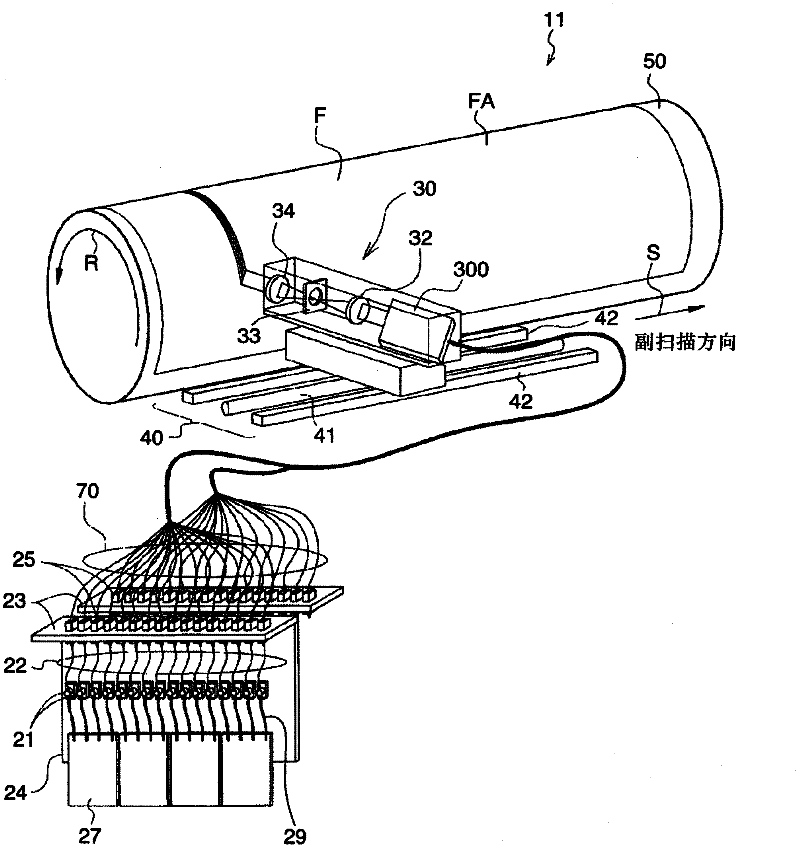

Multi-beam exposure scanning method and apparatus, and method for manufacturing printing plate

An exposure scanning, multi-beam technology, used in multi-beam exposure scanning and equipment, as well as in the field of manufacturing printing plates, can solve problems such as difficult to stabilize small dots and fine lines of fine shapes, and achieve the effect of optimizing the amount of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

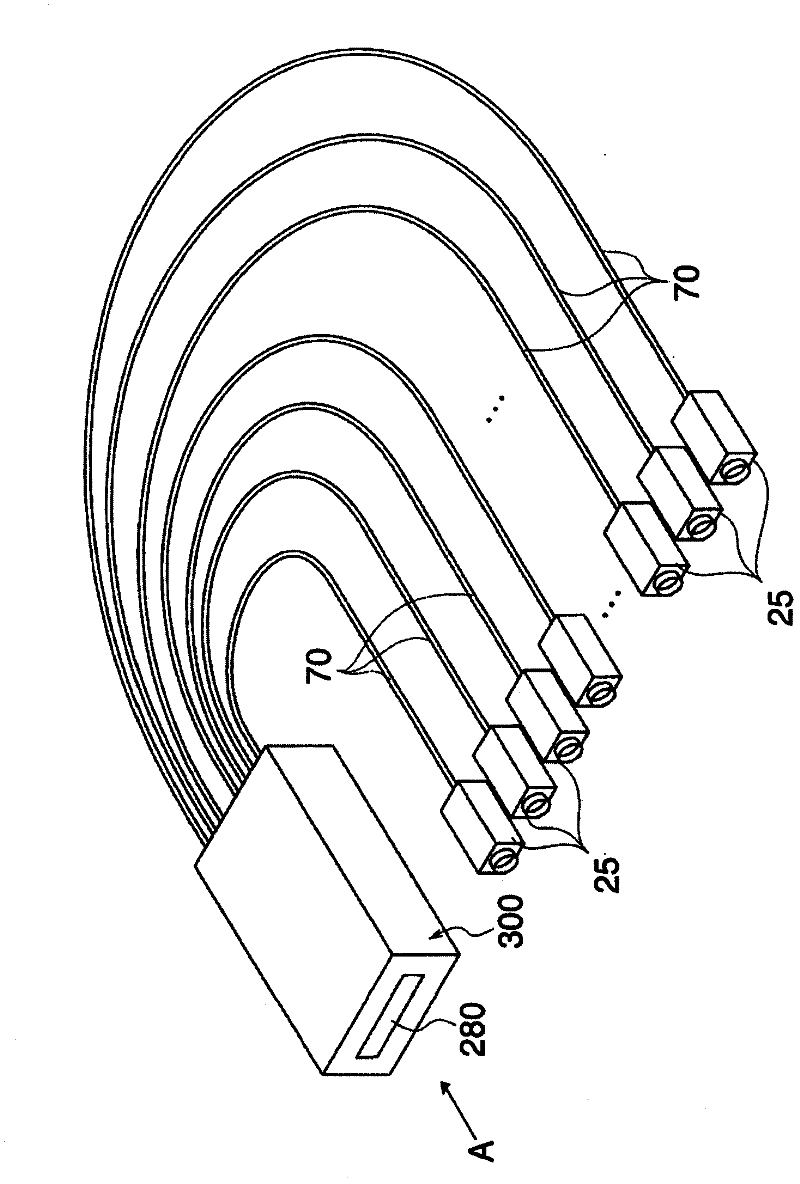

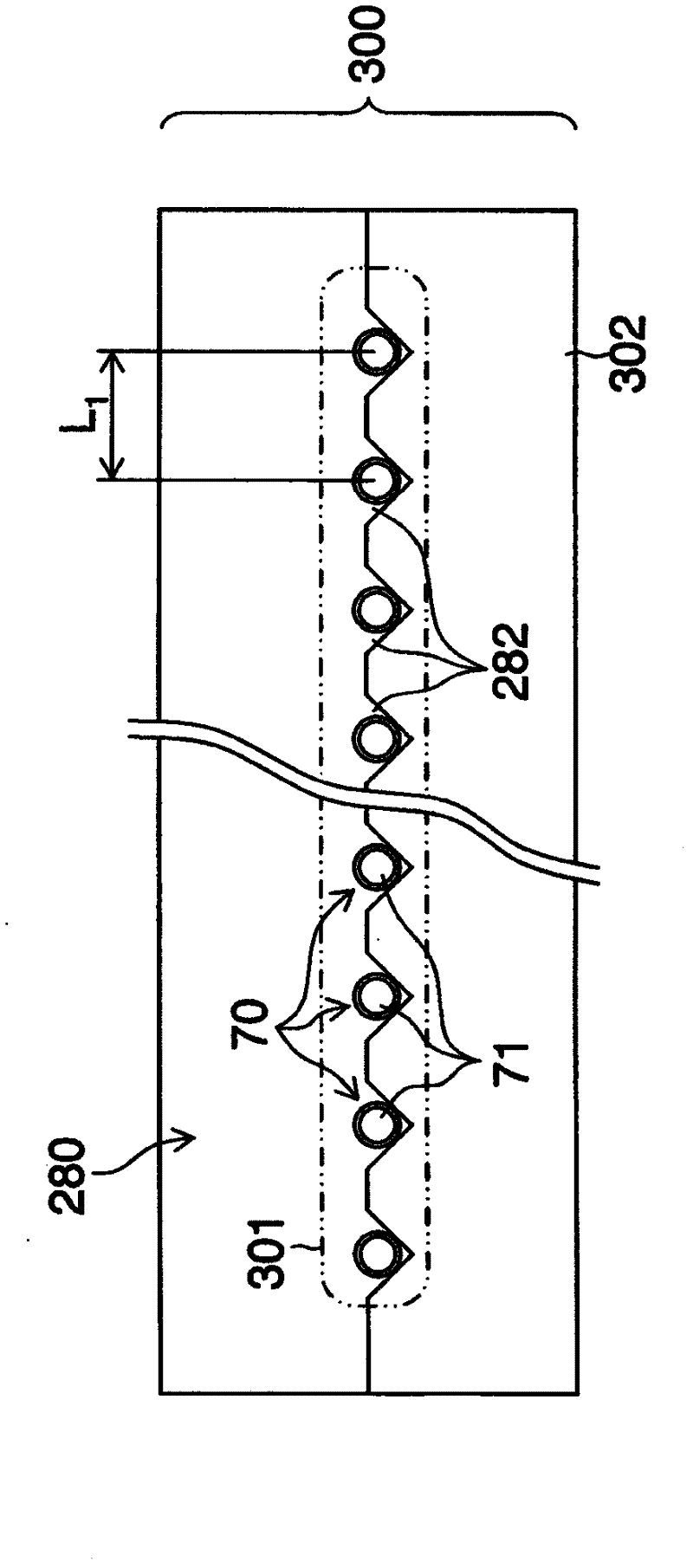

[0076] The above-mentioned first embodiment exemplifies where by using as reference image 3 An exposure head 30 is described with an array arrangement of optical fibers in a column, whereas a beam arrangement of beams of 32 lines (one trace) is arranged obliquely in a column. However, when carrying out the present invention, the beam arrangement is not limited to this one-column arrangement.

[0077] Figure 13 An example of another optical fiber array unit light source is shown. Figure 13 The illustrated fiber array unit light source 500 includes fiber array units 501, 502, 503, and 504 combined in four stages. In each array of stages of the fiber array unit light source 500 , 16 optical fibers 70 having a core diameter of 105 μm are linearly arranged in one column, and a total of 64 optical fibers 70 of four stages are arranged in the shape of an oblique matrix.

[0078] as in Figure 13 As shown in , in the case where, from the right end Set the channel label for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com