Indenting device for hand ornament processing

A technology of stamping device and jewelry, applied in the field of embossing device for jewelry processing, can solve problems such as the efficiency of order delivery, insufficient precision, and time-consuming that affect the company's benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

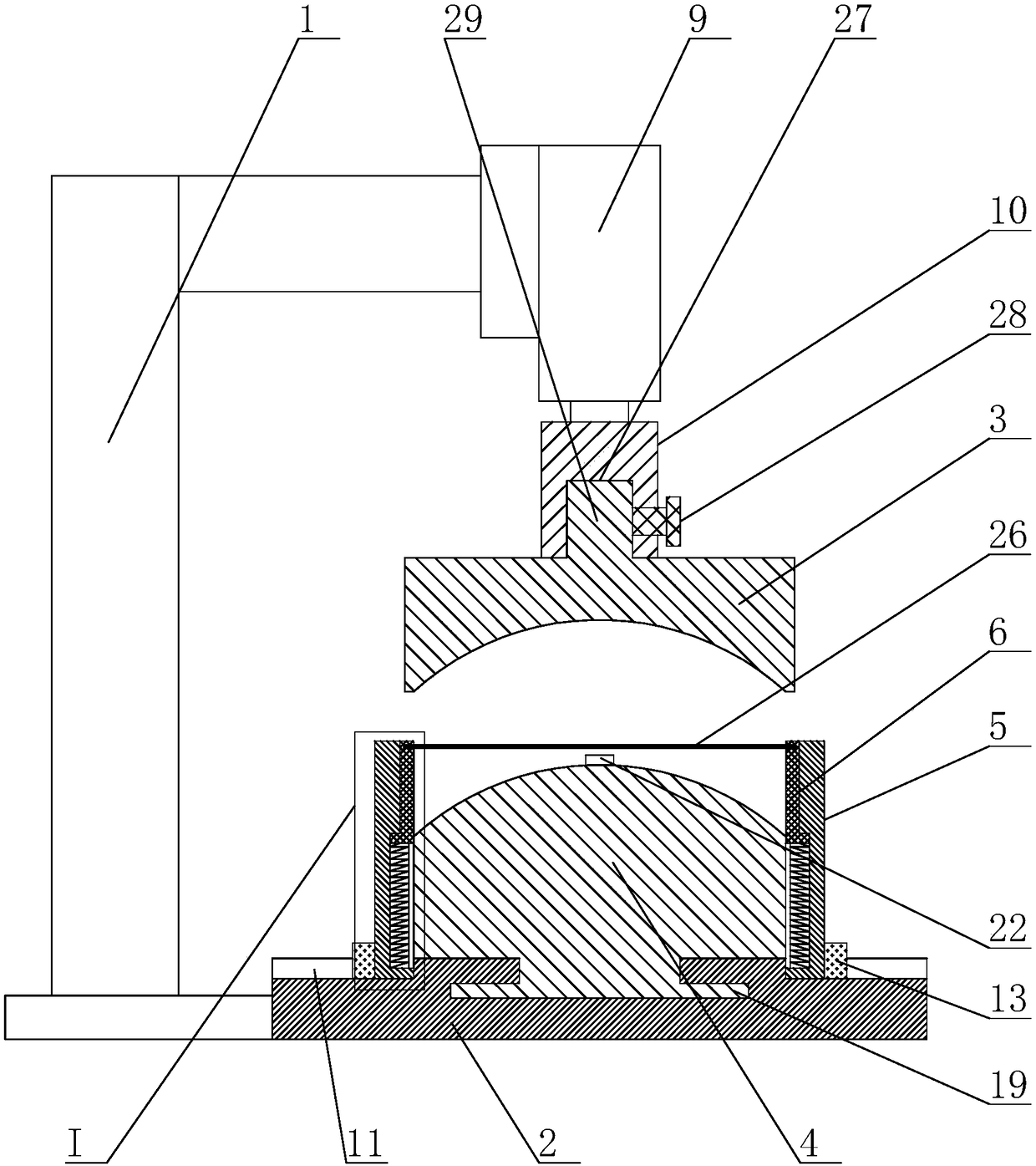

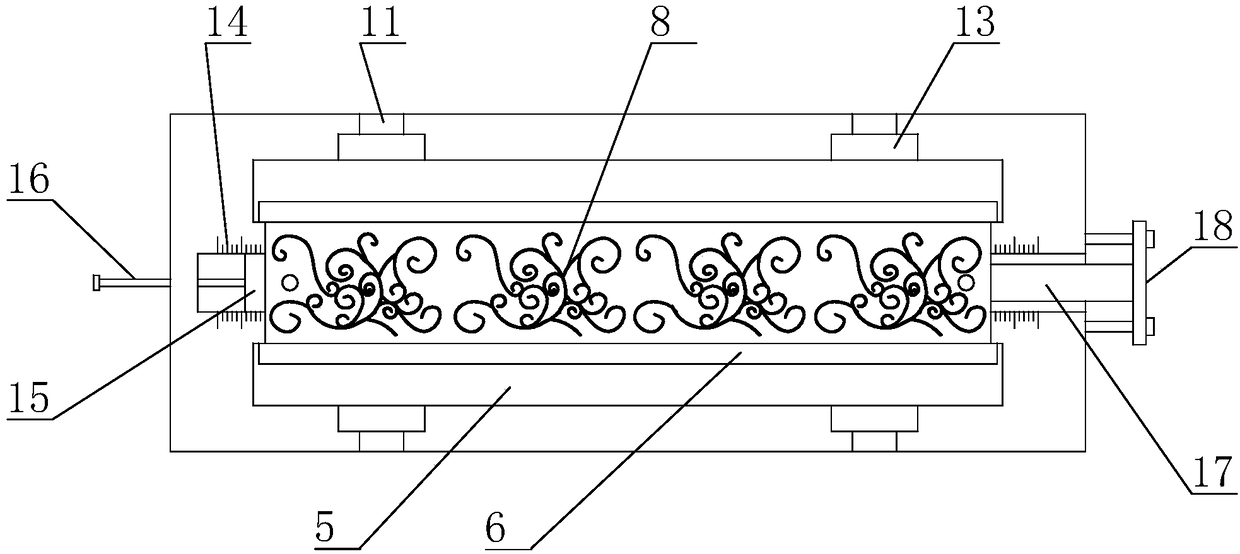

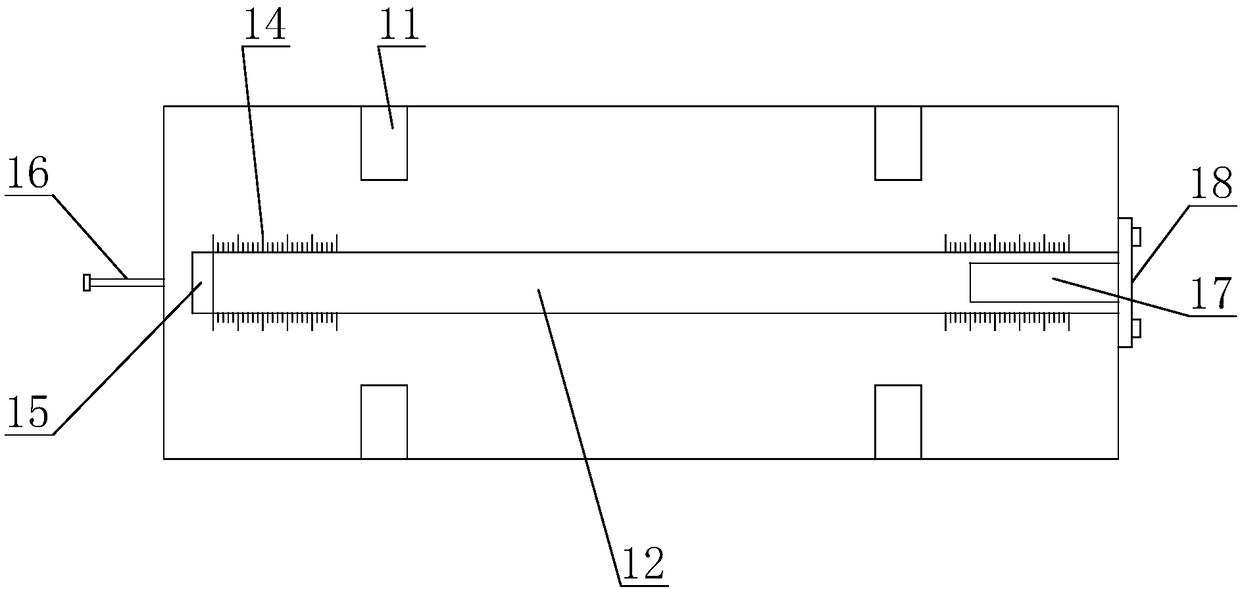

[0037] The present invention is an embossing device for jewelry processing. The main structure includes a bracket 1, a base 2, an upper mold 3 and a lower mold 4. The bracket 1 is provided with a liftable stamping device, and the liftable stamping device Including the servo electric hydraulic cylinder 9, the piston rod of the servo electric hydraulic cylinder 9 is connected with a fixed seat 10, the fixed seat 10 is provided with a fixed groove 27, the side of the fixed groove 27 is provided with a compression limit bolt 28, and the top of the upper mold 3 A post 29 is provided, and the post 29 is inserted into the fixing groove 27 and fixed by the compression limit bolt 28, so as to realize the detachable connection between the fixing seat 10 and the upper mold 3 . The base 2 is provided with side plates 5 on both sides, and the opposite side of the side plates 5 on both sides is provided with a liftable telescopic plate 6, and the liftable telescopic plate 6 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com