Cylindrical engraving machine

An engraving machine and cylinder technology, applied in decorative arts, processing models, etc., can solve the problems of inaccurate positioning and low engraving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

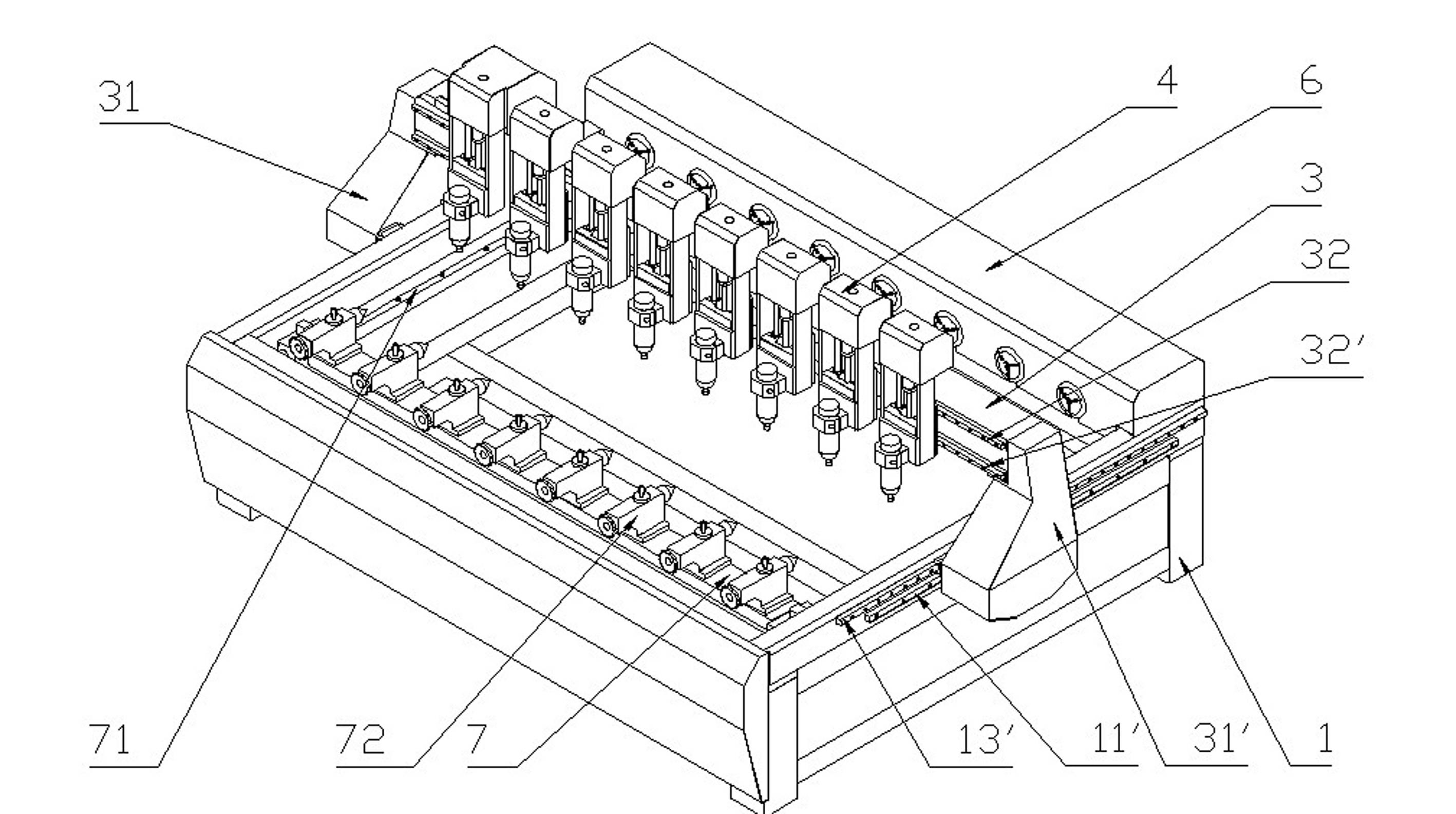

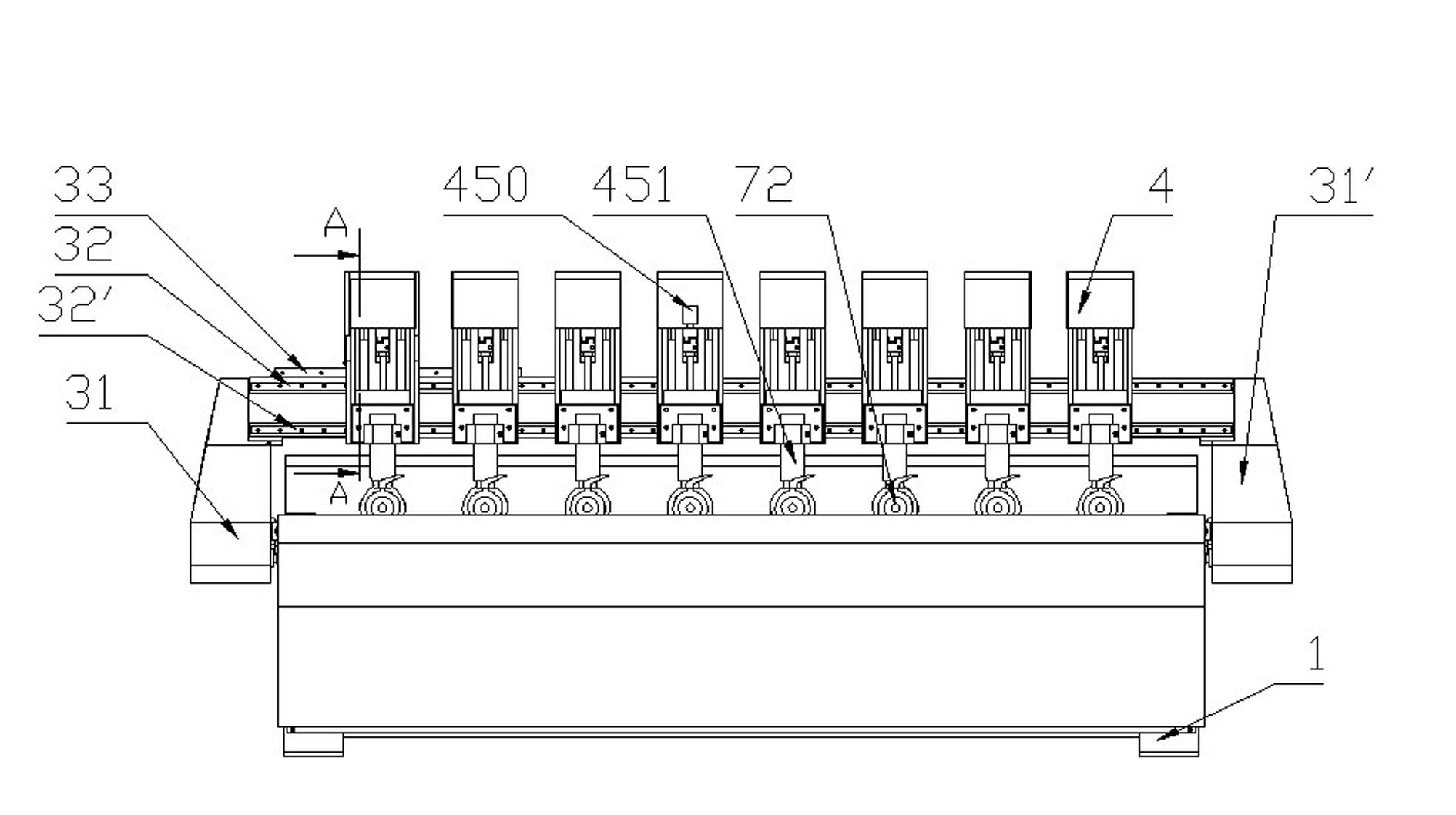

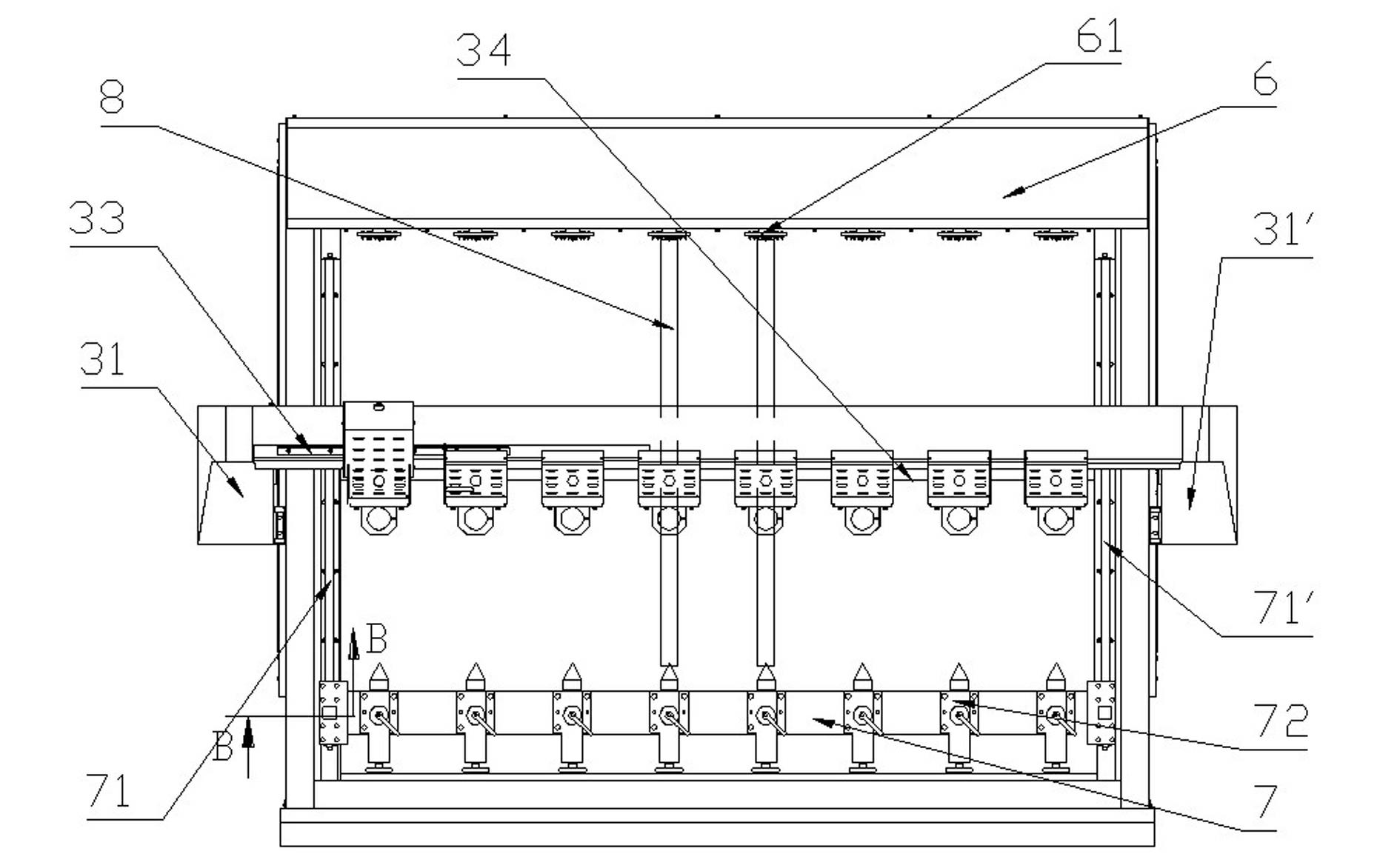

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 12 , Figure 13 It can be seen that this embodiment includes a bed body 1, a left upright post 31 and a right upright post 31' are respectively movably connected to both sides of the bed body 1 through Y-direction tracks, and a gantry 3 is fixedly arranged above the left upright post 31 and the right upright post 31', and the left upright post 31' 1, between the right column 31' and the bed body 1, a Y-direction driving device is respectively arranged; on the gantry 3, a plurality of engraving heads 4 are movably connected through upper and lower X-direction rails 32, 32', and a plurality of engraving heads 4 pass through The connecting rod 34 is fixedly connected, the gantry 3 is provided with an X-direction driving device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com