Self-adaptive plate press of carving machine for advertising production

An engraving machine and self-adaptive technology, applied in the field of platen presses, can solve the problems of non-normal use, impact on engraving quality, and warping of peripheral parts, and achieve the effect of fast engraving, improving engraving and forming effect, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

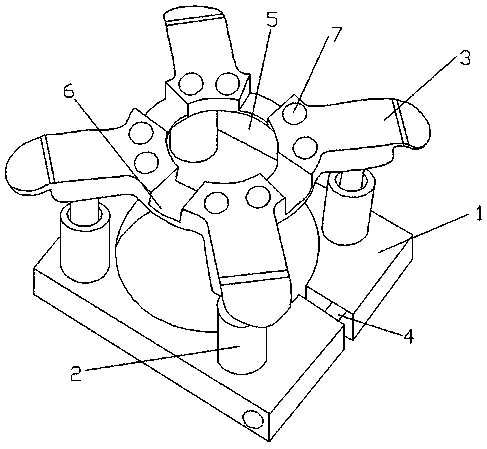

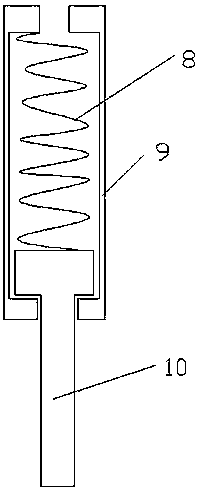

[0019] like figure 1 As shown, the self-adaptive presser for an engraving machine for advertisement production includes four telescopic connection components 2, a fixed ring 1 and a presser 3, the fixed ring 1 is provided with an opening, and one side of the fixed ring 1 is provided with an inner part that cooperates with the bolt 4. thread, and the other side is provided with a through hole matching with the bolt 4, and the two ends of the opening are locked by the bolt 4, such as figure 2 As shown, the telescopic connection assembly 2 includes a guide sleeve 9 and a push rod 10, the guide sleeve 9 is fixedly installed on the fixed ring 1, an elastic element 8 is arranged inside the guide sleeve 9, and one end of the push rod 10 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com