided by the technical schemes of the invention can be produced in batches, and is stable in quality.

Owner:HUAQIAO UNIVERSITY

Surface paster processing technology

The invention discloses a surface paster processing technology. The surface mounting processing technology comprises steps of 1) using engraving machine software to edit a program, 2) programming an engraving path, 3) successively performing two-dimensional engraving, two-dimensional drawing, two-dimensional cutting and three-time engraving technology, wherein diameters of cutters for the two-dimensional engraving, two-dimensional drawing and two-dimensional cutting are different, and the cutters include a 0.4mm pointed knife, a pointed knife and a 2mm pointed knife, 4) performing integration and checking of the surface paster material on the engraving path after the step 3. The 1MM pointed knife is used for the two-dimensional drawing processing technology which can accurately engrave character symbols on a PU double-color sheet material while controlling a cutter advancing extent according to a program; and the 0.4MM pointed knife is used for the two-dimensional engraving processing technology which has the 0.4MM pointed knife moving on a preset path. The surface paster processing technology is easy to operate, has multiple kinds of patterns, exquisite in making and worth popularization.

Owner:瑞鸣电气设备有限公司

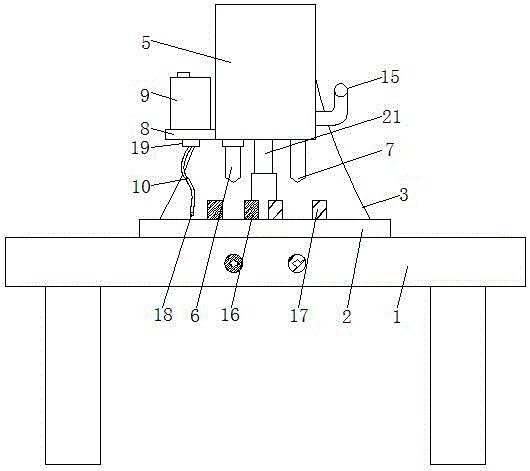

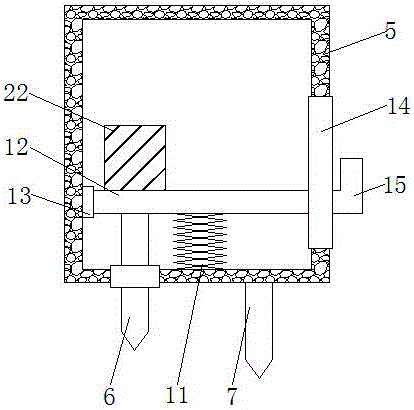

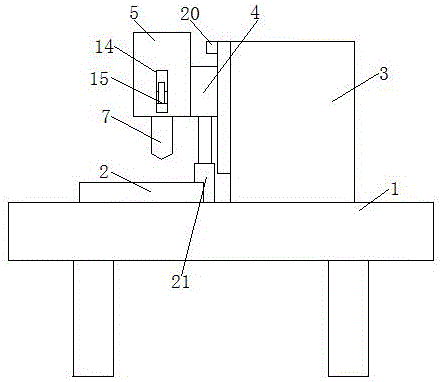

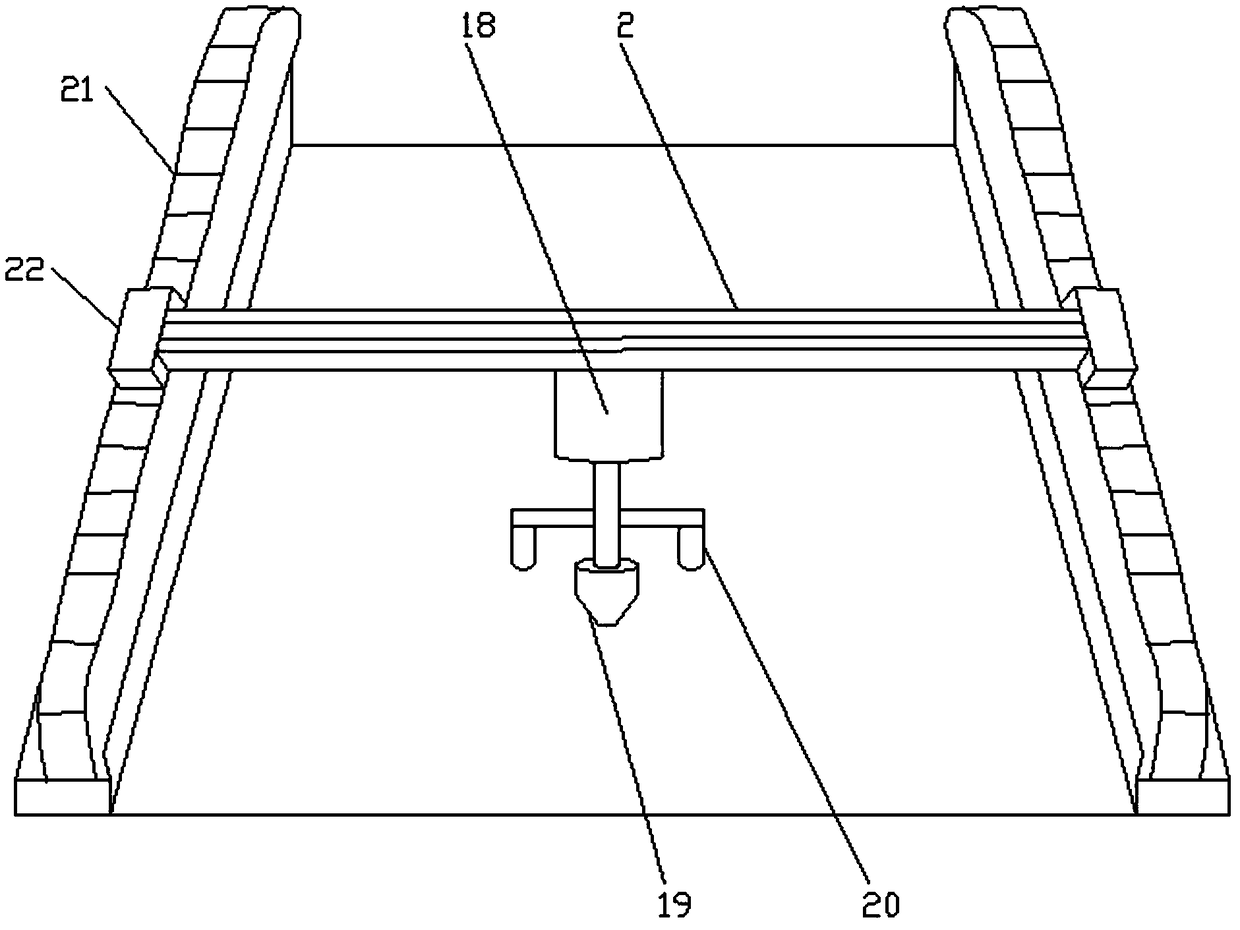

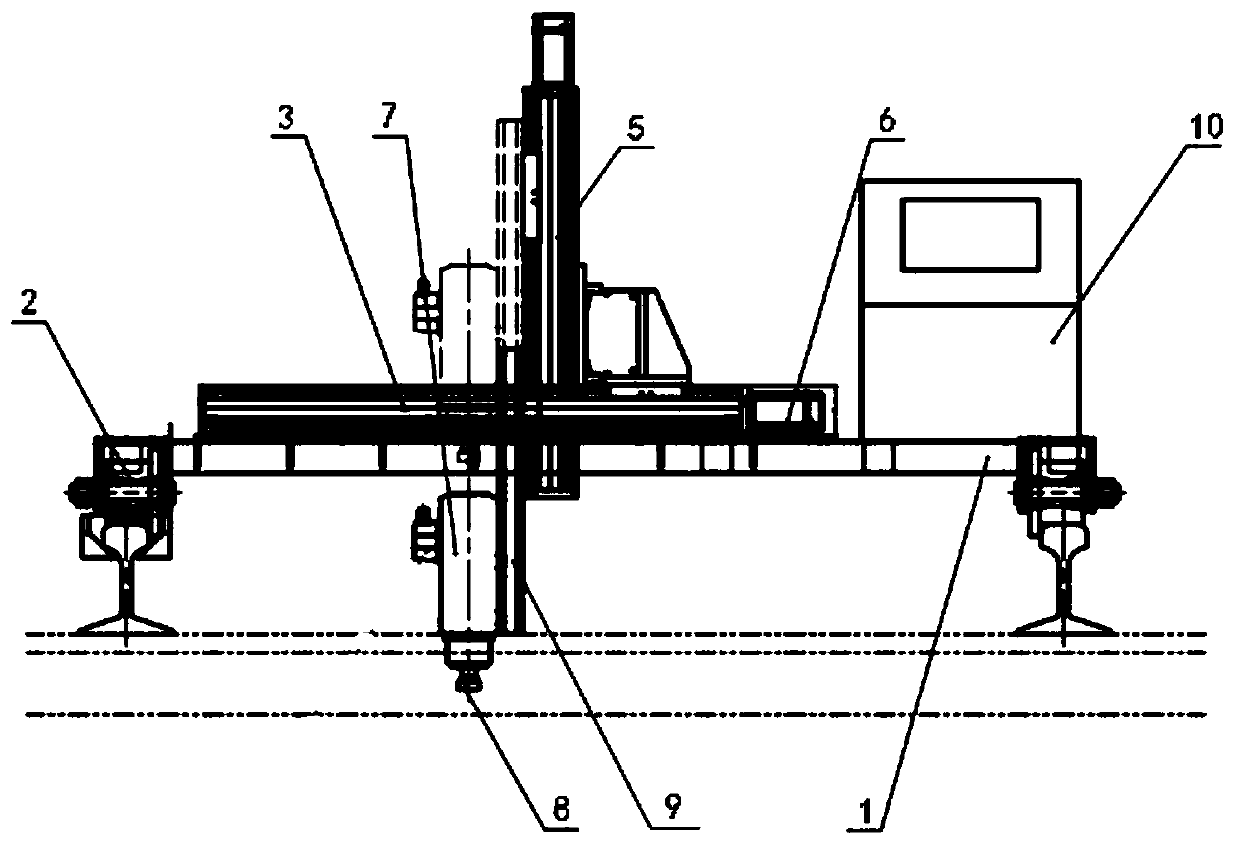

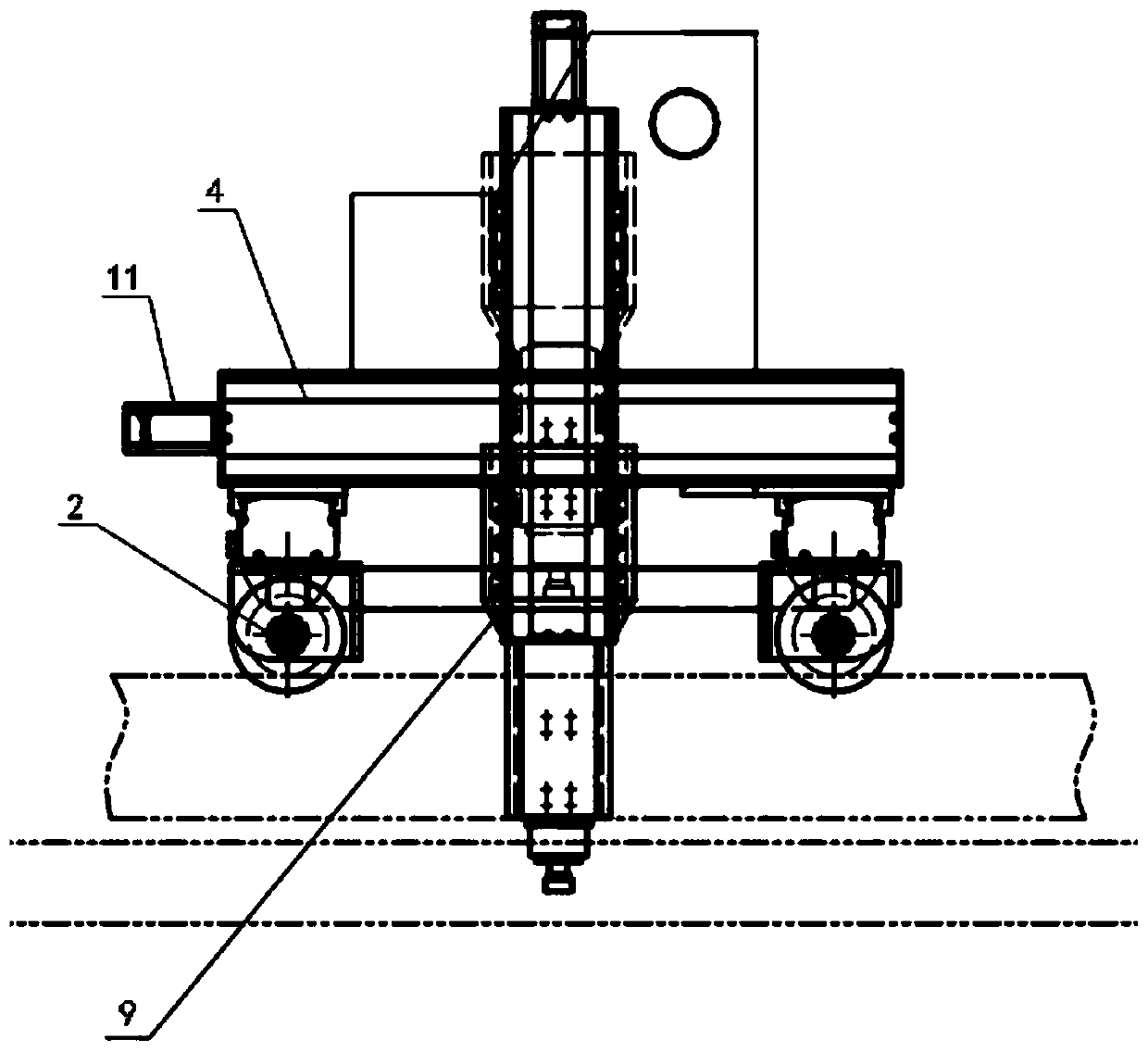

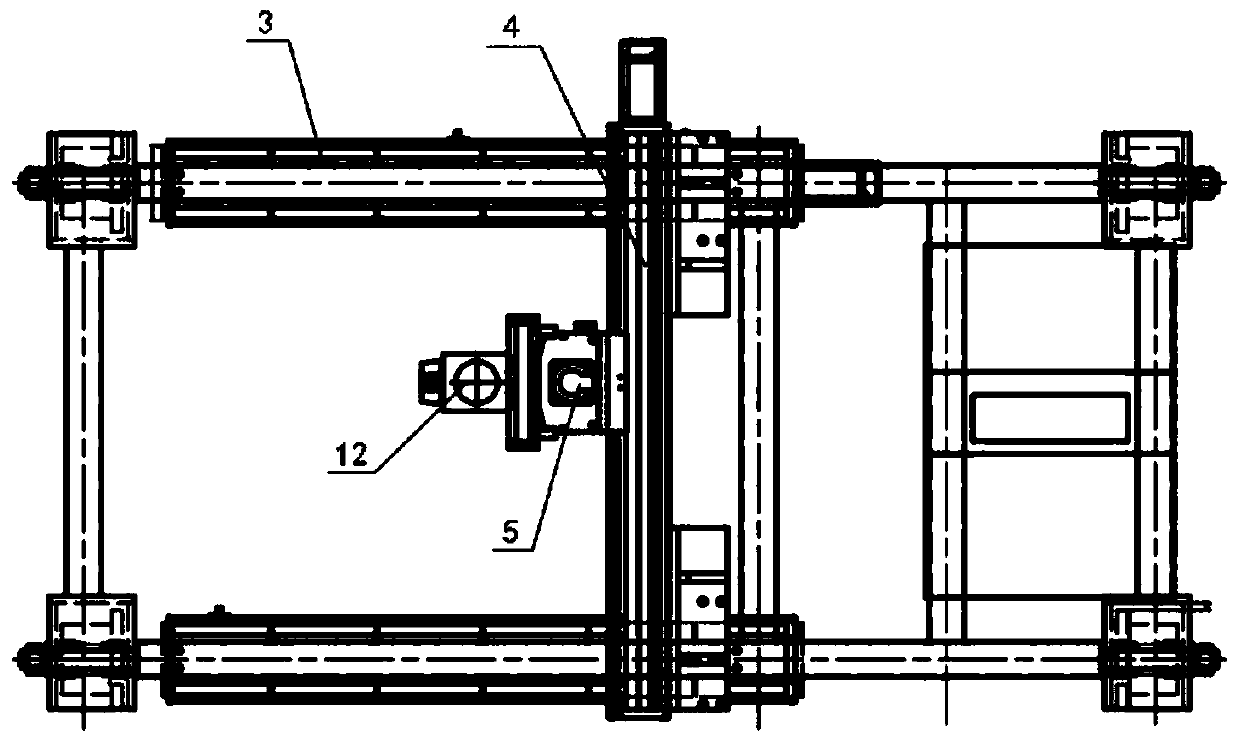

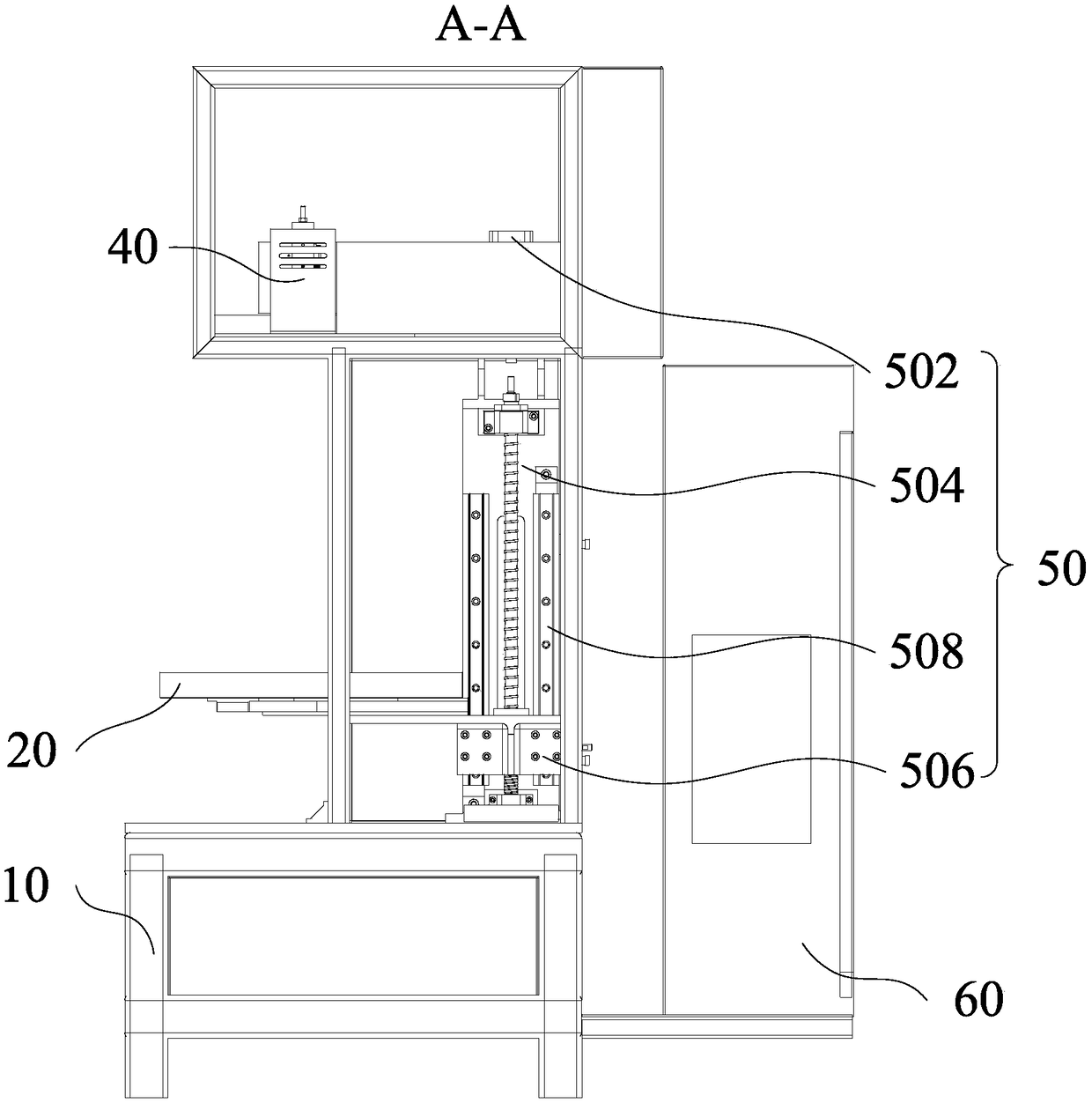

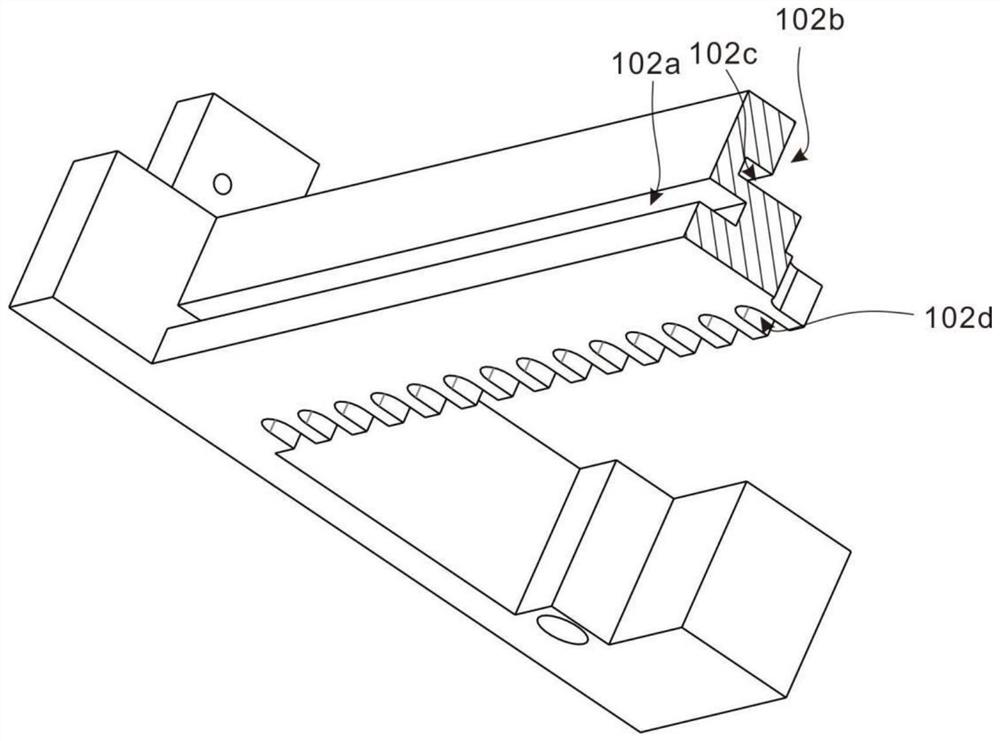

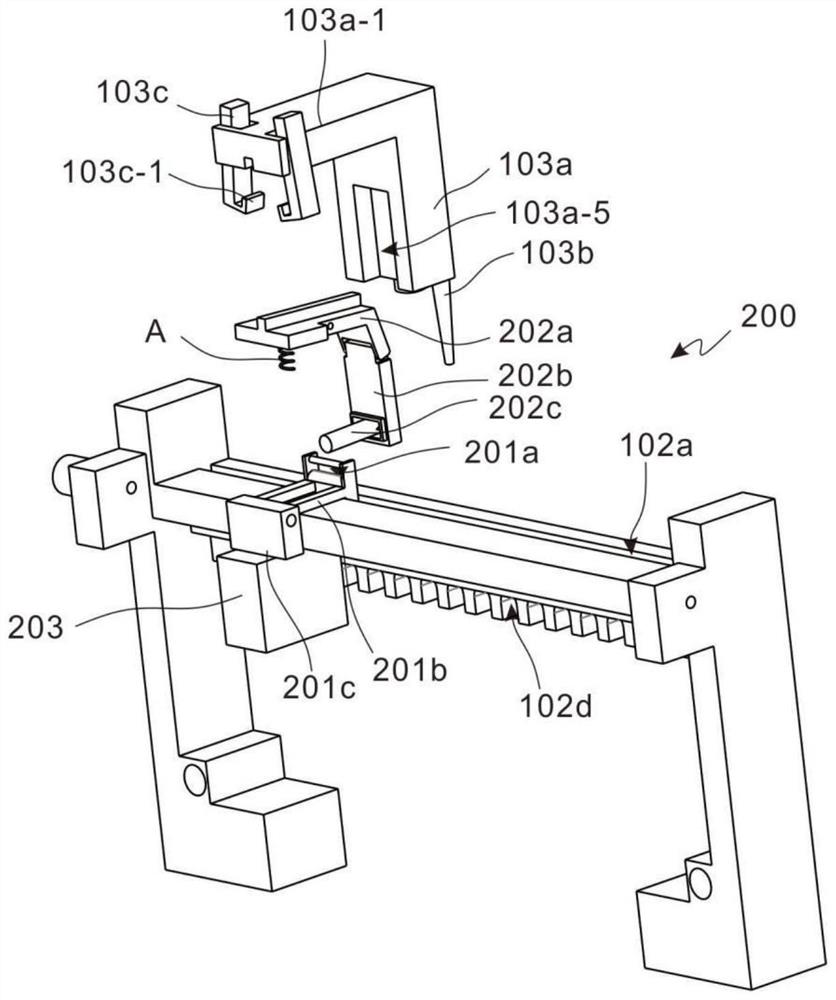

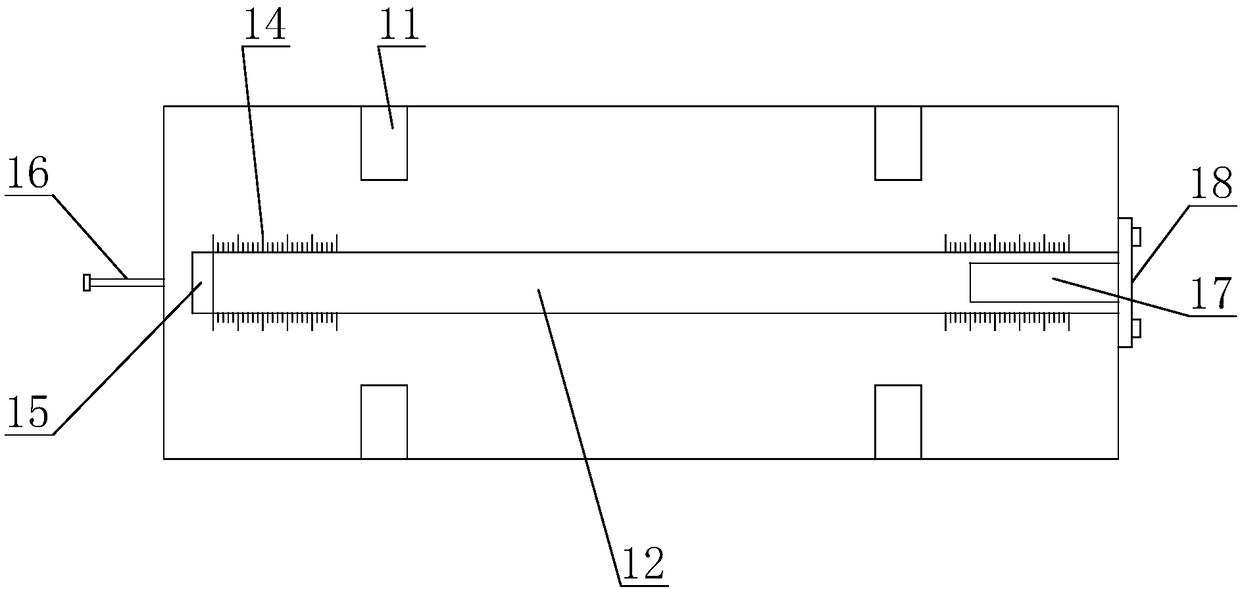

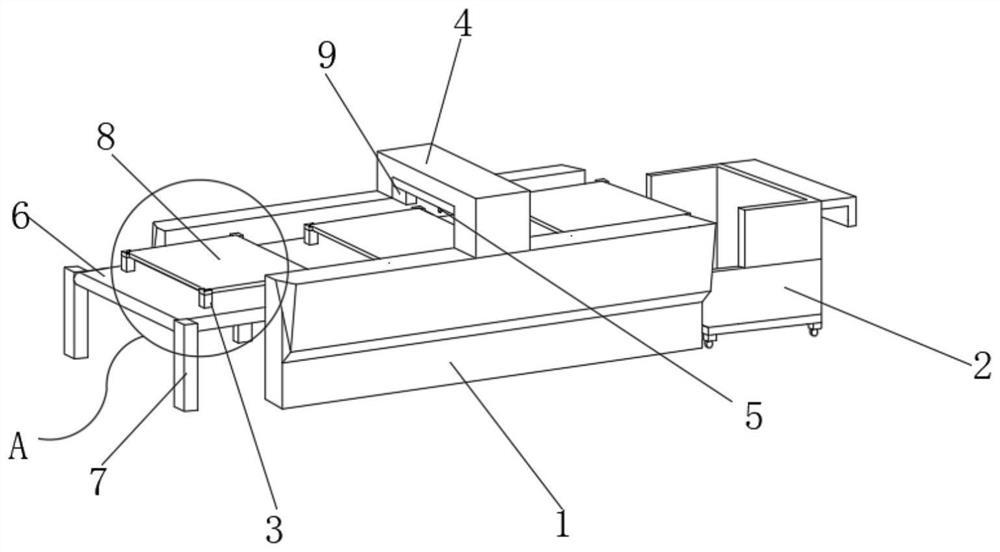

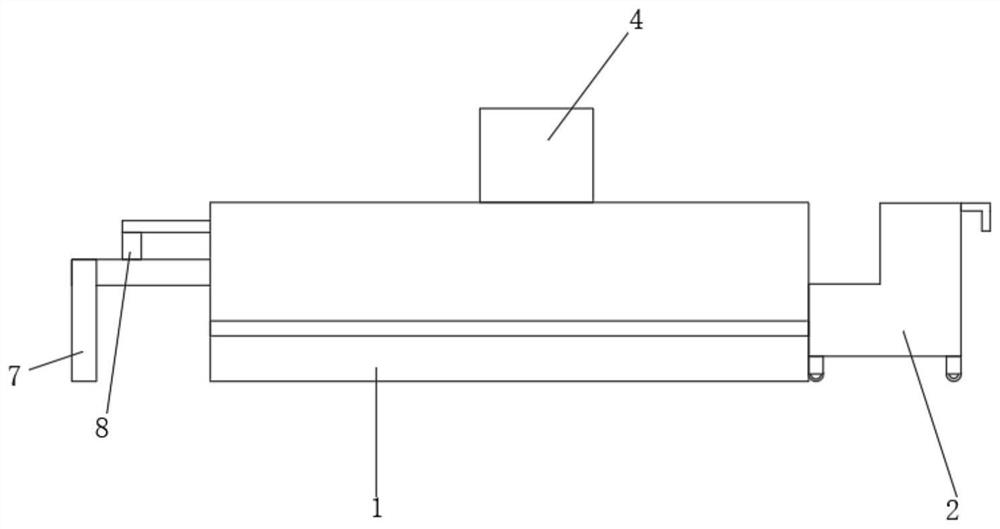

High speed rail line concrete track plate engraving machine and engraving method

PendingCN110027122AImprove stabilityHigh degree of automationWorking accessoriesStone-like material working toolsEngravingControl system

The invention provides a high speed rail line concrete track plate engraving machine and an engraving method. The high speed rail line concrete track plate engraving machine comprises a rack, a wheelset, a three-axis linkage mechanism, an engraving mechanism, a cooling system and a control system, wherein the rack moves on a track through the wheel set; and after a moving trail of the engraving mechanism is pre-programmed, the control system controls the three-axis linkage mechanism so as to drive to engraving mechanism to run according to the moving trail, so that permanent engraving is accomplished. The high speed rail line concrete track plate engraving machine provided by the invention is stable in performance, simple to operate, and capable of permanently marking concrete.

Owner:CHINA RAILWAY SCI & IND GRP RAIL TRANSPORTATION EQUIP LIMITED

Method of freely carving patterns on glasses

ActiveCN105882290ASimplify operational complexityEasy material selectionDecorative surface effectsNumerical controlUses eyeglasses

The invention relates to a method of freely carving patterns on a pair of glasses. The method of freely carving patterns on the pair of glasses comprises the steps that step 1, a camera with the automatic focal distance adjustment function is used for taking a photo of a lens to be carved, and an electronic photo is obtained; step 2, the electronic photo is uploaded to a computer, and image processing software is used for conducting image matting on the image on the lens to be carved; step 3, the image obtained from the image matting in step 2 is input to a numerical control laser carving machine; step 4, the numerical control laser carving machine is used for carving on each portion of the pair of glasses to obtain a rough pattern; step 5, a car paint pen is used for painting on the rough pattern obtained in step 4 until the rough pattern is painted evenly and completely covered; and step 6, alcohol is used for erasing paint outside the boundary of the rough pattern to obtain a refined pattern before the painted paint is completely dry. According to the method of freely carving patterns on the pair of glasses, control precision is high, and complicated patterns can be obtained.

Owner:颜丙刚

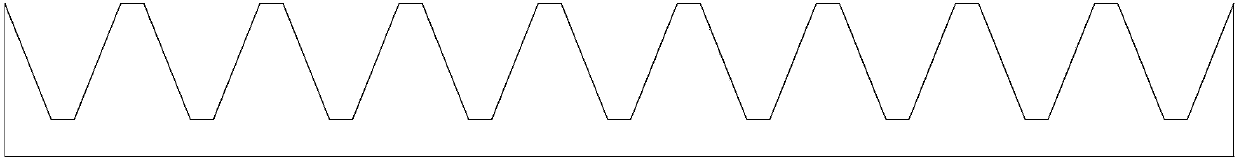

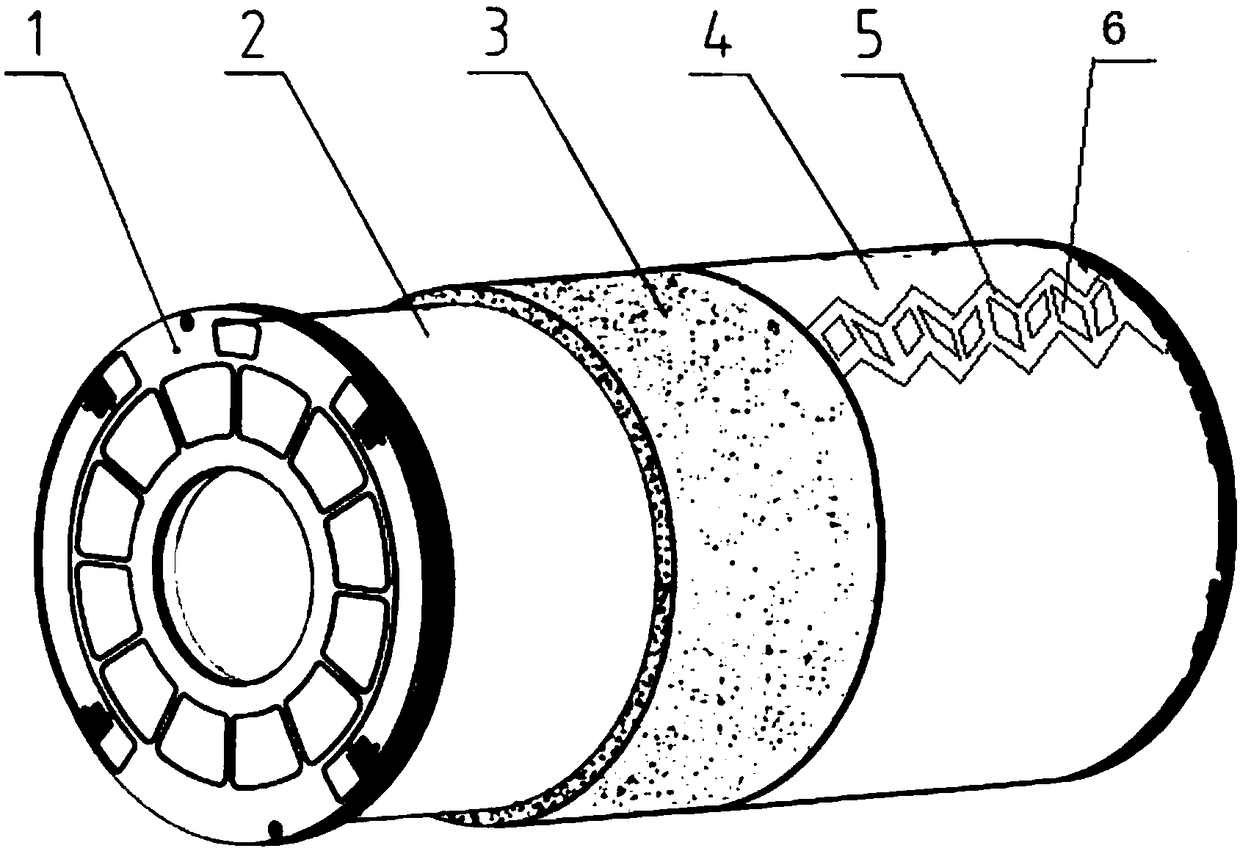

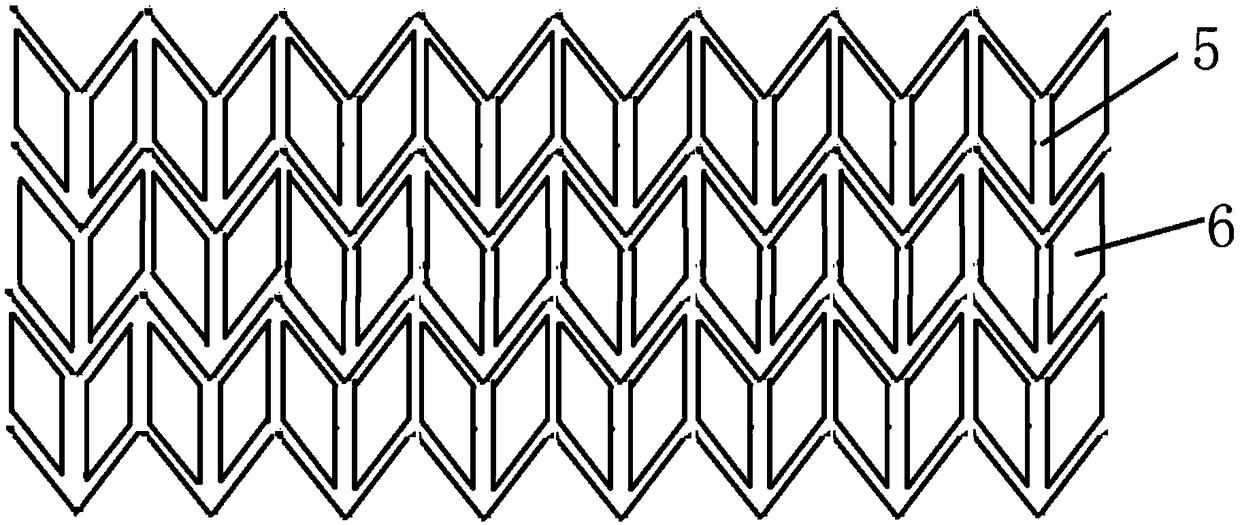

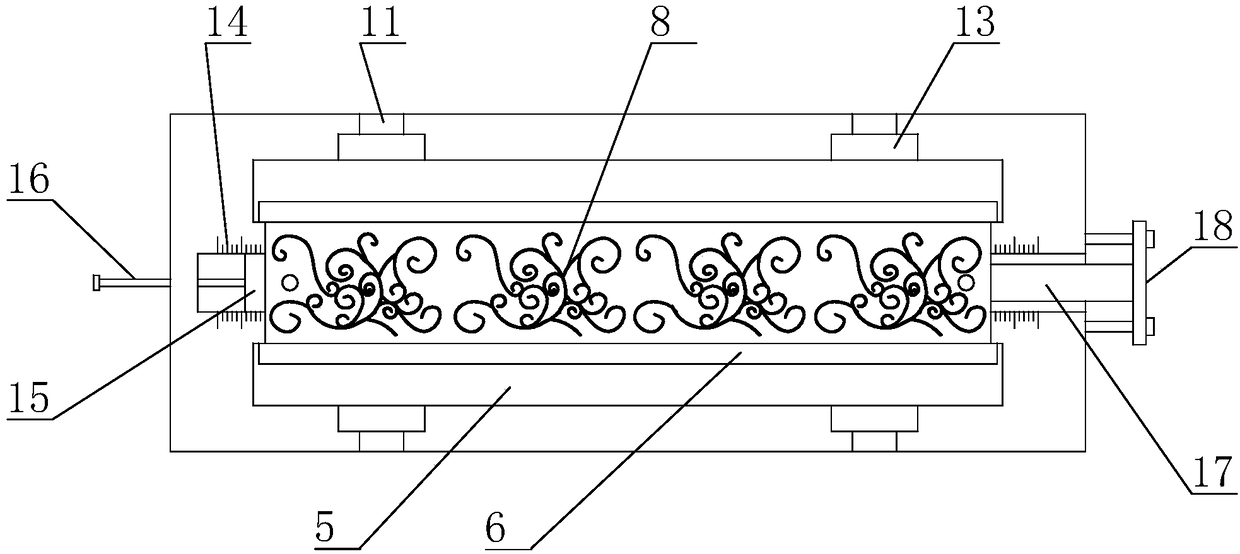

Roller for ceramic tile printing and preparation process thereof

ActiveCN108248200ASpeed up the flowImprove the level ofRotary pressesCeramic materials productionManufacturing technologyLaser engraving

The invention relates to a roller for ceramic tile printing and a preparation process thereof. The roller comprises a cylinder body and plugs arranged at the two ends of the cylinder body, wherein thecylinder body comprises an aluminum plate layer, a polyurethane sponge layer and a silica gel outer layer which are sequentially laminated from inside to outside. Mesh pits distributed in the axial direction of the cylinder body are formed in the surface of the silica gel outer layer, the edges of both sides of the mesh pits are serrated, and all the sawteeth of the edges of the mesh pits are ofthe same size; and rhombic mesh pits evenly distributed are formed in the middle of the mesh pits, and the two groups of opposite sides of the rhombic mesh pits are correspondingly parallel to the twosides of the edges of the sawteeth. Compared with the prior art, the roller for ceramic tile printing adopts the jagged mesh pits which are parallel to one another, so that ink carrying amount is large, the ink is not liable to flow in the mesh pits, and thus the leveling property of the roller is increased; another layer of the rhombic mesh pits is arranged in the jagged mesh pits, the ink carrying capacity of the roller is increased, and the thickness and the strength of a screen wall are ensured to facilitate printing; a laser engraving technology is adopted, the engraving of the mesh pitsis more accurate, and the manufacturing technology is more stable.

Owner:SHANGHAI YUNAN PLATE MAKING

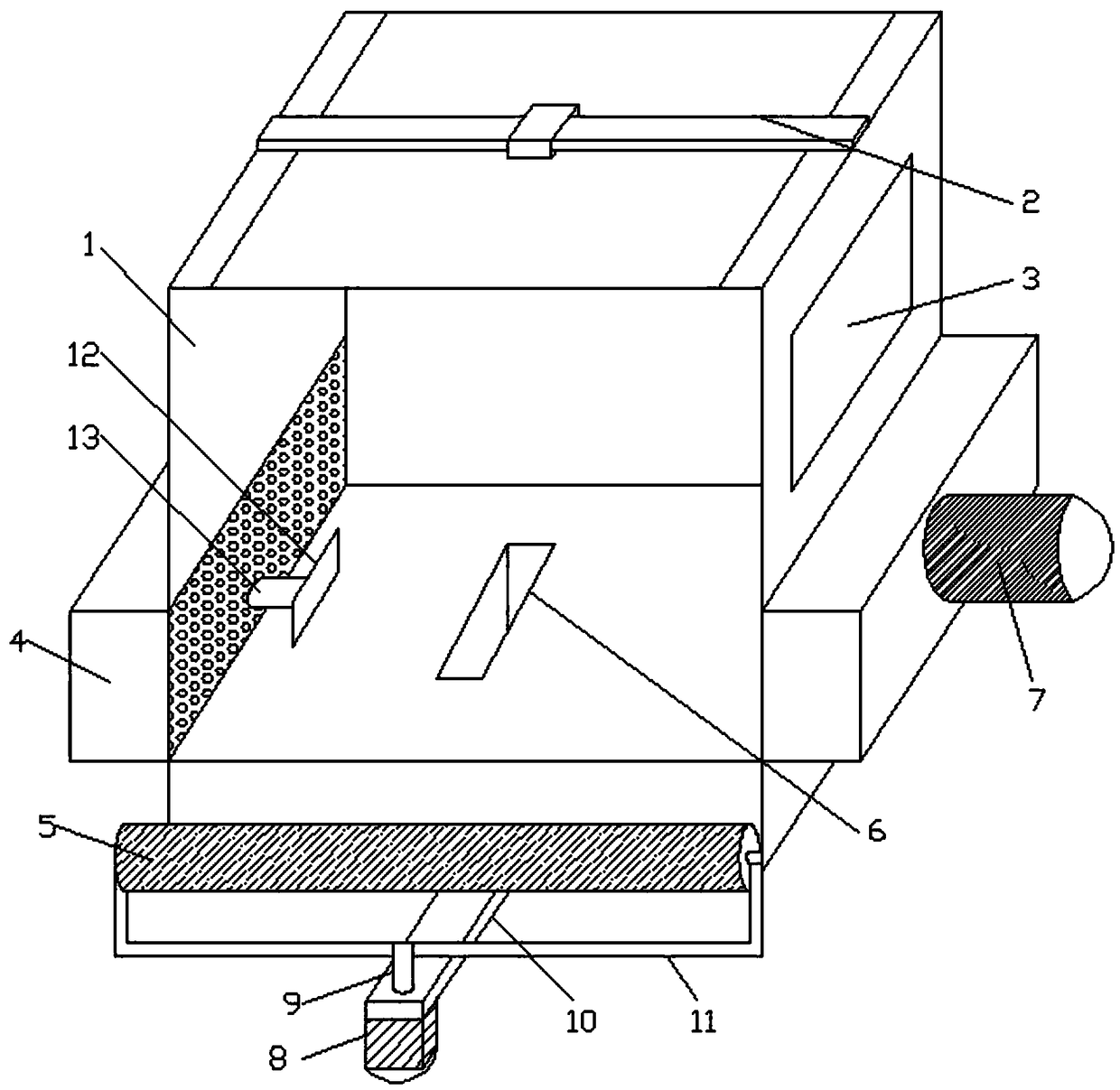

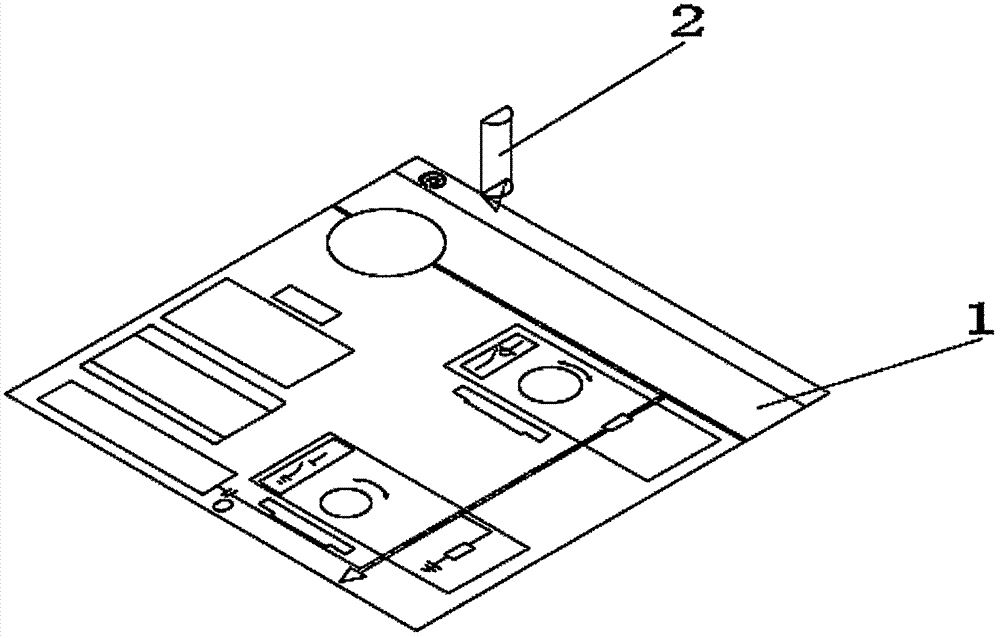

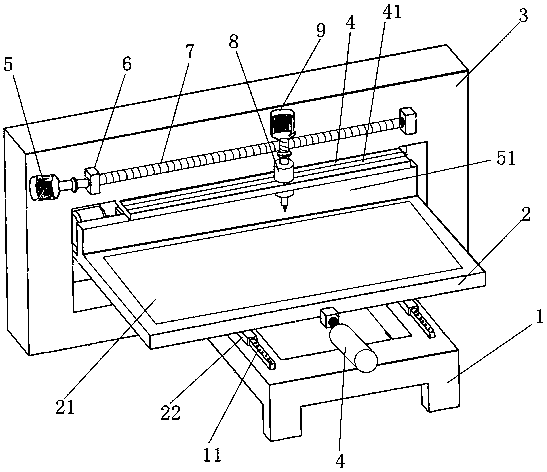

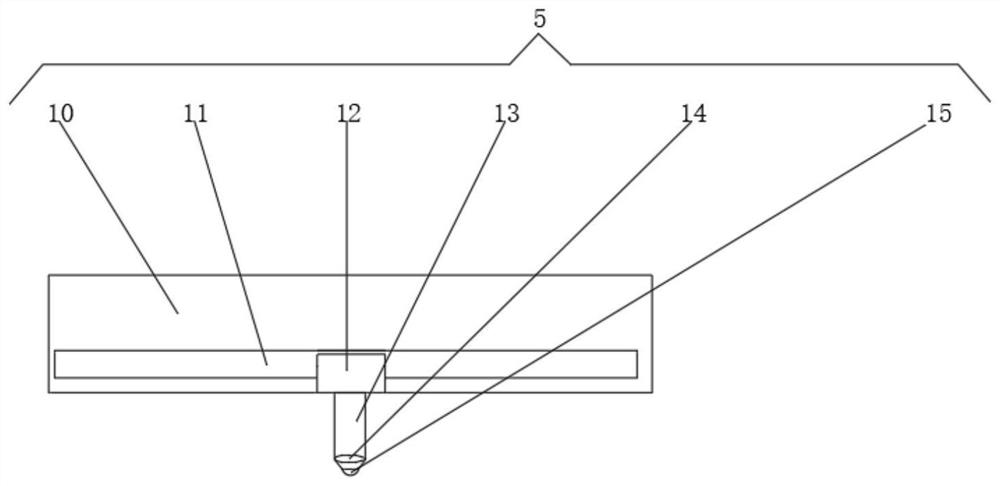

Device for manufacturing circuit through liner plate engraving process

PendingCN108357275AAccurate engravingConductive material mechanical removalOther artistic work equipmentsCircuit designManufacturing efficiency

The invention relates to a circuit engraving device, in particular to a device for manufacturing a circuit through a liner plate engraving process. A table rack used for fixing a liner plate is arranged on a rack; the table rack is connected with the rack through a first drive device; the rack is connected with a mounting frame; the mounting frame is connected with a supporting plate; a guide railis arranged on the supporting plate; the guide rail is in sliding connection with an engraving machine; a second drive device is arranged on the mounting frame; the second drive device is connected with a screw; the screw is connected with the engraving machine through threads; and the first drive device and the second drive device are connected with a main controller. The device can accurately and quickly engrave out the circuit according to a circuit design drawing, and improves circuit manufacturing efficiency.

Owner:GUANGDONG POWER GRID CO LTD +1

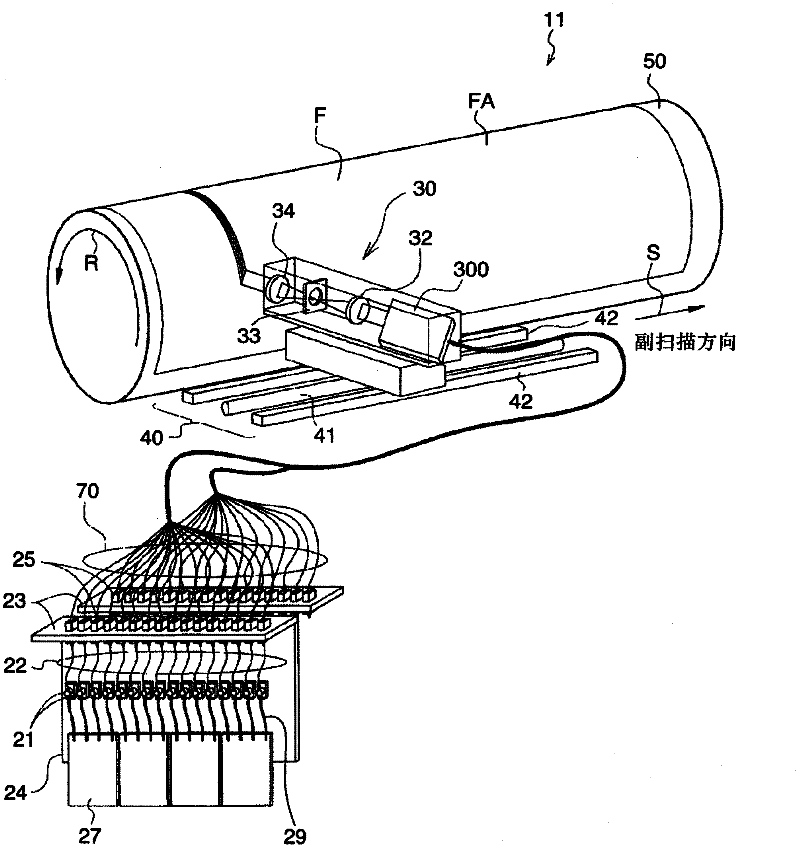

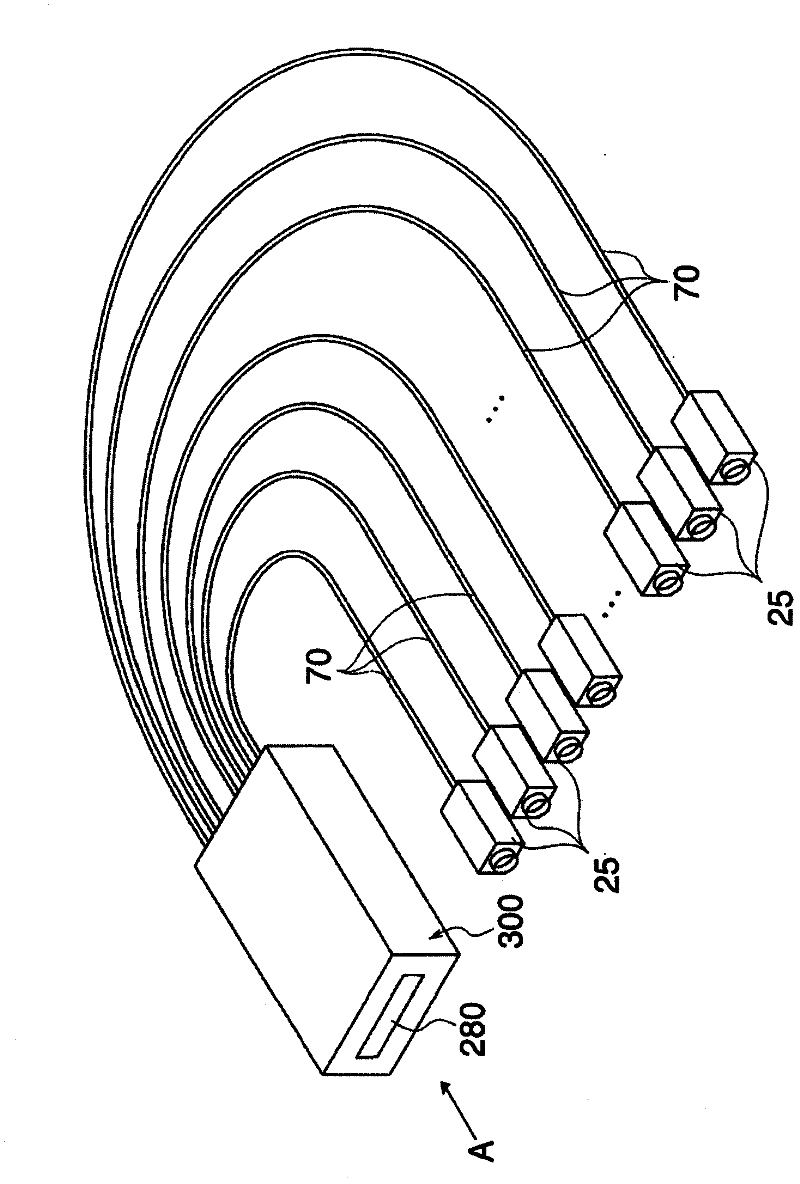

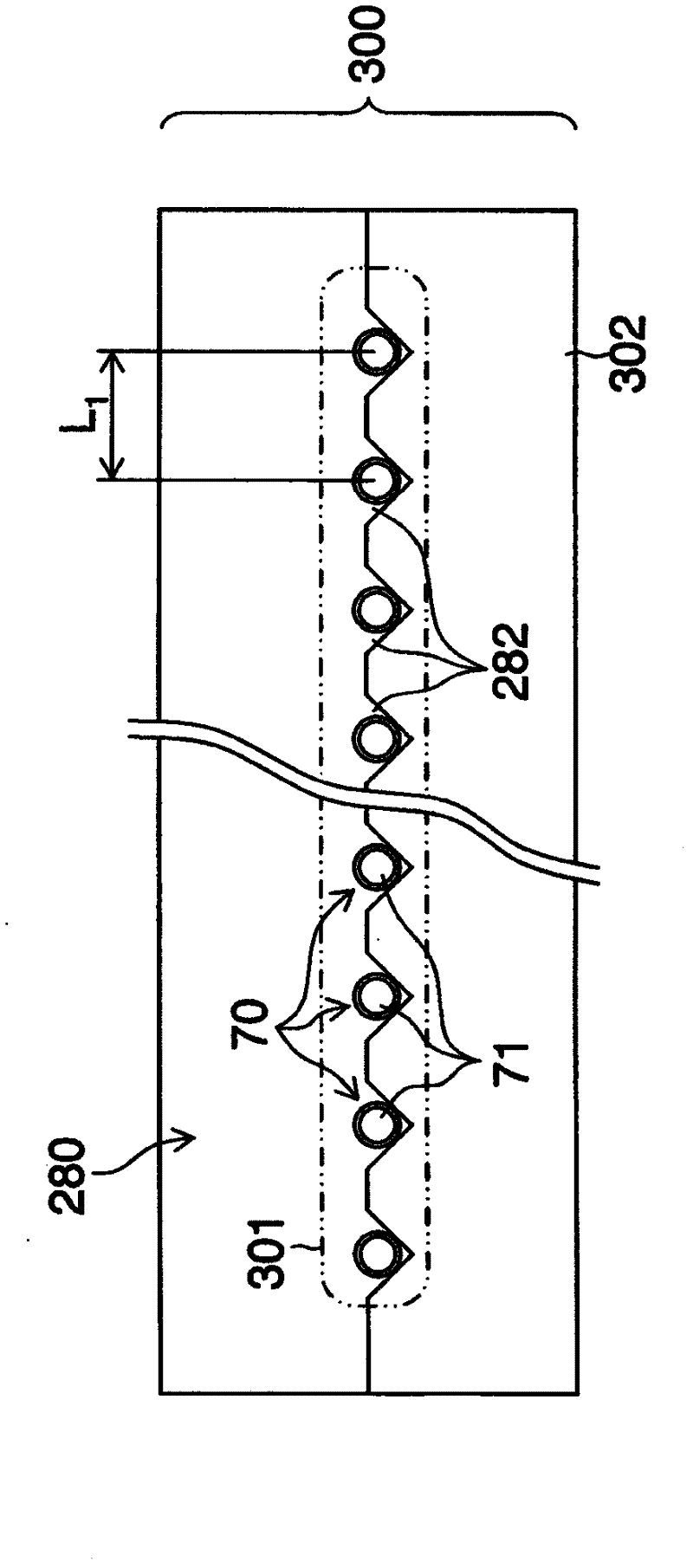

Multi-beam exposure scanning method and apparatus, and method for manufacturing printing plate

InactiveCN102239450AAccurate engravingPhotomechanical exposure apparatusMicrolithography exposure apparatusLight beamIrradiation

Owner:FUJIFILM CORP

Fixing clamp

InactiveCN108973475AEasy to fixHeight adjustable supportOther artistic work equipmentsModel makingEngravingEngineering

The invention discloses a fixing clamp comprising a strip-shaped bearing base. A clamp fixing mechanism is arranged on the upper surface of the strip-shaped bearing base. A supporting mechanism is arranged on the lower surface of the strip-shaped bearing base. The fixing clamp has the beneficial effects that fixing is achieved conveniently according to the sizes and shapes of building stone materials, the supporting height is adjusted, the engraving angle is convenient to adjust, fixing is good, and engraving is accurate.

Owner:瑞安市仙林鞋业有限公司

Automatic laser engraving machine

InactiveCN105855717AAccurate engravingHigh degree of automationLaser beam welding apparatusLaser engravingEngineering

The invention relates to an automatic laser engraving machine. The automatic laser engraving machine comprises a supporting table. Supports are connected to the two sides of the supporting table. A beam is connected between the two supports. A laser facing the supporting table is arranged on the beam. A conveying device is arranged on the supporting table. A locating device capable of moving in the longitudinal direction of the supports and locating products on the conveying device and a drive mechanism for driving the locating device to move in the longitudinal direction are connected between the two supports. By the adoption of the automatic laser engraving machine, keycaps placed on a keyboard in batches can be conveyed automatically, the keyboard is located, and therefore the keycaps are located; and all the keycaps can be engraved precisely through the laser, the automation degree is high, and machining efficiency is improved greatly.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

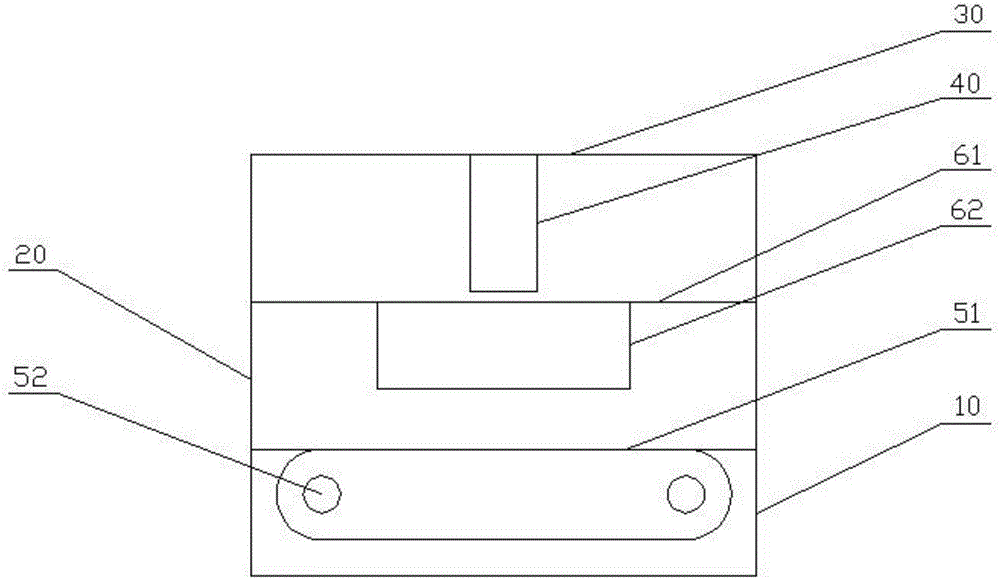

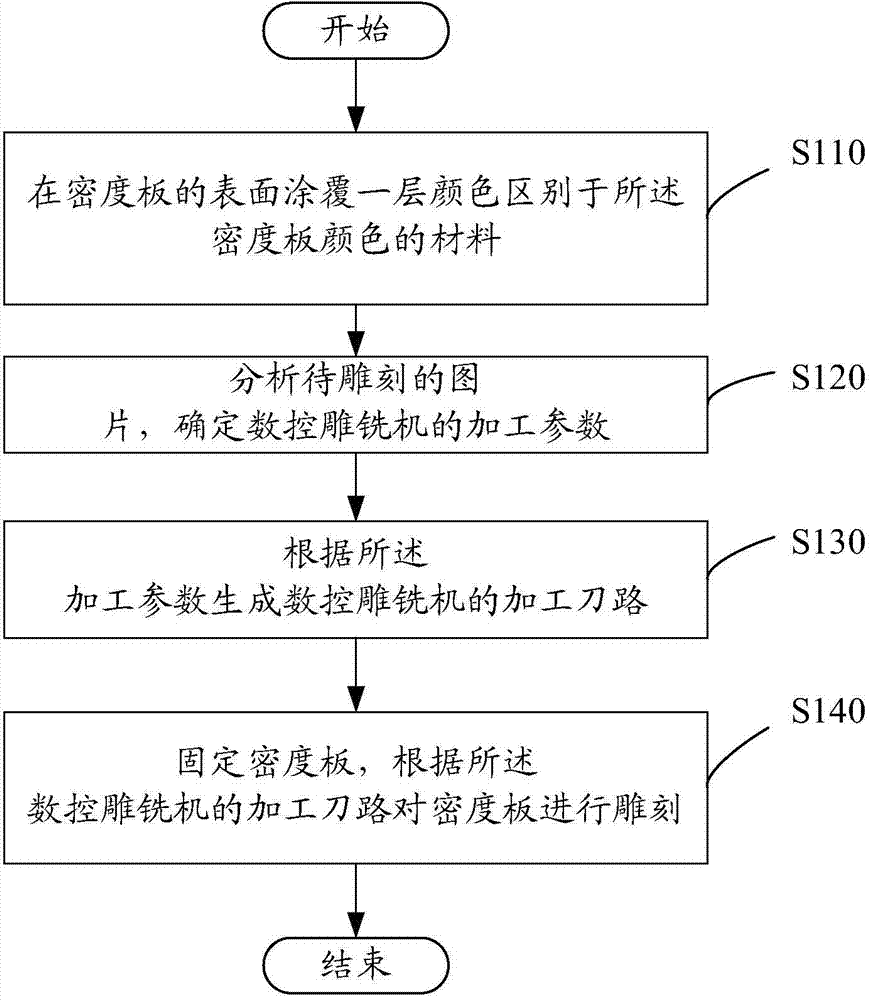

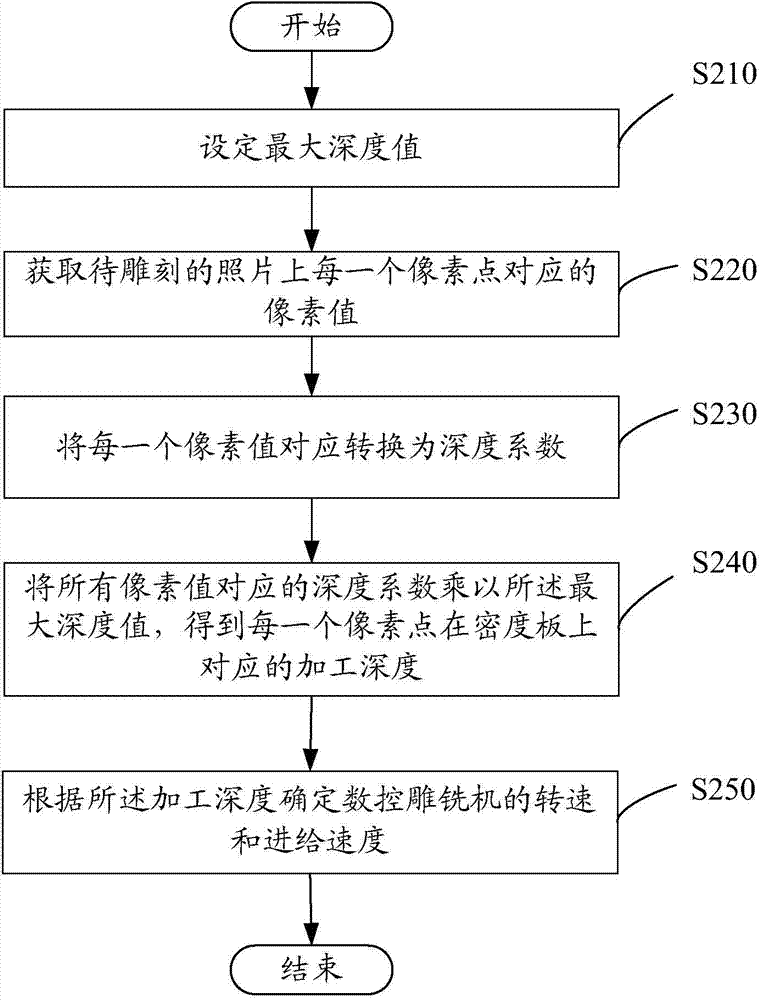

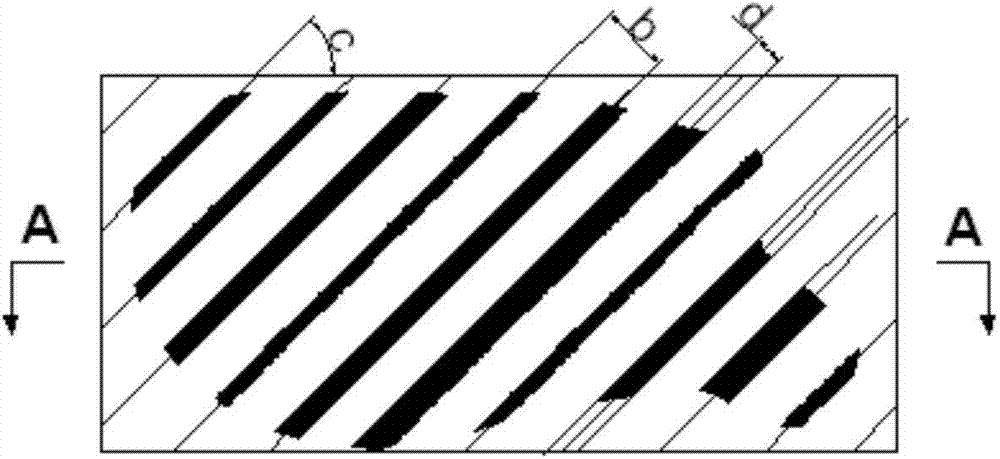

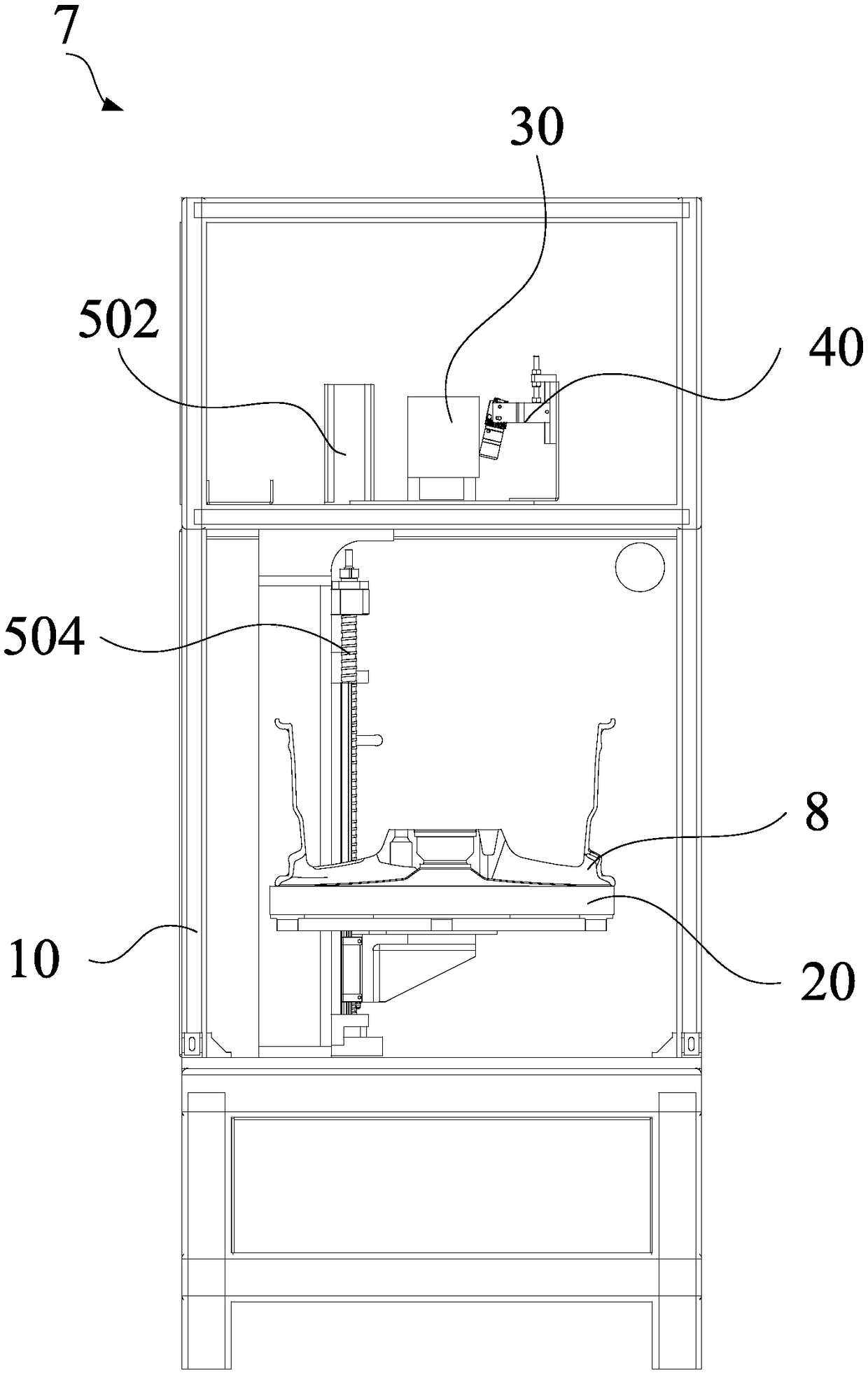

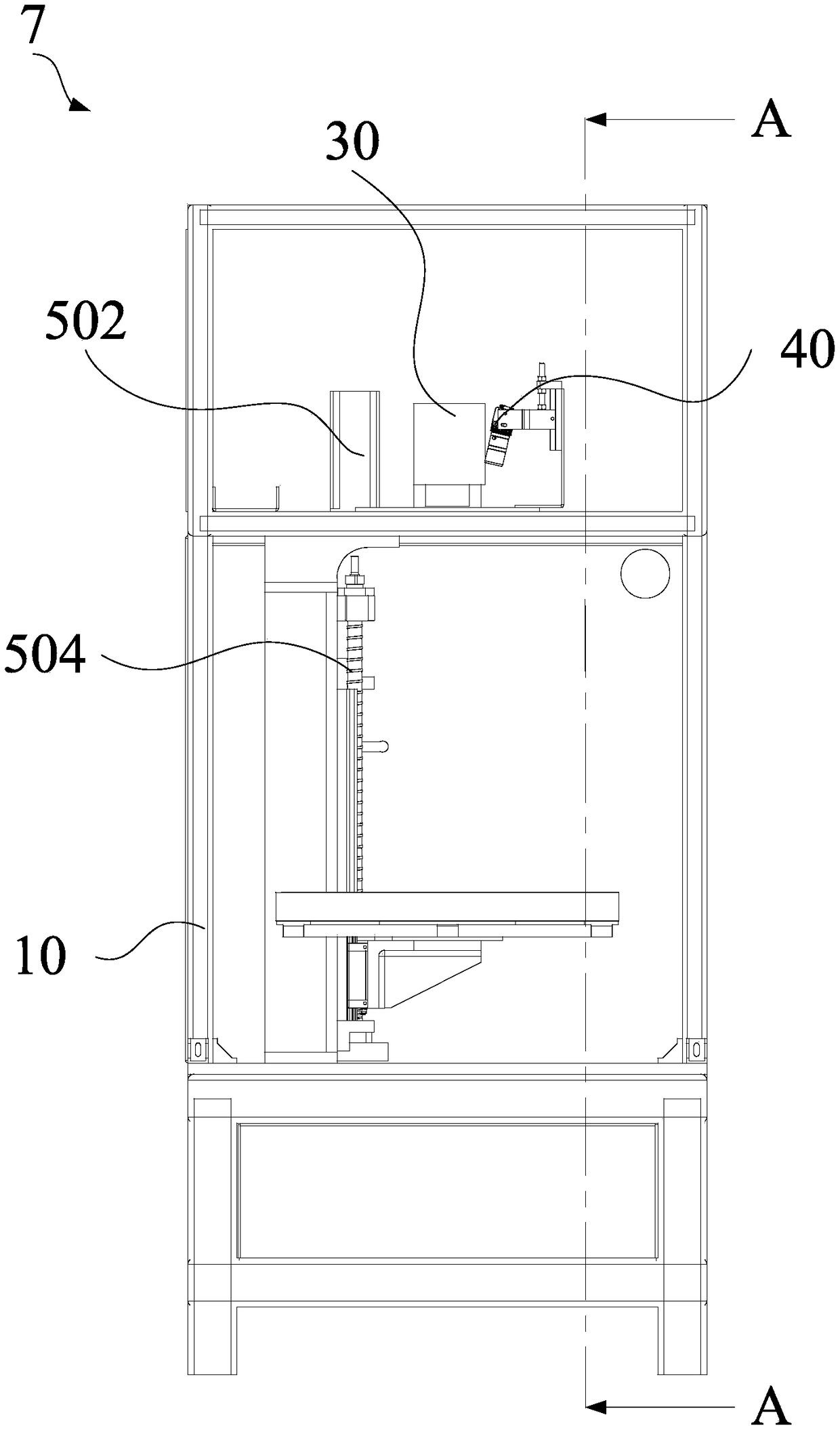

Production method and device for engraved picture of density board

InactiveCN103568675AAccurate engravingEfficient engravingDecorative surface effectsSpecial ornamental structuresEngineeringVolumetric Mass Density

The invention relates to a production method for an engraved picture of a density board. The production method comprises the following steps: coating the surface of the density board with one layer of a material with the color different from that of the density board; analyzing a picture to be engraved and determining machining parameters of a numerical control engraving and milling machine; generating a machining cutter path of the numerical control engraving and milling machine according to the machining parameters; and fixing the density board and engraving the density board according to the machining cutter path of the numerical control engraving and milling machine. According to the production method for the engraved picture of the density board, the step of engraving is automatically finished by the numerical control engraving and milling machine so that the production method has high efficiency and accuracy. Furthermore, the invention further provides a production method for the engraved picture of the density board; the device can effectively and accurately engrave the picture on the density board according to the production method for the engraved picture of the density board.

Owner:SUZHOU BC TECH

Metal part engraving equipment

InactiveCN108749436AEasy to follow upAppropriate distanceModel makingEngravingBiochemical engineeringReciprocating motion

The invention provides metal part engraving equipment which comprises a rack, a workbench, an engraving device, an acquiring assembly and a driving device, wherein the workbench is arranged on the rack and used for the placement of a metal part; the engraving device is arranged on the rack and positioned above the workbench; the acquiring assembly is arranged on the rack, and used for acquiring afirst mark and coding information on the metal part; and the driving device is arranged on the rack, connected with the workbench, and used for driving the workbench to perform reciprocating motion along the height direction of the rack. Through the metal part engraving equipment provided by the invention, the metal part can be accurately engraved by the engraving device according to the first mark and the coding information which are acquired by the acquiring assembly, thereby achieving the high degree of automation, the safety and the reliability, improving the engraving efficiency and the metal part engraving qualification rate, and effectively reducing the human cost.

Owner:ZHEJIANG JINYUE MACHINERY TECH DEV +3

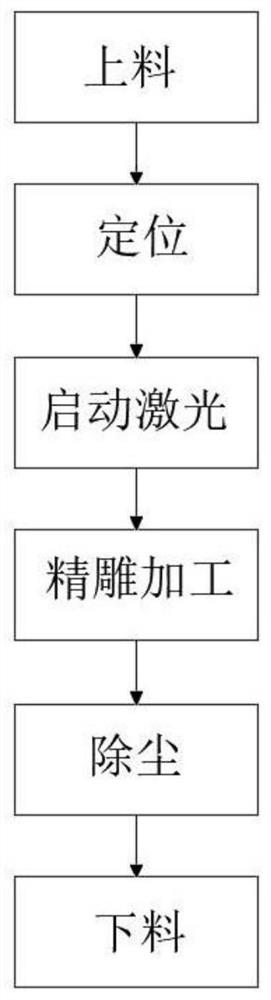

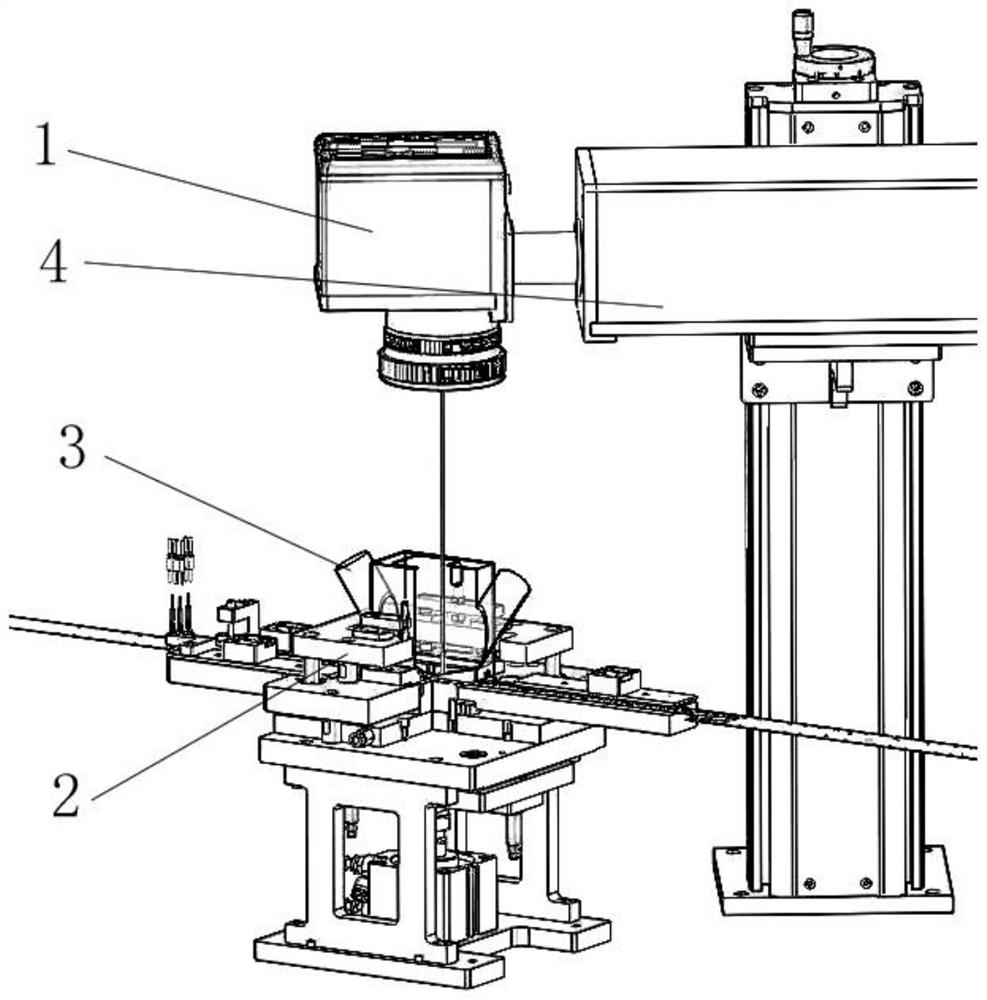

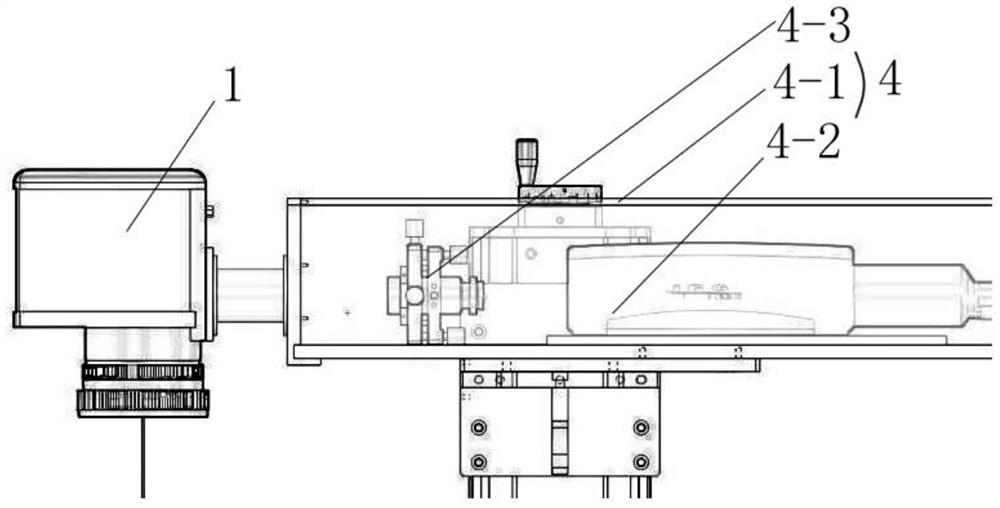

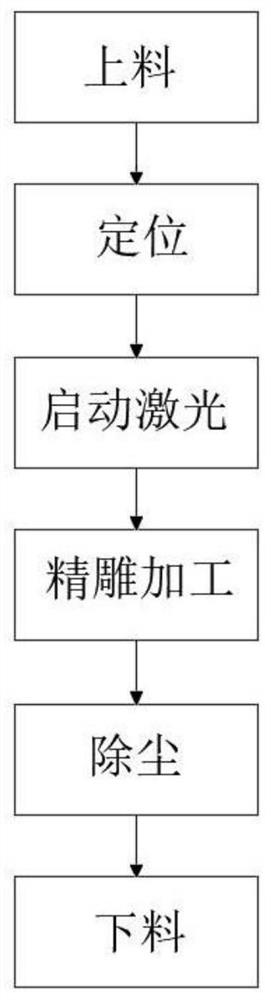

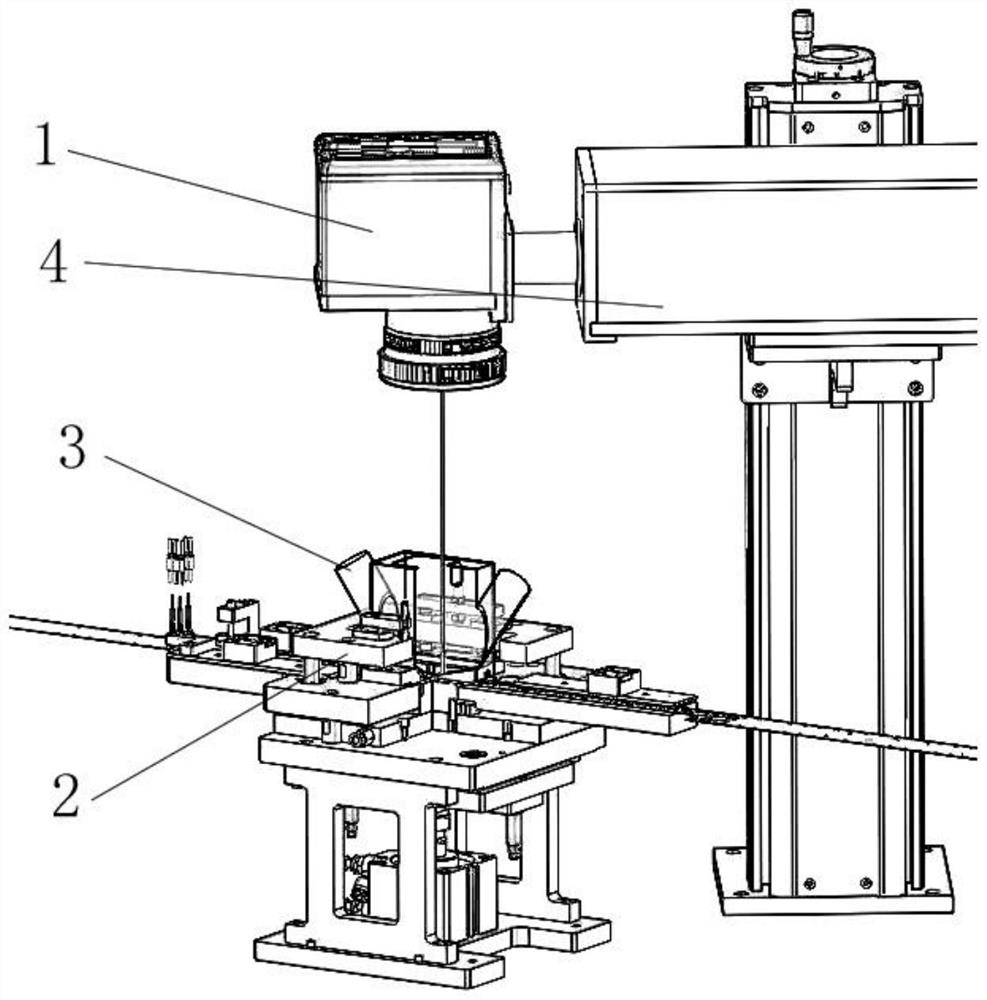

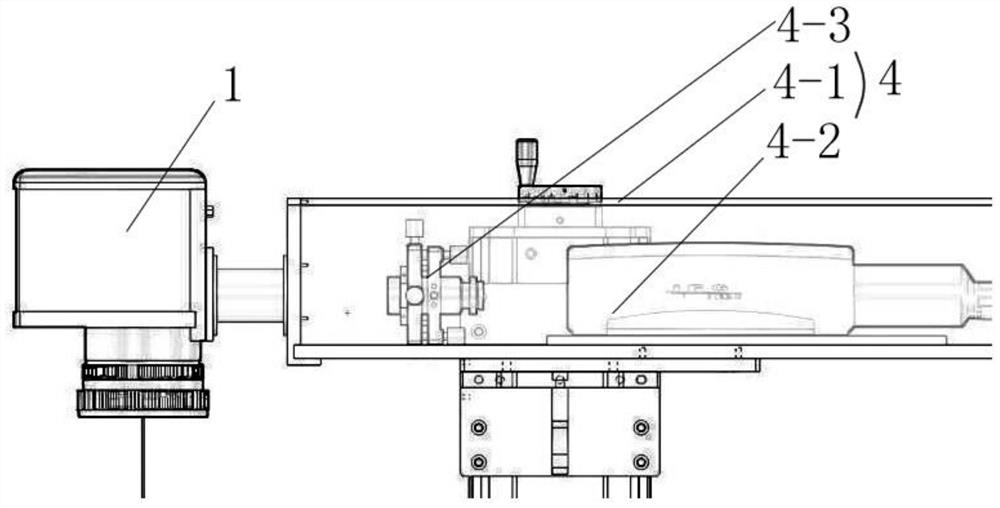

Ultrafast laser fine carving method for metal

ActiveCN112222628AHigh speedImprove efficiencyLaser beam welding apparatusGalvanometerLaser engraving

The invention discloses an ultrafast laser fine carving method for metal. The method comprises the following steps that firstly, a product to be carved is placed at the machining position of a fine carving device; secondly, after the product to be carved reaches the machining position of the fine carving device, pressing action is triggered by an inductor for the product to be carved, it is guaranteed that the surface to be carved and a galvanometer laser carving device are relatively horizontal through positioning of a jig mechanism, and ultrafast fine carving machining is achieved; thirdly,a laser device emits a laser beam which enters the galvanometer laser carving device through a laser path mechanism; fourthly, the galvanometer laser carving device controls the laser beam to act on the surface of the product to be carved for fine carving machining; fifthly, a dust removal mechanism blows away smoke dust generated on the surface of the product and carries out pumping and discharging treatment; and sixthly, after fine carving machining is completed, the product is recycled. Consistency of automation and the high efficiency of machining are guaranteed, meanwhile, the technological requirements needed by fine carving can be met, products can be carved rapidly, accurately and finely, and the production and machining efficiency and yield are improved.

Owner:SHENZHEN DADE LASER TECH CO LTD

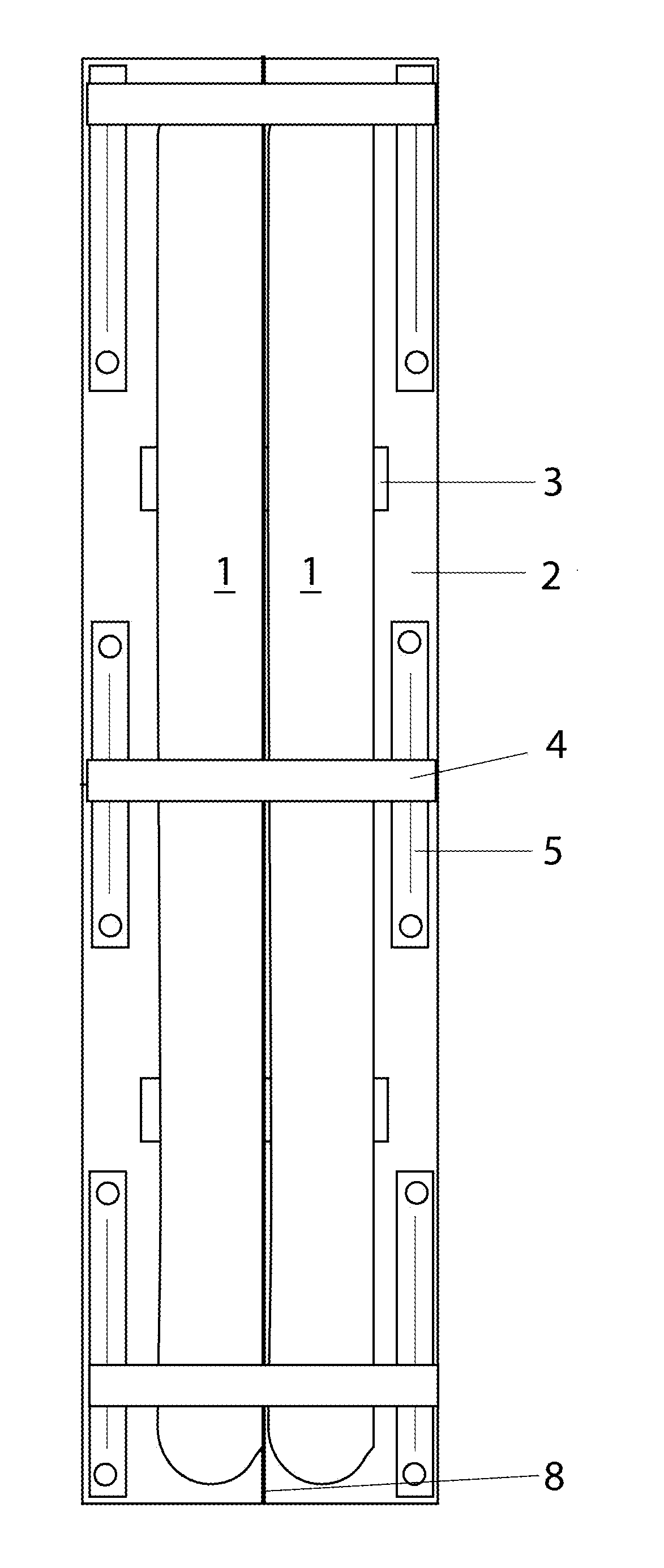

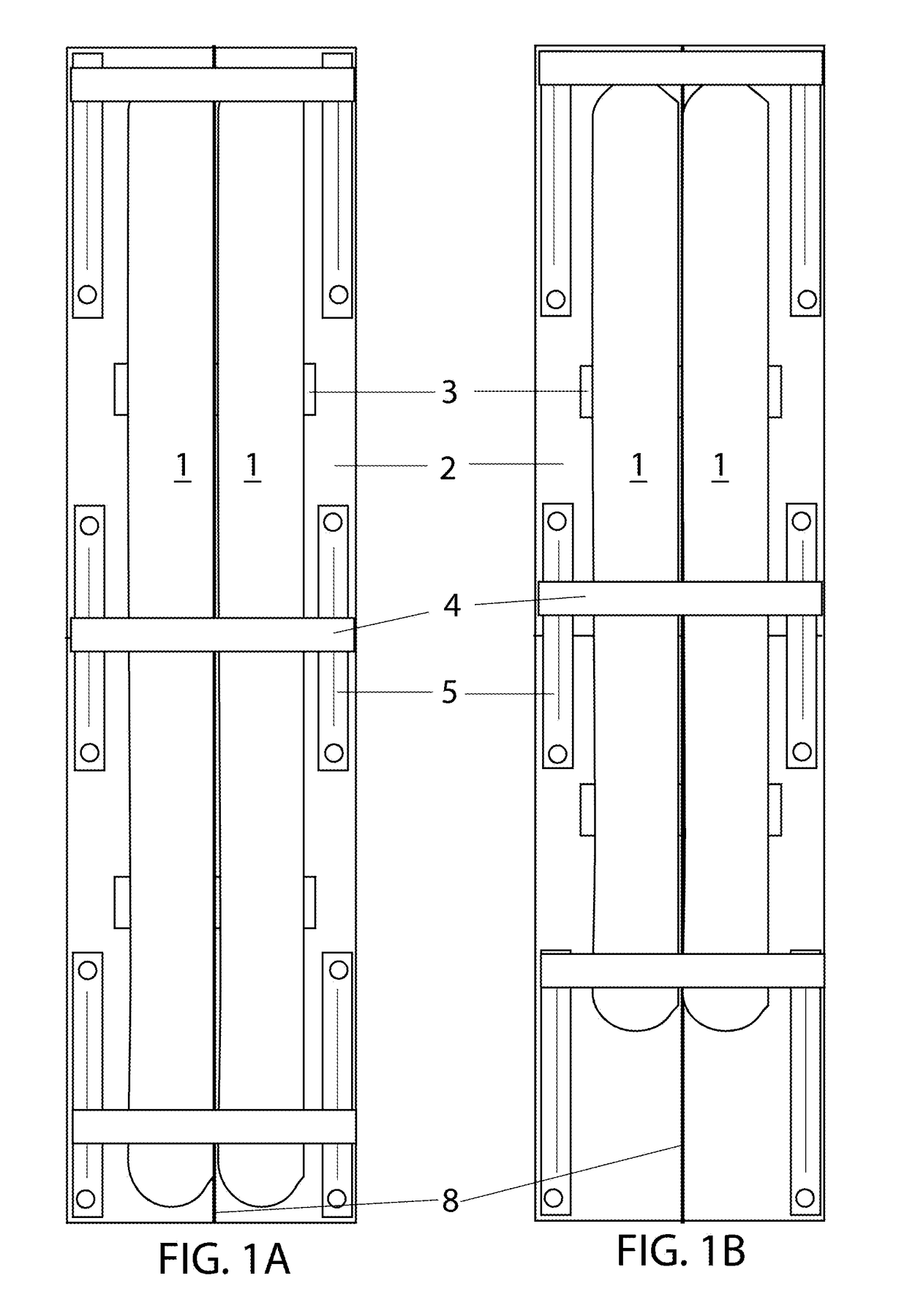

Apparatus and method for flattening and laser engraving skis

InactiveUS20170072288A1Reduce turnaround timeAccurate engravingSnowboard bindingsSnowboardsLaser engravingEngineering

The invention relates to an apparatus for flattening the top surface of skis to facilitate laser engraving thereof, to the method of laser engraving of skis employing such apparatus, and to a custom laser-engraved ski production and inventory management system wherein blank skis are manufactured, defects culled, and the blank ski of suitable length etc. is matched to the customer and laser engraved, preferably using the disclosed flattening apparatus.

Owner:GRACE SKIS

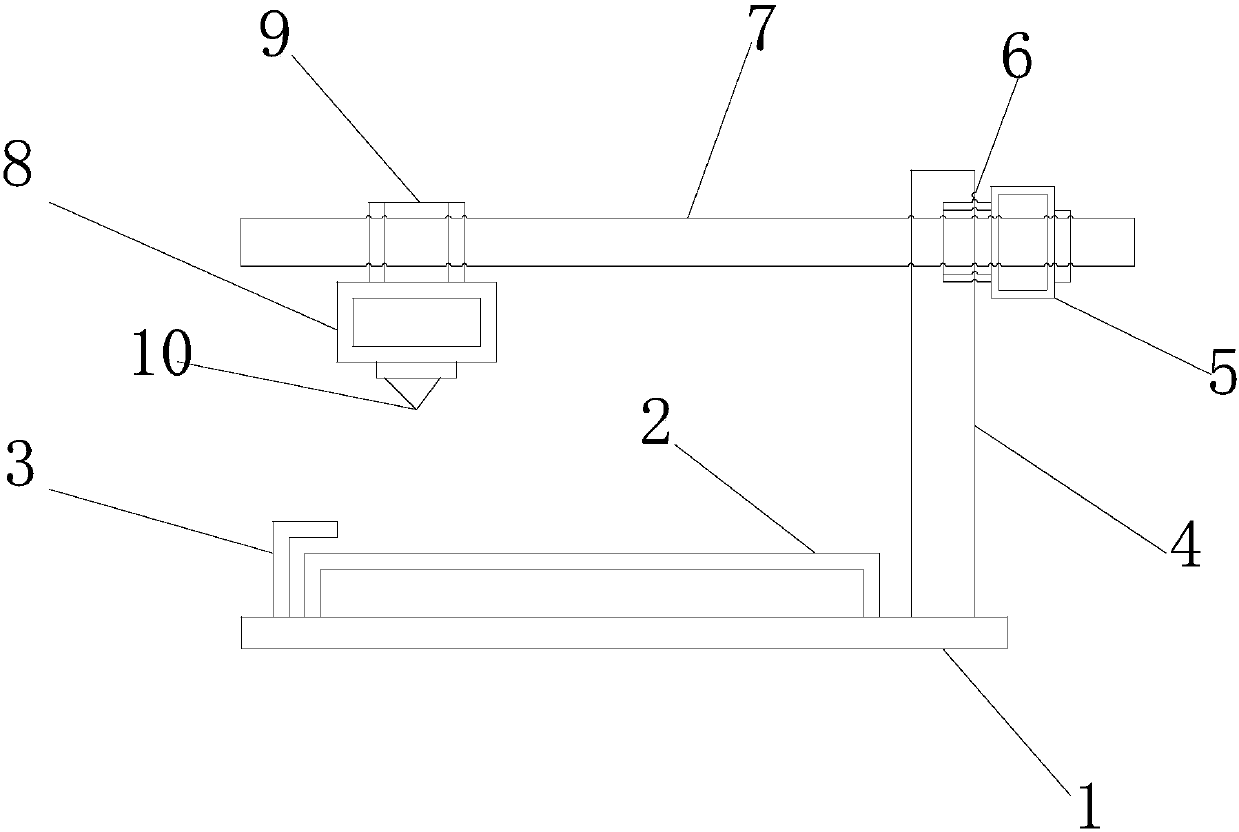

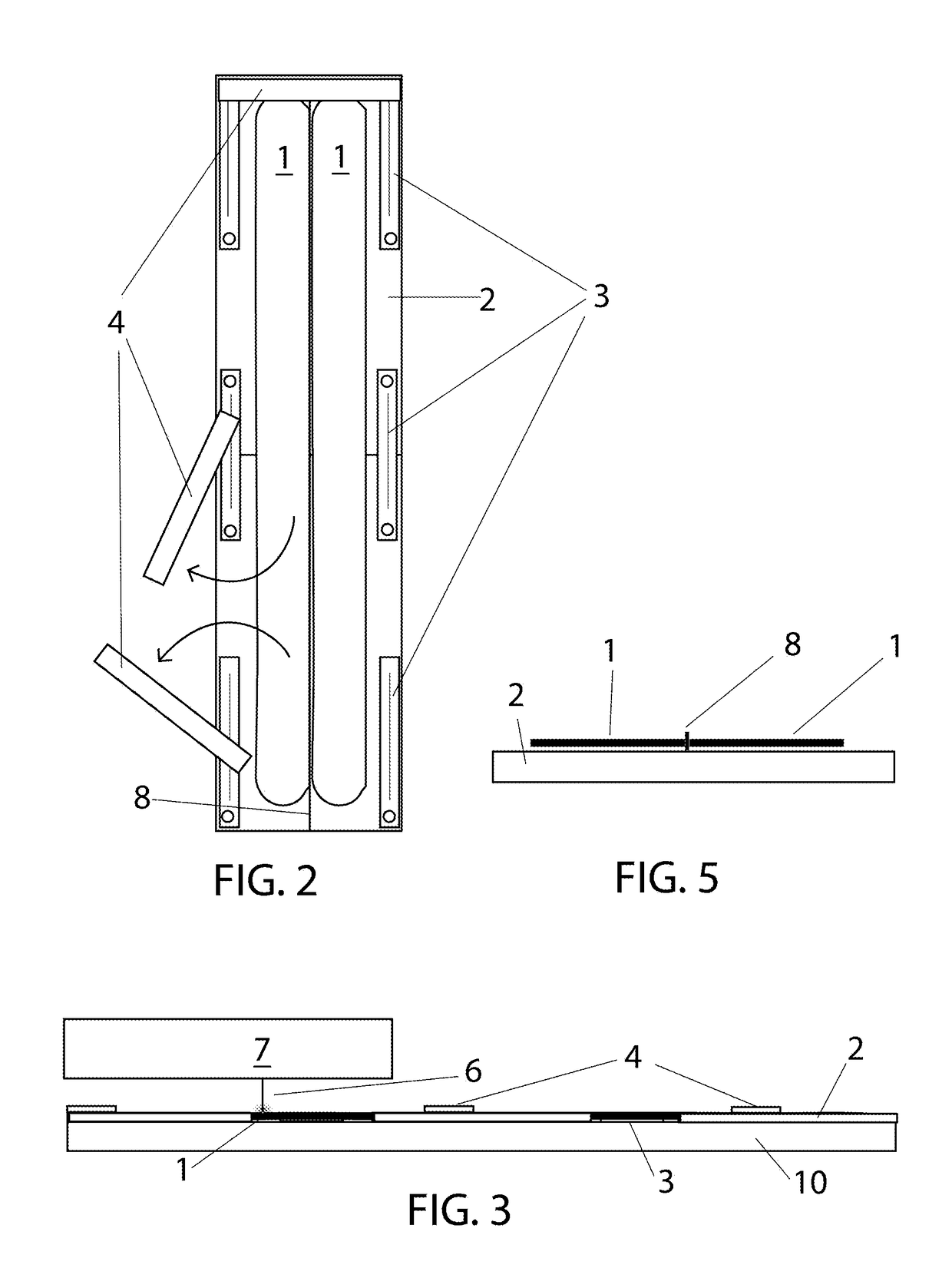

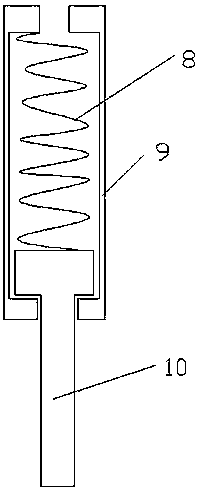

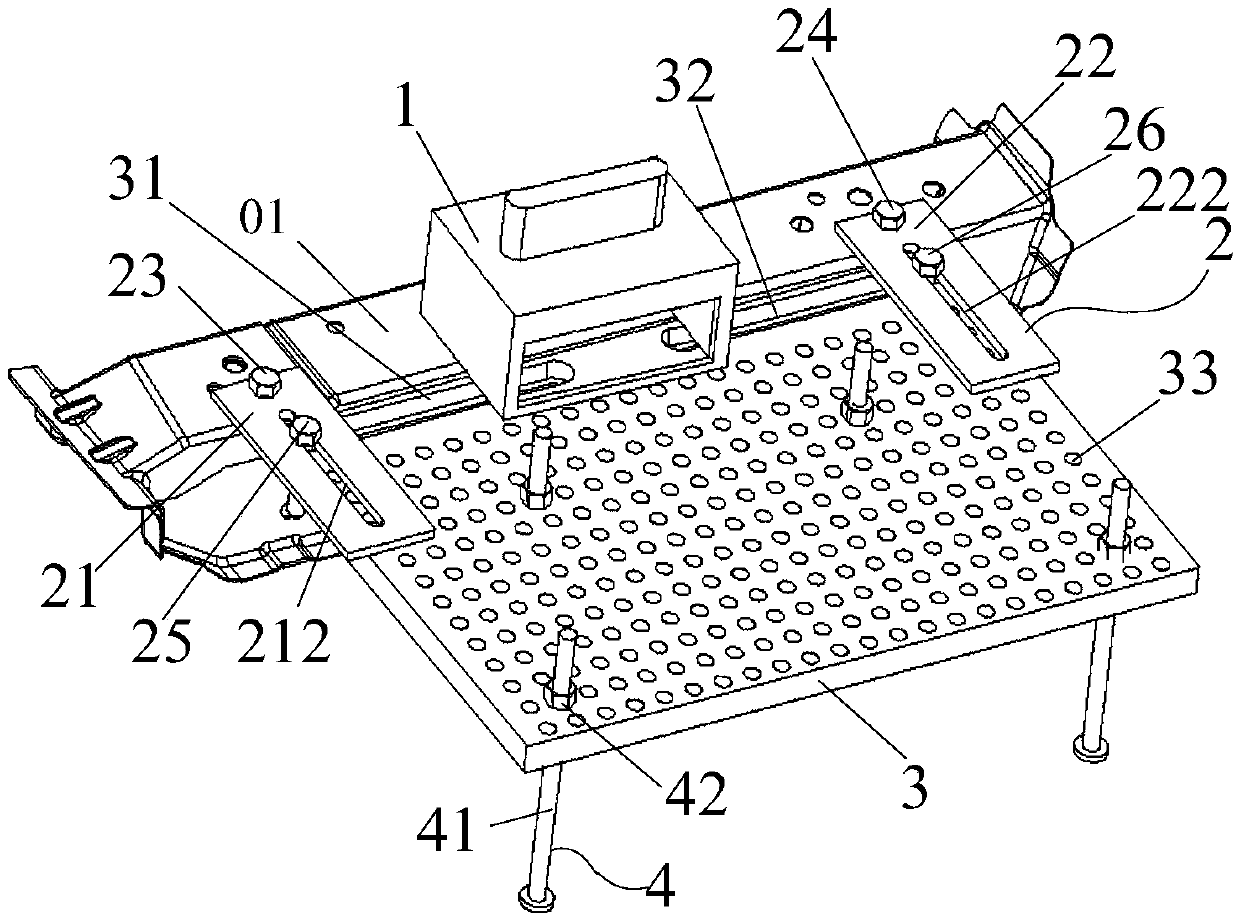

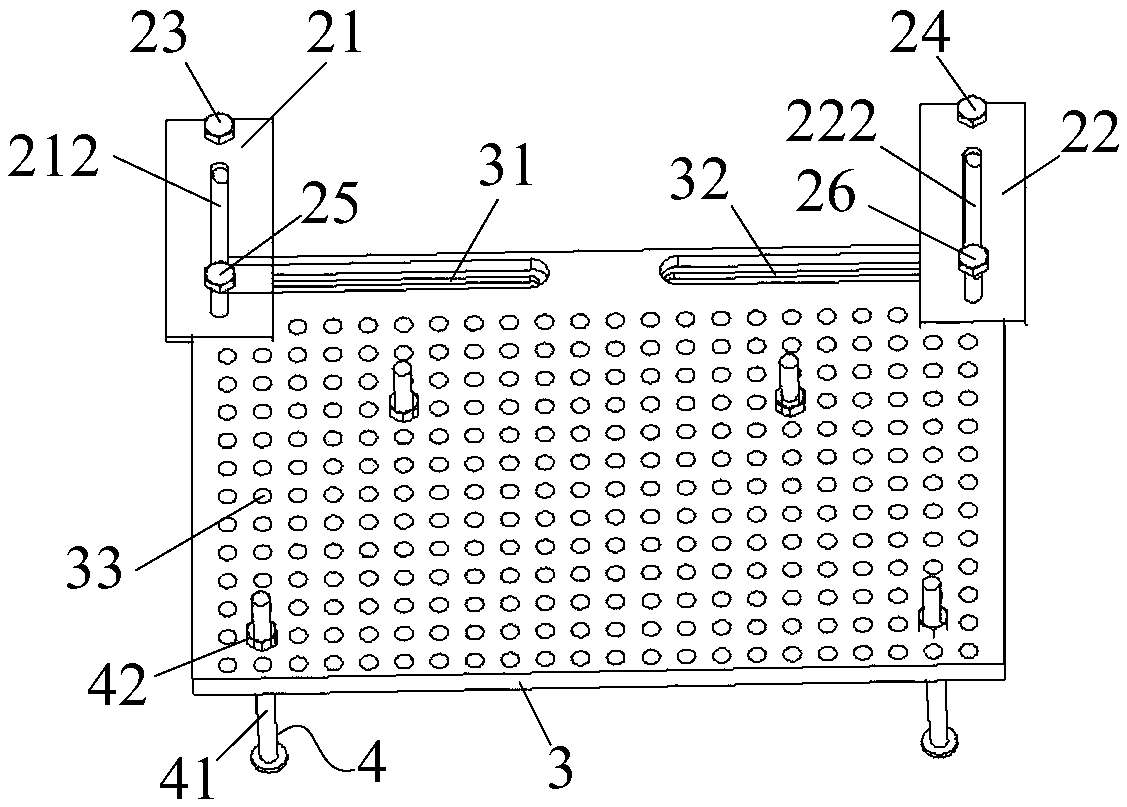

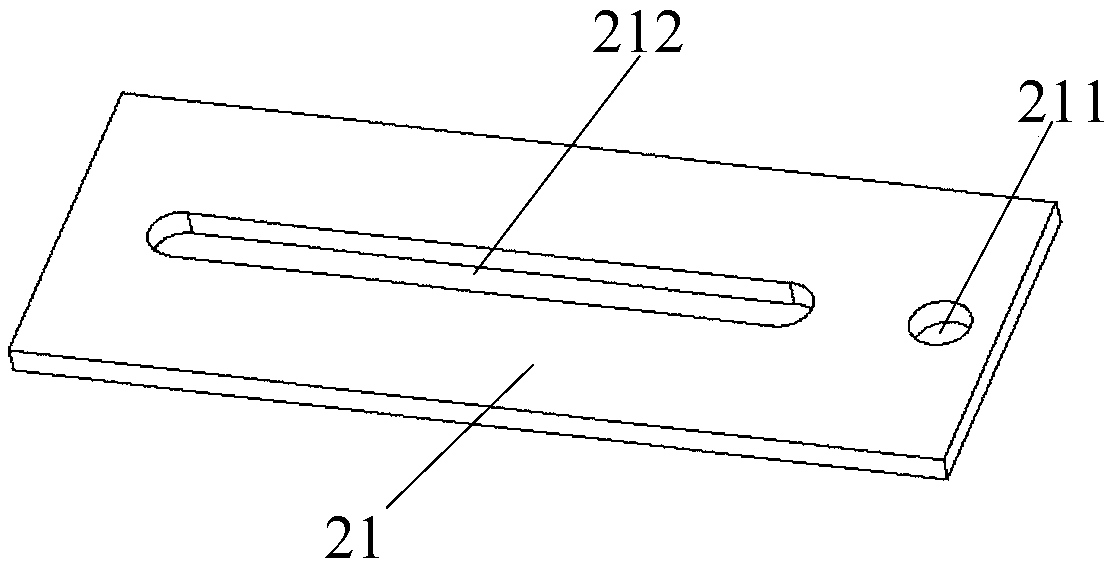

Self-adaptive plate press of carving machine for advertising production

InactiveCN107627774AAvoid jitterImprove the effect of engravingModel makingEngravingEngineeringSteel ball

The invention discloses a self-adaptive plate press of a carving machine for advertising production. The self-adaptive plate press comprises at least three telescopic connection assemblies (2), a fixing ring (1) and pressing plates (3); the fixing ring (1) is provided with an opening, and the two ends of the opening are locked through a bolt (4); each telescopic connection assembly (2) comprises aguide casing pipe (9) and an ejector rod (10), wherein the guide casing pipe (9) is fixedly installed on the fixing ring 91) and internally provided with an elastic element (8), one end of the ejector rod (10) is fixedly installed on the corresponding pressing plate (3), and the other end of the ejector rod (10) is connected with the movable end of the elastic element (8); and the pressing plateof each pressing plate (3) is provided with a plurality of universal steel balls (7) and at least one guide groove (6). The pressing plates are provided with the guide grooves, by means of the guide grooves, waste produced by carving can be guided out of the guide grooves smoothly, the problem that a plate press is blocked by waste is solved, and carving is more quick, accurate and stable.

Owner:成都缔上广告装饰有限公司

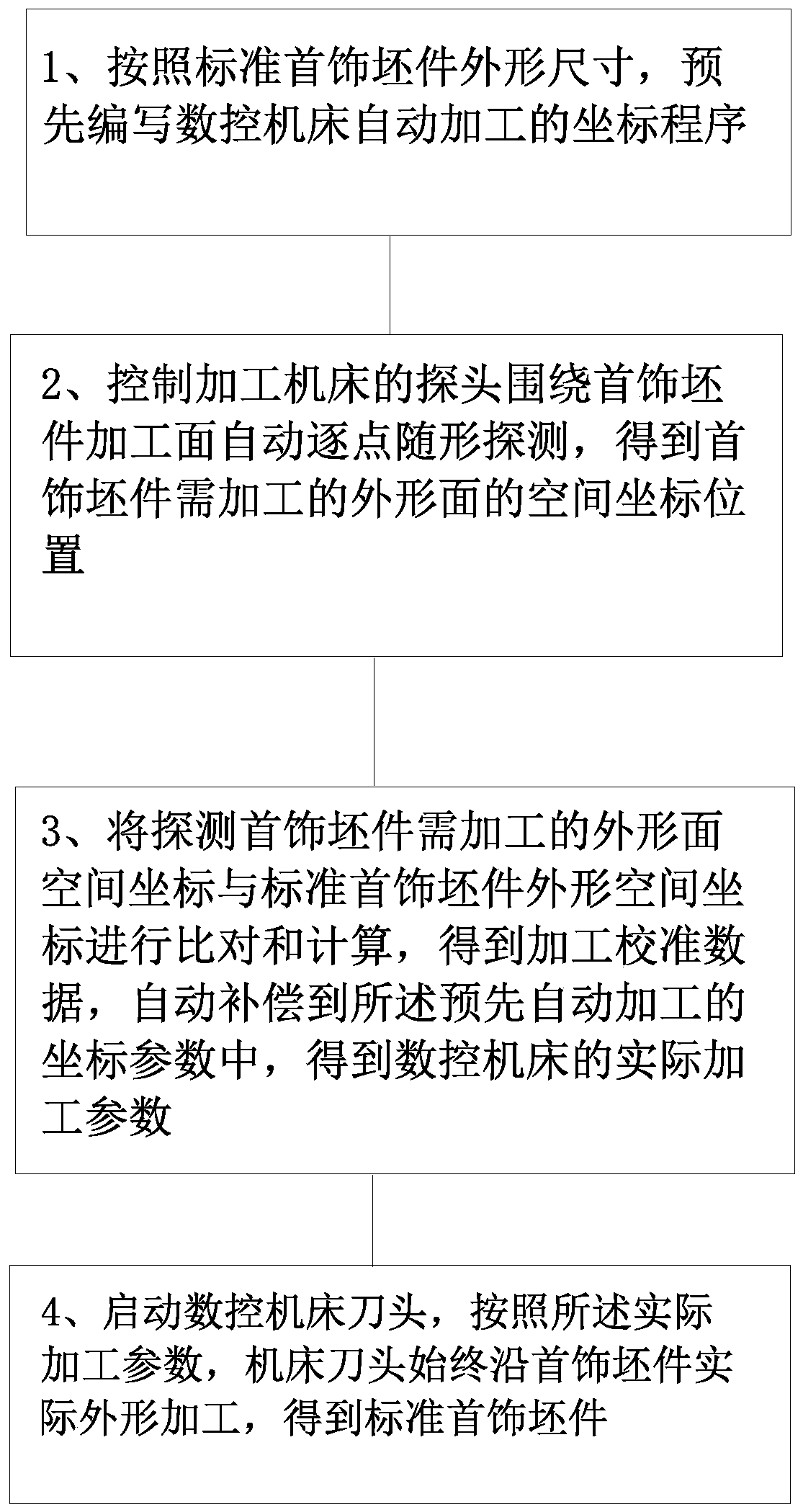

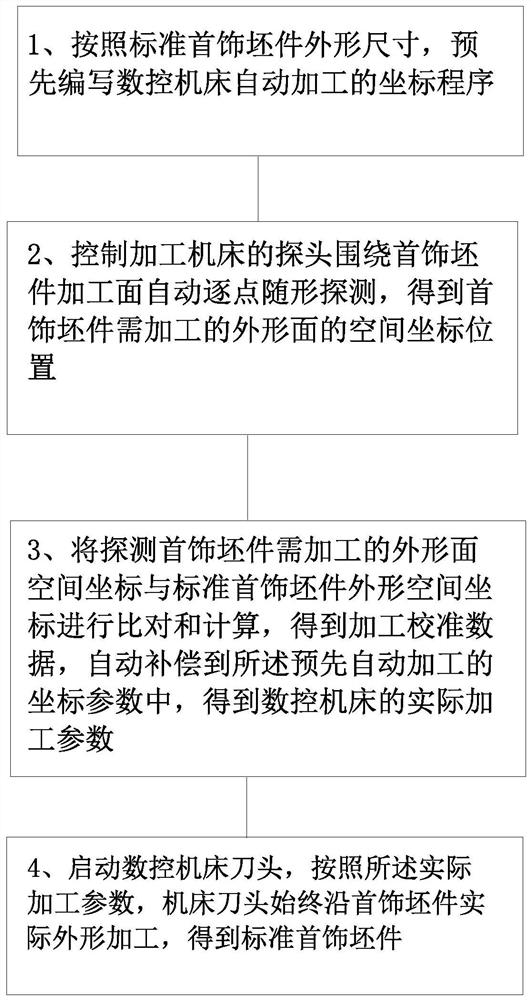

Conformal measurement processing control method and its application in the field of jewelry processing

ActiveCN111300212BAchieve precision machiningRealize industrialized environmental protection productionGrinding feed controlUsing optical meansNumerical controlProcess engineering

The invention discloses a conformal measurement processing control method and its application in the field of jewelry processing. The method includes steps 1. Pre-programming a coordinate program for automatic processing of a CNC machine tool according to the external dimensions of a standard jewelry blank; 2. Controlling the probe of the processing machine tool to surround Jewelry blanks are automatically detected point by point along with the shape, and the spatial coordinate position of the outer surface of the jewelry blank to be processed is obtained, and fed back to the computer of the CNC machine tool; 3. The spatial coordinates of the outer surface of the detected jewelry blank are compared with the standard jewelry blank The outer space coordinates are compared and calculated to obtain processing calibration data, which is automatically compensated to the coordinate parameters of the pre-automatic processing to obtain the actual processing parameters of the CNC machine tool; 4. Start the CNC machine tool head processing to obtain a standard jewelry blank. It can dynamically measure each piece of jewelry according to the shape, automatically and precisely correct and compensate the deviation, which greatly improves the processing accuracy of the CNC machine tool, so that the pass rate of all kinds of jewelry processing can reach more than 99.8%, and the scrap rate is significantly reduced.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV

An ultrafast laser metal engraving method

ActiveCN112222628BHigh speedImprove efficiencyLaser beam welding apparatusLaser engravingEngineering

The invention discloses an ultrafast laser metal fine carving method, comprising the following steps: step 1, placing the product to be carved at the processing position of the fine carving device; step 2, after the product to be carved reaches the processing position of the fine carving device, The product to be engraved is triggered by the sensor to press down, and the positioning of the jig mechanism ensures that the surface to be engraved is relatively horizontal to the laser engraving device of the vibrating mirror, so as to realize ultra-fast fine engraving processing; step 3, the laser beam emitted by the laser enters the vibrating mirror through the laser optical path mechanism Laser engraving device; Step 4, the vibrating mirror laser engraving device controls the laser beam to act on the surface of the product to be engraved for fine carving processing; Step 5, the dust removal mechanism blows away the smoke generated on the product surface and performs exhaustion treatment; Step 6, Fine carving After the processing is completed, the product is recycled; the consistency of automation and the efficiency of processing are guaranteed, and at the same time, it can meet the process requirements required by Jingdiao, which is helpful for fast, accurate and fine carving products, and improves the efficiency and yield of production and processing.

Owner:SHENZHEN DADE LASER TECH CO LTD

A method for freely engraving patterns on glasses

ActiveCN105882290BSimplify operational complexityEasy material selectionDecorative surface effectsUses eyeglassesNumerical control

The invention relates to a method of freely carving patterns on a pair of glasses. The method of freely carving patterns on the pair of glasses comprises the steps that step 1, a camera with the automatic focal distance adjustment function is used for taking a photo of a lens to be carved, and an electronic photo is obtained; step 2, the electronic photo is uploaded to a computer, and image processing software is used for conducting image matting on the image on the lens to be carved; step 3, the image obtained from the image matting in step 2 is input to a numerical control laser carving machine; step 4, the numerical control laser carving machine is used for carving on each portion of the pair of glasses to obtain a rough pattern; step 5, a car paint pen is used for painting on the rough pattern obtained in step 4 until the rough pattern is painted evenly and completely covered; and step 6, alcohol is used for erasing paint outside the boundary of the rough pattern to obtain a refined pattern before the painted paint is completely dry. According to the method of freely carving patterns on the pair of glasses, control precision is high, and complicated patterns can be obtained.

Owner:颜丙刚

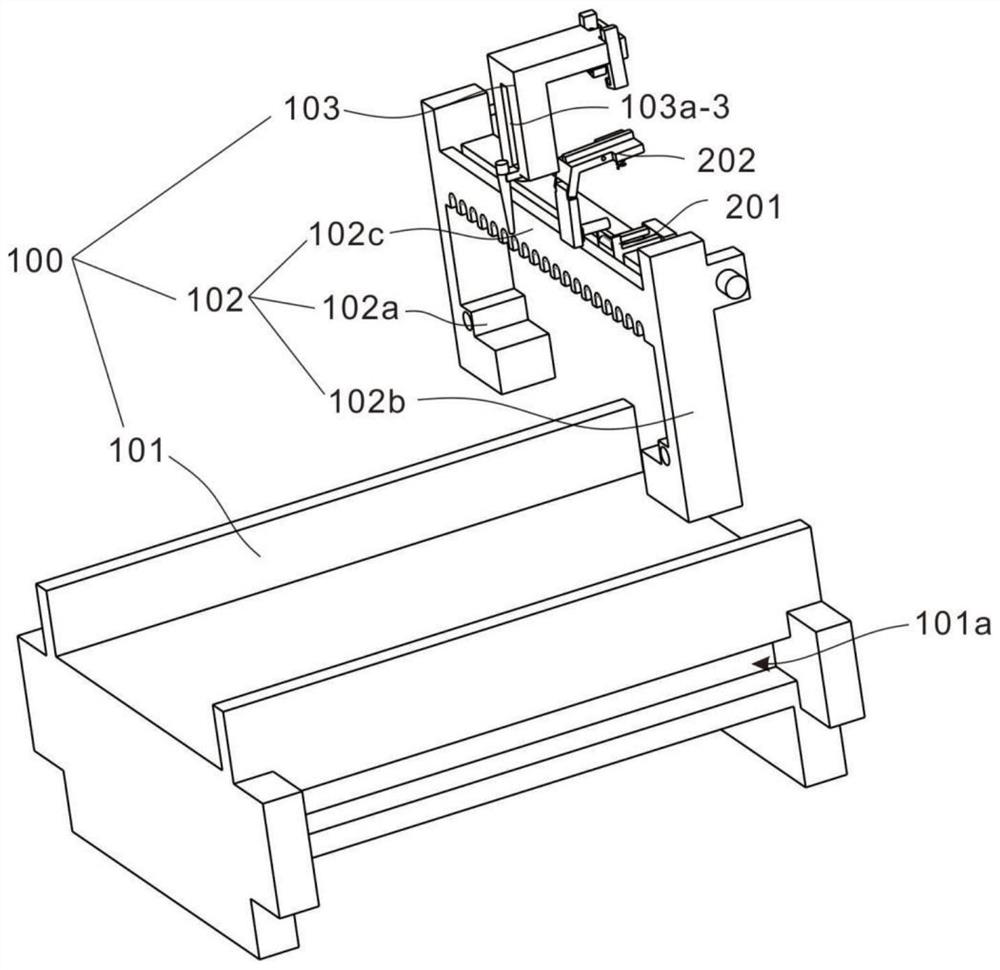

Large multifunctional three-dimensional numerical control carving machine

PendingCN113682070AReduced stabilityPrecise positioningWorking accessoriesModel makingNumerical controlControl engineering

The invention discloses a large multifunctional three-dimensional numerical control carving machine. The large multifunctional three-dimensional numerical control carving machine comprises a carving module and a locking module, wherein the carving module comprises a platform, a sliding rail and a carving piece, the sliding rail is installed on the platform, the carving piece is movably installed on the sliding rail, the locking module comprises a sliding block, a clamping piece and an electromagnetic block, the sliding block is installed on the sliding rail, the clamping piece is installed on the sliding block and movably connected to the carving piece, and the electromagnetic block is installed on the sliding rail in a sliding mode and matches with the clamping piece. According to the large multifunctional three-dimensional numerical control carving machine, a carving mold can be detachably connected and is convenient to maintain and replace, an carving point is accurately positioned by adopting a power electronic control method, the stability of the carving mold can be controlled, errors caused by manual operation are reduced, carving is more accurate, and the efficiency is high.

Owner:SUZHOU JIANGNAN AEROSPACE MECHANICAL& ELECTRICAL IND CO LTD

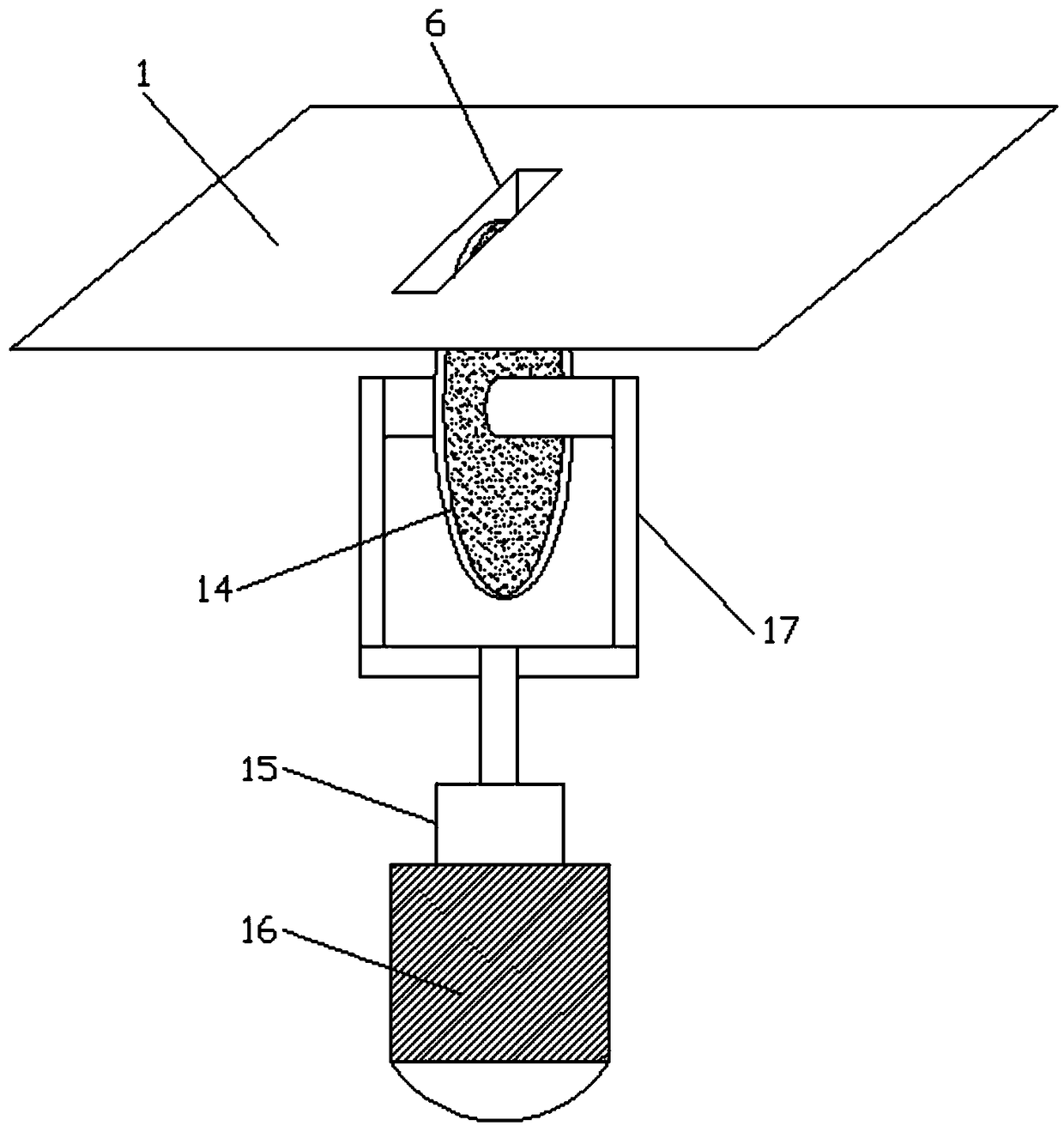

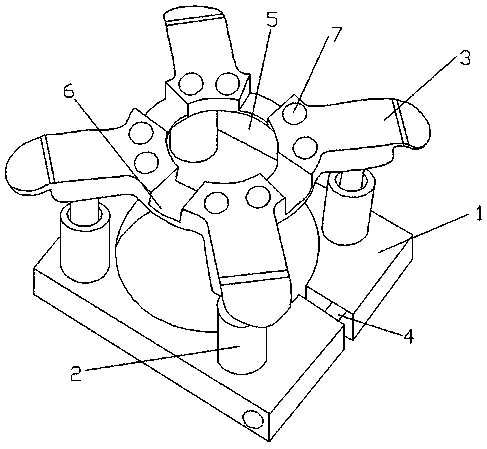

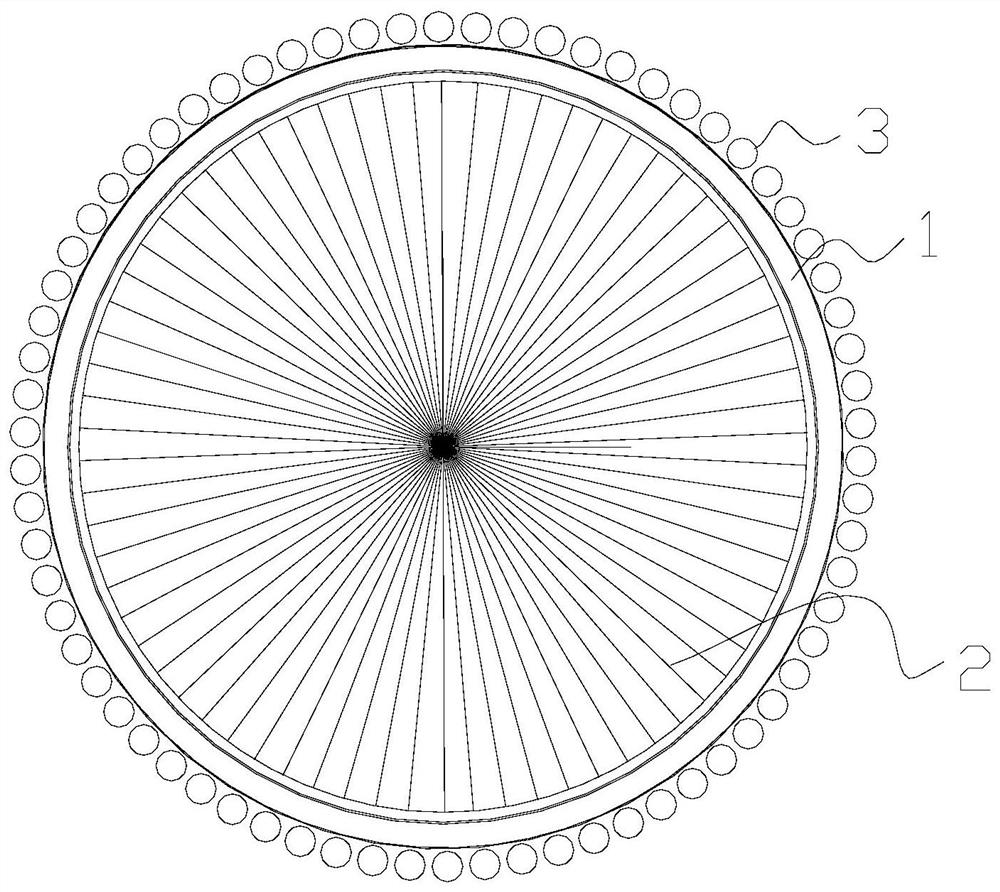

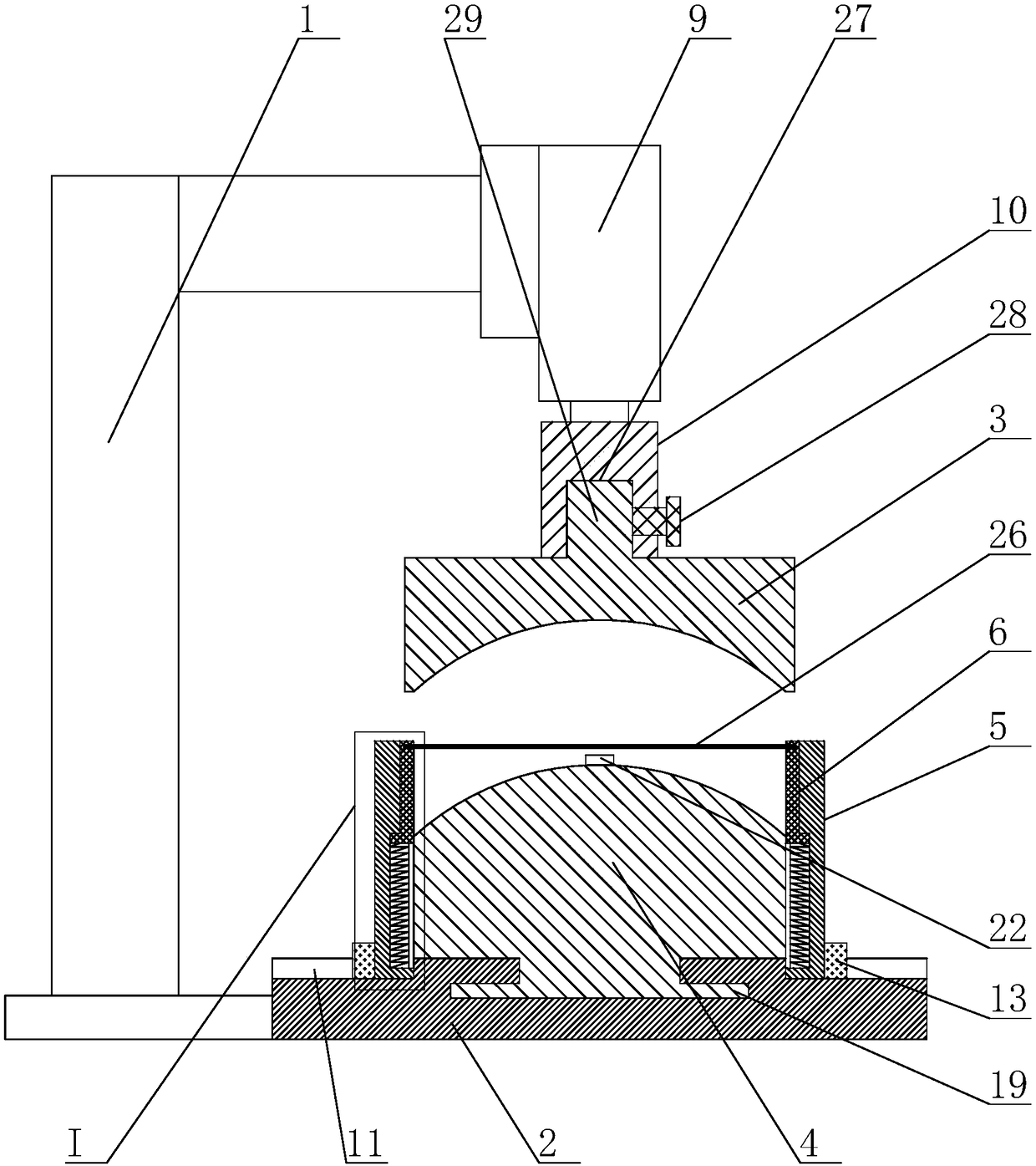

Indenting device for hand ornament processing

ActiveCN108311585AGuaranteed accuracyAccurate engravingShaping toolsEjection devicesEngravingEngineering

The invention discloses an indenting device for hand ornament processing, and mainly relates to the field of hand ornament processing devices. The indenting device comprises a support, a base, an upper mold and a lower mold. A stamping device capable of ascending and descending is arranged on the support and connected with the upper mold. Side plates on the two sides are arranged on the base. Telescopic plates capable of ascending and descending are arranged on the opposite sides of the side plates on the two sides. Corresponding plate grooves are formed in the telescopic plates capable of ascending and descending. The lower mold cooperates with the upper mold. Convex patterns are arranged on the top face of the lower mold. The lower mold is arranged between the two side plates on the twosides. The indenting device has the advantages that the two procedures of arc public face processing and concave pattern engraving can be completed at a time, the precision of an arc public face indenting mold is greatly improved, and concave pattern engraving is more precise; and through test processing statistics, the percent of pass of finished products is greatly improved, the efficiency and the rate of finished products are guaranteed, meanwhile, the processing hours are greatly reduced, and the company benefits and the book-to-bill efficiency are improved.

Owner:深圳市奢珠科技有限公司

Vehicle code marking device

The invention discloses a vehicle code marking device. The vehicle code marking device comprises a code marking device, a connecting assembly, a supporting plate and an adjusting assembly. The supporting plate is connected with the connecting assembly, the connecting assembly is set to be used for being connected with a code marking transverse beam, and one edge of the supporting plate abuts against the side face of the transverse beam. The code marking device is installed on one side of the supporting plate. The adjusting assembly is installed on the supporting plate and is set to be used foradjusting the levelness of the supporting plate so that the side, close to the code marking device, of the supporting plate and the face, to be marked with a code, of the code marking transverse beamcan be located on the same horizontal plane. The vehicle code marking device can accurately and rapidly conduct code marking on vehicles.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

An Intelligent Laser Engraving System Based on Industry 4.0

ActiveCN111906442BAccurate engravingMeet personalized engraving needsLaser beam welding apparatusComputer graphics (images)Laser engraving

The invention relates to an intelligent laser engraving system based on Industry 4.0, which continuously sends animal images (including image backgrounds) collected at the zoo to the laser engraving center through image acquisition equipment, and the laser engraving center performs these sent images Processing, to obtain the animal image that can be used for engraving at present, accept the processing requirements of the user to use the mobile terminal on the engraving parameters of the animal image for engraving, and then the laser engraving center orders the background wall to adjust the background on the curtain and the animal The backgrounds of the images are consistent with each other, so that the laser engraving center orders the laser engraving device to work, and switches the engraving head between the first laser engraving tool and the second laser engraving tool according to the actual needs of engraving, so as to engrave more accurately The animal bionic carving products with the best size and the best state meet the user's personalized carving needs for animal bionic carving products.

Owner:NINGBO UNIV

Batch scribing equipment for galvanized thin steel plate machining and machining method of batch scribing equipment

PendingCN113894413AHigh precisionReduce mistakesLaser beam welding apparatusLaser scribingSteel plates

The invention discloses batch scribing equipment for galvanized thin steel plate machining and a machining method of the batch scribing equipment. The batch scribing equipment comprises a device plate, a conveying channel is arranged on the inner side face of the device plate, a supporting frame is fixedly connected to the upper surface of the device plate, a plate collecting trolley is arranged at the end, close to the supporting frame, of the conveying channel, a plurality of fixing mechanisms are fixedly connected to the outer surface of the conveying channel, a laser scribing mechanism is arranged on the lower surface of the supporting frame and comprises a connecting plate, a sliding groove is formed in the connecting plate, an electric sliding block is slidably connected to the inner wall of the sliding groove, and a laser head is fixedly connected to the lower surface of the electric sliding block. According to the batch scribing equipment for galvanized thin steel plate machining and the machining method of the batch scribing equipment, the laser head is driven by the electric sliding block to conduct laser scribing, and compared with manual scribing, scribing can be more accurate, the burden of people is greatly relieved, labor is saved, the rejection rate during machining is reduced, and better use prospects are brought.

Owner:江苏澳洋顺昌科技材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com