Large multifunctional three-dimensional numerical control carving machine

A CNC engraving machine and multi-functional technology, applied in the field of engraving, can solve the problems of low degree of automation, heavy engraving machine, low precision, etc., and achieve the effect of easy maintenance and replacement, accurate engraving, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

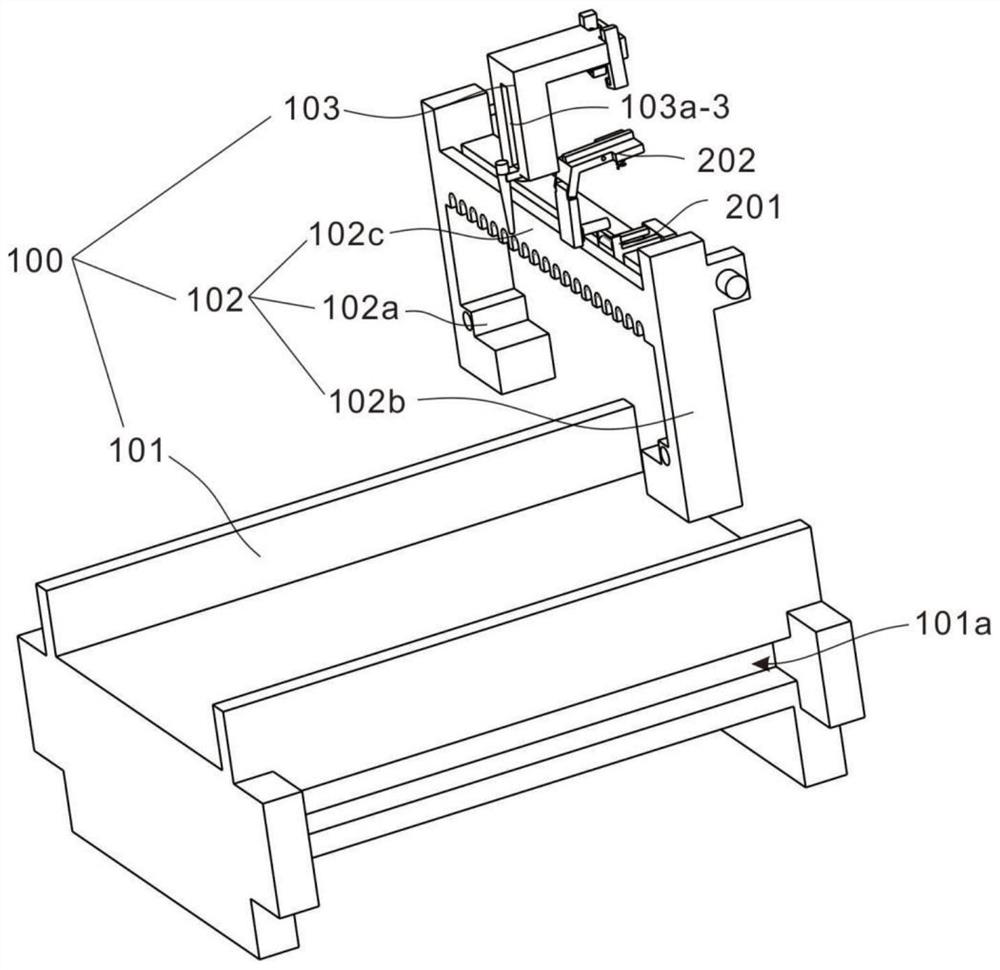

[0026] Refer Figure 1 ~ 3 For the first embodiment of the present invention, this embodiment provides a large multi-function three-dimensional number-control engraving machine including engraving module 100 and lock module 200.

[0027] The engraving module 100 includes a platform 101, a slide rail 102, and a engraving member 103, and the rail 102 is mounted on the platform 101, and the engraving member 103 is active on the slide rail 102.

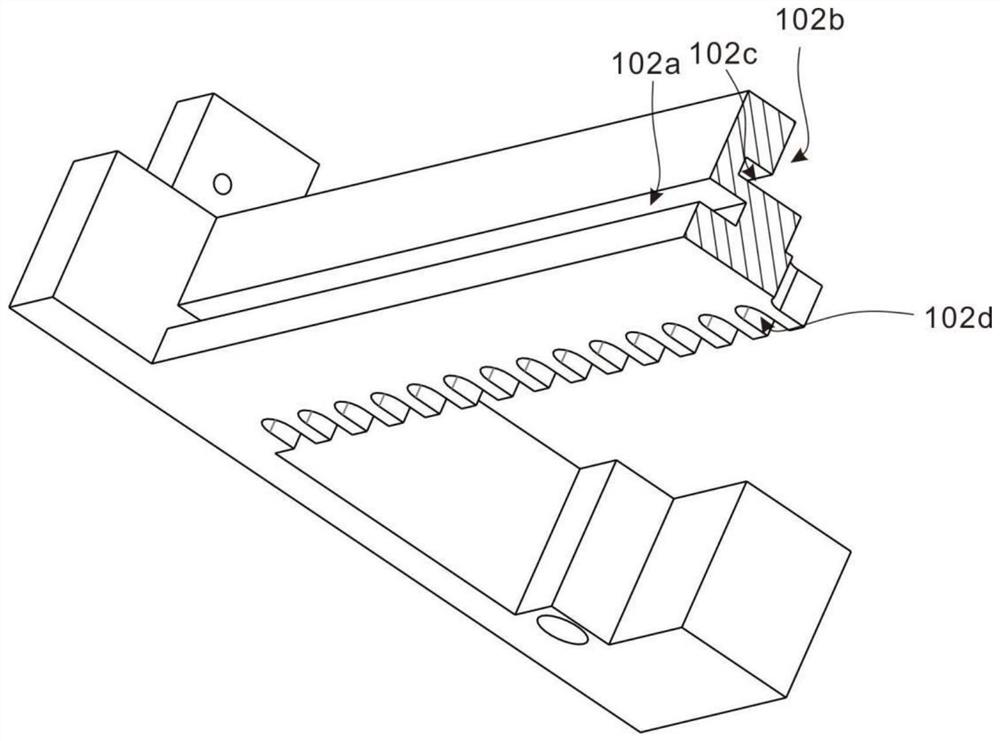

[0028] The lock module 200 includes a slider 201, a cartridge 202, and an electromagnetic block 203, and the slider 201 is mounted on the rail 102, and the engaging member 202 is mounted on the slider 201 and active with the engraving member 103, the electromagnetic block 203 slides mounting On the rail 102 and cooperate with the engaging member 202. Specifically, rail 102 includes a left support rail 102a, a right support rail 102b, and a cross-rail 102c, and the left-rail 102c is connected to the left support rail 102a. On the other end, the...

Embodiment 2

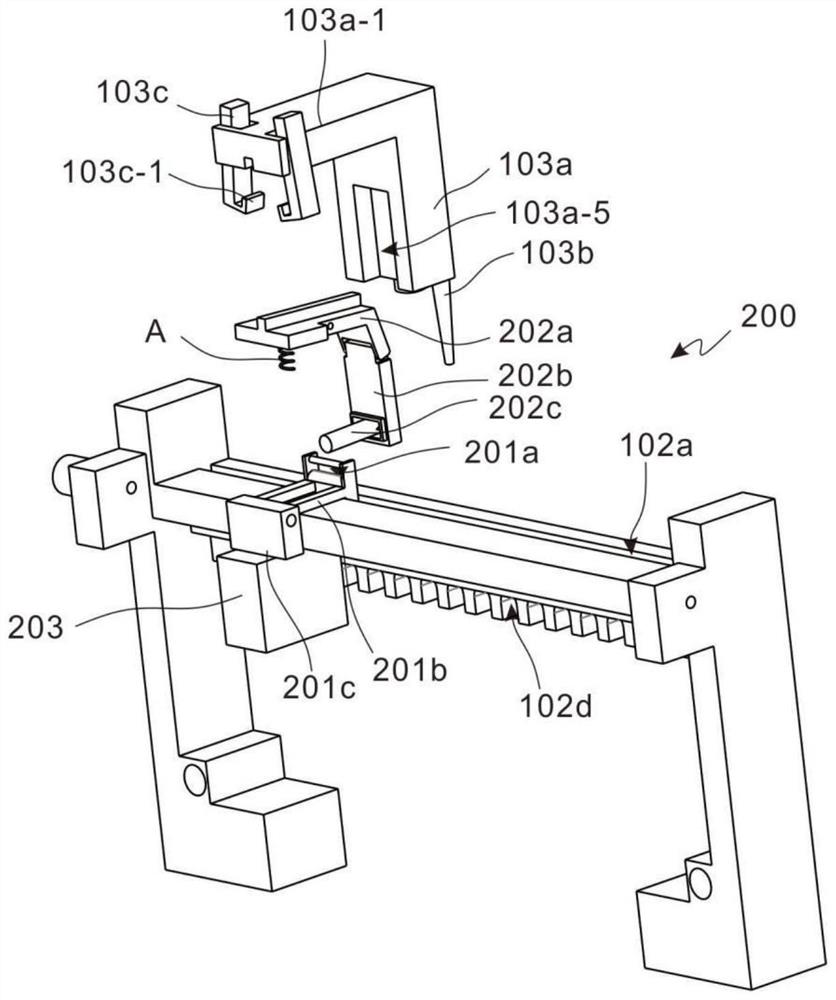

[0032] Refer Figure 2 ~ 5 For a second embodiment of the present invention, the embodiment includes a connecting plate 202a, a transfer plate 202b, and a card shaft 202c.

[0033] One end of the connecting plate 202a is hinged to the rotation plate 202b and the hinges of the connecting plate 202a and the transfer plate 202b are elastically connected by a torsion spring, and the groove 201a is provided at the top of the slider 201, and the connecting plate 202a extends into the groove 201a and the connecting plate 202a. The side is hinged from both sides of the groove 201a, and one end of the card shaft 202c is vertically connected to the transfer plate 202b, and the other end is disposed in the direction of the electromagnetic block 203.

[0034] Further, the connecting frame 202b-1 is provided on the transfer plate 202b, and one end of the card shaft 202c is perpendicular to the connecting frames 202b-1 and the two side walls of the connecting frames 202b-1 are elastically couple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com