Engraving precision improvement device and axis and table adjustment device for stereo engraving machine

A three-dimensional engraving machine and shaft center technology, applied in the field of engraving machines, can solve problems such as insufficient engraving accuracy, and achieve the effect of improving engraving accuracy and facilitating loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

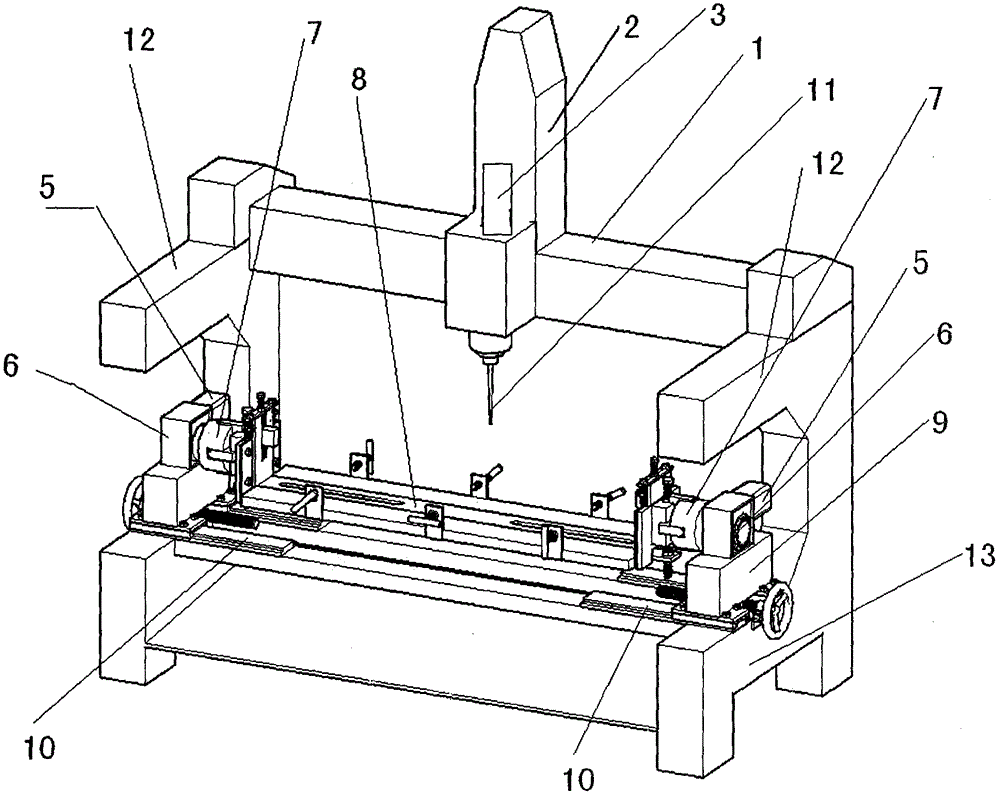

[0016] Embodiment 1 An embodiment of improving engraving precision. See Picture 1-1 , the output shaft of the servo motor is connected with the reducer, the reducer is installed on the support, and the support is located on the dovetail lower frame, and the present embodiment links to each other with two sets of servo motors and the precision reducer. After the power is turned on, the two sets of servo motors start at the same time, which can reduce the backlash of the reducer and improve the engraving accuracy of the three-dimensional engraving machine.

Embodiment 2

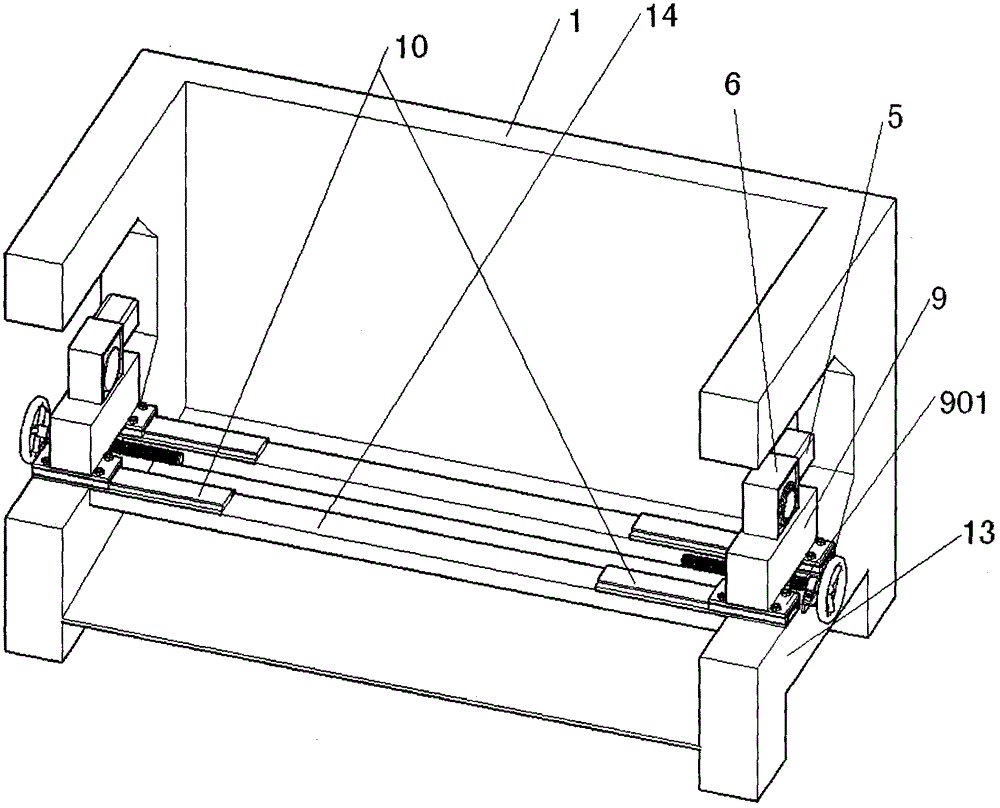

[0017] Embodiment two, three-dimensional engraving. Install the centering chuck on the output shaft of the reducer, set the trapezoidal clip on the centering chuck, install the reducer on the machine base, the machine base is located under the dovetail upper frame, and set the bottom plate under the machine base, the bottom plate and the guide rail It fits and can slide left and right along the guide rail. The bottom plate and guide rail are located on the upper part of the dovetail lower frame, and the two centering chucks can be moved to a position suitable for clamping the object to be carved. See figure 2 , Figure 2-1 . Place the object to be engraved on the trapezoidal clips of the two centering chucks, and when working, the motor drives the reducer, and the reducer drives the chuck to rotate, so the object to be engraved cooperates with the engraving on the Z-axis slide table according to the signal of the computer The knife rotates and rotates or turns to achieve t...

Embodiment 3

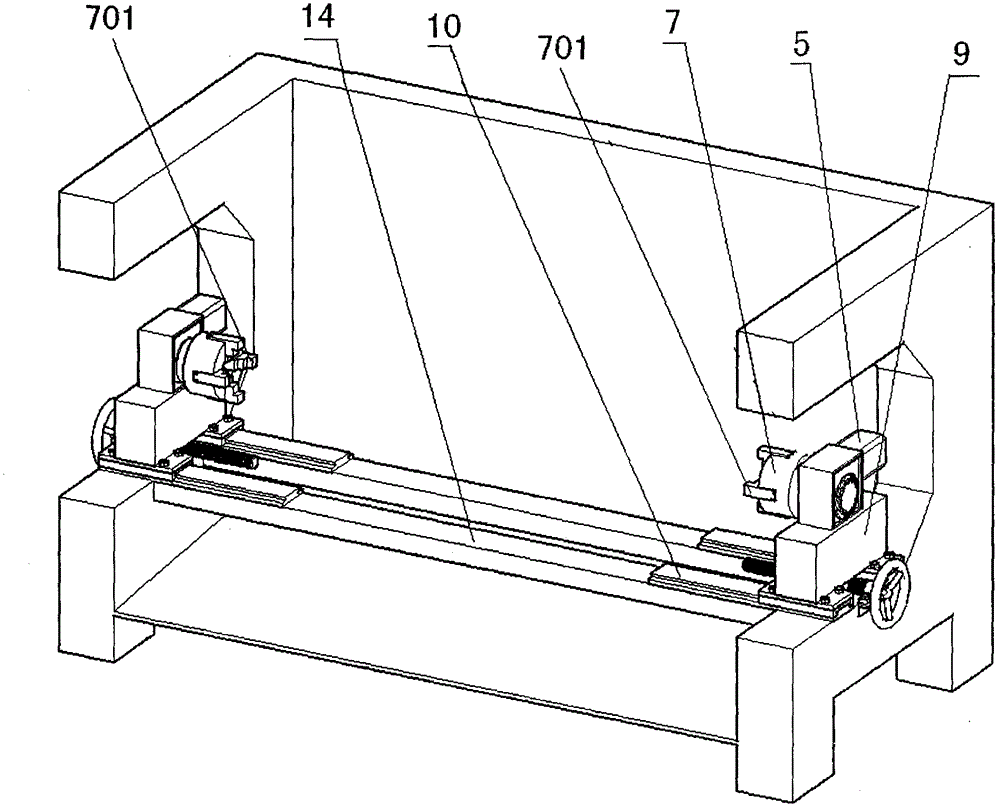

[0018] Embodiment 3, in practice, in many occasions, only semi-stereo arc carvings such as Roman columns, marble door frames, etc., so the inventor invented the axis-adjusting table top device of this embodiment according to the needs of different customers, which is in the embodiment On the basis of the second, additional components such as eccentric plate surface, clamping plate, positioning plate, positioning screw, screw, insert, plate groove, clamping block, fixed plate, and combined screw are added. See image 3 , Figure 4 . Use the height adjusting screw and positioning screw to adjust the rotation axis of the engraved object from the Z axis and the Y axis to align with the center of rotation, that is, the center of the centering chuck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com