Two-dimensional scanning precision laser exposure system

A two-dimensional scanning and exposure system technology, which is applied in the direction of microlithography exposure equipment, photolithography exposure device, etc., can solve the problems of poor precision, engraving error, low production efficiency, etc., achieve easy operation and reduce engraving error , Easy installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

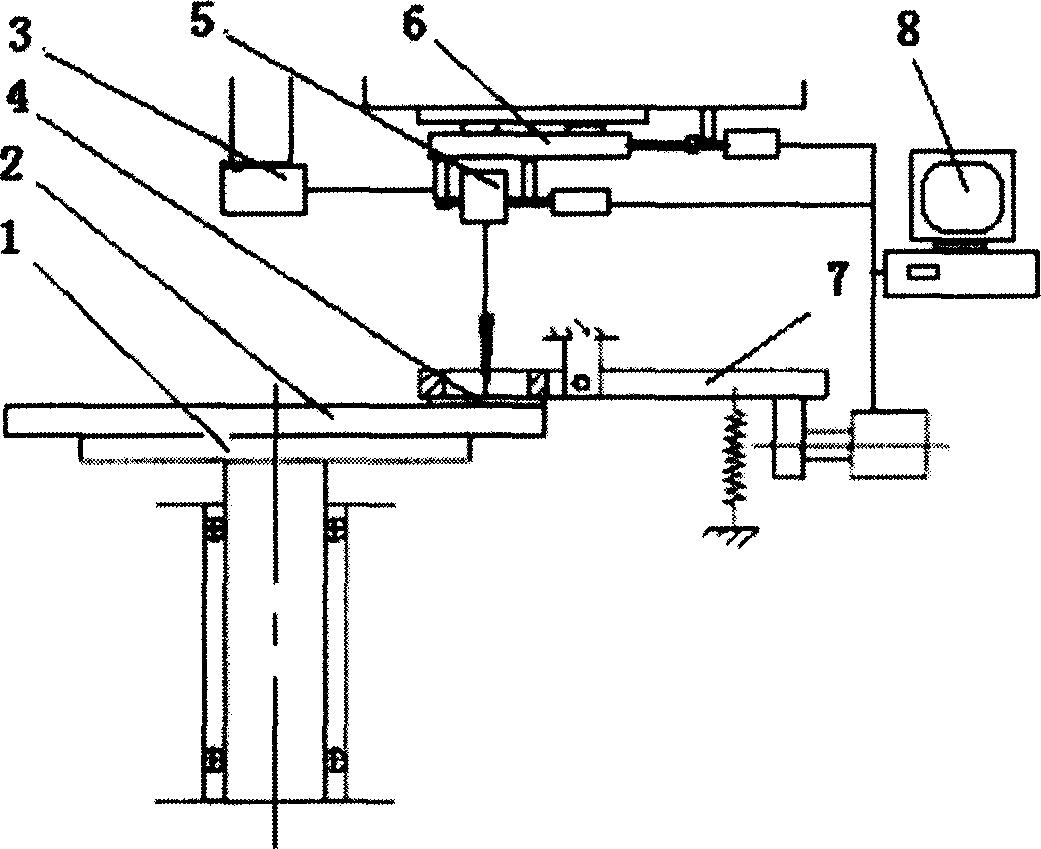

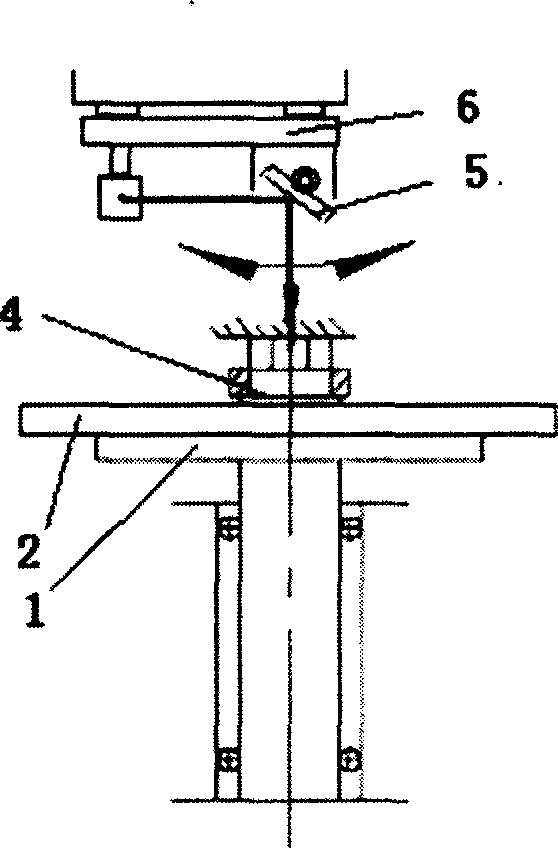

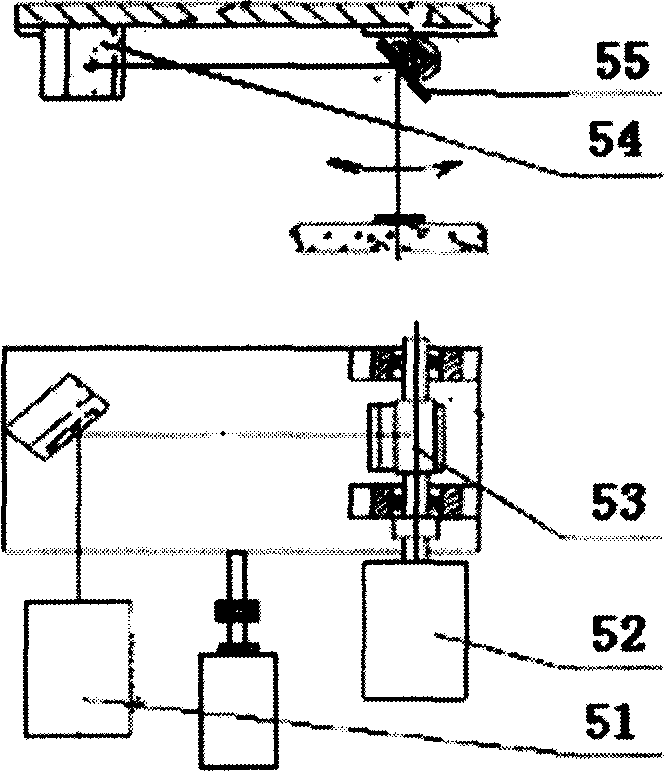

[0016] like figure 1 , 2 As shown, the embodiment of the present invention consists of a circular engraving machine table 1, a code disc to be engraved 2, a laser 3, a mask 4, a swing scanning system 5, a precision laser stepping table 6, a mask lifting mechanism 7 and a computer control system 8 components, the laser 3 is used as the light source, the beam is shaped and projected onto the scanning system 5, the computer control system 8 completes the two-dimensional scanning illumination mask 4 by controlling the movement of the swing scanning system 5 and the precision laser stepping stage 6, and the mask 4 The photolithography of a region is completed on the pattern replication on the engraved code disc 2, the circular engraving machine table 1 is driven by the engraved code disc 2 to rotate to select the area to be photo-etched, and the mask lifting mechanism 7 will mask the area when the code disc rotates. Die 4 lifts up and falls down during exposure.

[0017] The lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com