Independent-tool-setting type 3D multi-functional numerical control carving machine

A CNC engraving machine, multi-functional technology, applied in the direction of engraving, processing models, decorative arts, etc., can solve the problem of lack of multi-functional engraving machines, and achieve the effect of improving engraving accuracy, high work efficiency, and improving equipment adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

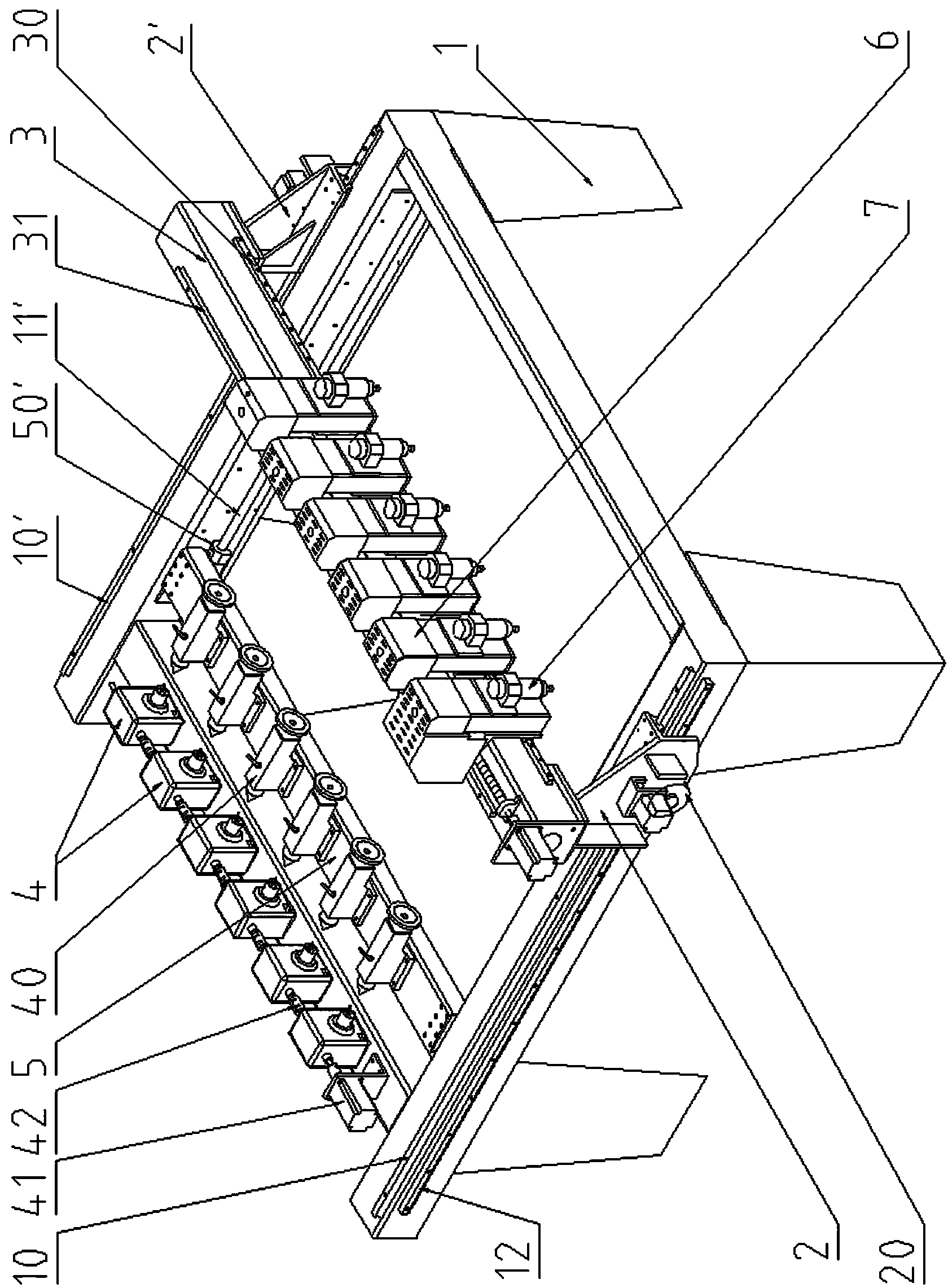

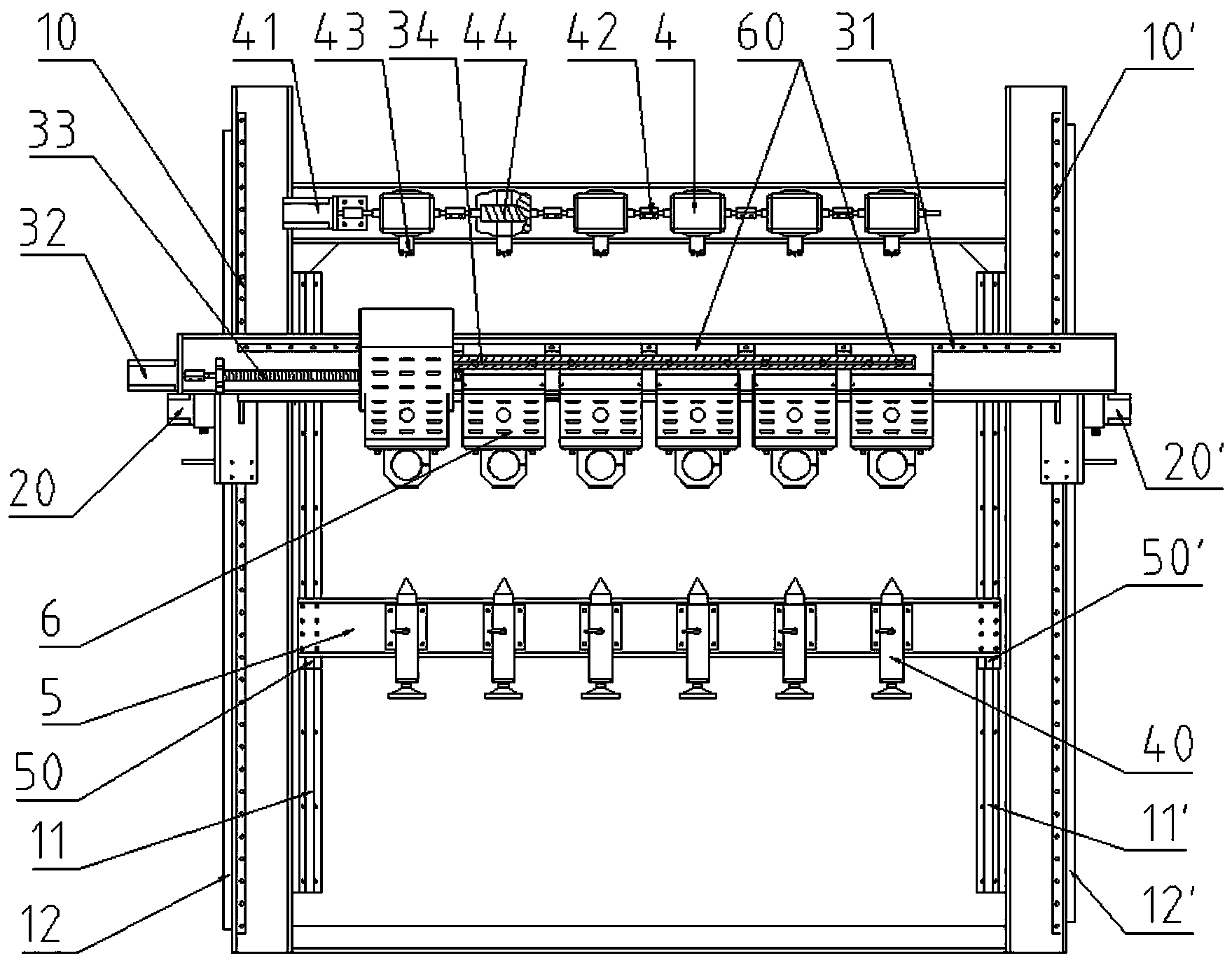

[0043] Depend on Figure 1 to Figure 6 It can be seen that, in this embodiment, the Y-direction drive device adopts a rack drive mode, and both sides are synchronously driven.

[0044] In the independent knife-setting type 3D three-dimensional multifunctional CNC engraving machine of this embodiment, its Y-direction driving device includes left and right Y-direction racks 12, 12' arranged on the bed body 1, and also includes left and right columns 2, 12', The left and right Y-direction drive motors 20, 20' on the column 2', the main shafts of the left and right Y-direction drive motors 20, 20' are in drive connection with the left and right Y-direction racks 12, 12' .

[0045] In this embodiment, the Y direction adopts the rack transmission mode, and the left and right Y direction racks 12, 12' are arranged on both sides of the bed body 1, and the left and right Y direction drive motors 20, 20' simultaneously perform bilateral synchronization on the gantry 3 drive, so as to ...

Embodiment 2

[0057] On the basis of Embodiment 1, this embodiment provides the situation that the present invention is used as a plane engraving machine.

[0058] Such as Figure 1 to Figure 7 It can be seen that the independent knife-setting type 3D three-dimensional multifunctional CNC engraving machine of this embodiment moves the thimble support plate 5 to the end of the bed body 1, closes the chuck driving device through the control system, and sets the panel 13 on the bed body 1. X-direction, Y-direction, Z-direction, engraving motor four-axis linkage, the flat workpiece is placed on the panel 13, the purpose of surface relief can be achieved, so this machine also has the function of a plane engraving machine.

Embodiment 3

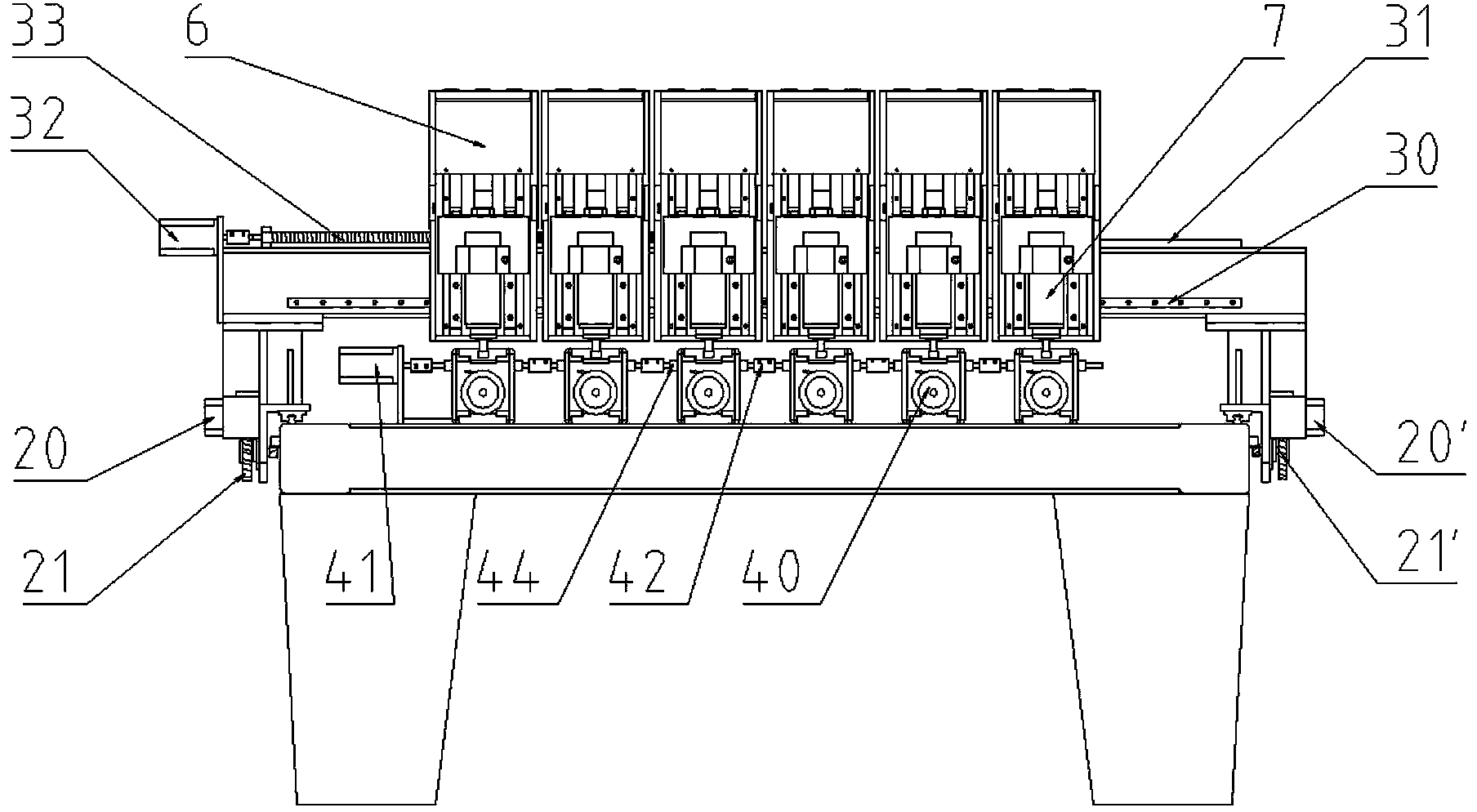

[0060] Such as Figure 5 , Image 6 , Figure 8 , Figure 9 , Figure 10 It can be seen that the difference between this embodiment and the first embodiment is that a rack transmission mode is adopted in the X direction.

[0061] The X-direction driving device includes an X-direction rack 35 arranged on the gantry 3, and at least one engraving head 6 is provided with an active engraving head X-direction motor 36. In this embodiment, the active engraving head X-direction motor 36 is arranged on Inside the first engraving head 6 on the left. An X-direction gear 37 is arranged on the main shaft of the X-direction motor 36 of the active engraving head, and the X-direction gear 37 meshes with the X-direction rack 35 .

[0062] In the width direction of the gantry 3, the X-direction rack 35 is arranged between the X-direction vertical guide rail 30 and the X-direction horizontal guide rail 31. The X-direction rack 35 is arranged on the horizontal plane of the gantry 3 relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com