Fixing clamp

A technology for fixing jigs and jigs, which is applied in painting tools, decorative art, processing models, etc., can solve the problems of inconvenient carving, poor fixing effect, inconvenient adjustment of bearing height and angle, etc., and achieve good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

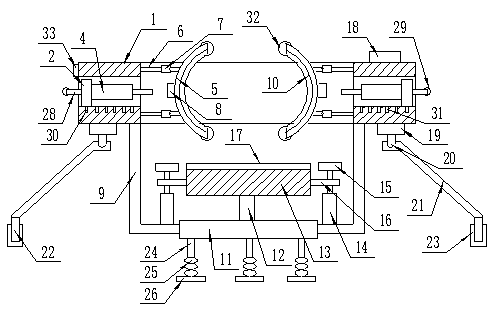

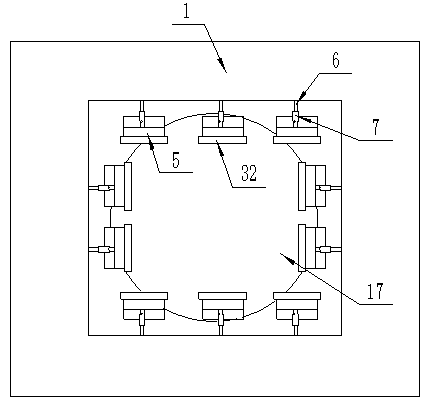

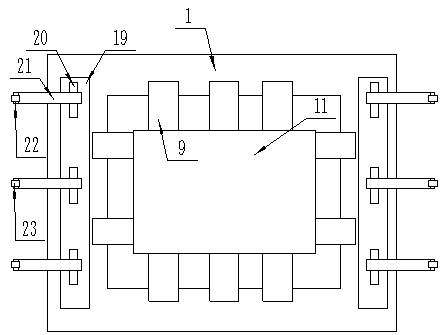

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, a kind of fixing clamp comprises a strip bearing base 1, the upper surface of the strip bearing base 1 is provided with a clamp fixing mechanism, the lower surface of the strip bearing base 1 is provided with a support mechanism, and the clamp fixing mechanism It is mainly composed of the No. 1 bar-shaped opening processed on the upper surface of the bar-shaped bearing base 1, a number of circular through holes processed on the inner surface of the No. 1 bar-shaped opening, and a number of circular through holes processed on the inner surface of each circular through hole. For the horizontal sliding grooves, the sliding frame 2 arranged in each horizontal sliding groove, the mobile carrier 3 arranged in the circular through hole and connected with the corresponding sliding frame 2, arranged in the mobile carrier 3 and The telescopic device 4 with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com