High speed rail line concrete track plate engraving machine and engraving method

A concrete and engraving machine technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of high work intensity, poor molding quality, peeling, etc., to prevent overlapping and series connection of railway lines, improve automation, and engraving neat track effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

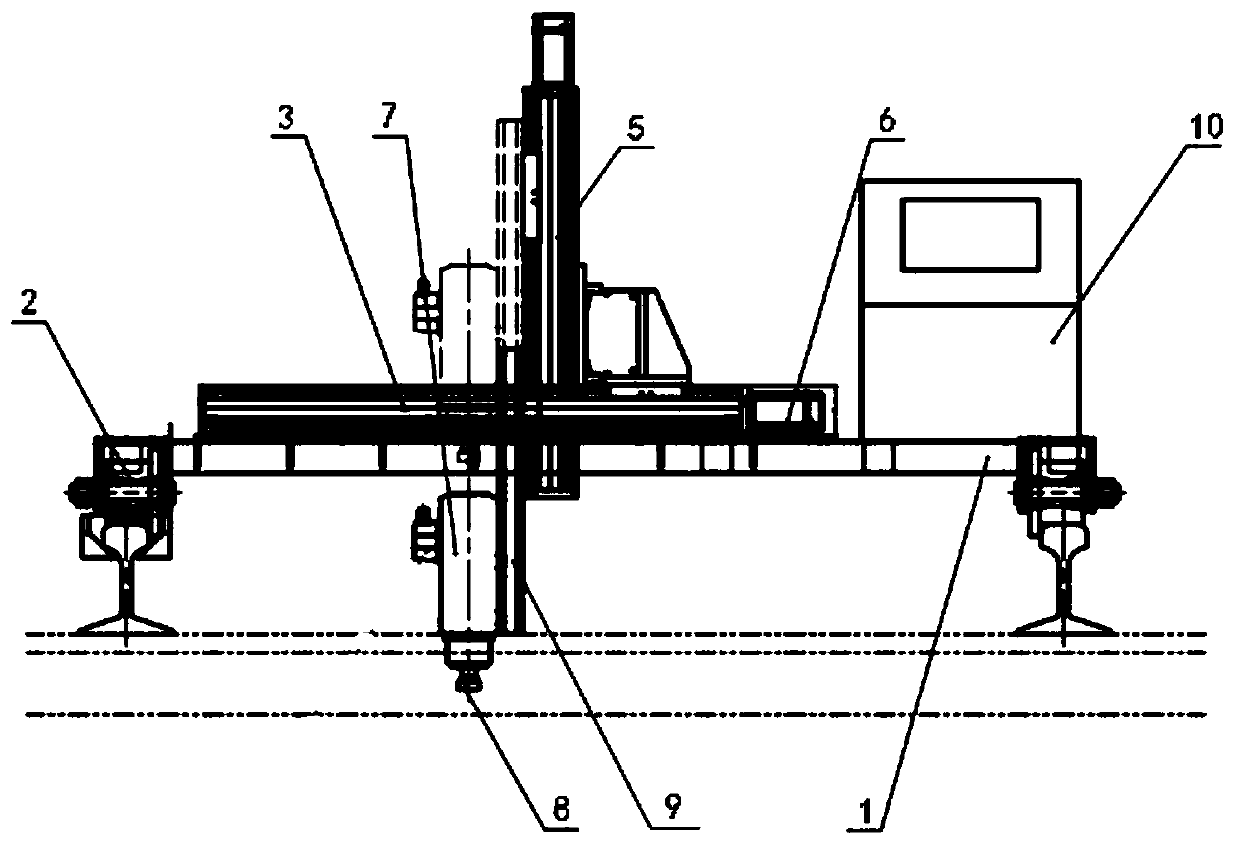

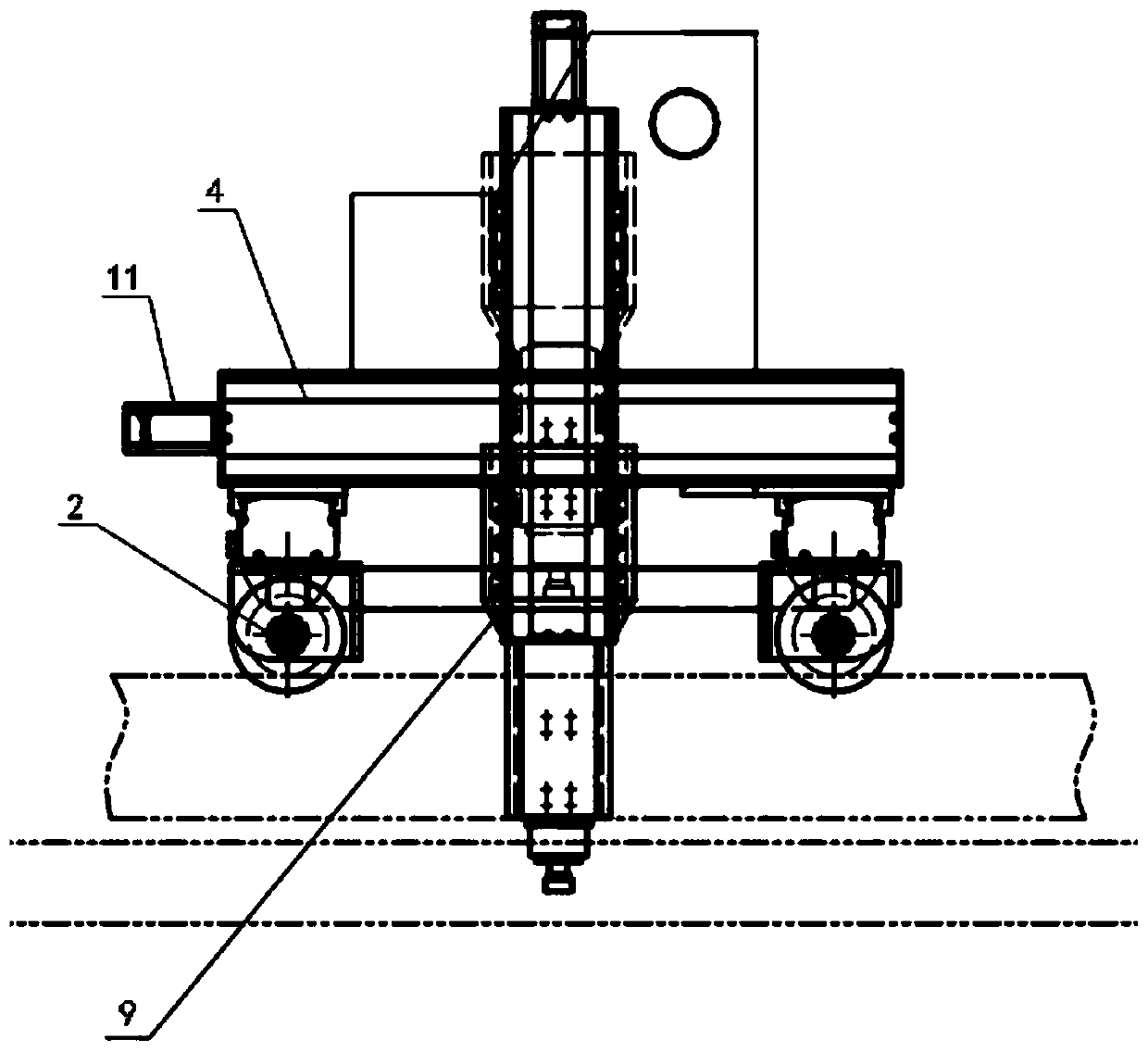

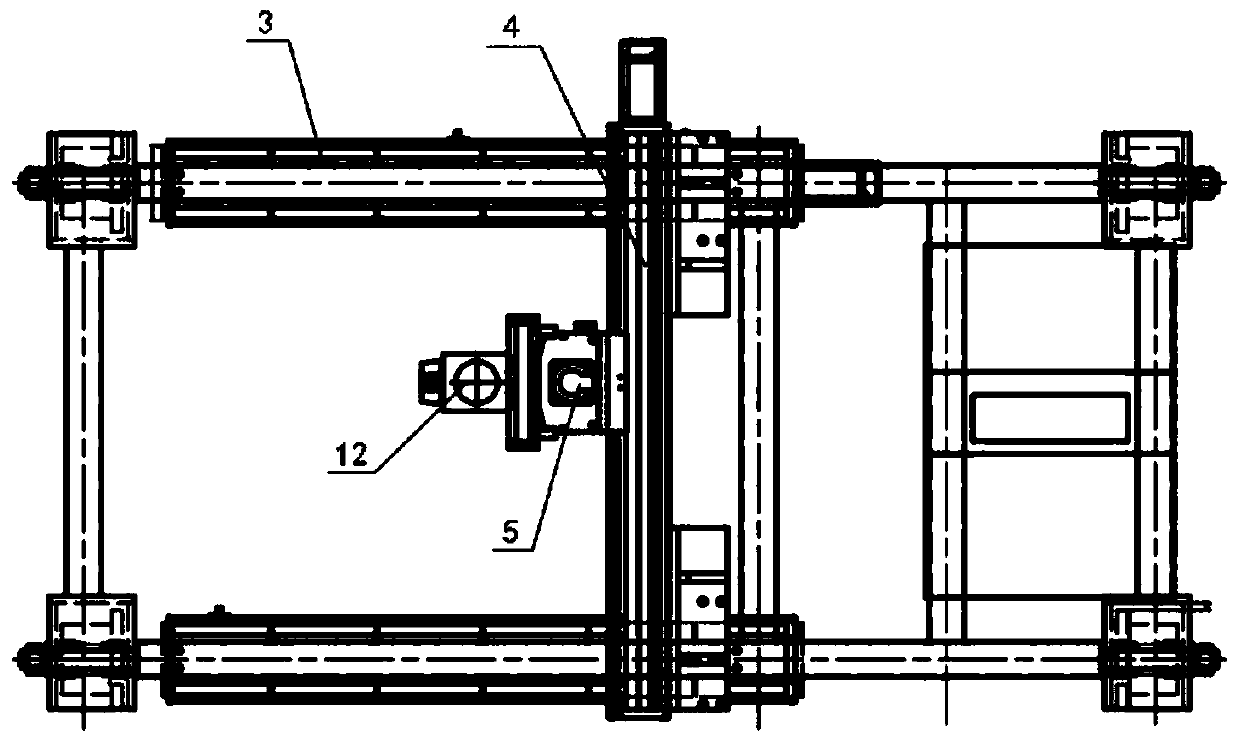

[0018] Such as Figure 1-Figure 3 As shown, the high-speed rail line concrete track slab engraving machine is characterized in that it includes a frame 1, a wheel set 2, a three-axis linkage mechanism 3, an engraving mechanism, a cooling system and a control system. The frame is a rectangular frame structure, and the wheel set includes four Two walking wheels are respectively arranged at the bottom of the four corners of the frame, and are connected to the rotating shaft fixed on the frame through bearings. The walking wheels are provided with braking devices to facilitate the stop and positioning of the engraving machine. Before processing the frame, first measure the distance from the applied track concrete to the cutter head with an elevation ruler, set the cutter according to the distance, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com