Small stone carving laser carving equipment

A laser engraving and stone carving technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of engraving depth deviation, inaccurate engraving, large deviation of lateral moving frame, etc., to reduce depth deviation and improve engraving accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

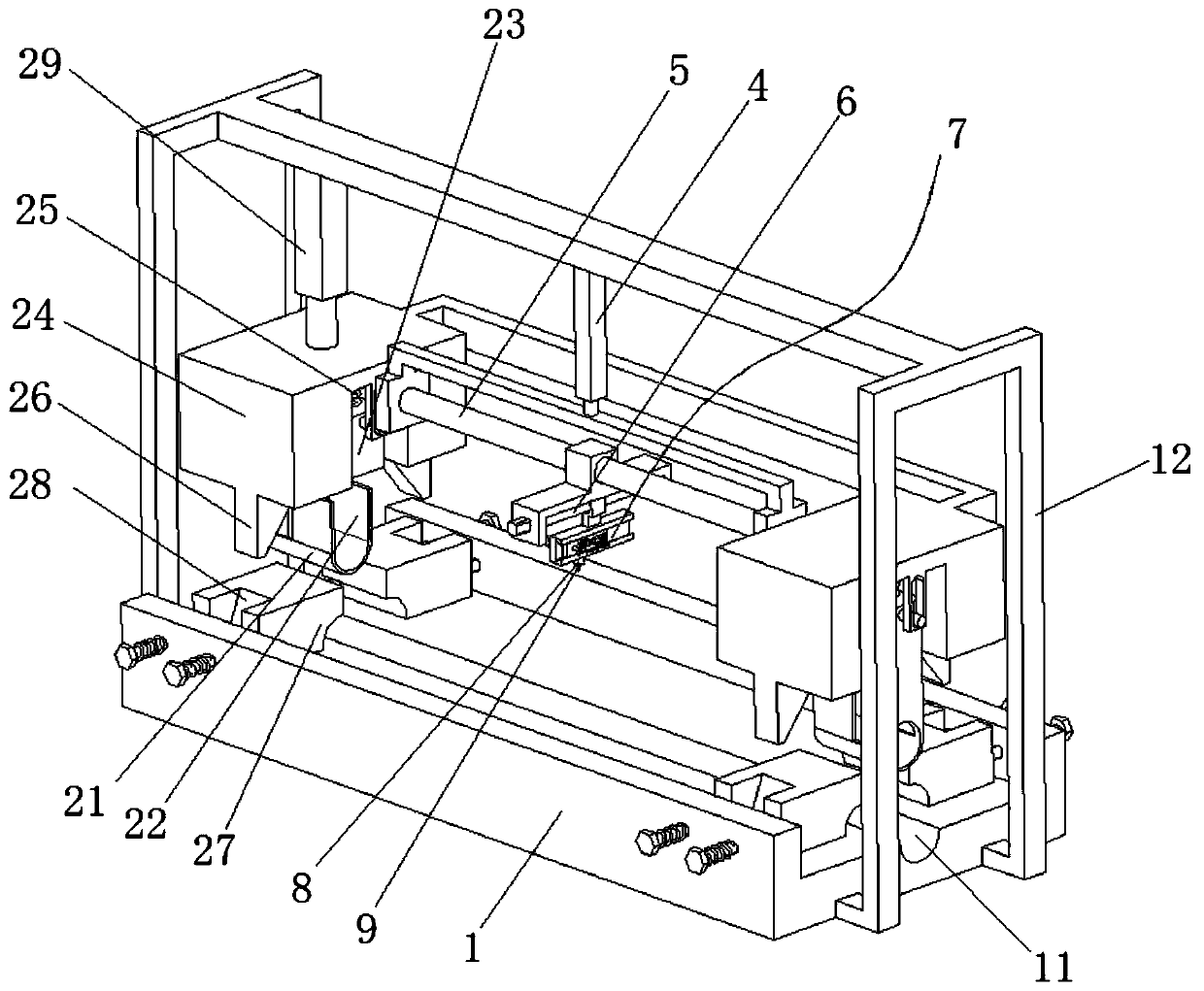

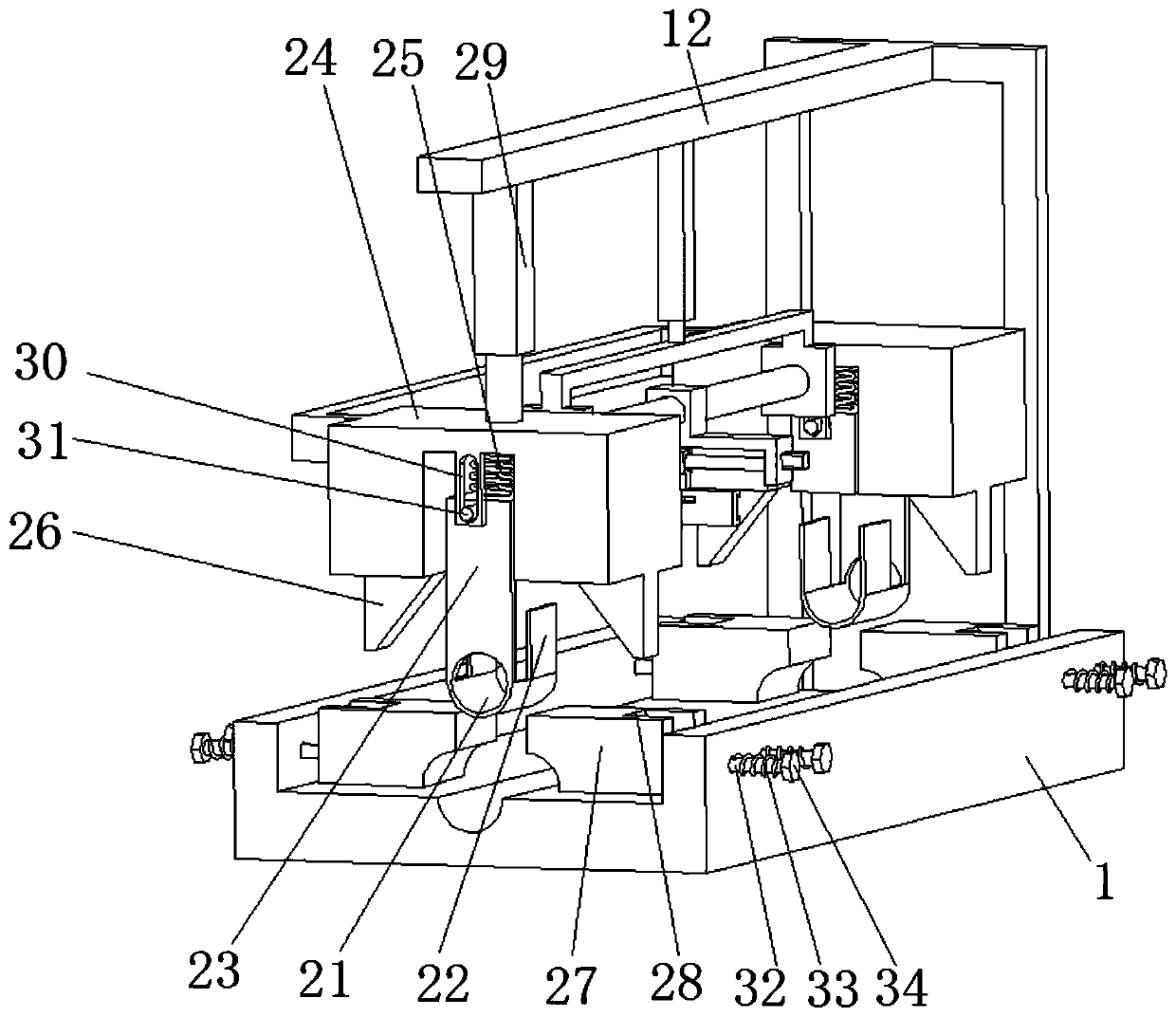

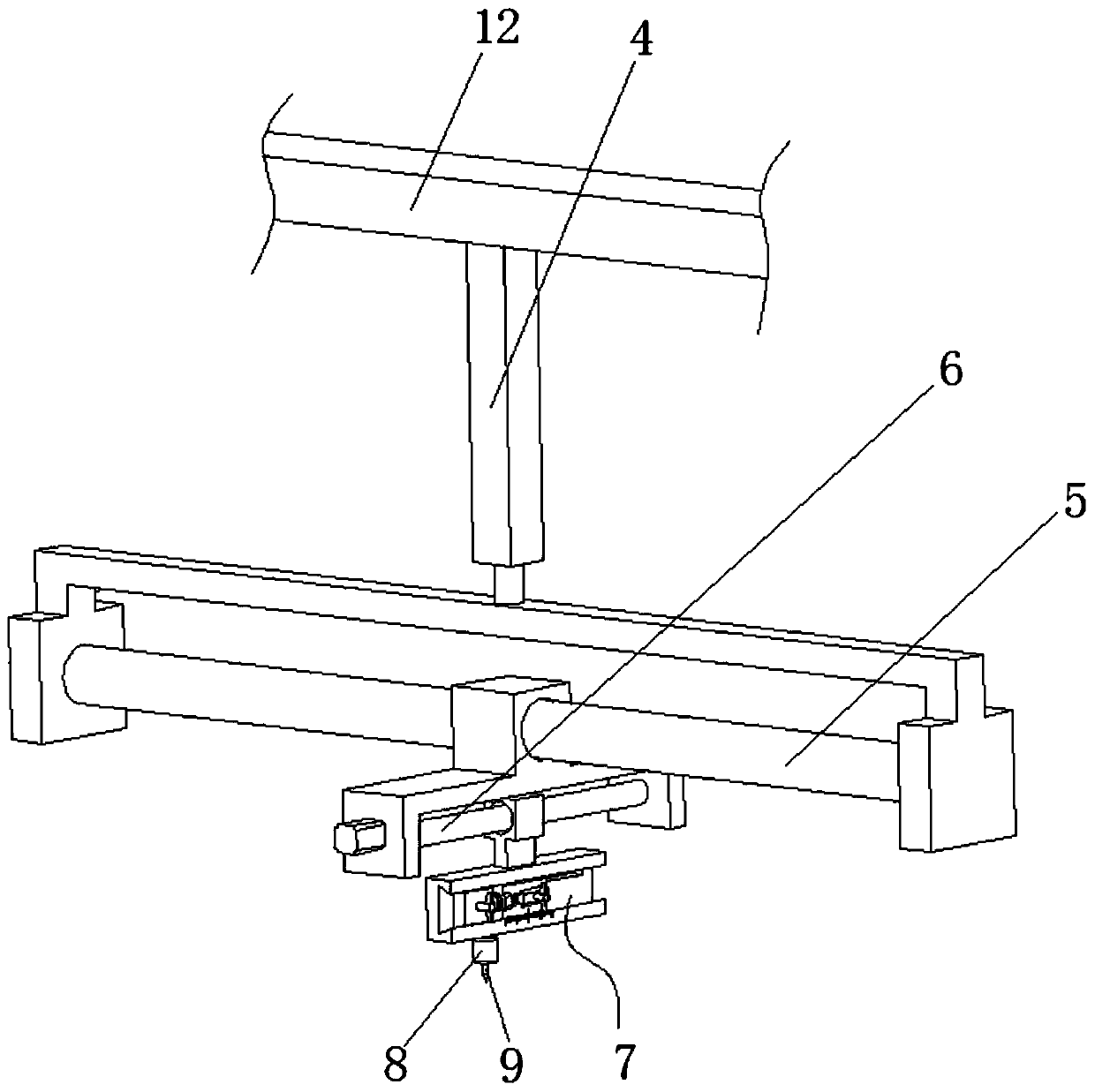

[0026] Embodiments of the present invention provide a small stone carving laser engraving equipment, such as Figure 1-6 As shown, it includes a base 1, a support beam 12 arranged on the base 1, a clamping mechanism for clamping cylindrical stones, a cylinder 4, a vertical axis slide rail 5, a horizontal axis slide rail 6, a spindle motor 8, and a main shaft The engraving cutter head 9 that motor 8 links to each other.

[0027] Such as figure 1 As shown, the cylinder 4 is arranged on the support beam 12, and the cylinder 4, the vertical axis slide rail 5, the horizontal axis slide rail 6, and the spindle motor 8 are connected in sequence.

[0028] Both the vertical axis slide rail 5 and the horizontal axis slide rail 6 are in the prior art, and the specific models are HG series ball linear slide rails. The cylinder 4 can drive the engraving head 9 to move vertically, the vertical axis slide rail 5 can drive the engraving head 9 to move longitudinally, and the horizontal axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com