Patents

Literature

31results about How to "High walking accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

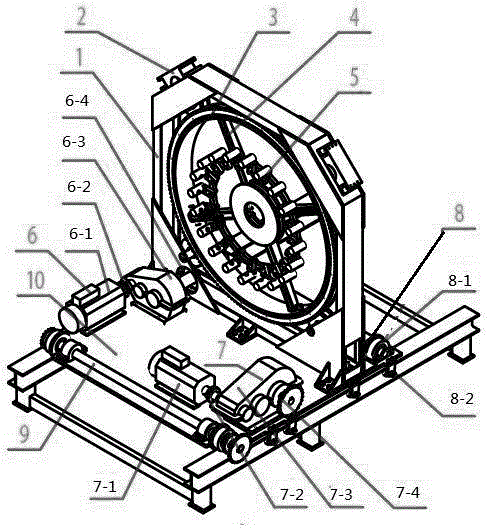

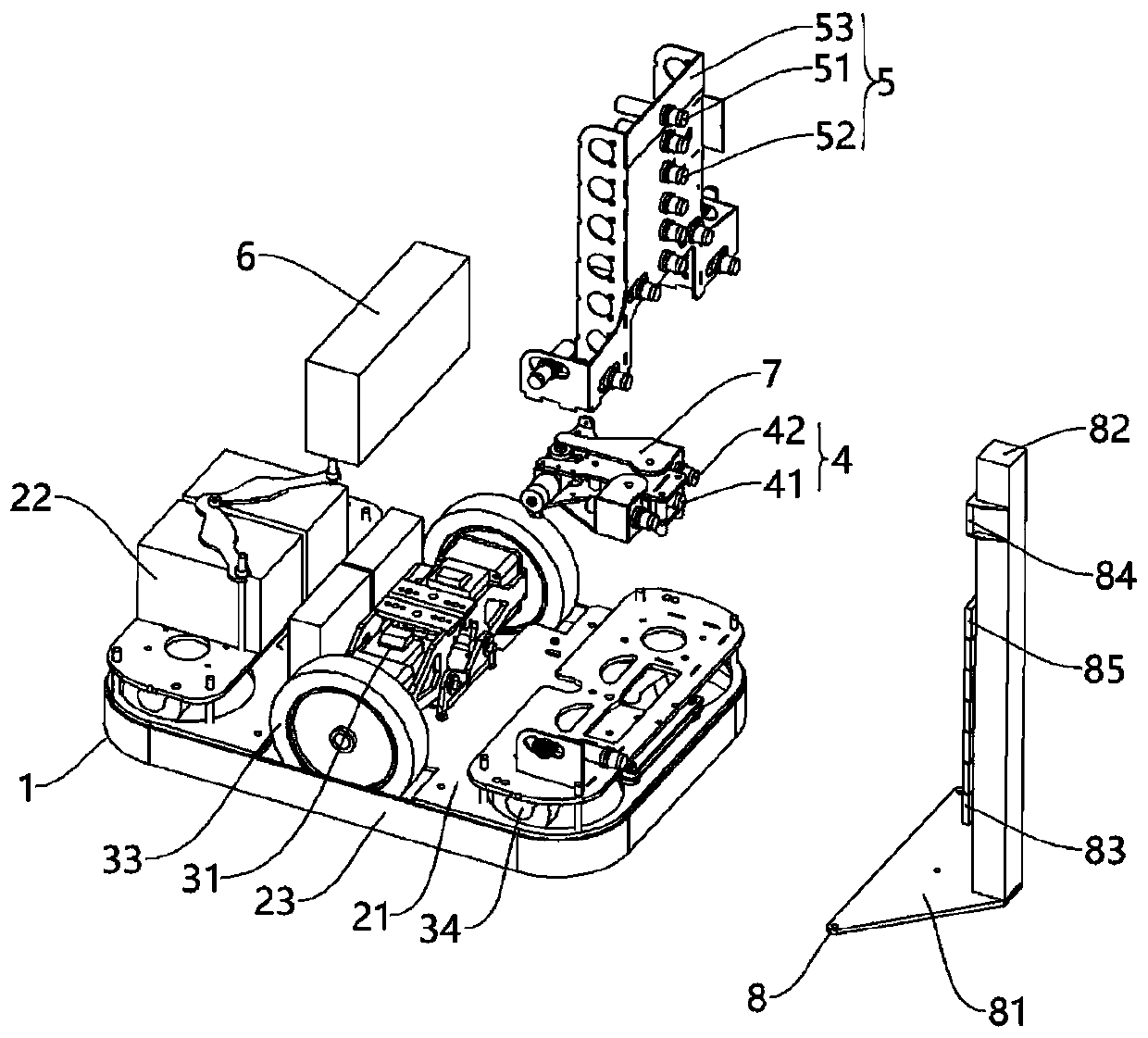

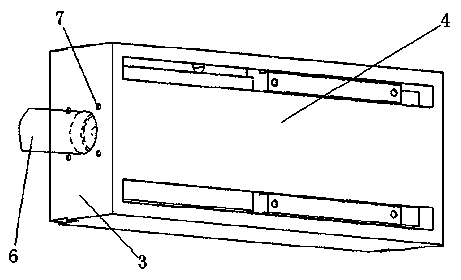

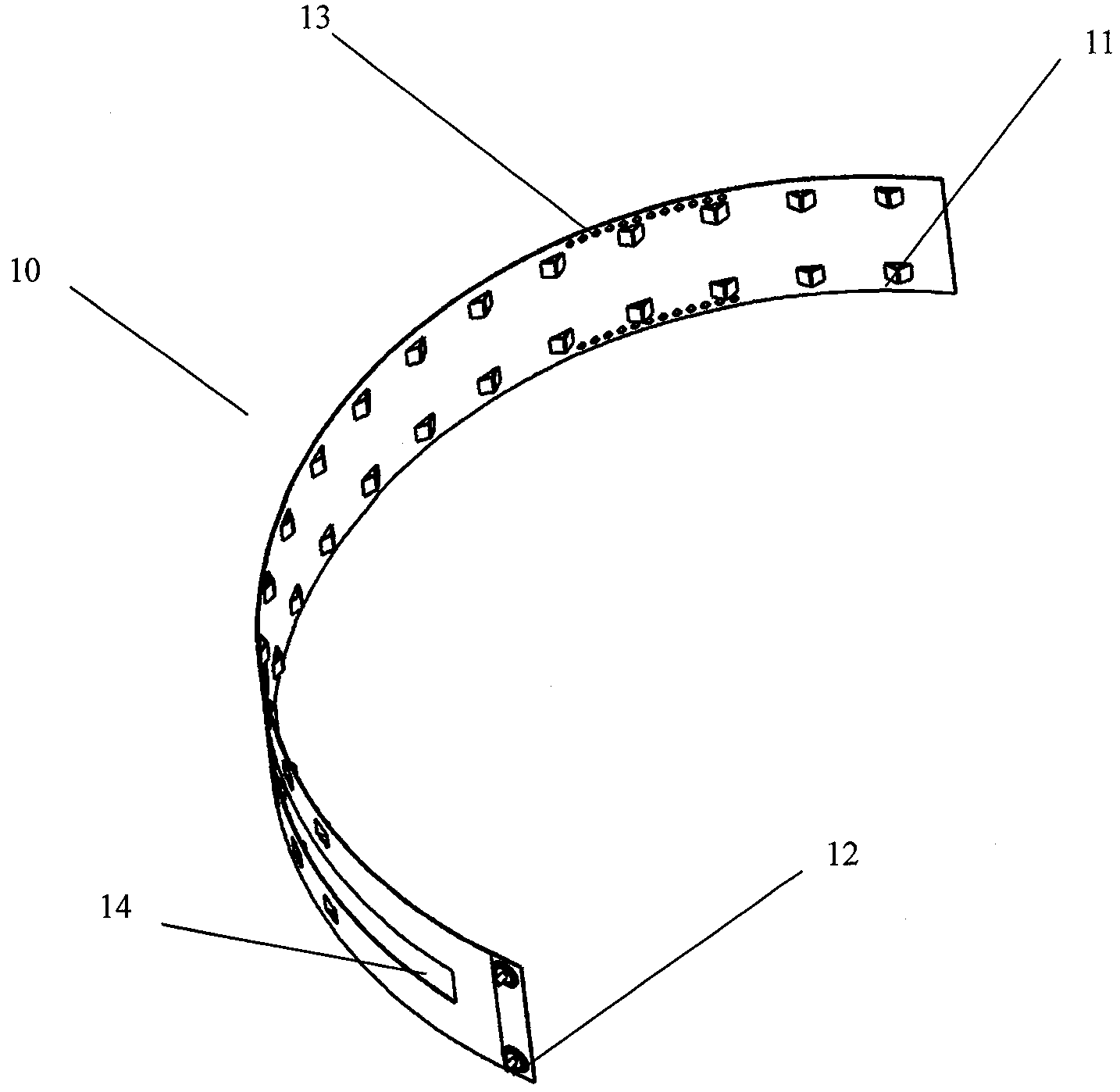

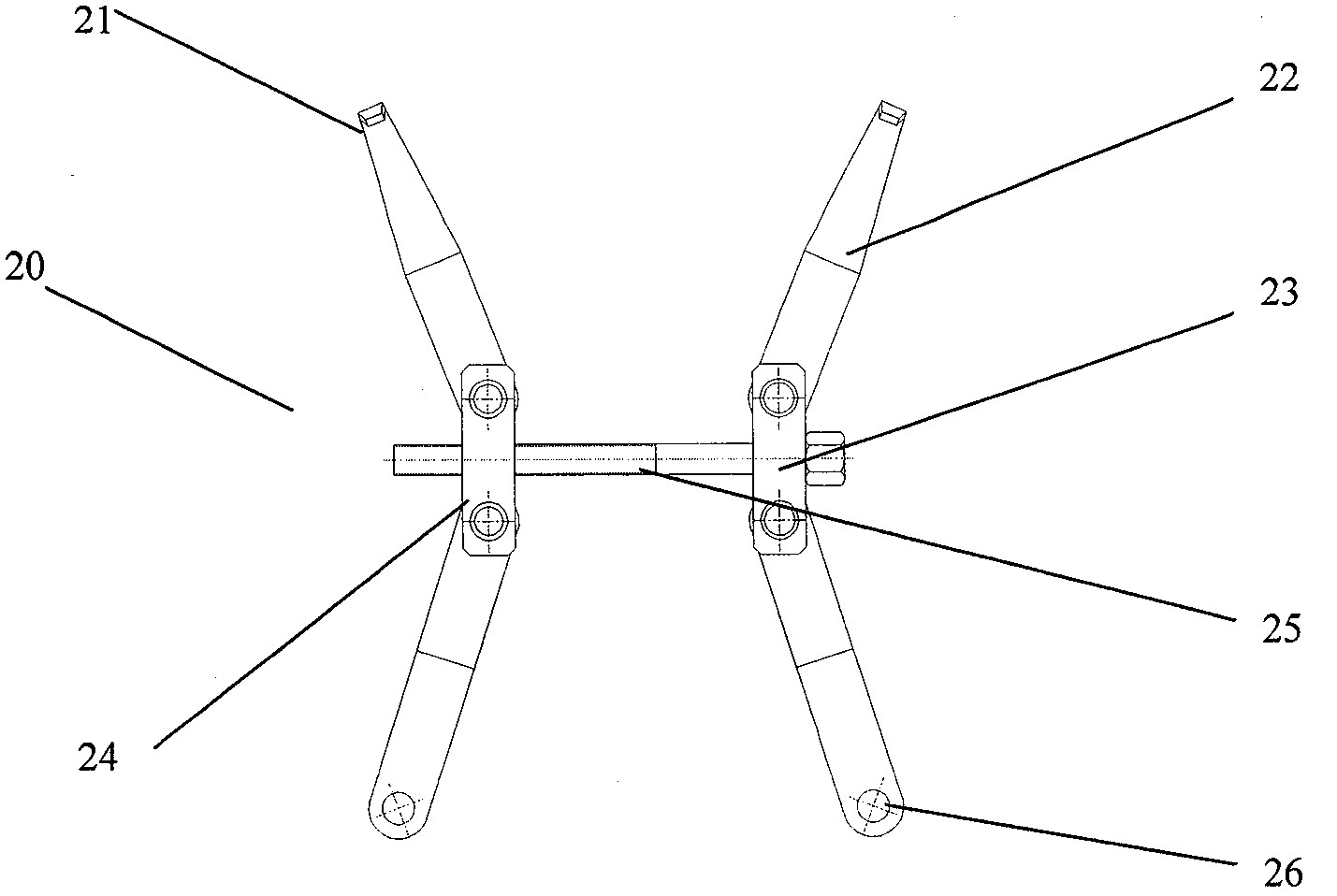

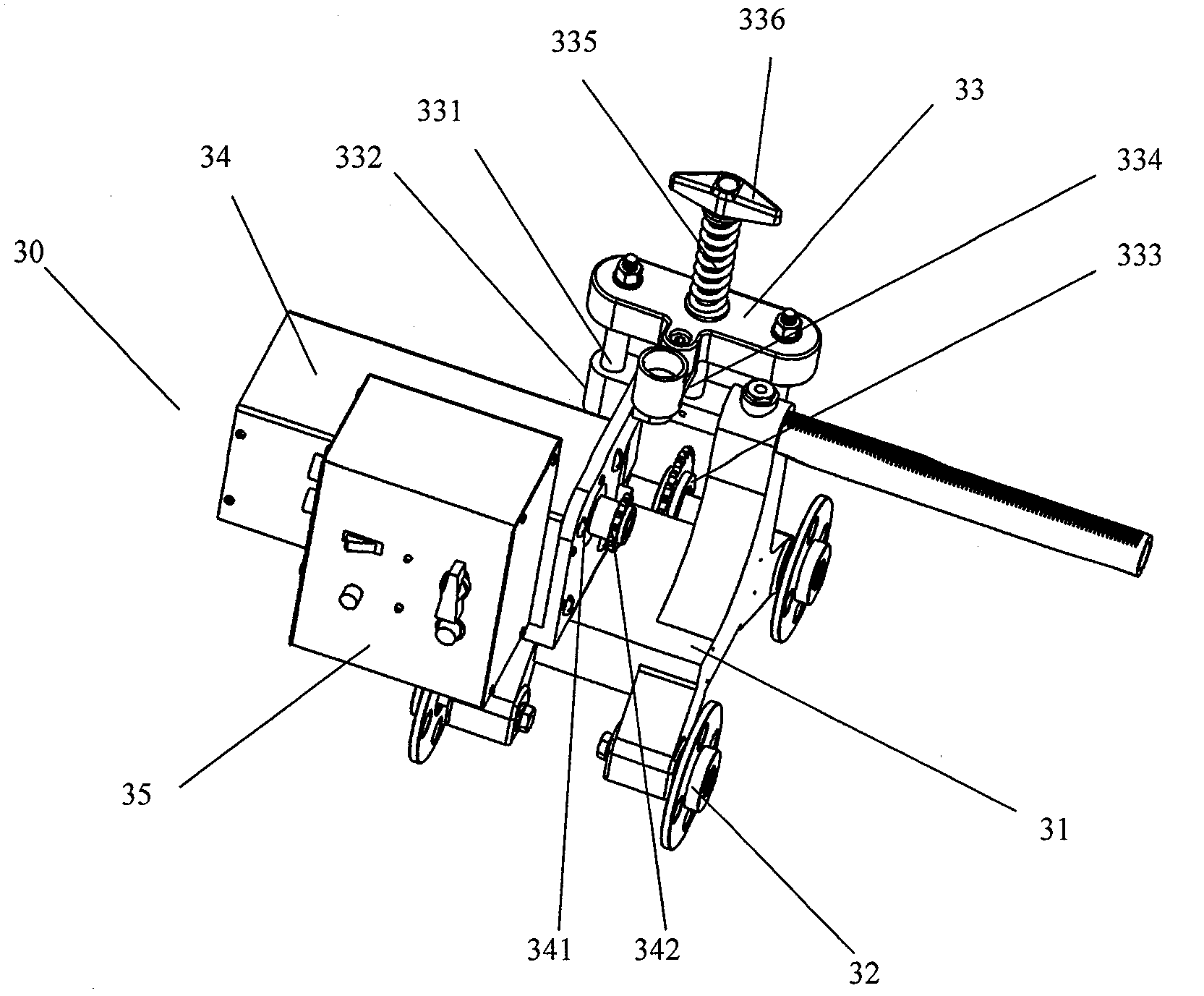

Portable pipeline automatic circumferential walking device and pipeline processing method

ActiveCN102000928AGuaranteed coincidenceHigh walking accuracyWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

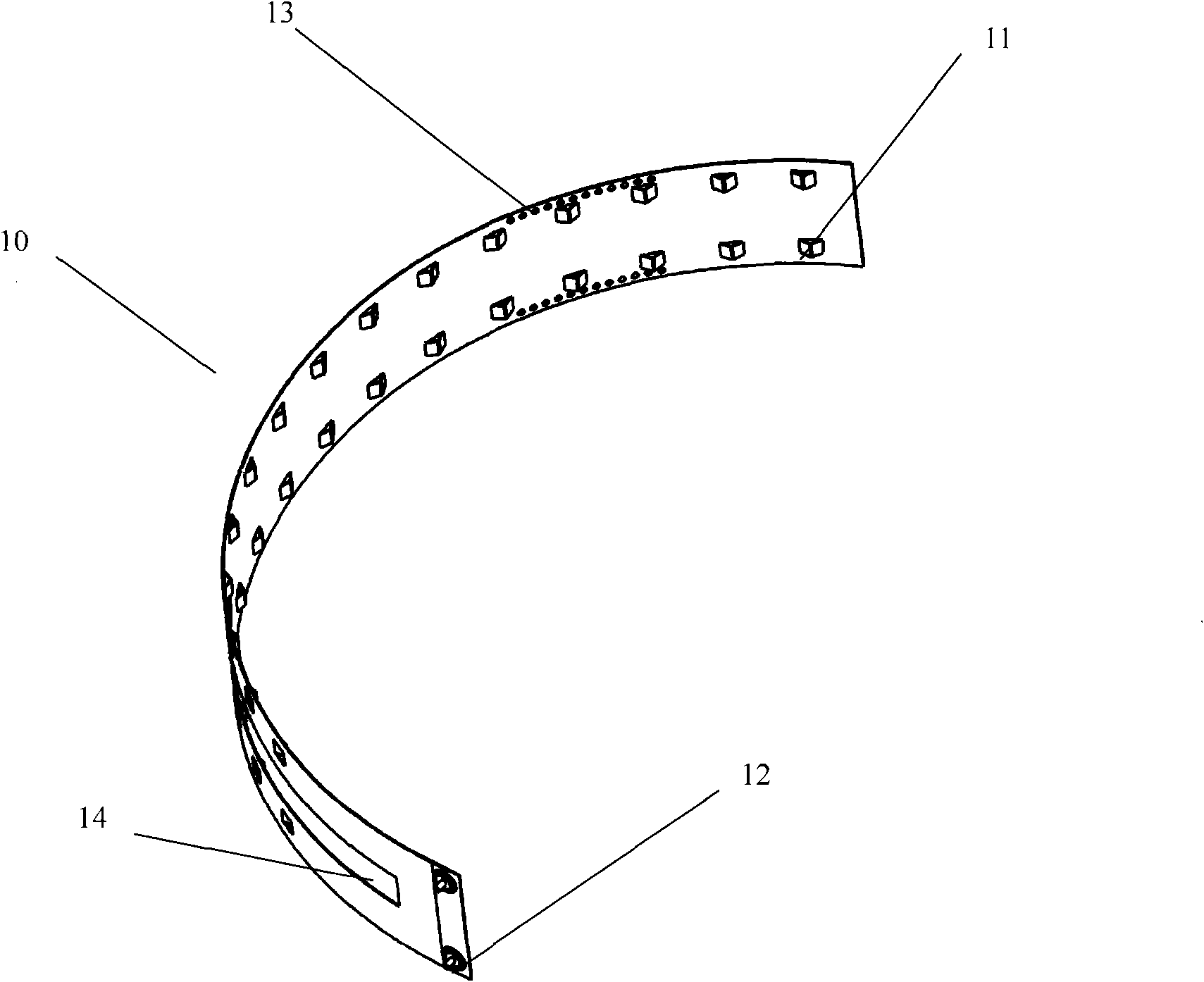

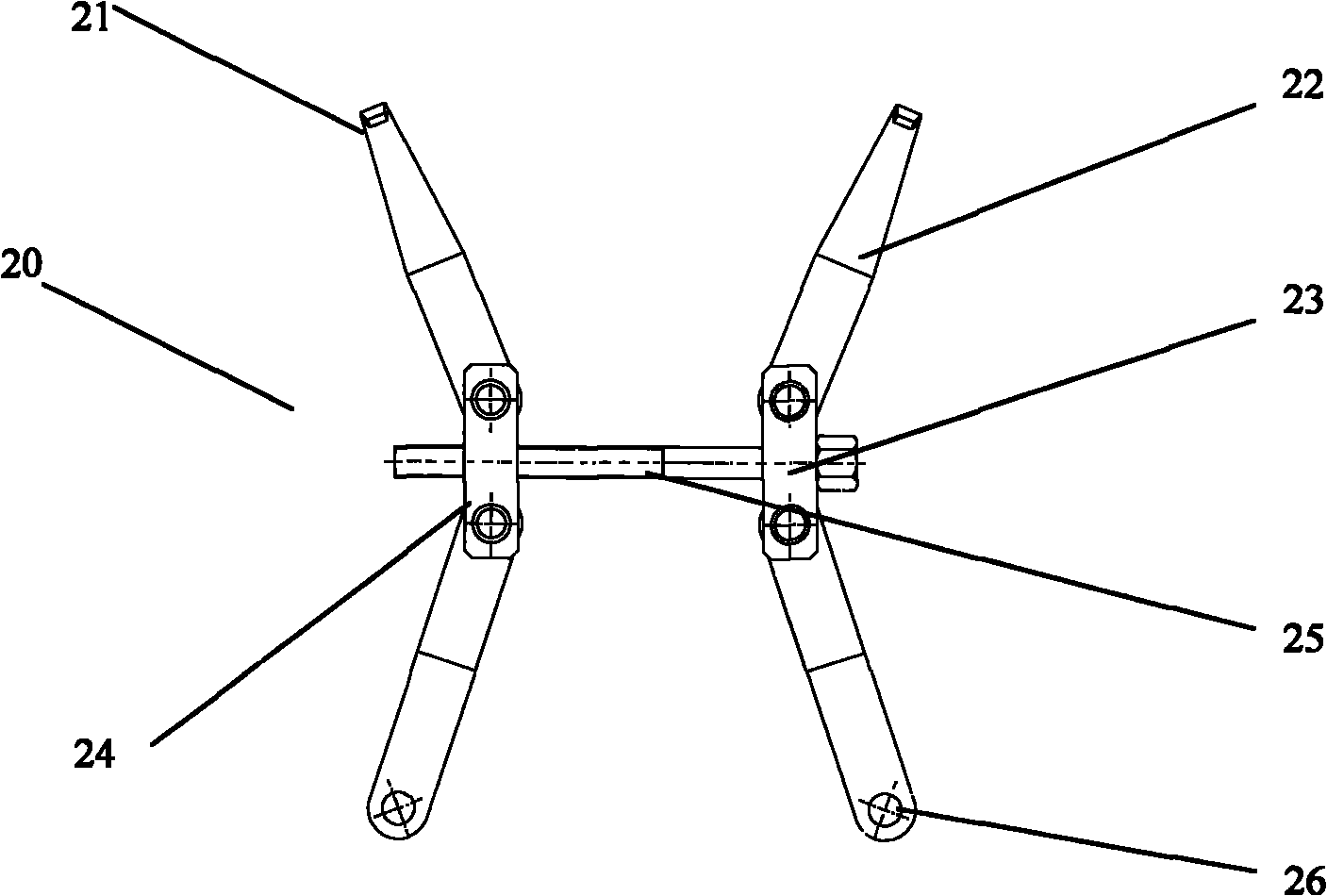

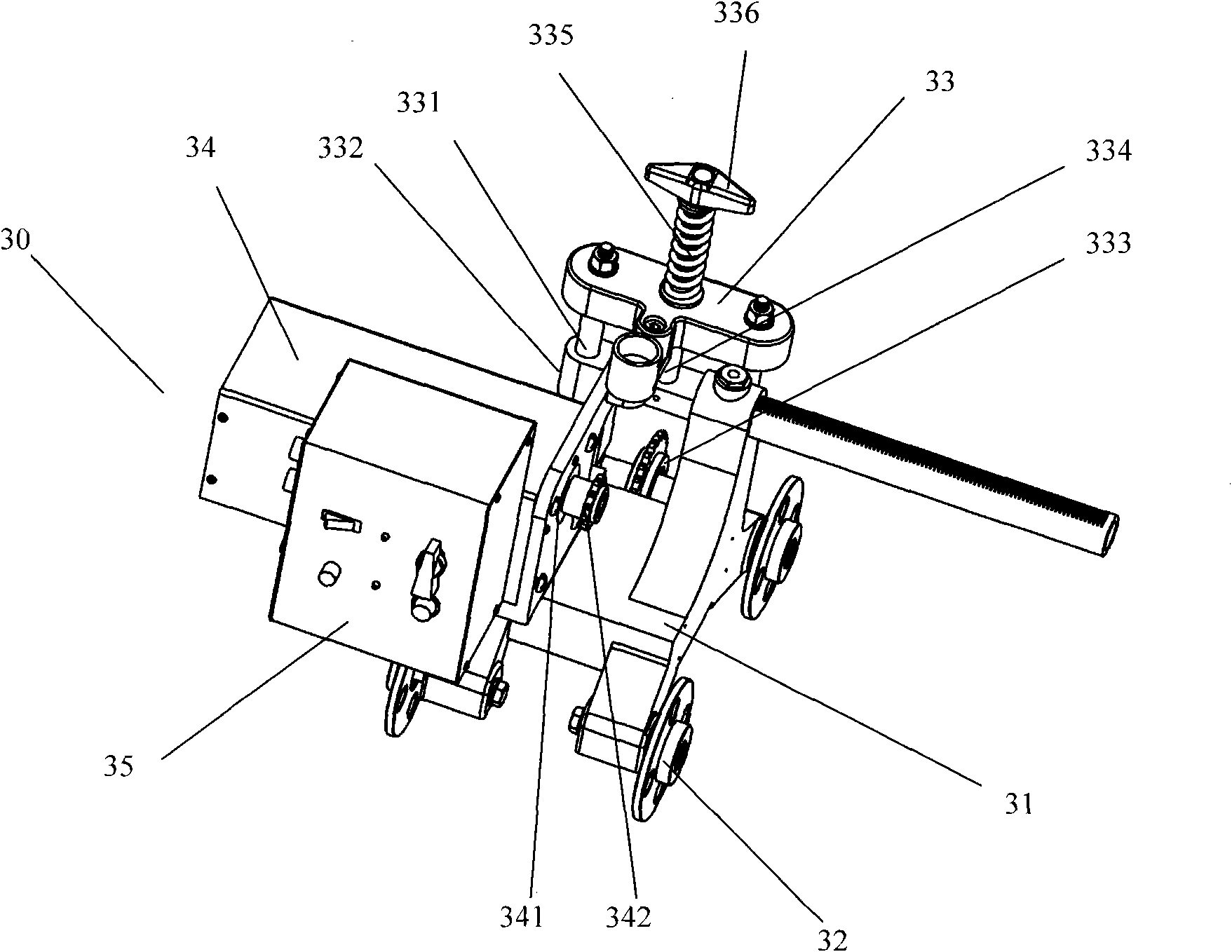

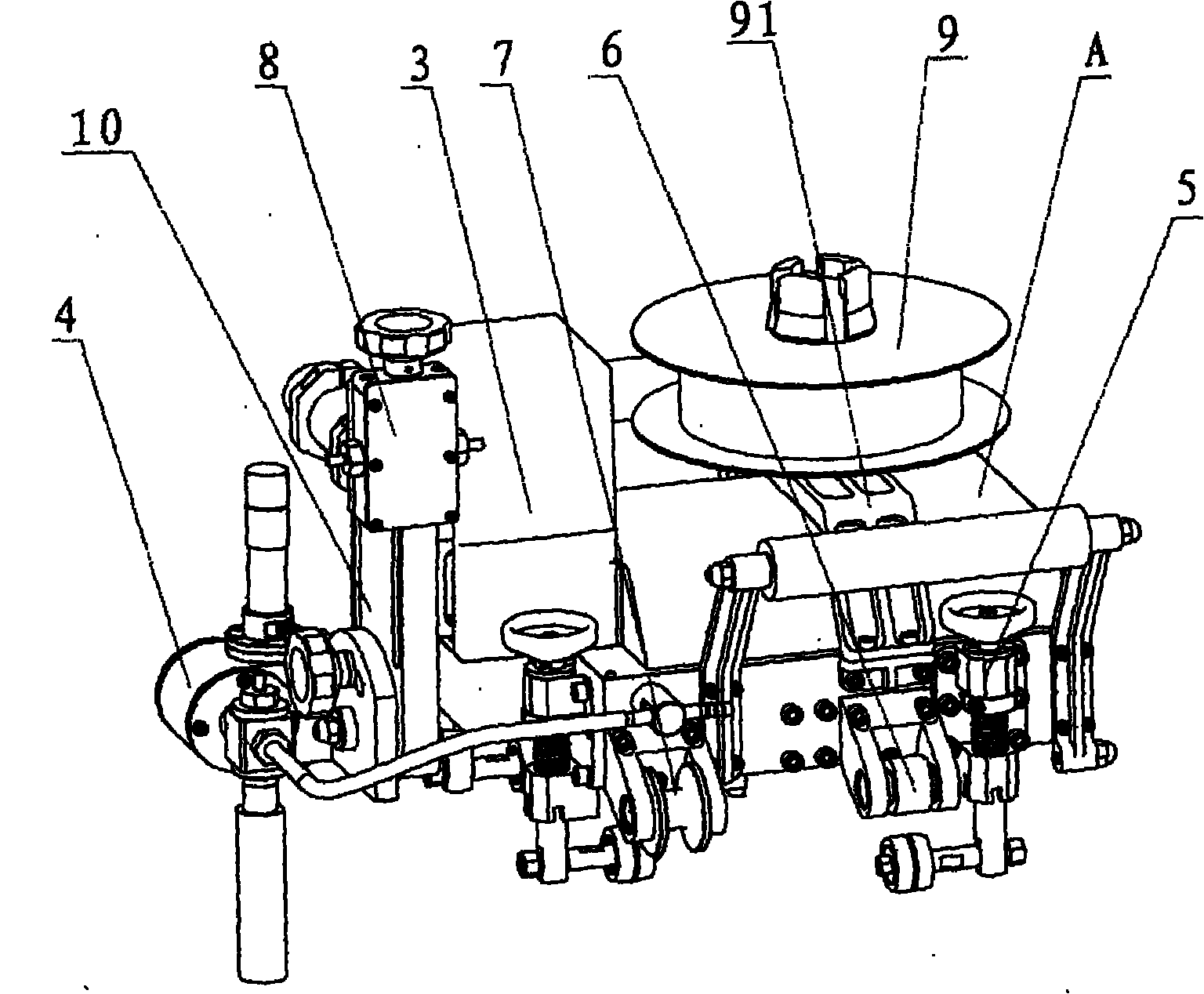

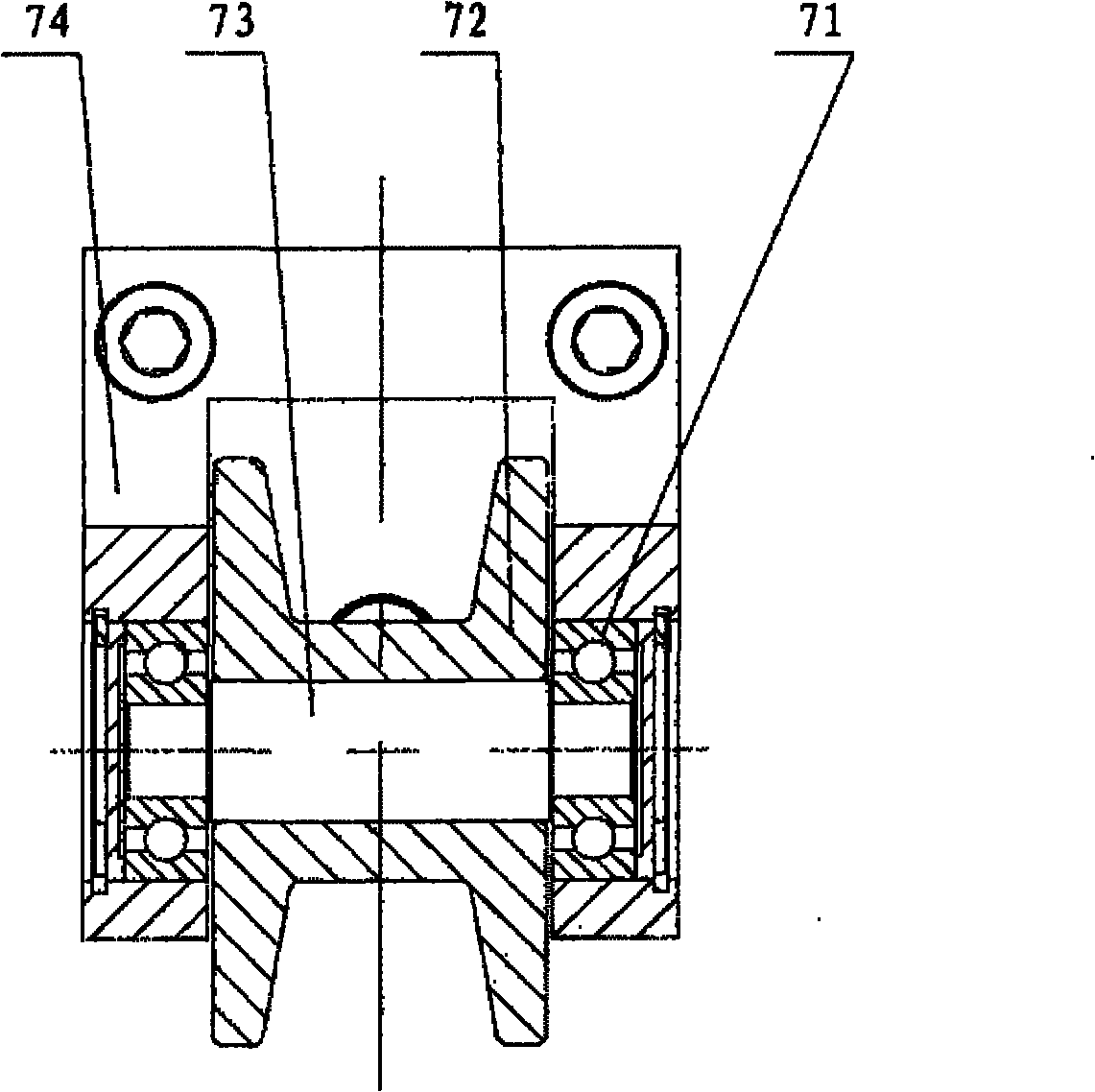

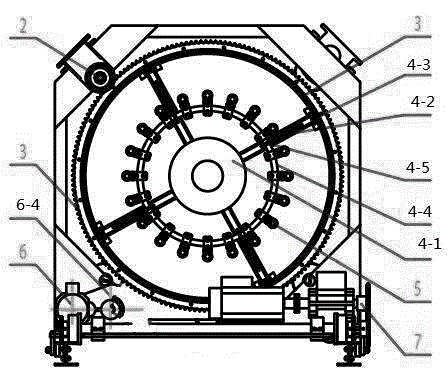

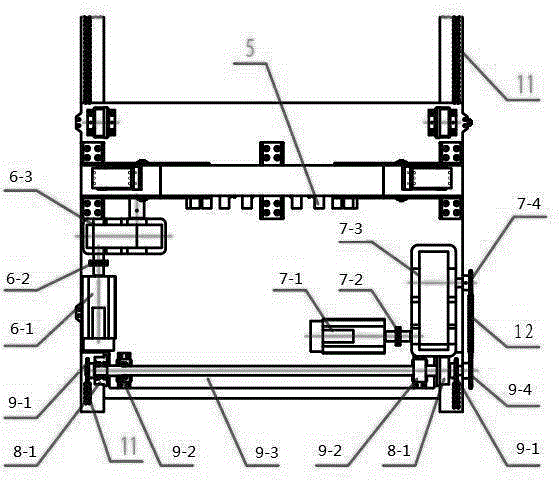

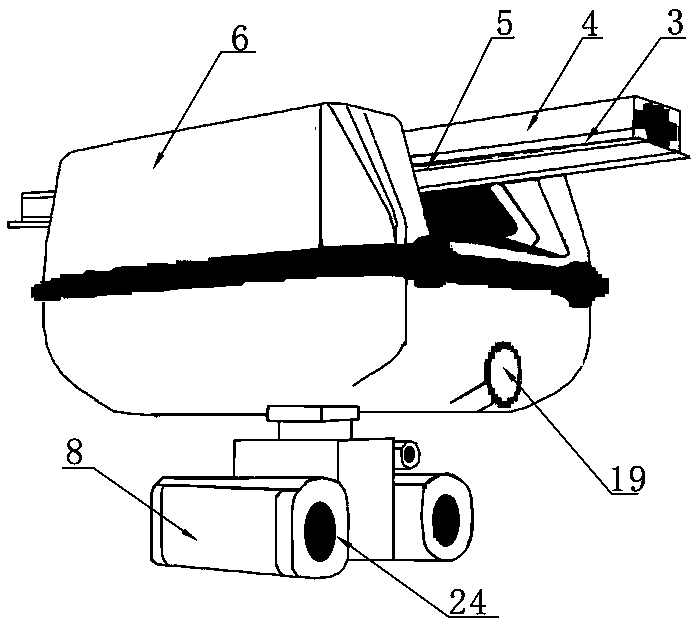

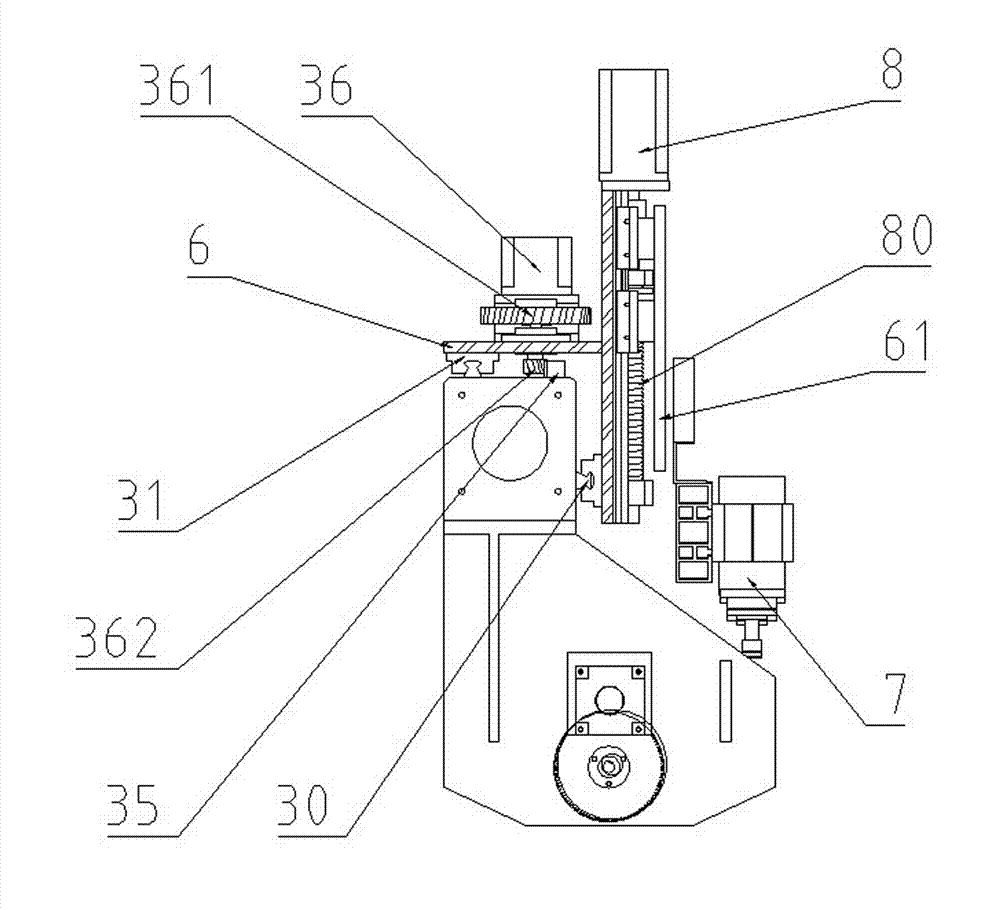

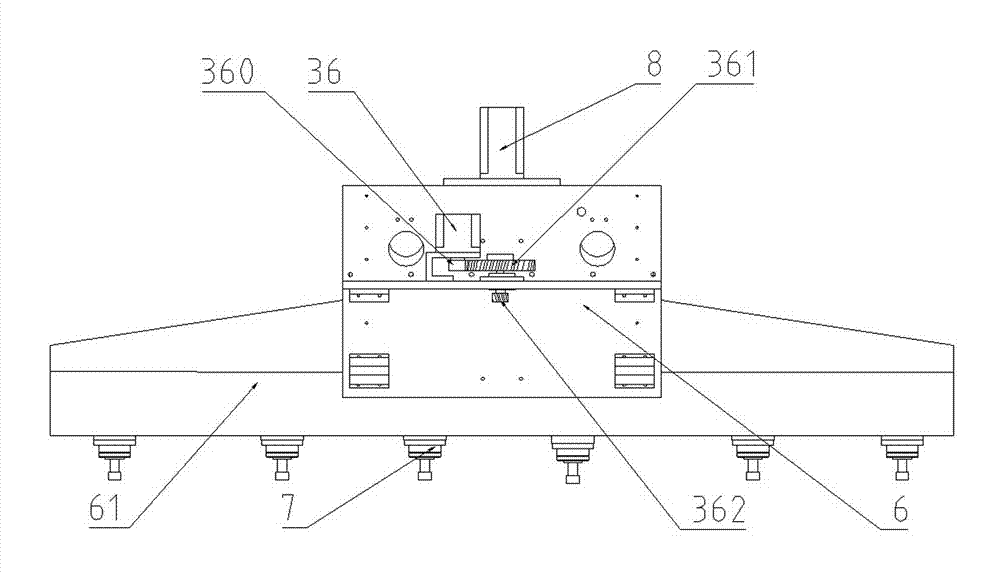

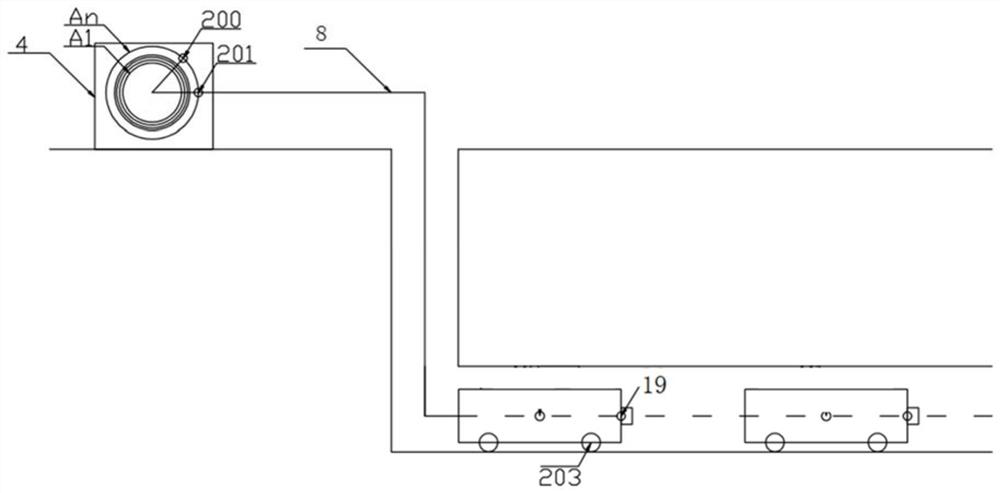

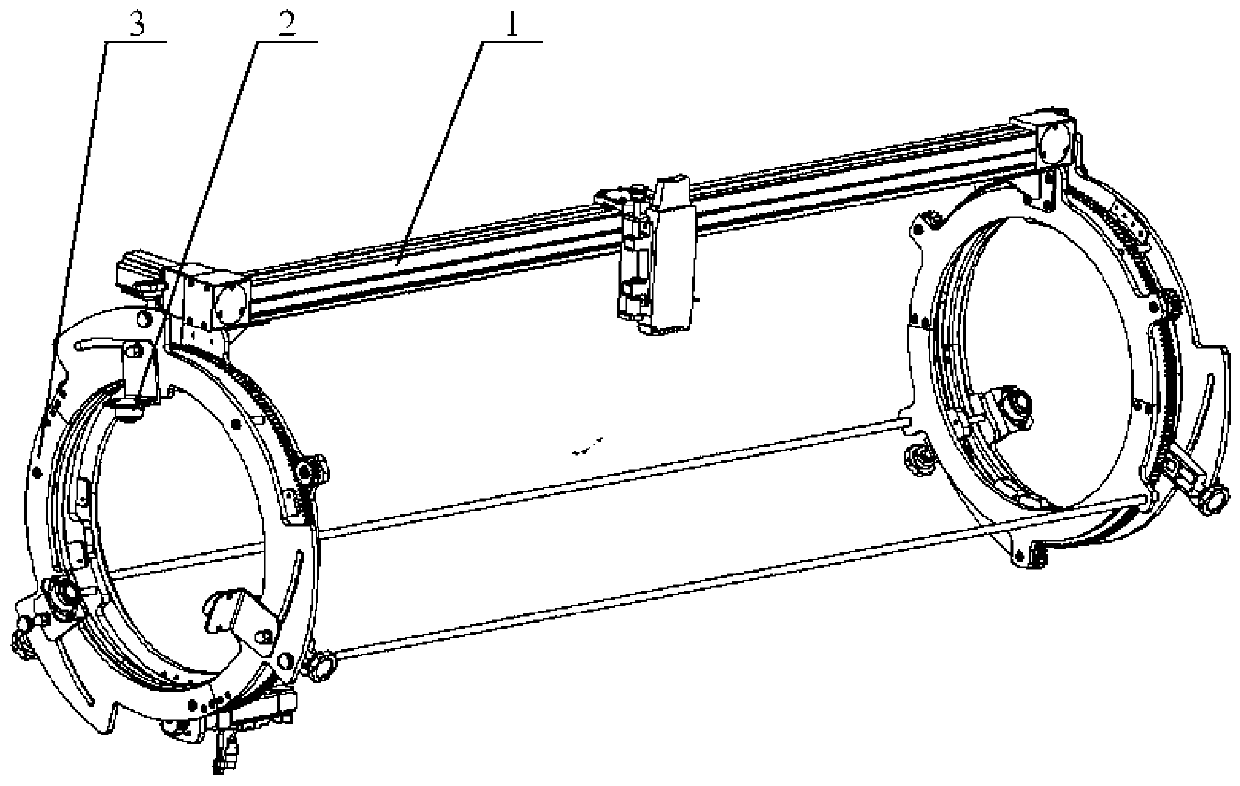

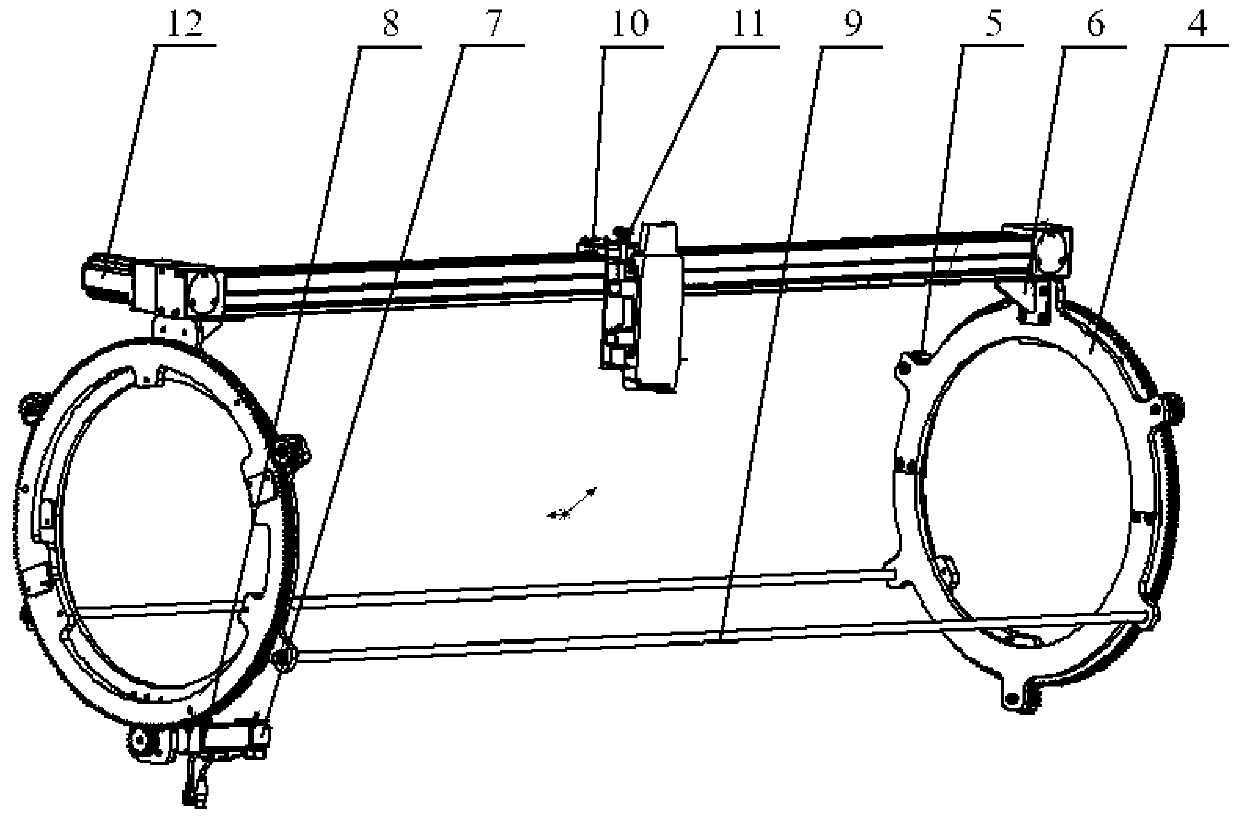

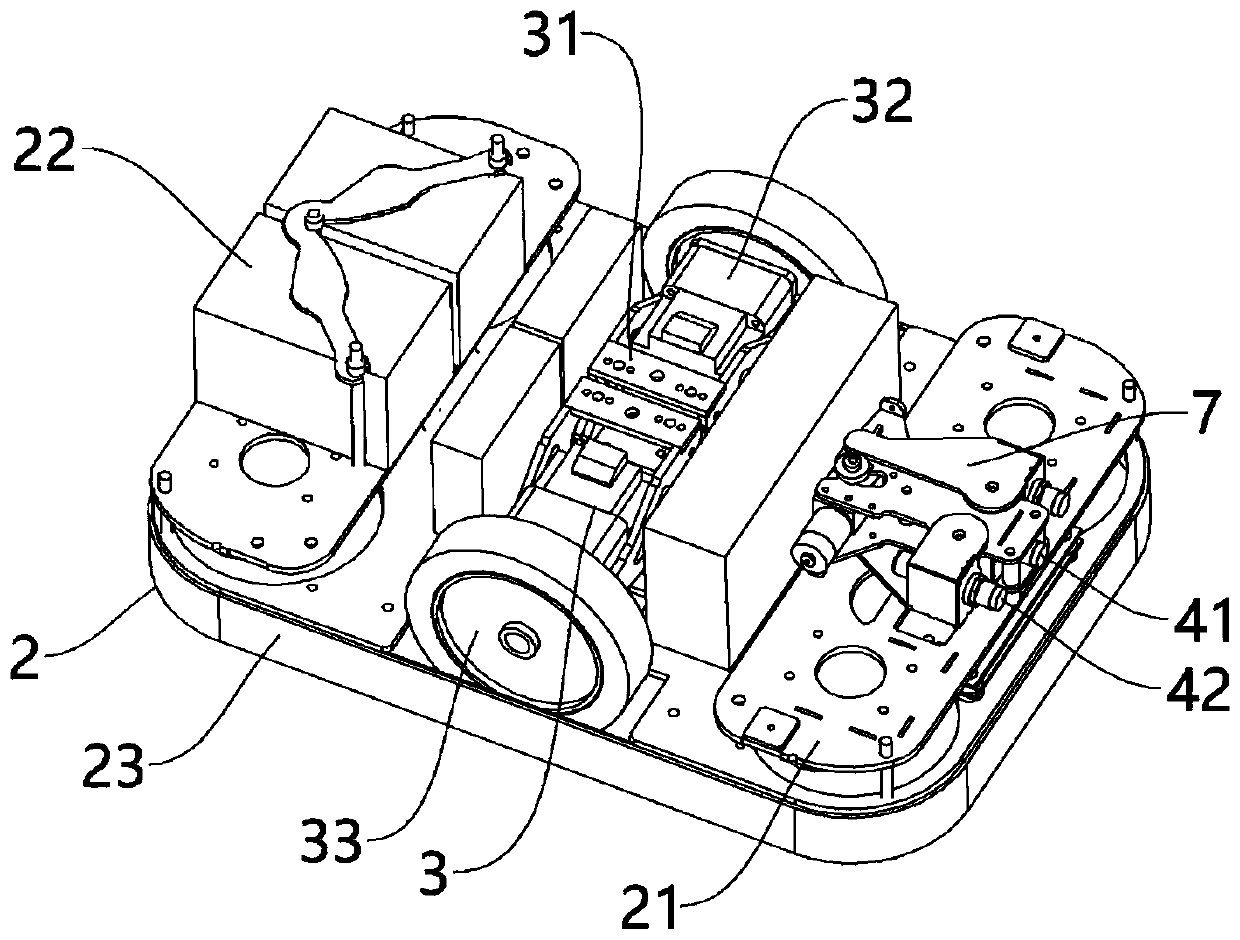

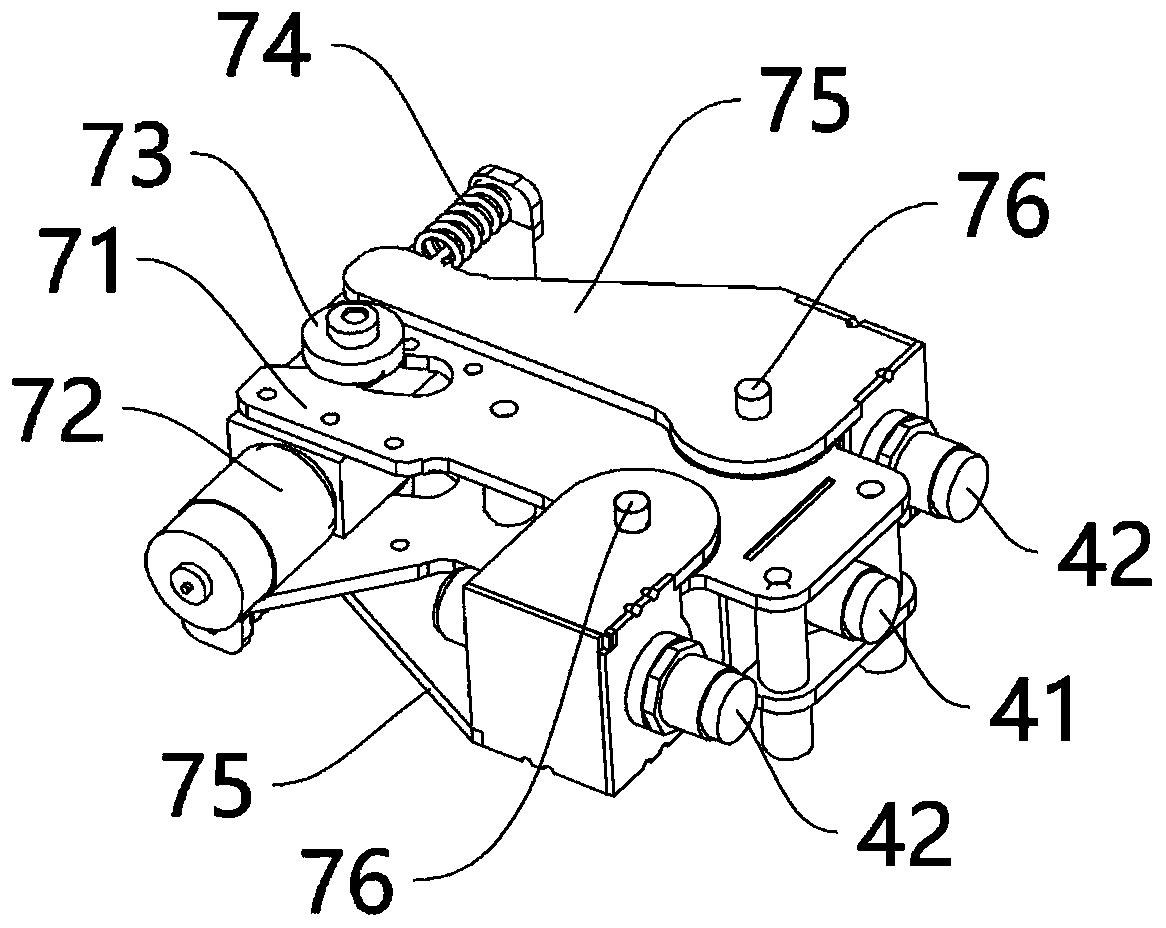

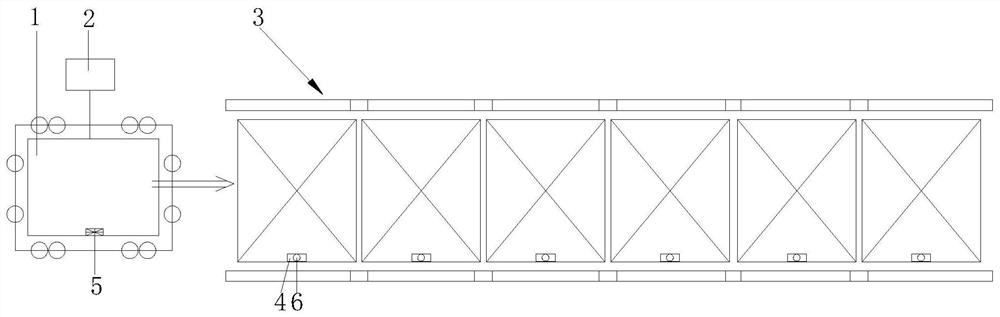

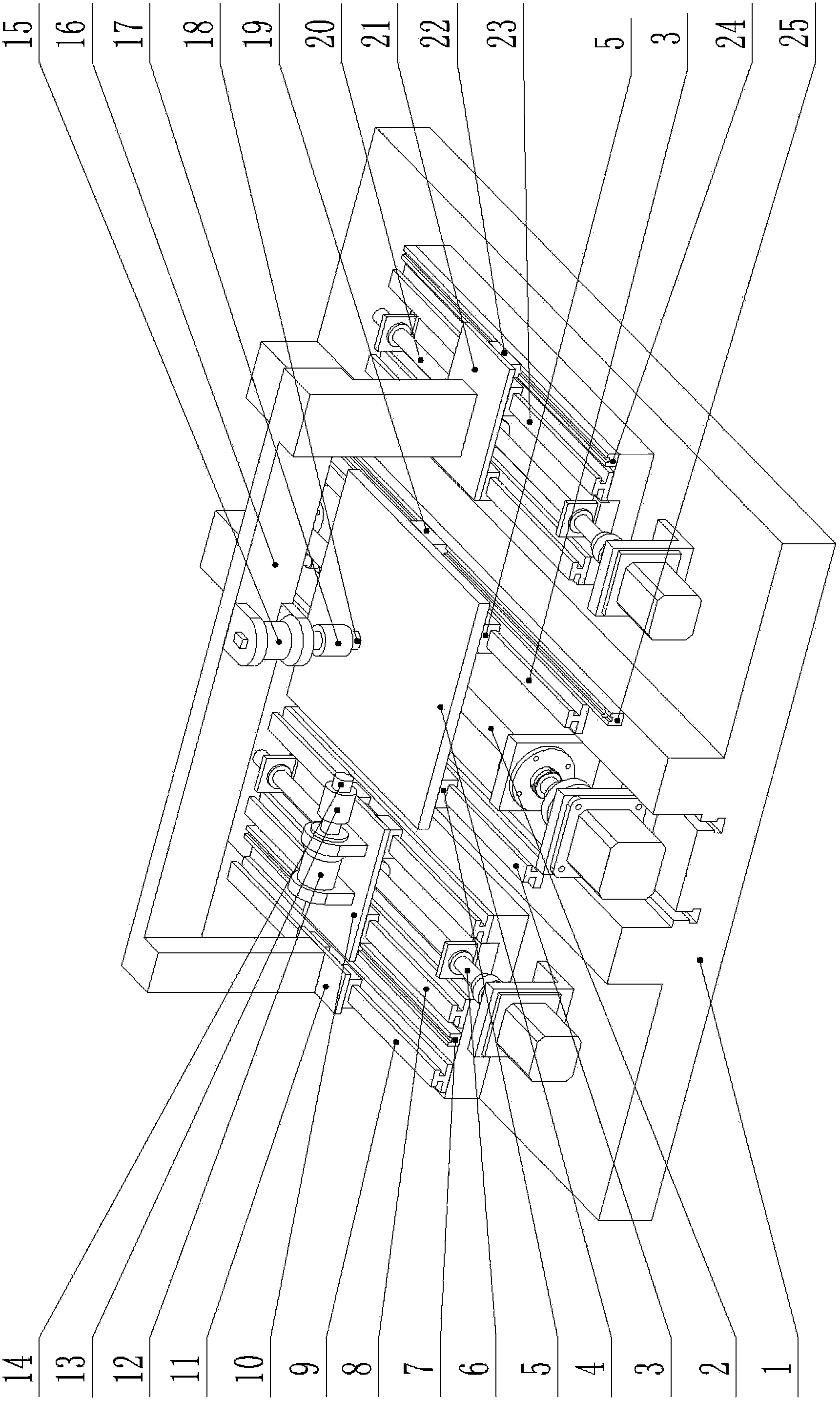

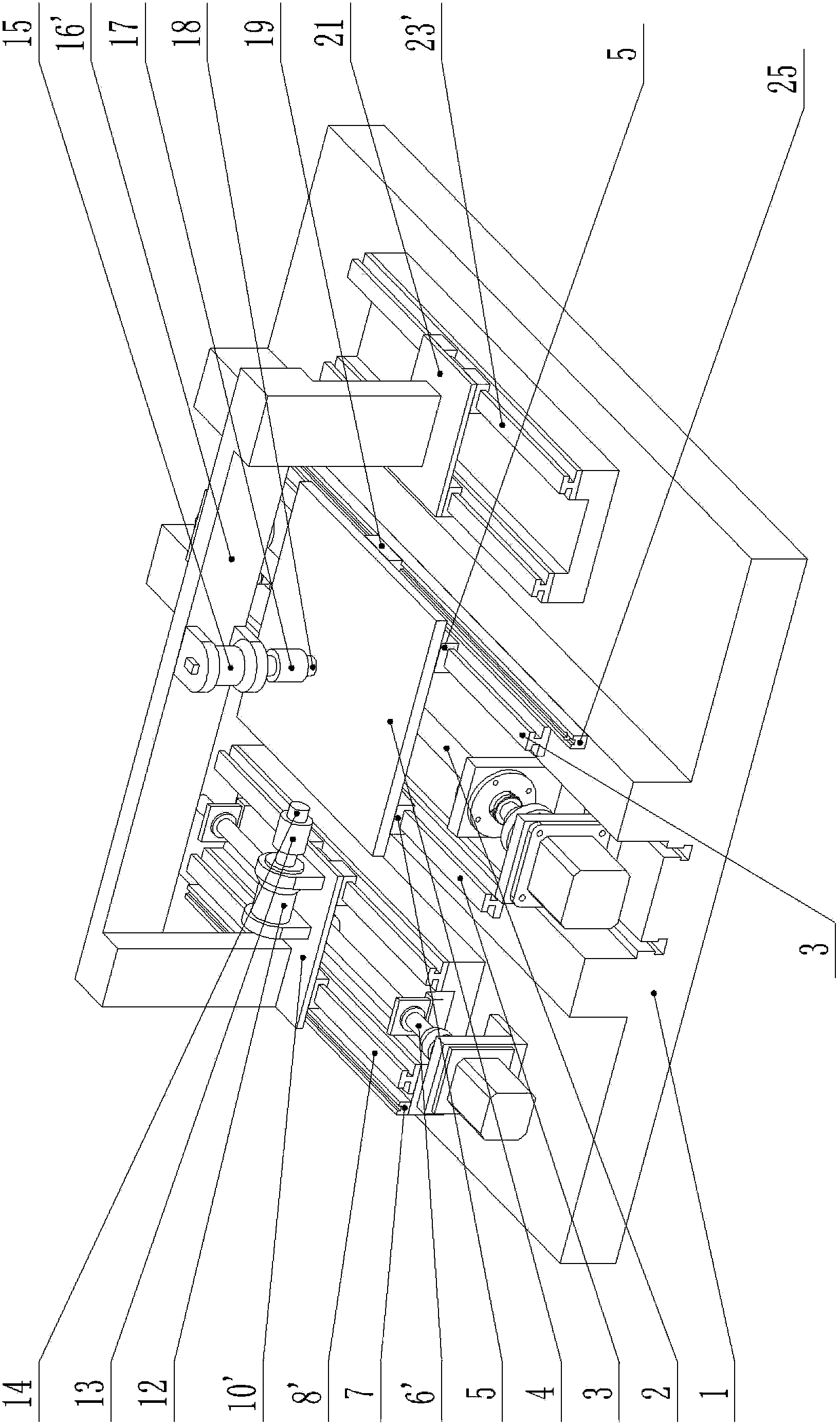

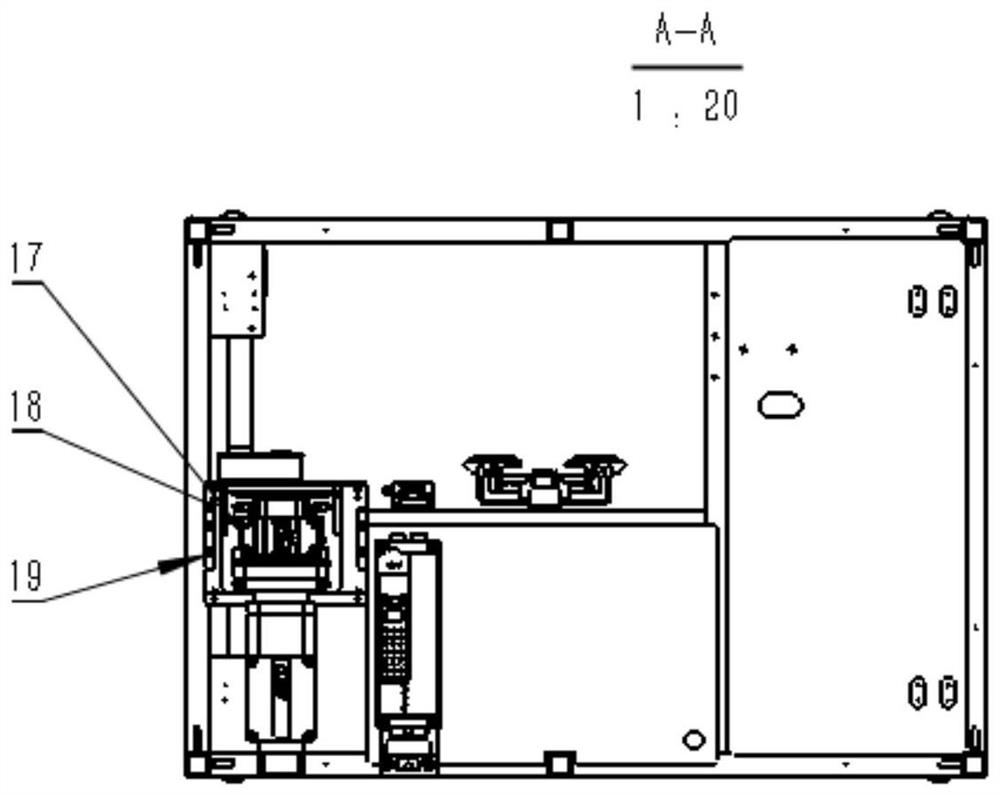

The invention discloses a portable pipeline automatic circumferential walking device and a pipeline processing method, which belong to the technical field of pipeline processing and construction. The portable pipeline automatic circumferential walking device consists of a circular rail, a walking mechanism and a control part. The circular rail consists of a rail and a grab for mounting the rail. The portable pipeline automatic circumferential walking device has the characteristics that one type of rail is adaptable to a plurality of types of pipe diameters, and a plurality of types of rails is adaptable to more pipe diameters in a matching mode. The walking mechanism consists of a machine frame, wheels, a chain tensioning mechanism, a driving motor system and a chain. The control part consists of a local controller and a remote controller. The local controller can adjust positive rotation and negative rotation of a motor, and can adjust the walking mechanism to perform clockwise rotation or counterclockwise rotation around a pipeline. The remote controller can control the walking mechanism at a distant place, and is compact and convenient. The portable pipeline automatic circumferential walking device is convenient to mount, has high walking accuracy, is not affected by whether the pipeline has a coating layer or not, and is suitable for meeting requirements on circumferential construction of an onsite pipeline.

Owner:宣邦机器人(苏州)有限公司

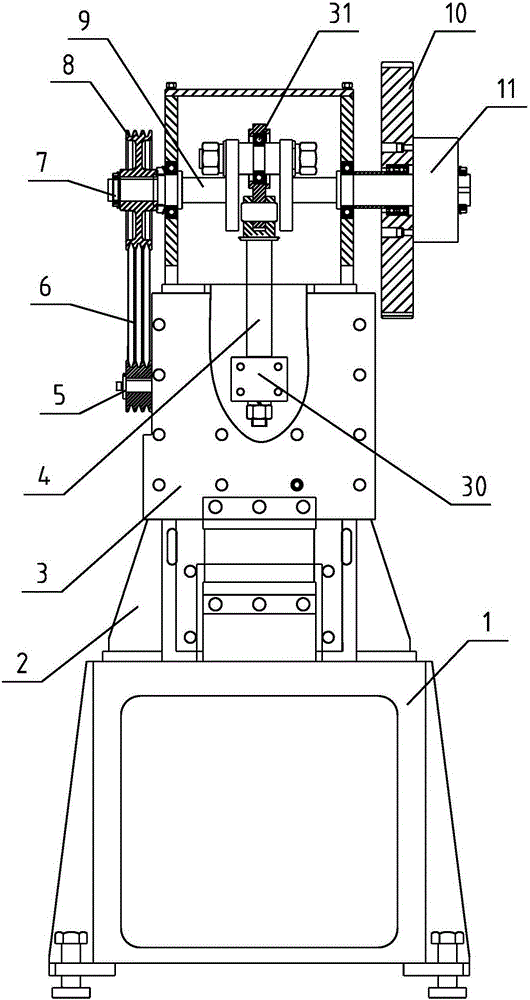

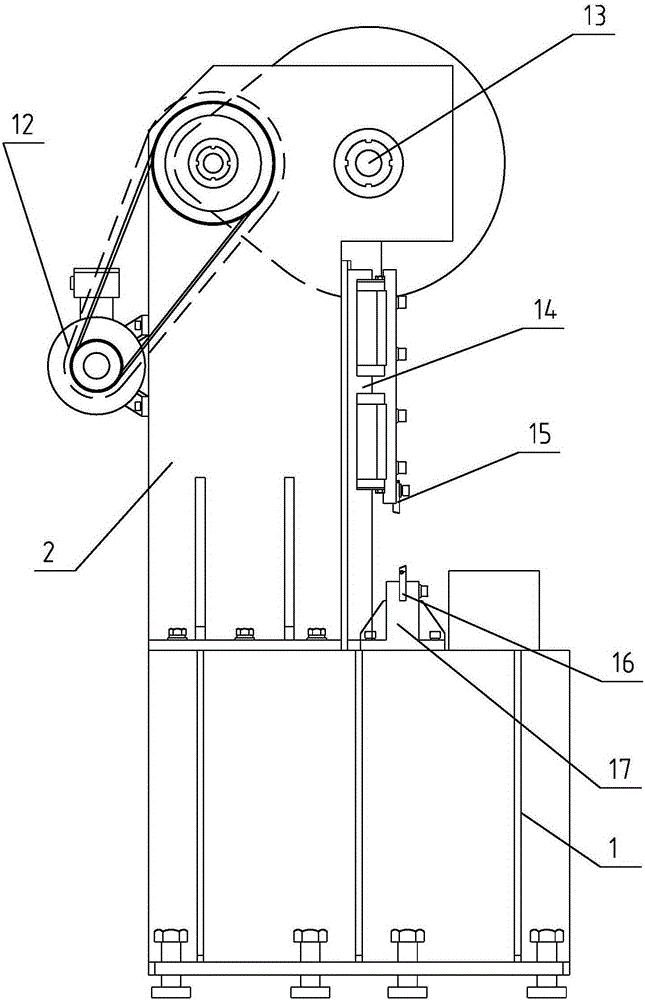

Welding tractor with steel structure being subjected to gas shielded welding

InactiveCN102211240AGuaranteed uptimeRestricted direction of lateral movementArc welding apparatusLocking mechanismTractor

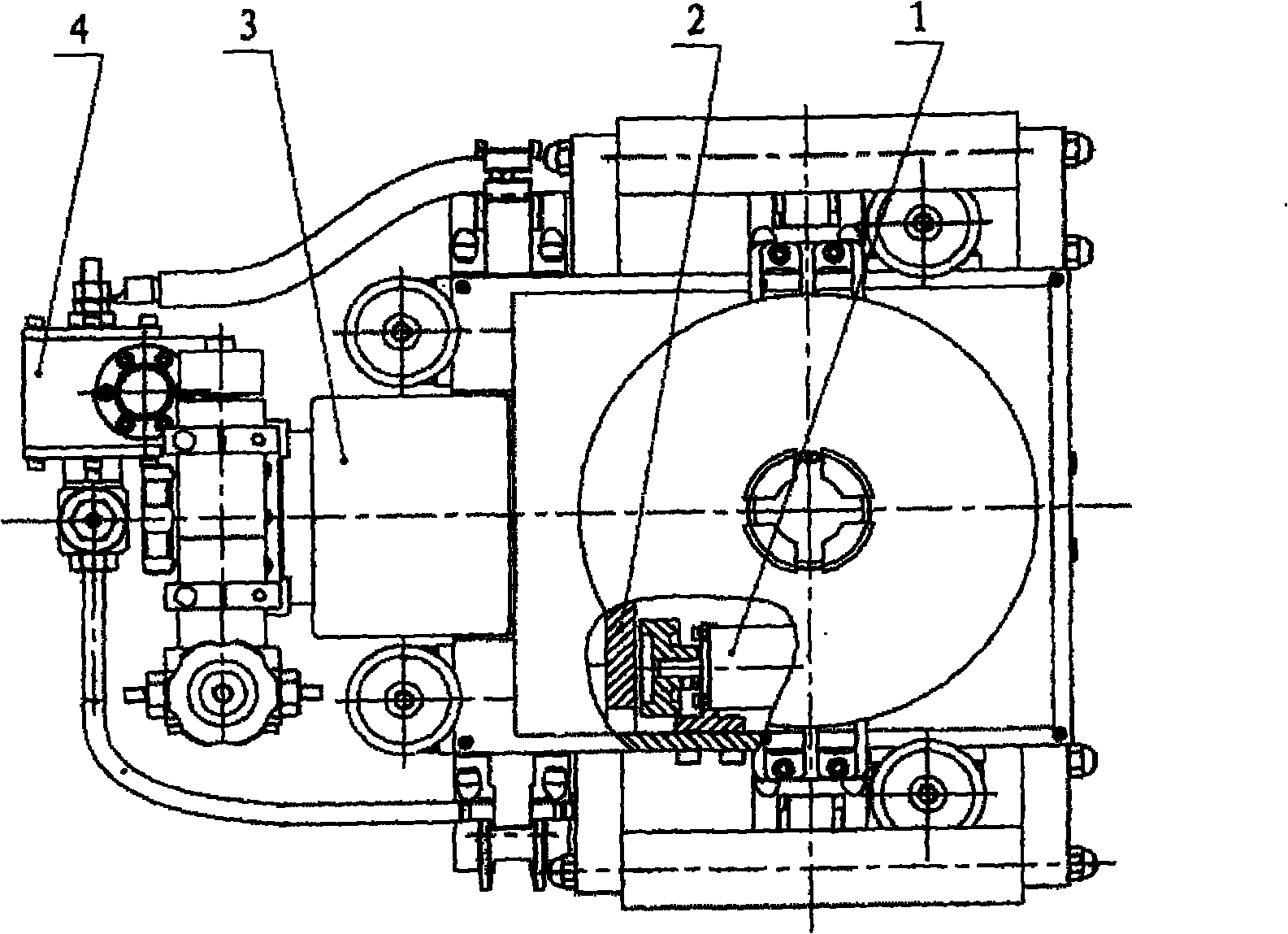

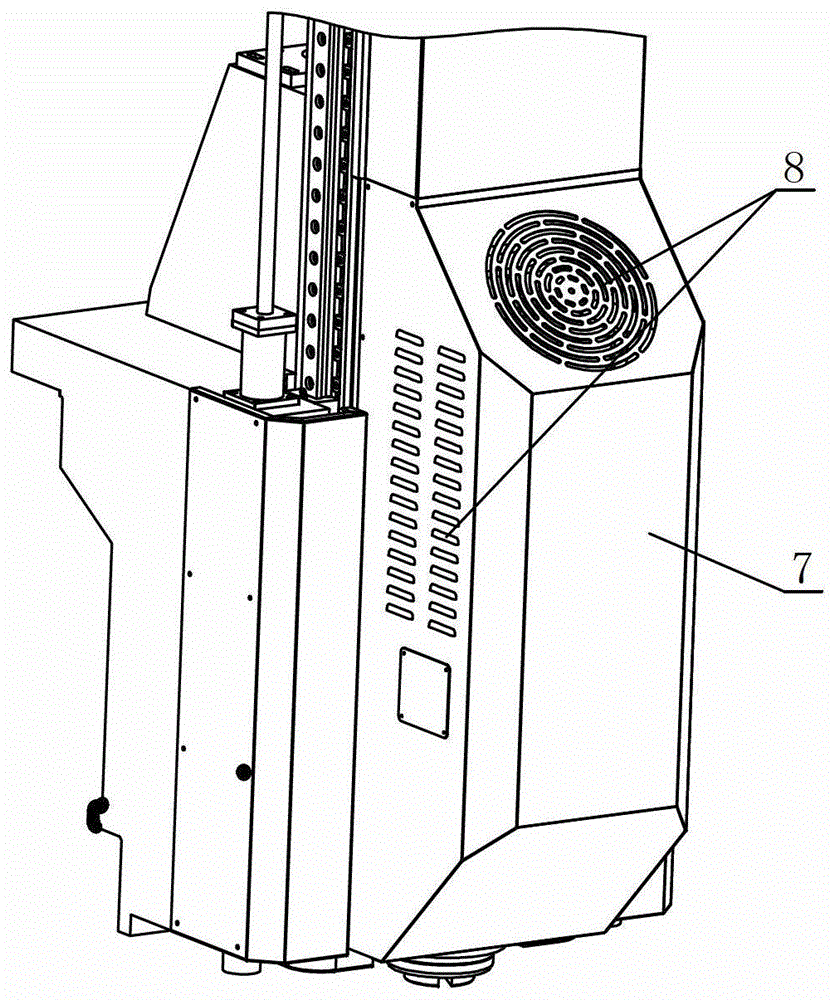

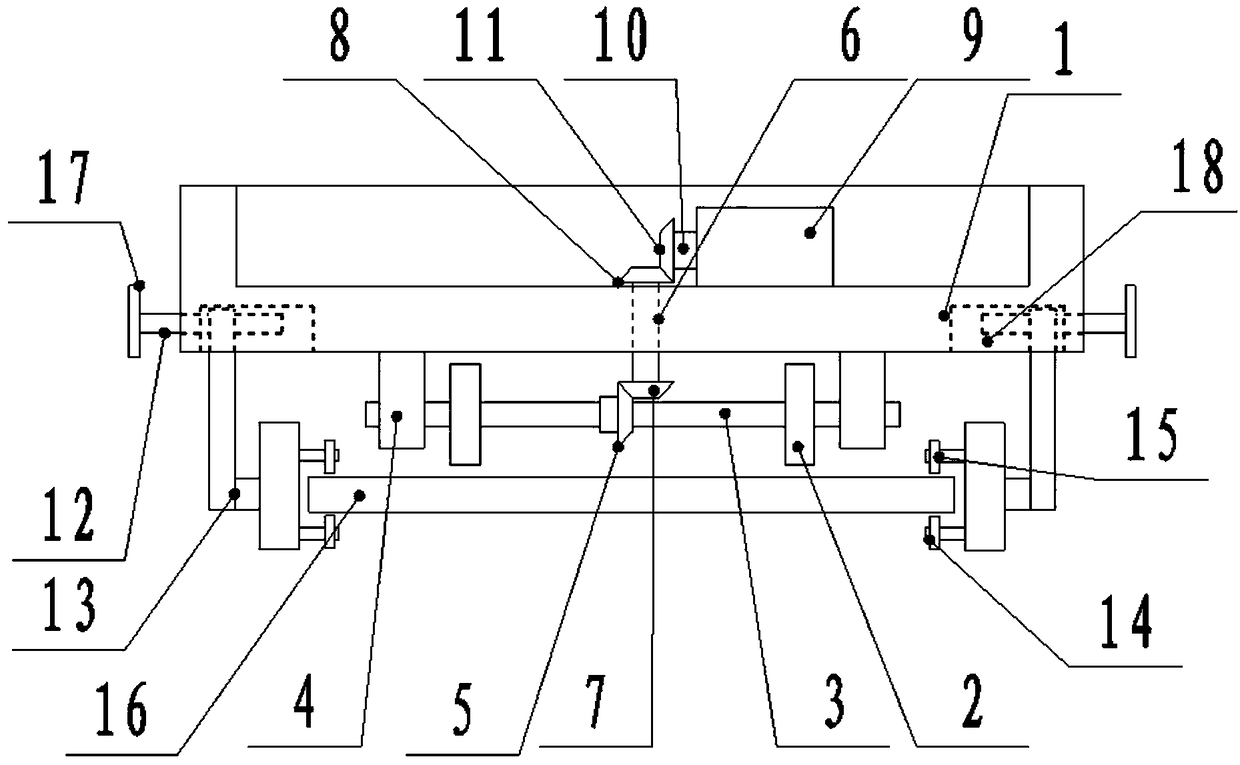

The invention provides a welding tractor with a steel structure being subjected to gas shielded welding. The welding tractor comprises a travelling mechanism and an axial welding gun adjusting mechanism, both of which are arranged on interior of a shell. The welding tractor further comprises a radial welding gun adjusting mechanism, a welding gun included angle swinging mechanism, a hanging locking mechanism, a guiding mechanism, a wire feeder and a welding wire plate, all of which are arranged on exterior of the shell; and the travelling mechanism, the axial welding gun adjusting mechanism, the radial welding gun adjusting mechanism, the welding gun included angle swinging mechanism and the wire feeder are respectively connected to a control mechanism. The tractor is automatically welded by running along a welding track under the control of the control mechanism. The welding tractor has the advantages of reasonable structure design, convenience in mounting and high control precision.

Owner:CHINA NAT OFFSHORE OIL CORP +1

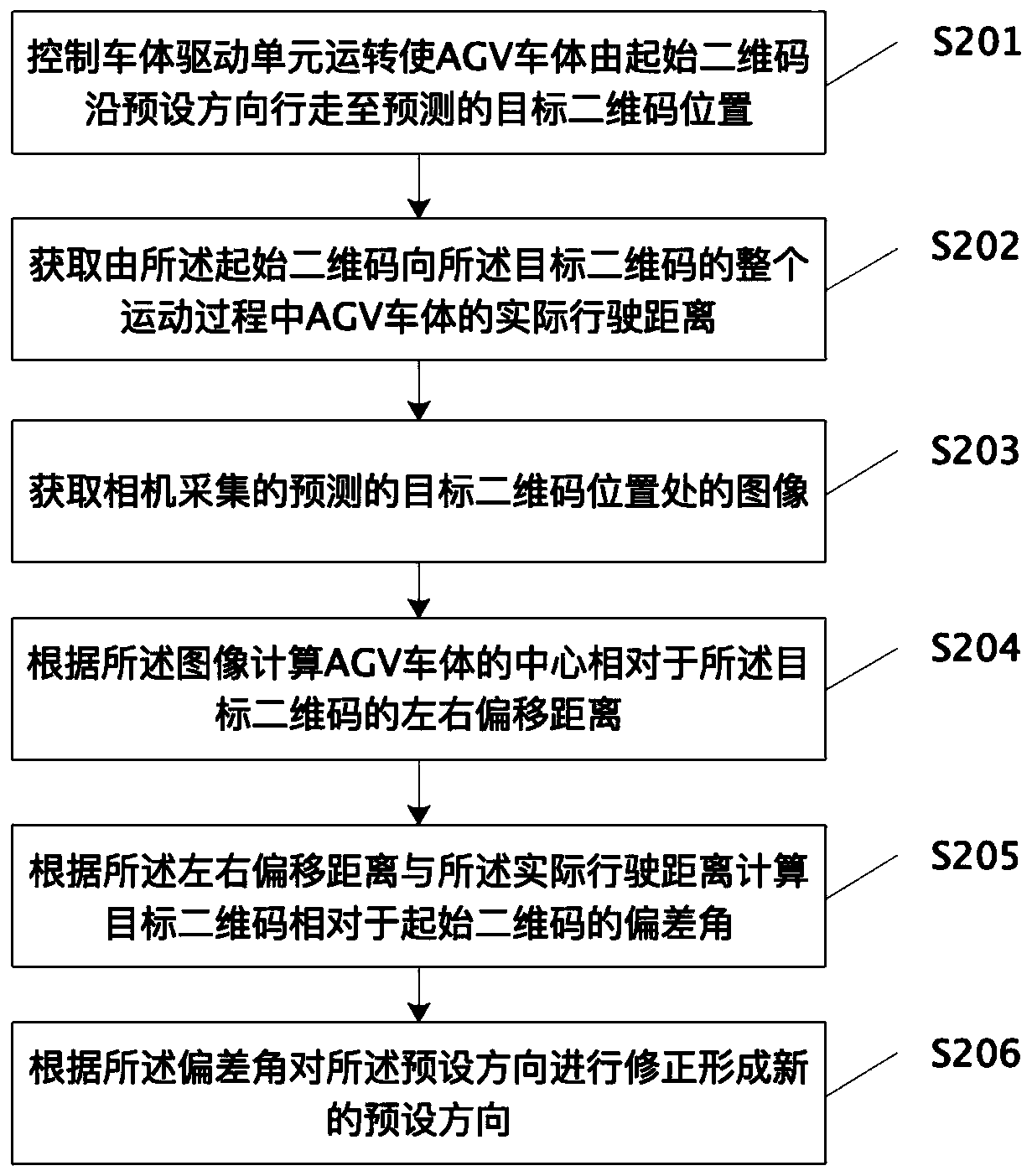

AGV navigation angle compensation method and system, AGV and storage medium

ActiveCN110794838AHigh walking accuracyEliminate the effects ofPosition/course control in two dimensionsControl engineeringControl theory

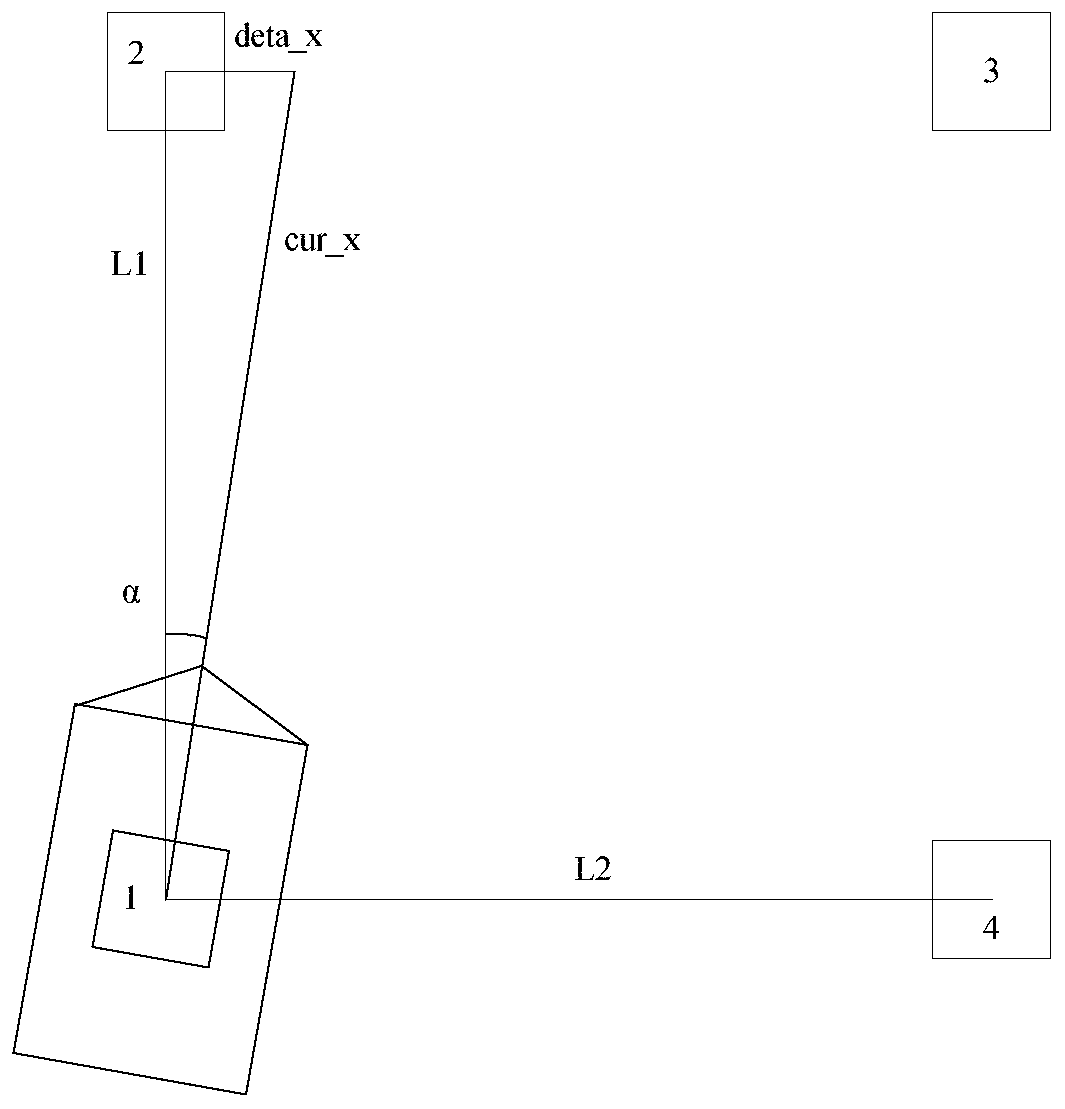

The invention discloses an AGV navigation angle compensation method and system, an AGV and a storage medium. The method comprises the steps that a vehicle body driving unit is controlled to operate toenable an AGV body to walk from a starting two-dimensional code to a predicted target two-dimensional code position in a preset direction; the actual driving distance of the AGV body in the whole movement process from the starting two-dimensional code to the target two-dimensional code is acquired; an image, collected by a camera, at the predicted target two-dimensional code position is acquired;the left-right offset distance of the center of the AGV body relative to the target two-dimensional code is calculated according to the image; the deviation angle of the target two-dimensional code relative to the starting two-dimensional code is calculated according to the left-right offset distance and the actual driving distance; and the preset direction is corrected according to the deviationangle to form a new preset direction. According to the AGV navigation angle compensation method and system, the AGV and the storage medium, the preset direction is compensated by calculating the deviation angle, so that the subsequent AGV can drive in the compensated preset direction when driving between the two-dimensional codes, and the walking precision of the AGV is improved.

Owner:牧星机器人(江苏)有限公司

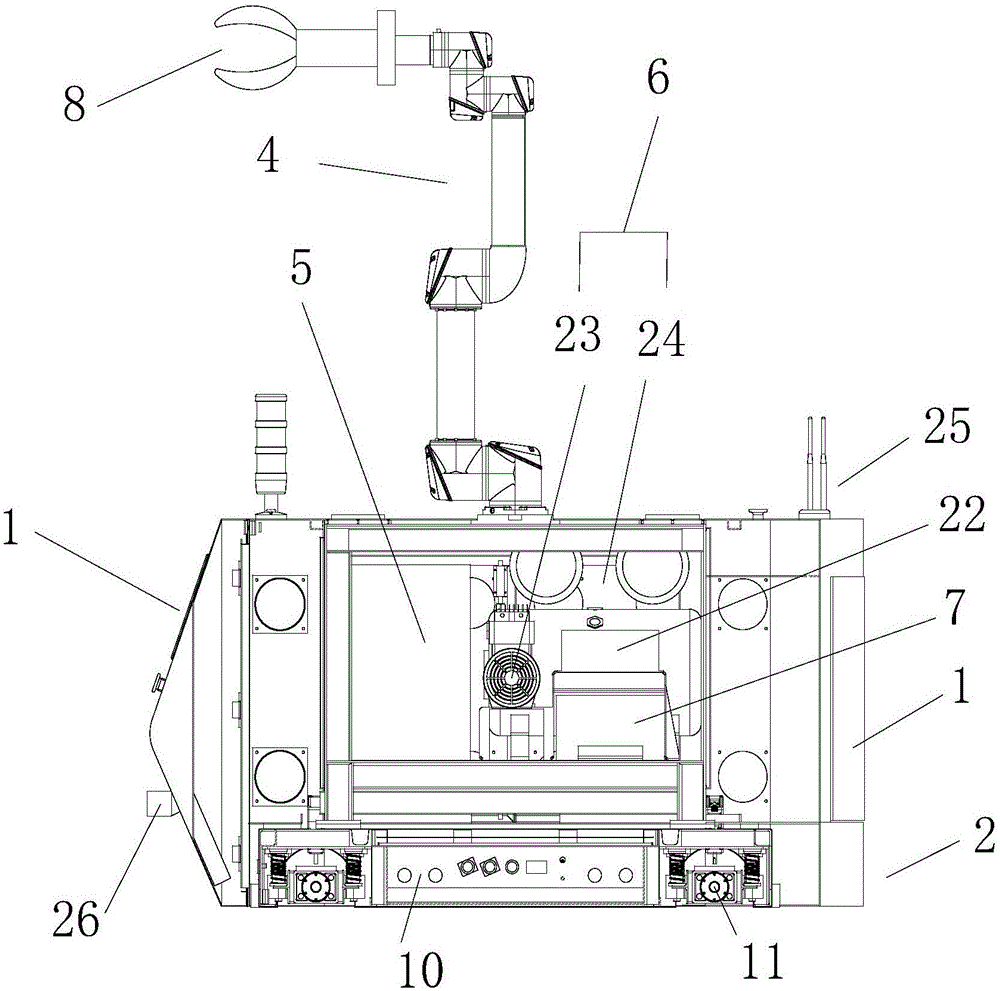

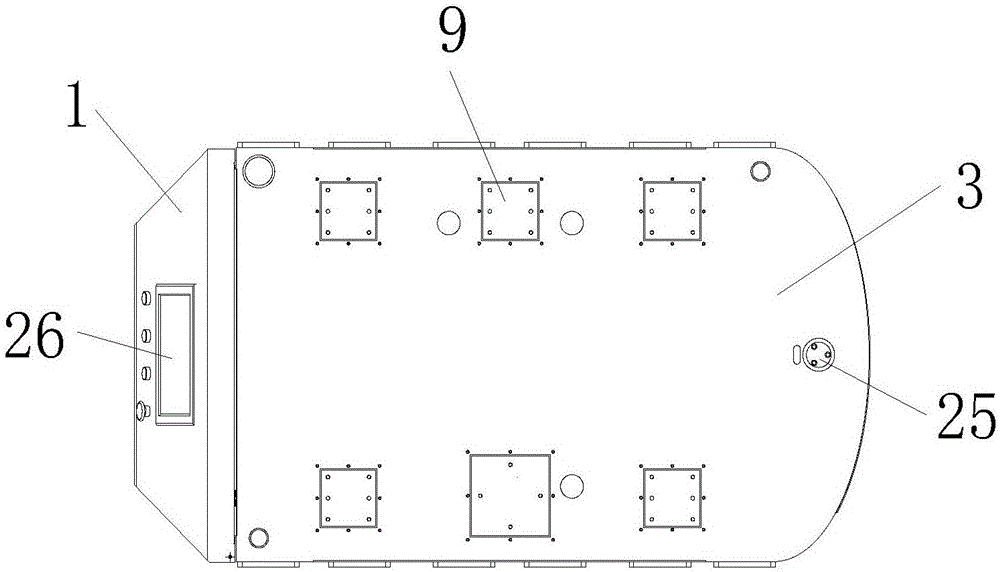

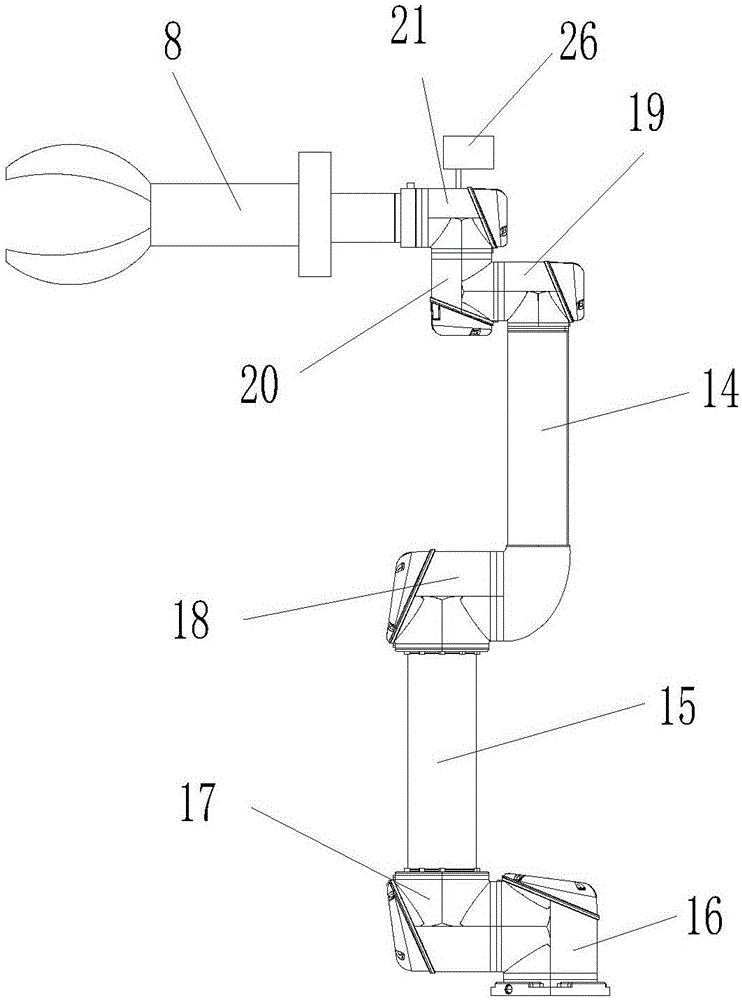

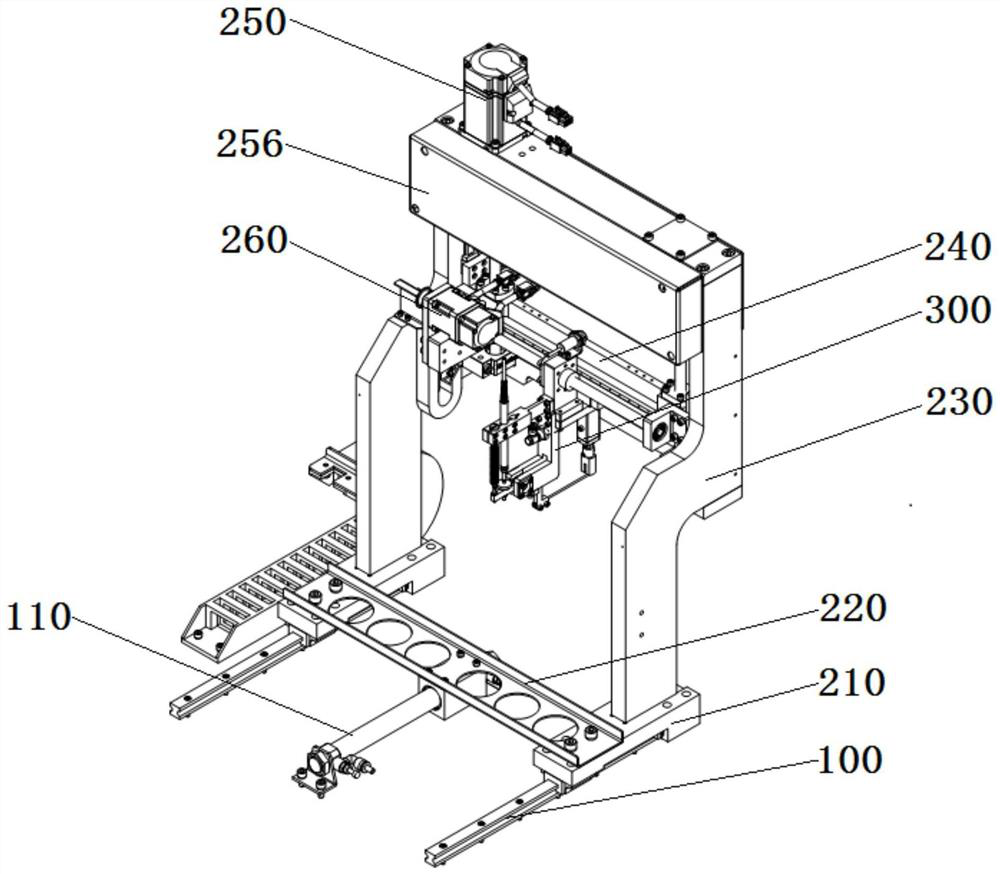

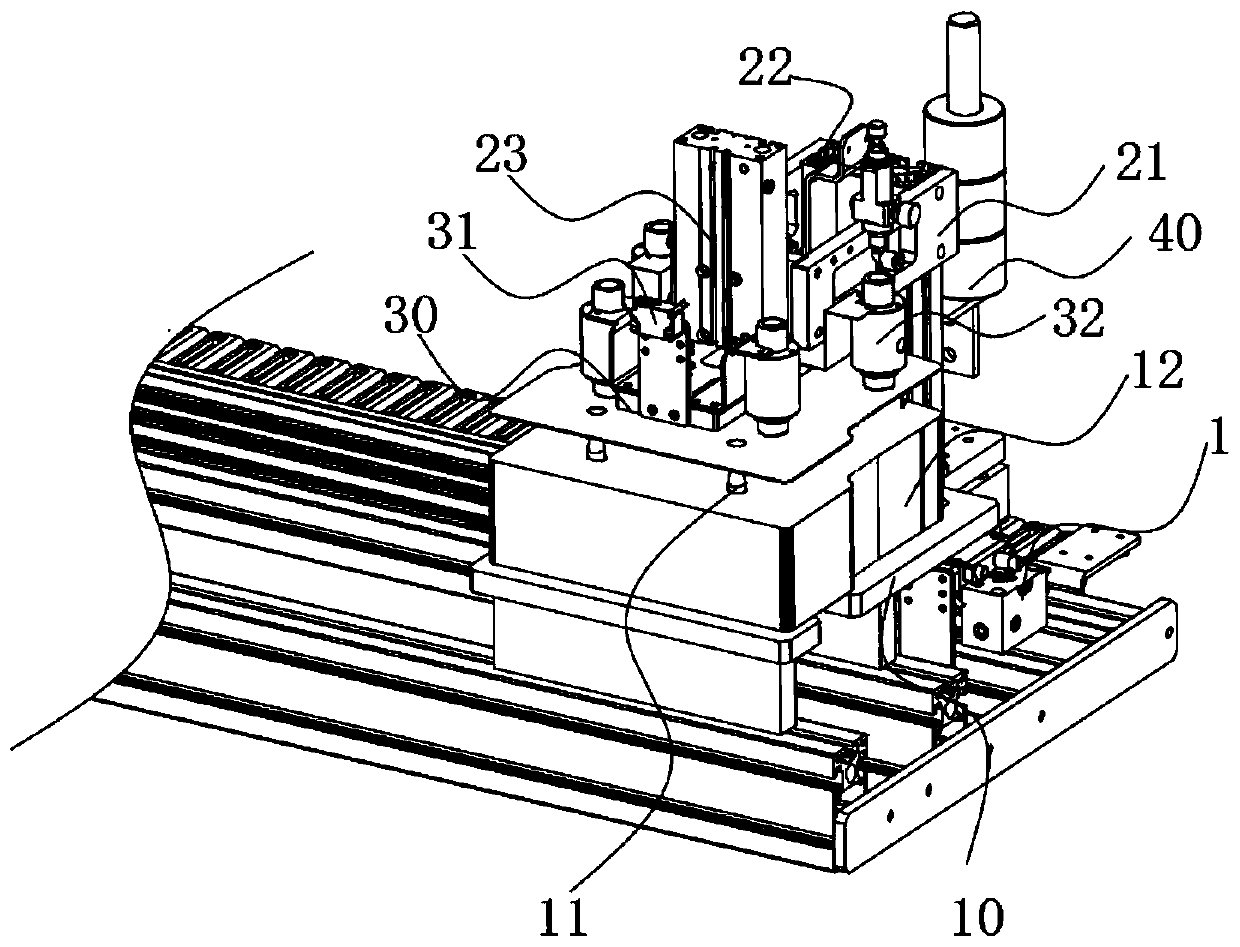

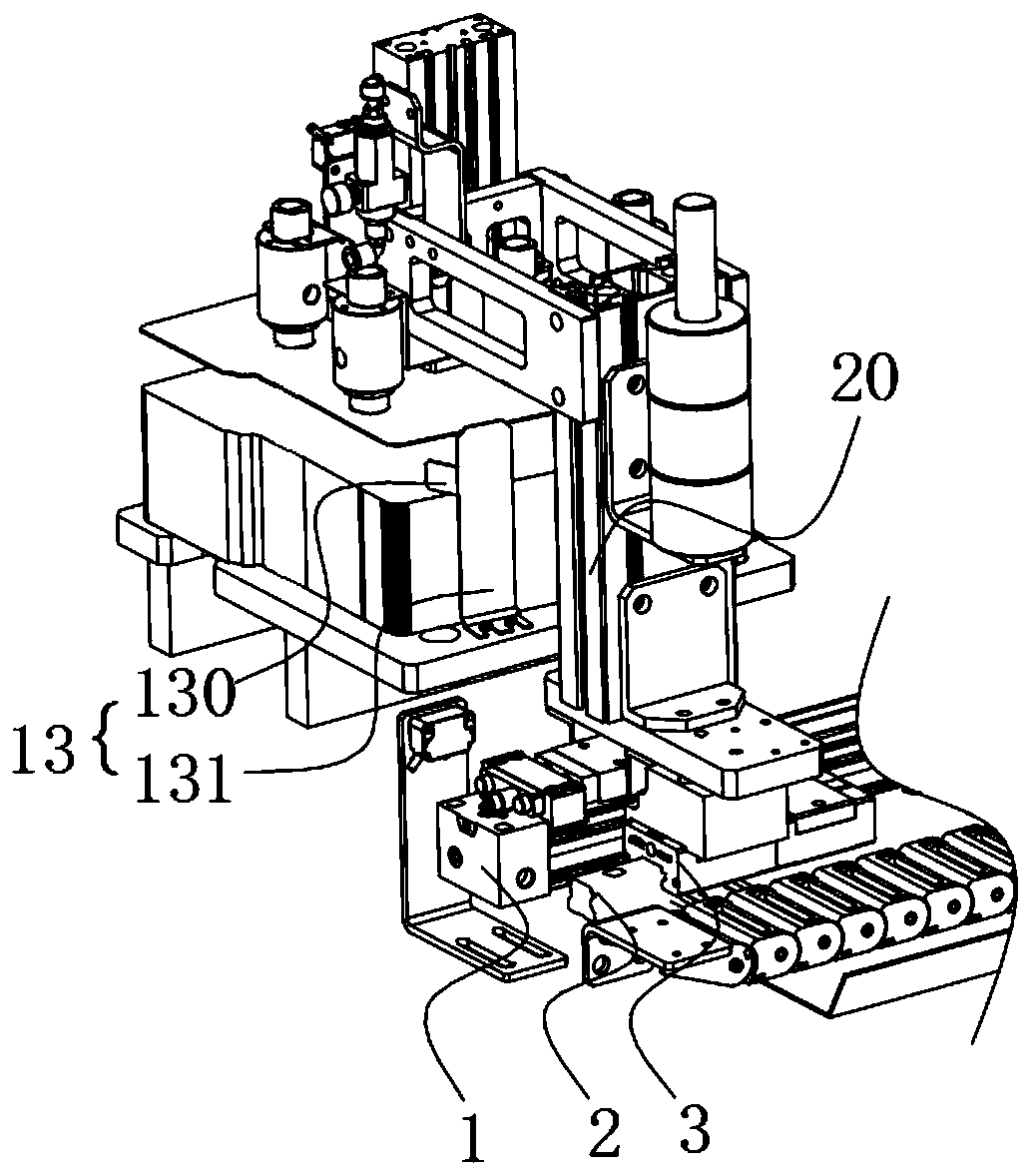

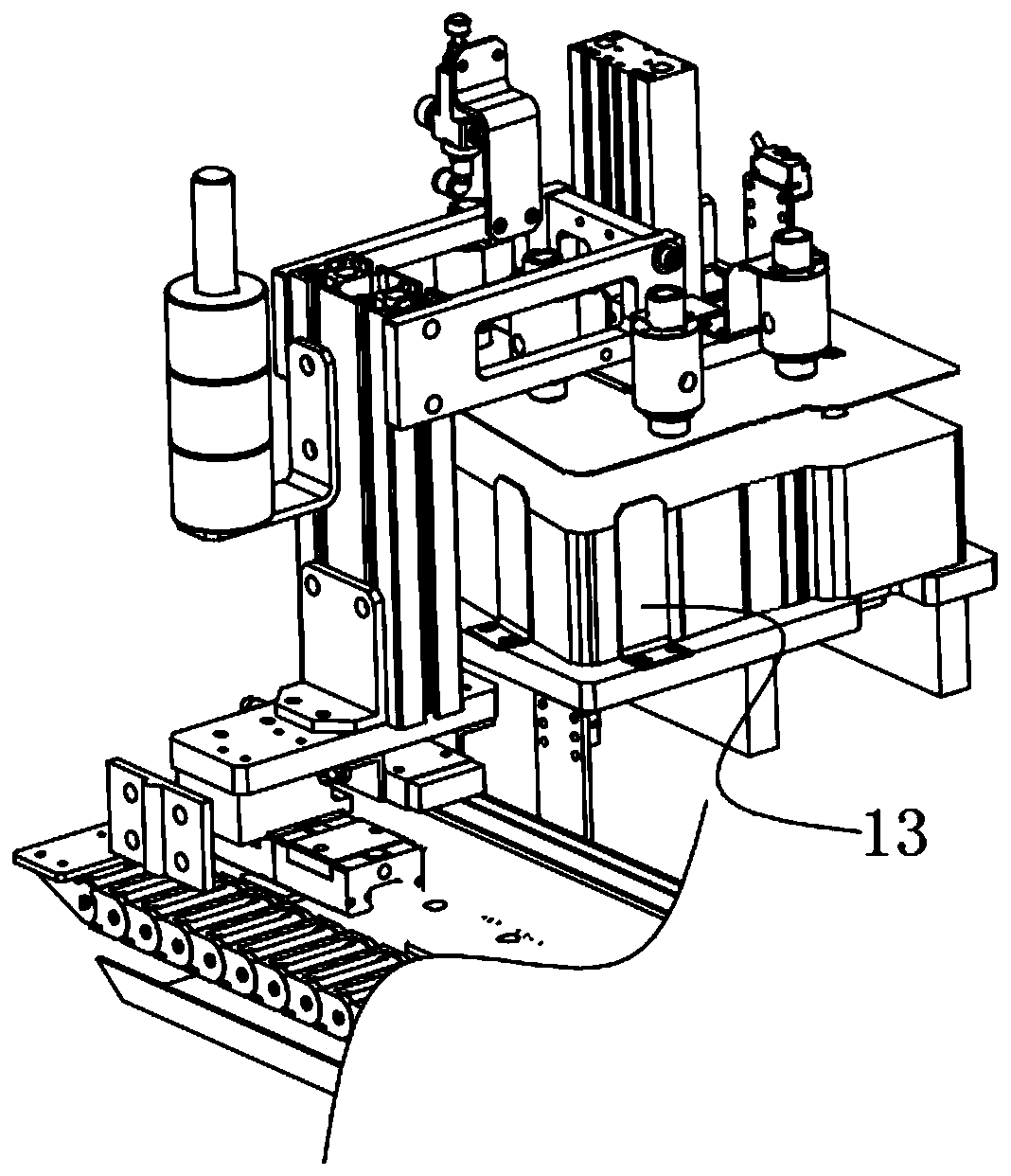

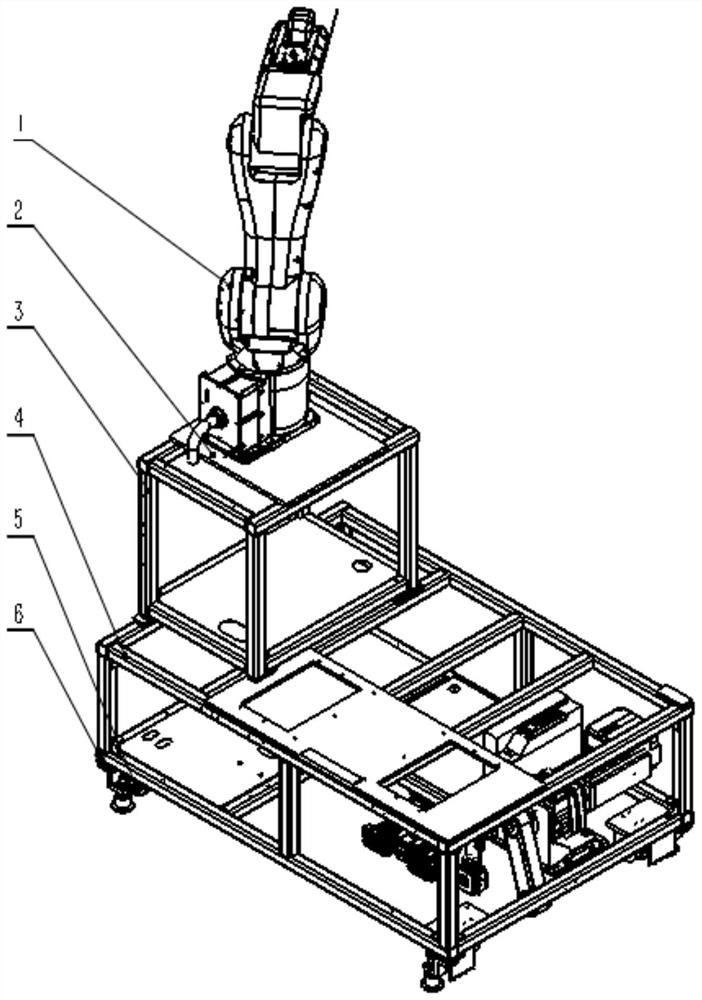

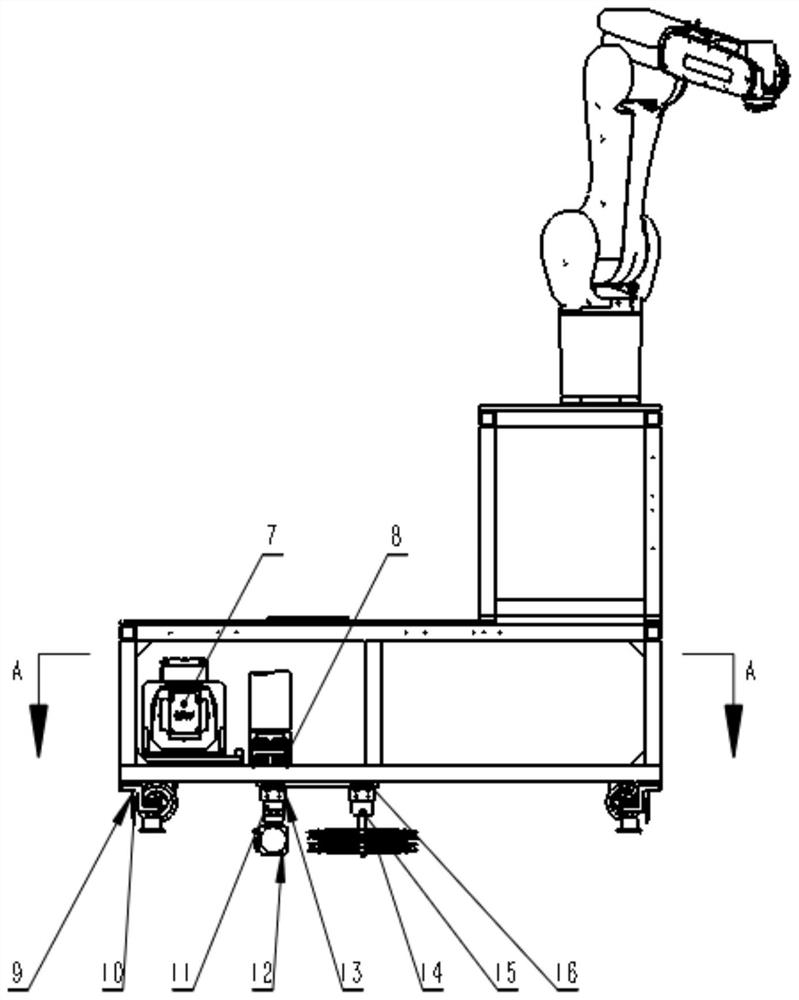

Movable machining platform

PendingCN106826784AHigh walking accuracyImprove machining accuracyProgramme-controlled manipulatorEngineeringManipulator

The invention discloses a movable machining platform comprising a machine body. An AGV platform is arranged at the bottom of the machine body; a machining table is arranged on the top of the machine body; a manipulator is arranged on the machining table; the manipulator is detachably connected relative to the machining table; and a controller, a pneumatic mechanism and a battery are arranged inside the machine body. The controller controls the AGV platform, the pneumatic mechanism and the manipulator. A pneumatic manipulator is arranged at the end of the manipulator, and the pneumatic mechanism is connected with the pneumatic manipulator. The battery provides power for the controller, the pneumatic mechanism, the AGV platform and the manipulator. A vision positioning system is arranged, on the outer side of the machine body, on the manipulator and connected with the controller. The AGV platform can walk freely, by combining different machining modules, different machining requirements are met, and the walking precision and machining precision are improved through the visual system.

Owner:芜湖德力自动化装备科技有限公司

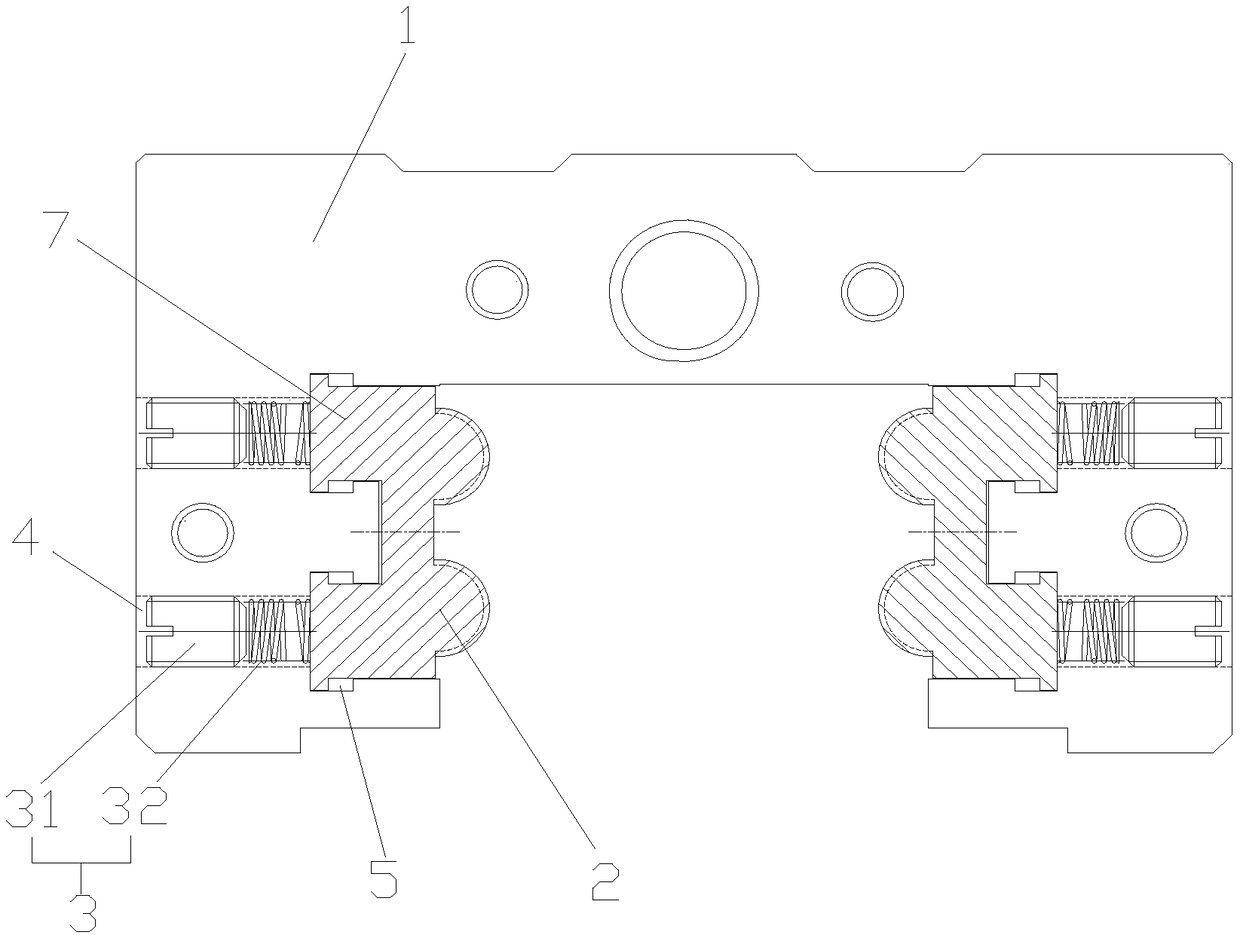

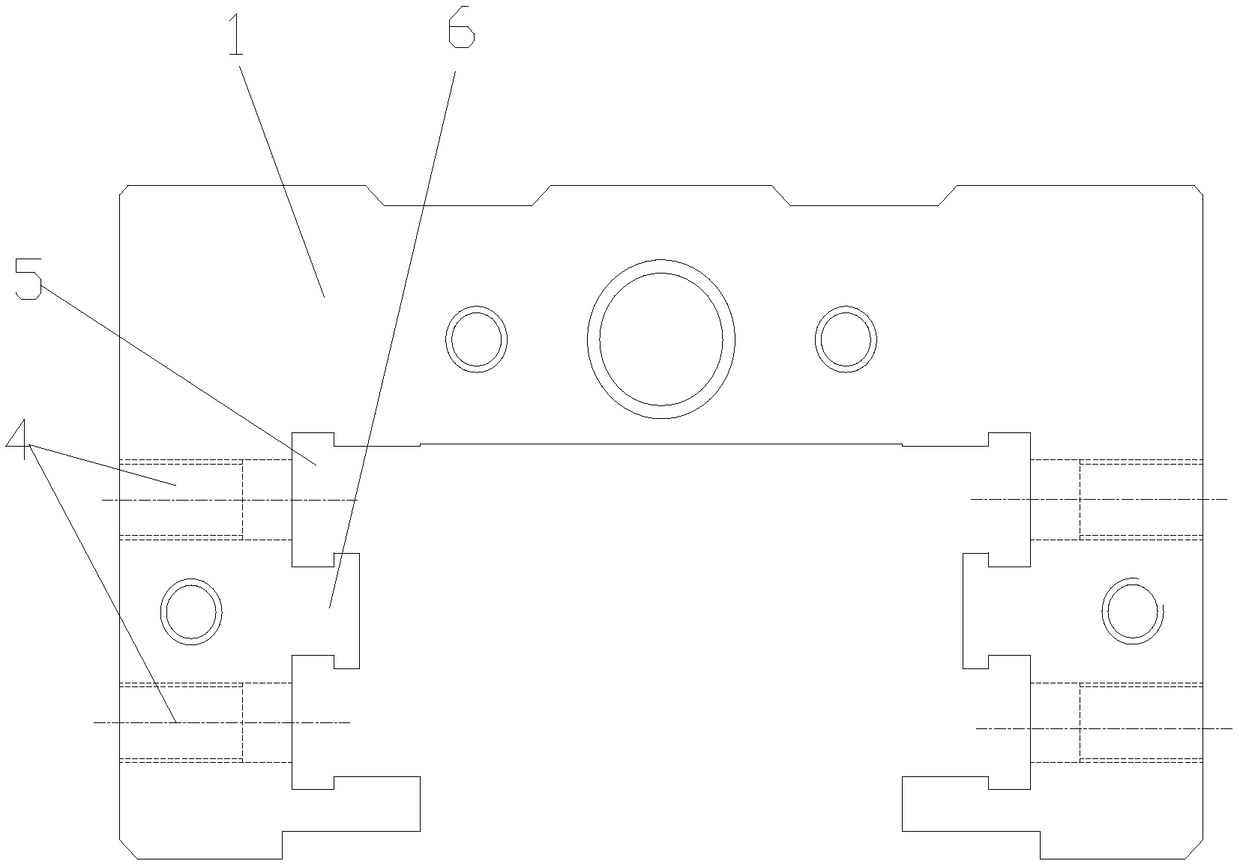

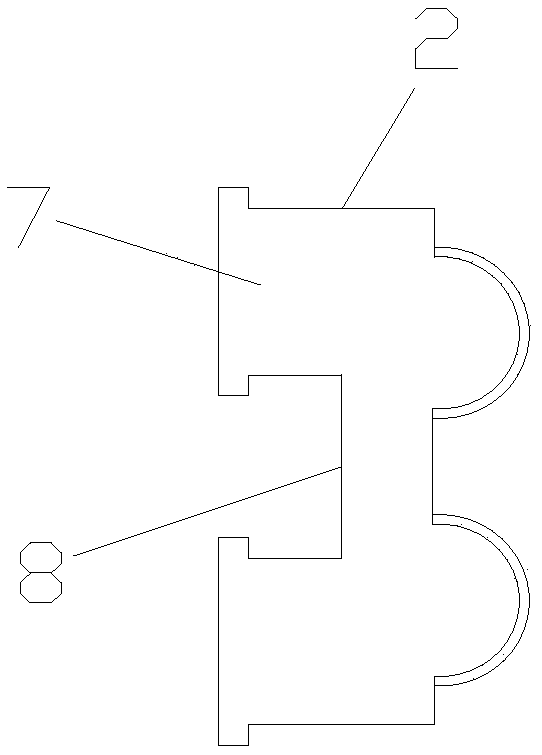

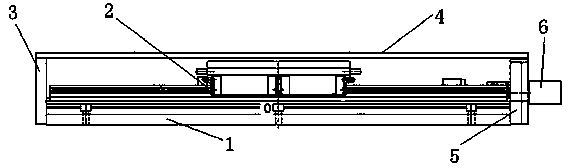

Linear guide rail

PendingCN108825653AFit closelyGuaranteed walking accuracyLinear bearingsEngineeringMechanical engineering

Owner:浙江赤航科技有限公司

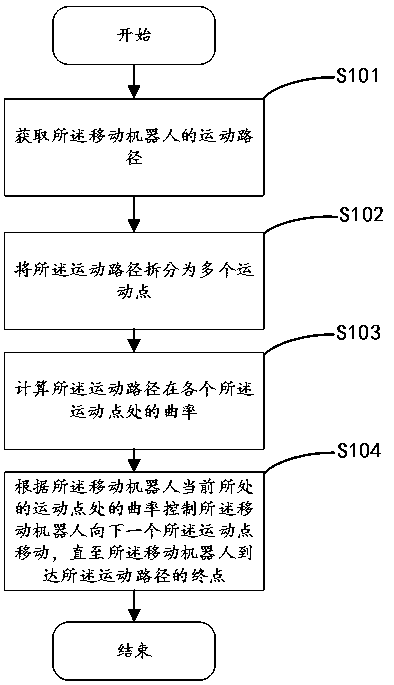

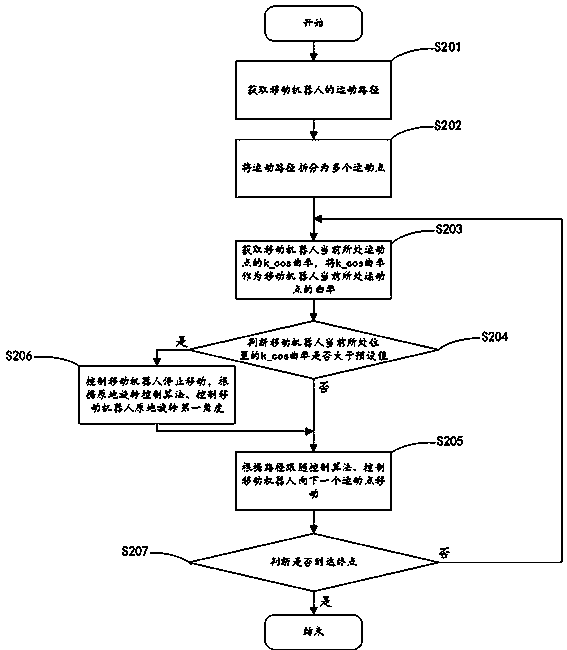

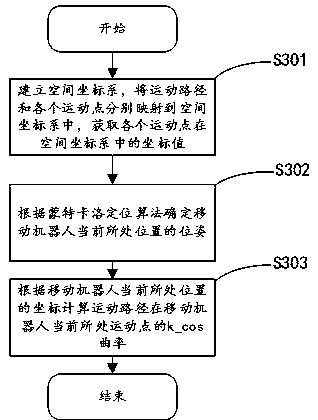

Movement control method and device of mobile robot

ActiveCN109557929AHigh control precisionHigh walking accuracyPosition/course control in two dimensionsVehiclesSimulationMovement control

The embodiment of the invention relates to the field of movement control, and discloses a movement control method and a device of a mobile robot. The movement control method of the mobile robot comprises the following steps of: obtaining a motion path of the mobile robot; splitting the motion path into a plurality of motion points; calculating a curvature of the motion path at each of the motion points; and controlling the mobile robot to move towards to a next movement point according to the curvature at the movement point where the mobile robot is currently located until the mobile robot reaches the end point of the motion path. The movement control method and the device of the mobile robot have the advantage of improving the control precision of the mobile robot when the mobile robot moves along the movement path of a non-stationary curvature.

Owner:深兰机器人产业发展(河南)有限公司

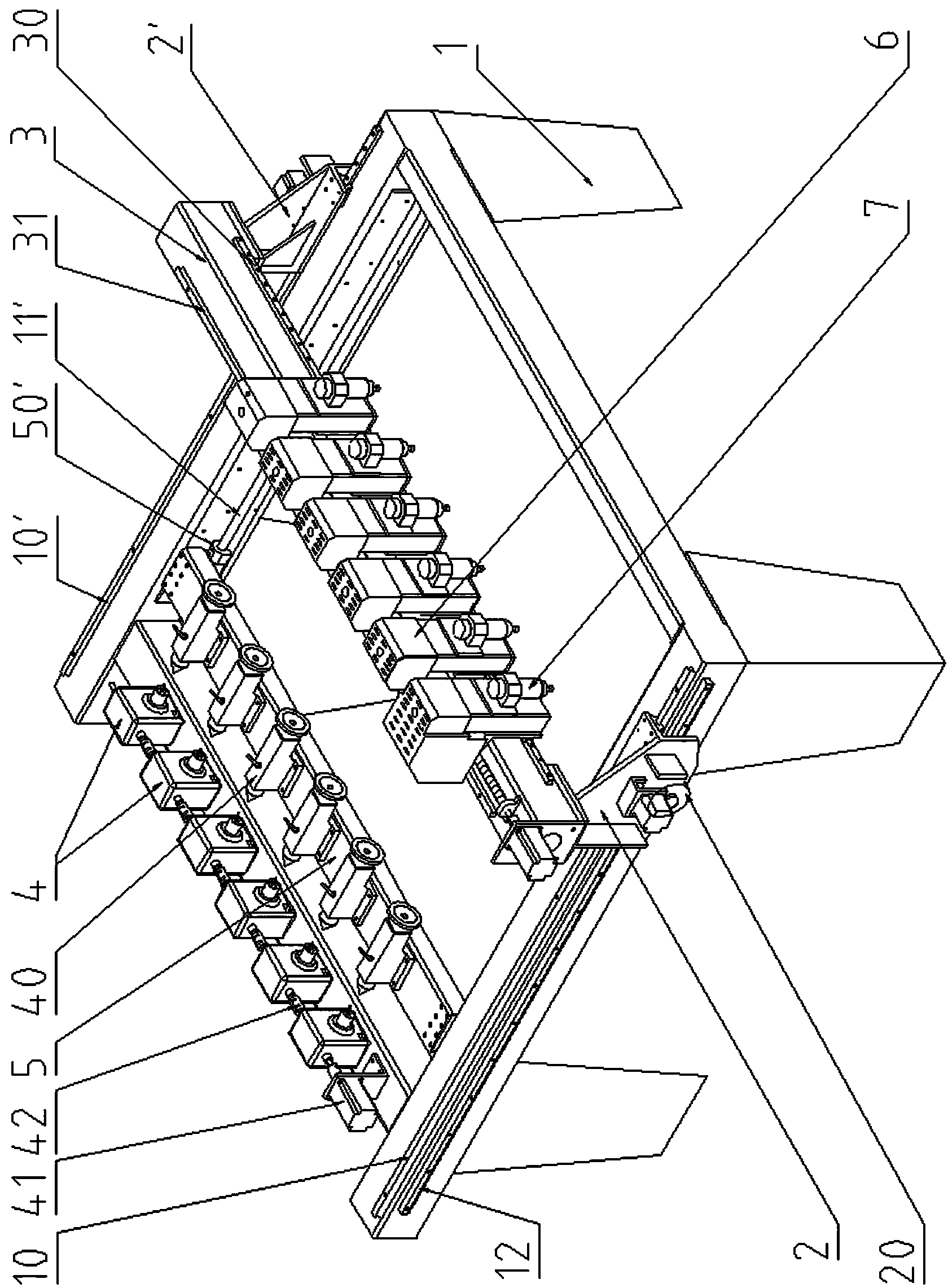

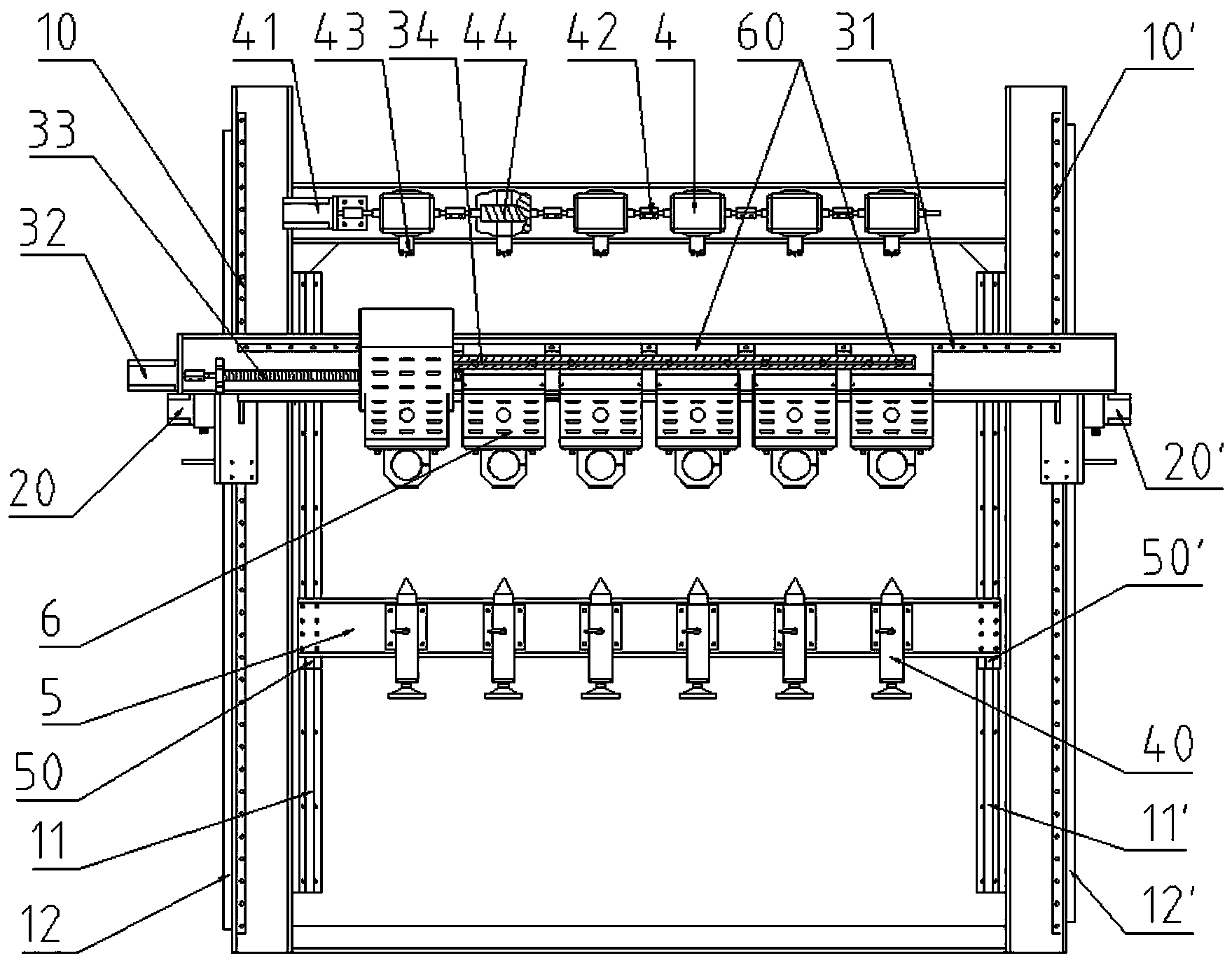

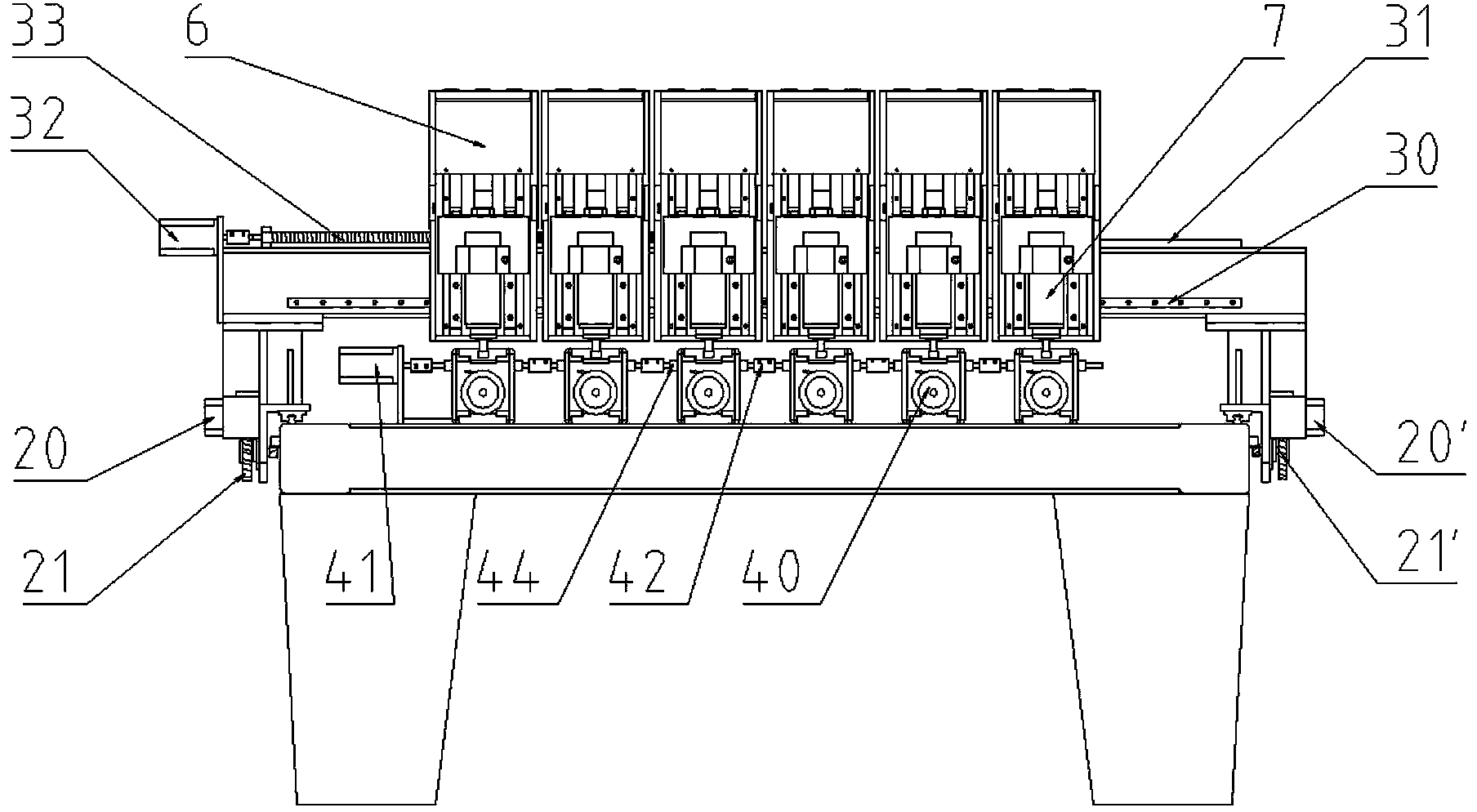

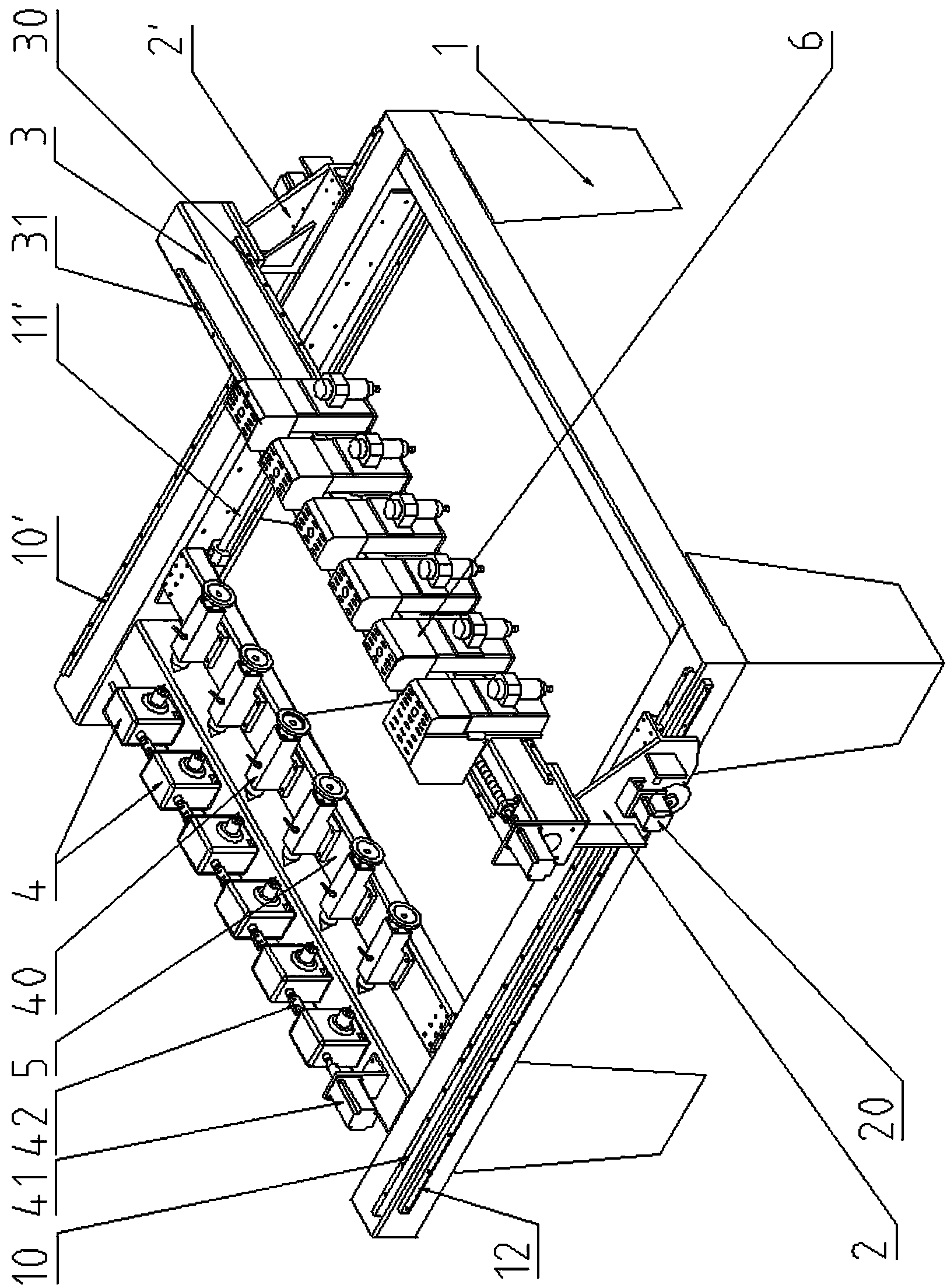

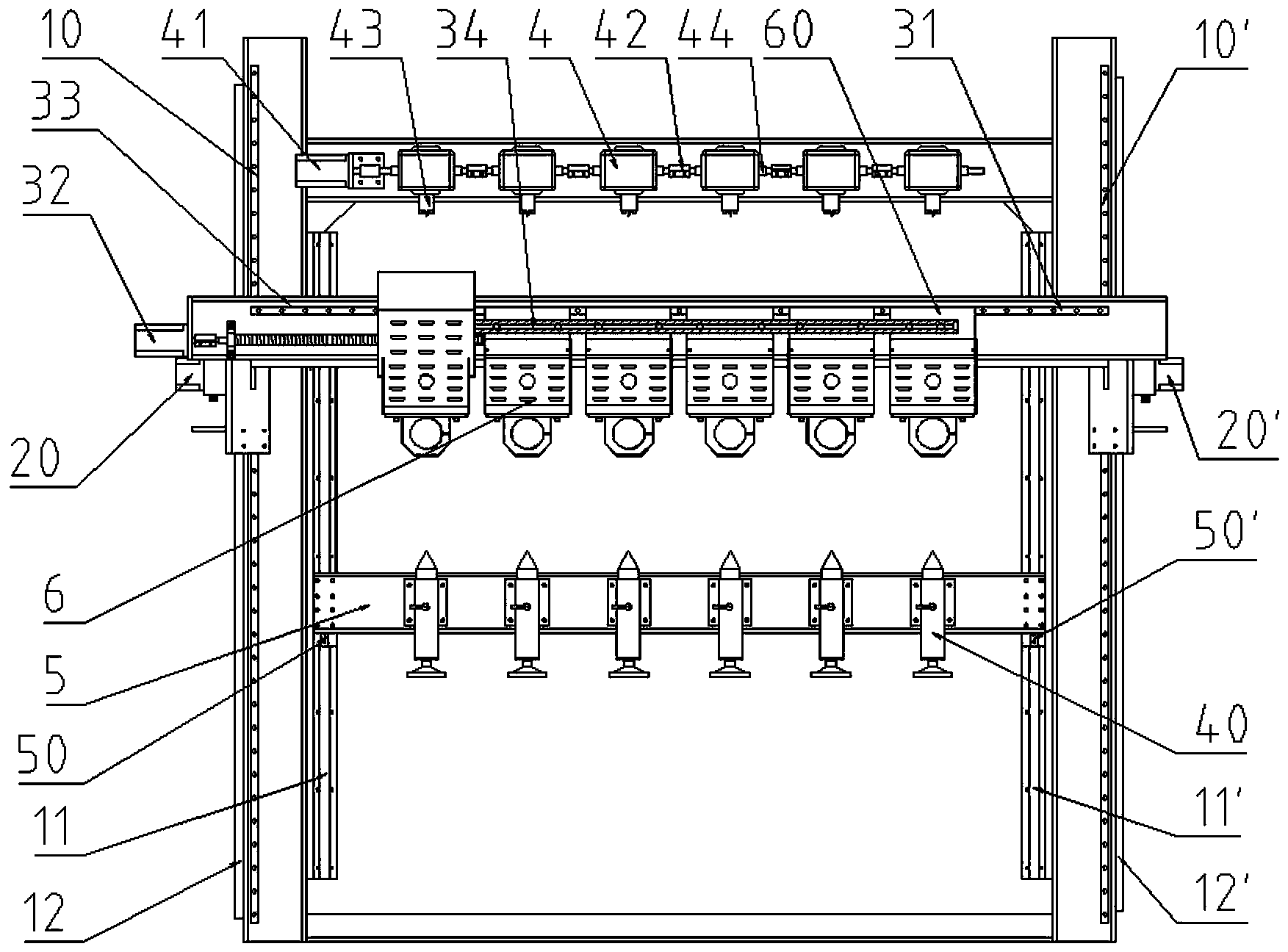

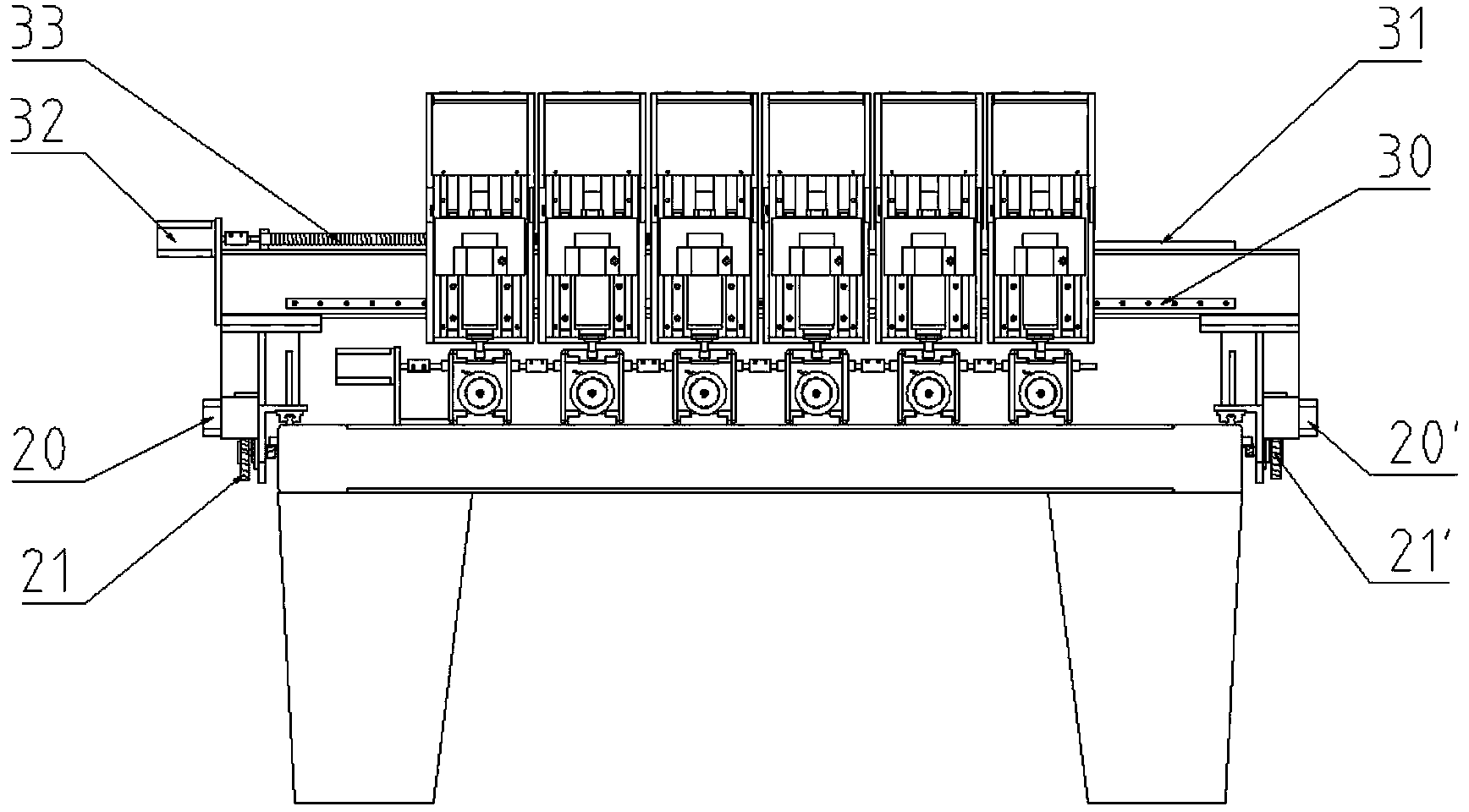

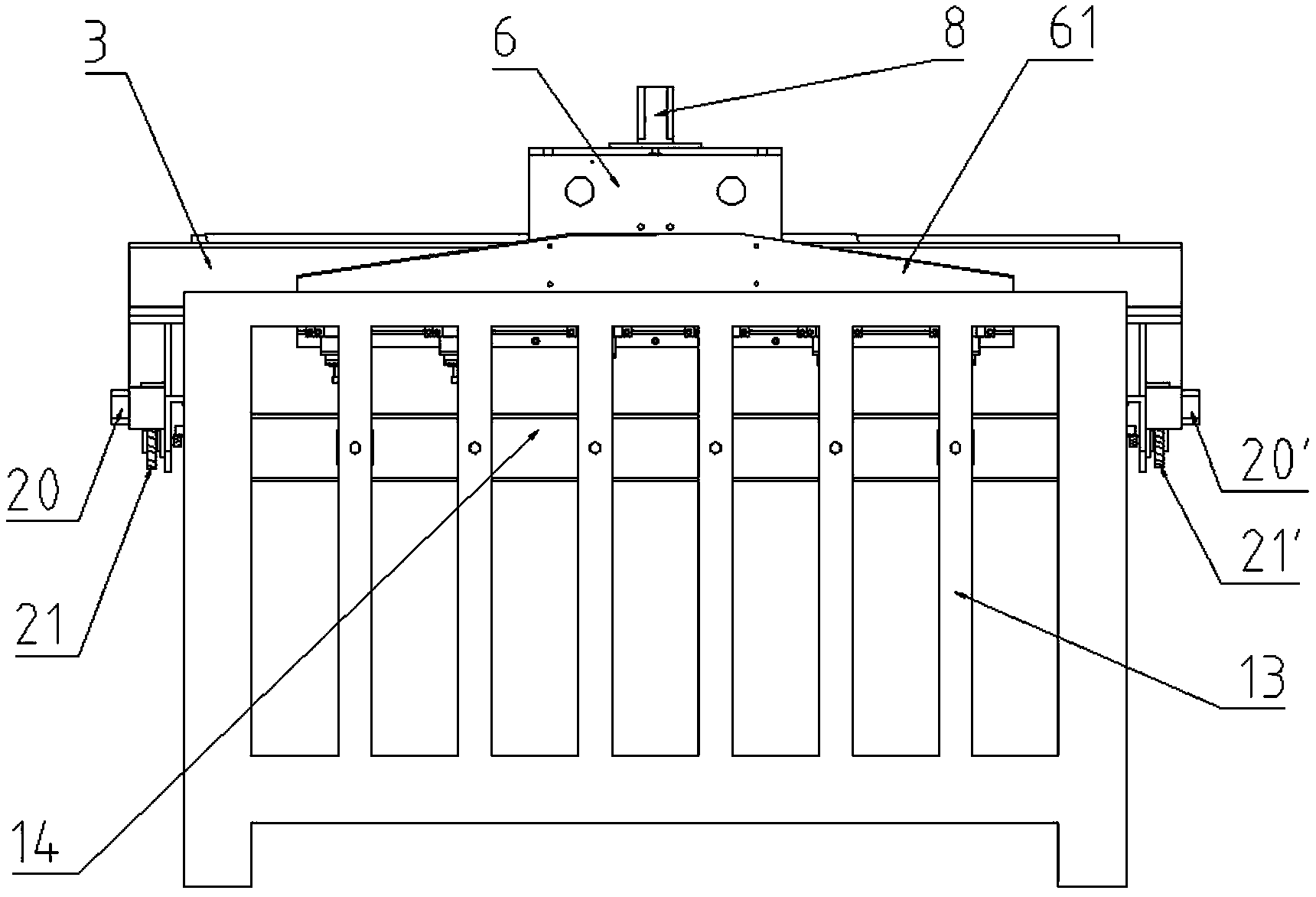

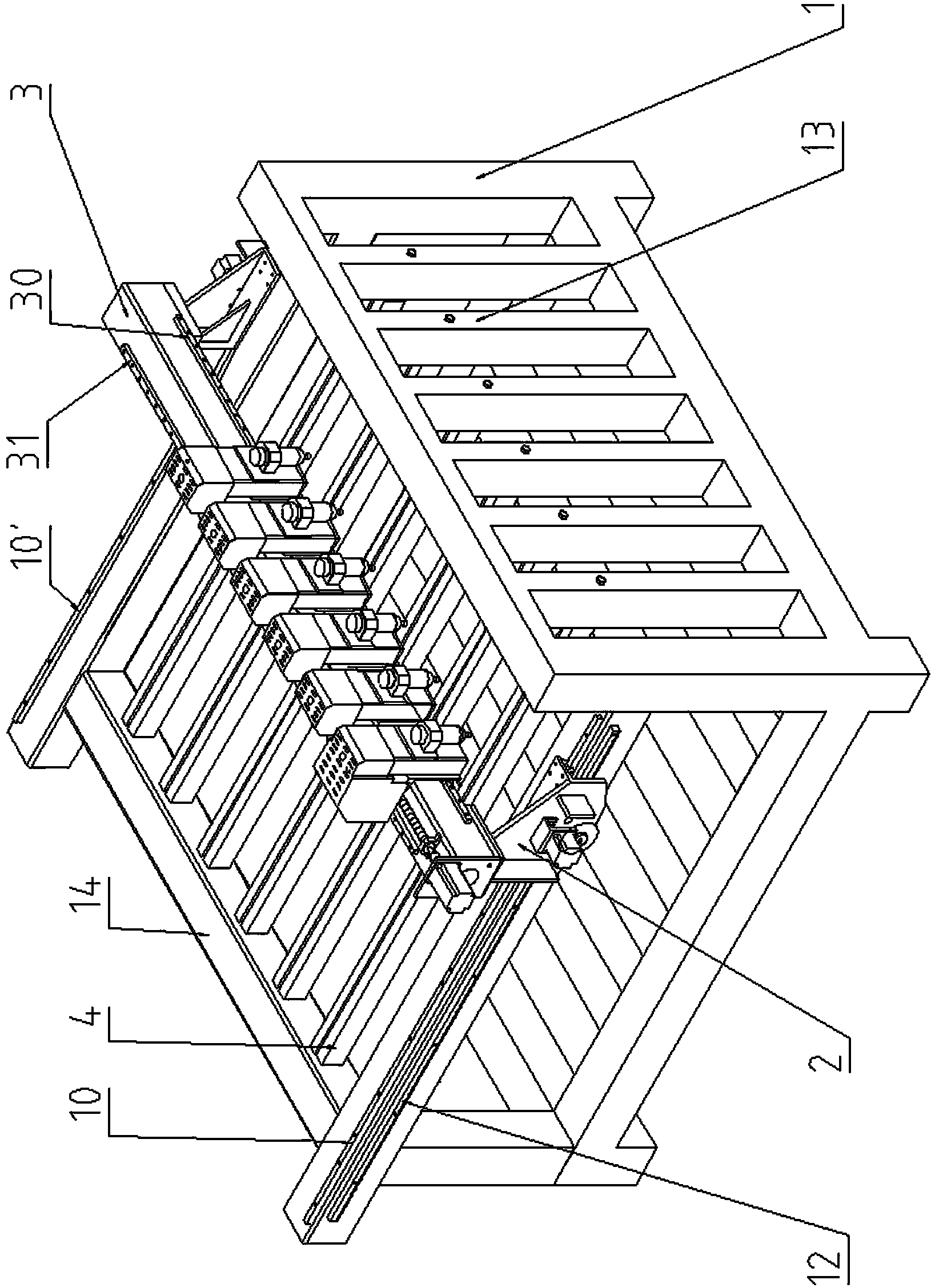

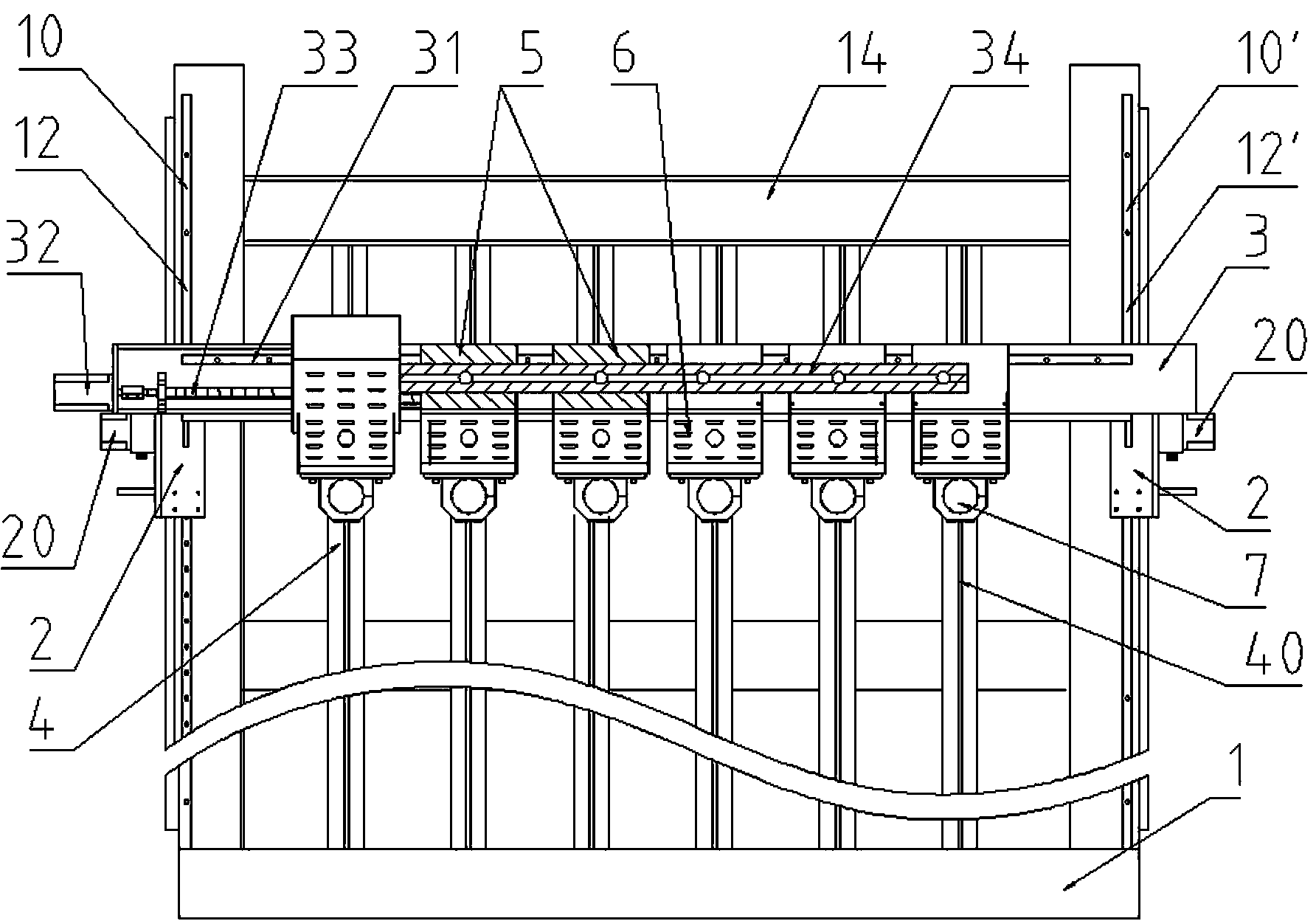

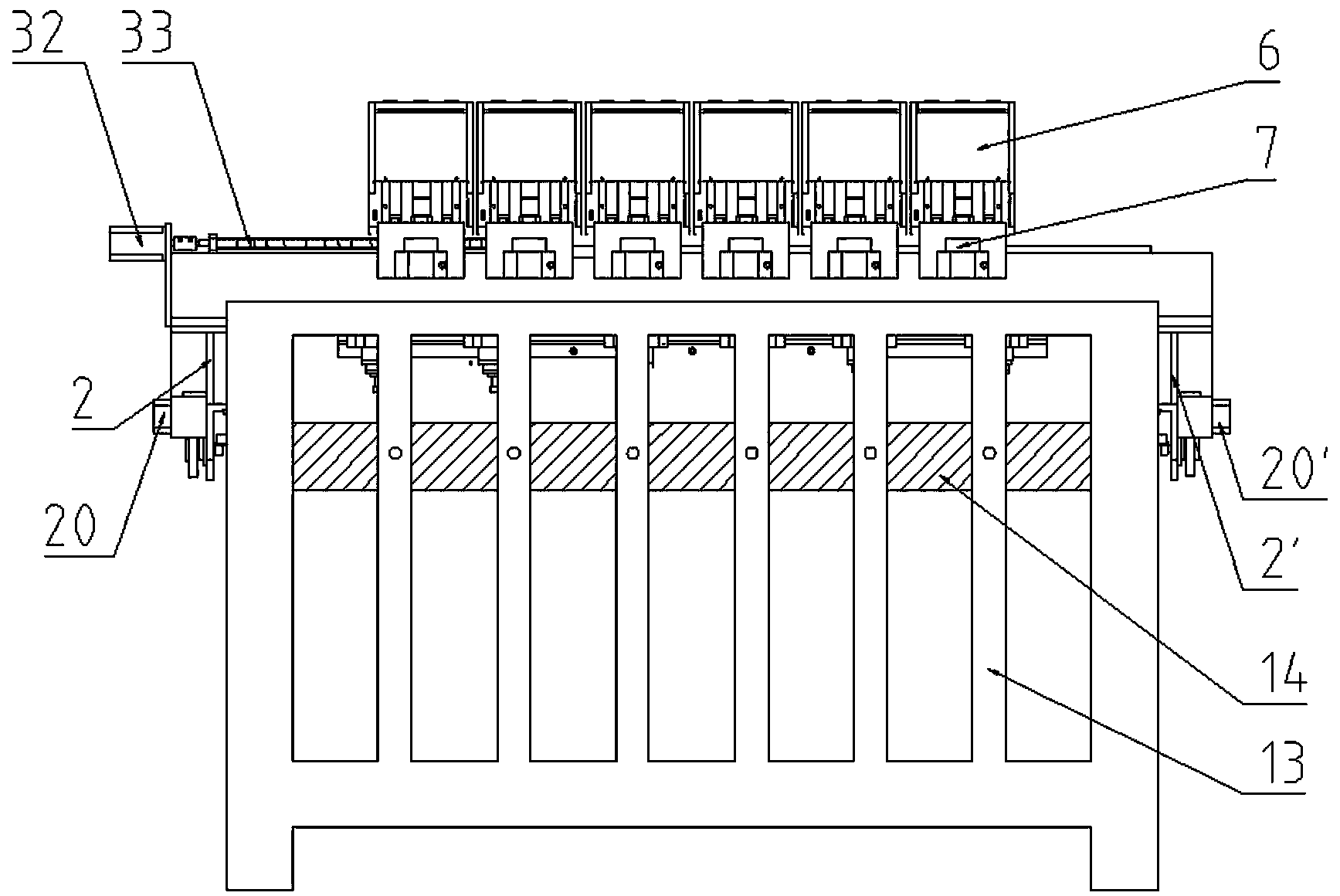

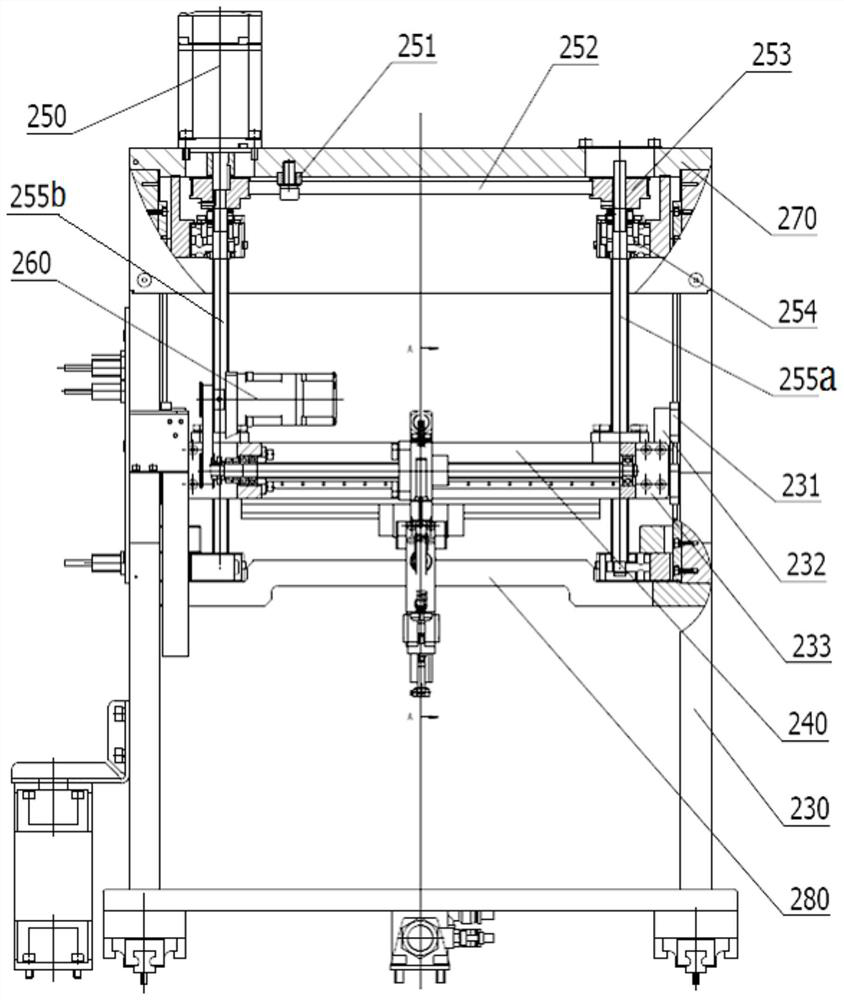

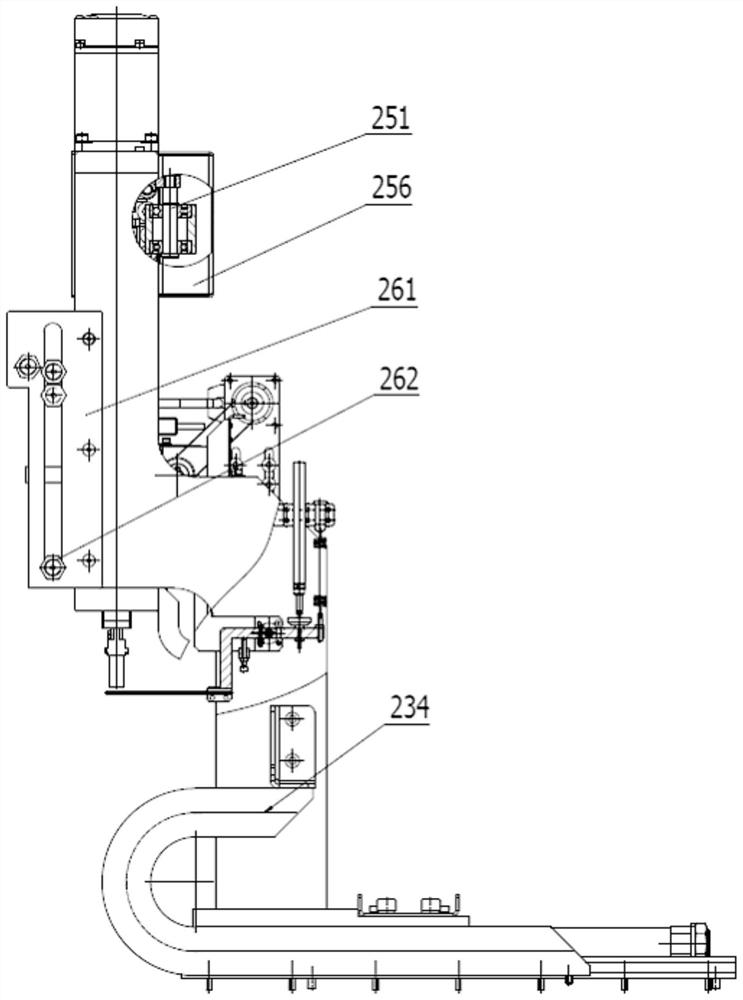

Independent-tool-setting type 3D multi-functional numerical control carving machine

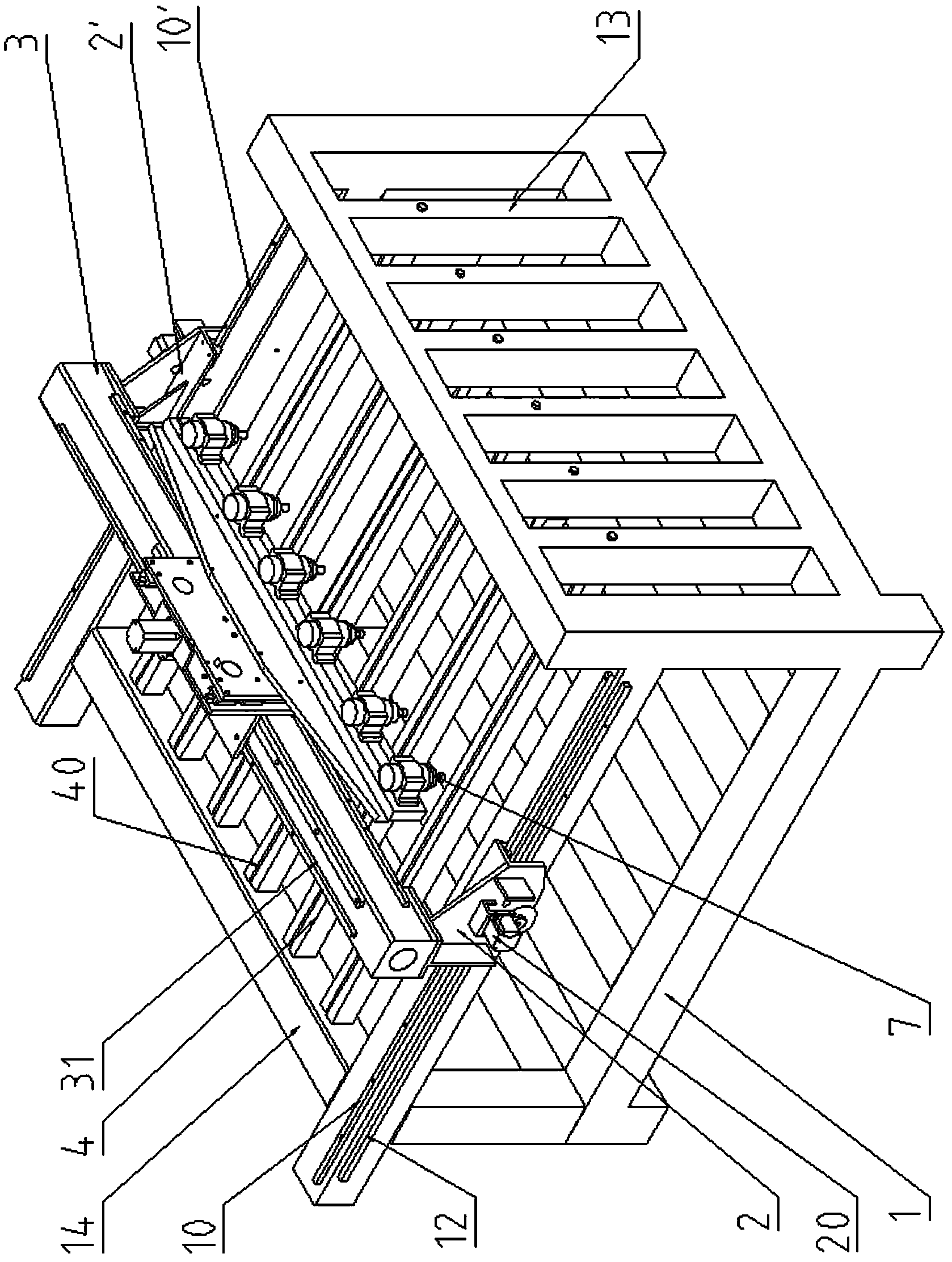

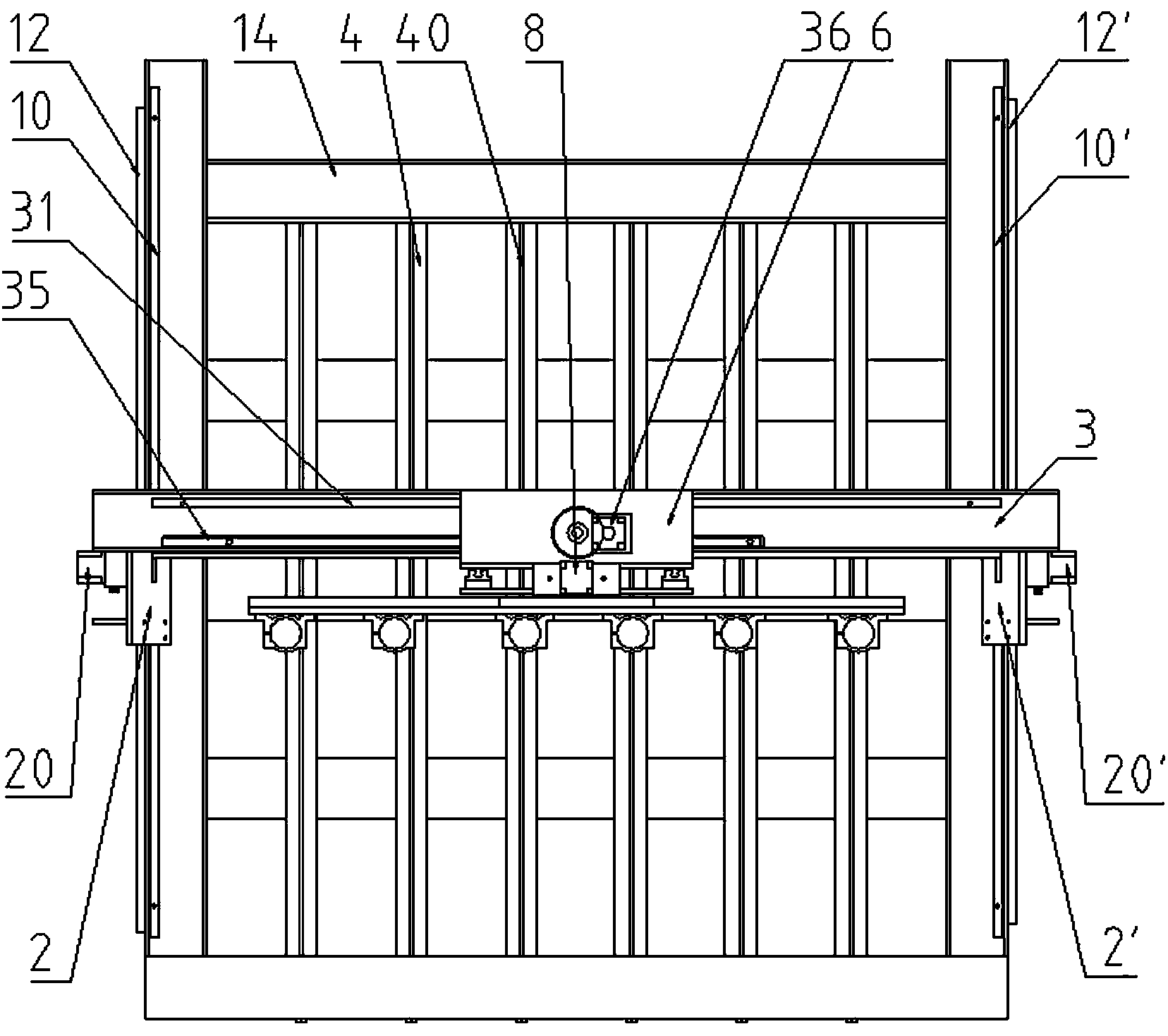

InactiveCN103522813AImprove work efficiencyImprove engraving accuracyModel makingEngravingNumerical controlEngineering

The invention provides an independent-tool-setting type 3D multi-functional numerical control carving machine which has the functions of periphery carving, 3D carving, planar carving and the like, and is high in carving precision and working efficiency. A left stand column and a right stand column are movably connected to a machine tool body through a left guide rail and a right guide rail, a Y-direction drive device is further arranged among the left stand column, the right stand column and the machine tool bed, a gantry is arranged above the left stand column and the right stand column, and multiple U-shaft clamping devices are arranged on the machine tool body below the gantry. A left inner guide rail and a right inner guide rail are arranged on the inner side of the machine tool body, an ejector pin supporting plate is movably arranged between the left inner guide rail and the right inner guide rail, a left locking device and a right locking device are arranged among the ejector pin supporting plate, the left inner guide rail and the right inner guide rail, and multiple ejector pins are arranged on the ejector pin supporting plate. The gantry is provided with multiple carving heads through an X-direction perpendicular guide rail and an X-direction horizontal guide rail, wherein the carving heads are mutually connected through an X-direction connecting rod, and the gantry further comprises an X-direction drive device connected with the carving heads. The carving heads are provided with independent Z-direction vertical structures.

Owner:安庆市宏大涛业精啄数控科技有限公司

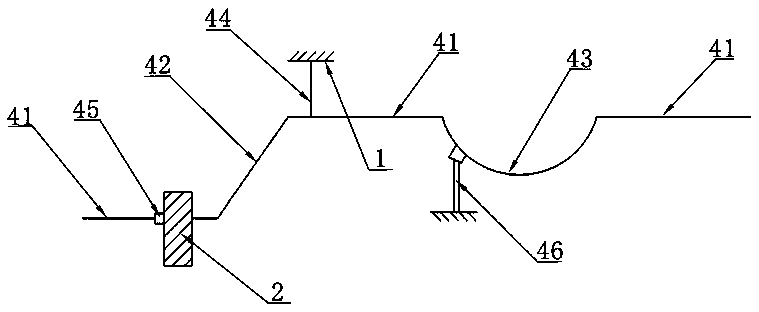

Y-direction assembly of numerical control carving machine

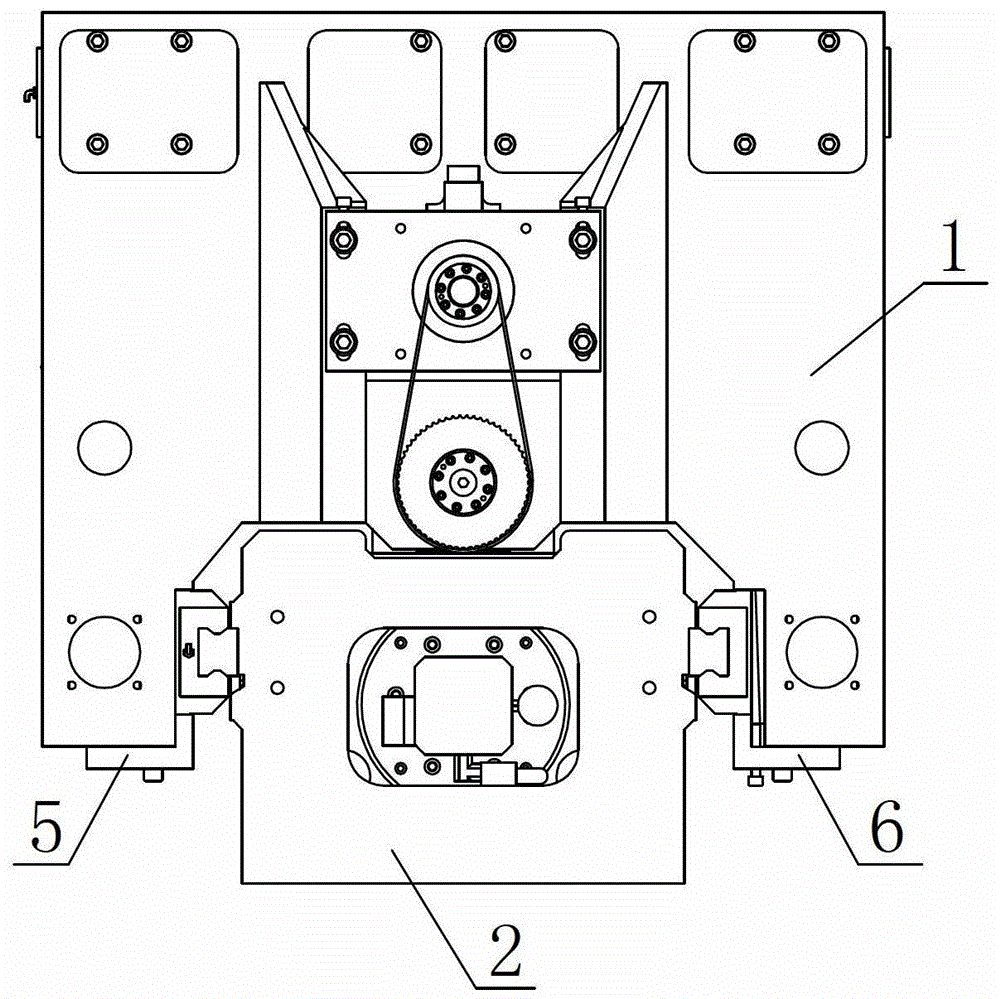

The invention provides a Y-direction assembly of a numerical control carving machine. The Y-direction assembly comprises a left guide rail and a right guide rail which are arranged on the two sides of a tool body and a left Y-direction rack and a right Y-direction rack which are arranged on the tool body. A left column and a right column are movably connected onto the tool body through the left guide rail and the right guide rail. A left Y-direction drive motor and a right Y-direction drive motor are arranged on the left guide rail and the right guide rail respectively, left and right Y-direction drive motor spindle gears are arranged on spindles of the left and right Y-direction drive motors respectively, and left and right Y-direction large gears and left and right Y-direction small gears are arranged on the left column and the right column respectively. The left and right Y-direction large gears are connected with the left and right Y-direction small gears through transmission shafts respectively, the left and right Y-direction drive motor spindle gears are meshed with the left and right Y-direction large gears respectively, and the left and right Y-direction small gears are meshed with the left and right Y-direction racks respectively. The Y-direction assembly is flexible in walking, easy to control and capable of improving the carving accuracy and the service life effectively.

Owner:安庆市宏大涛业精啄数控科技有限公司

Two-dimensional code detecting robot, system and method

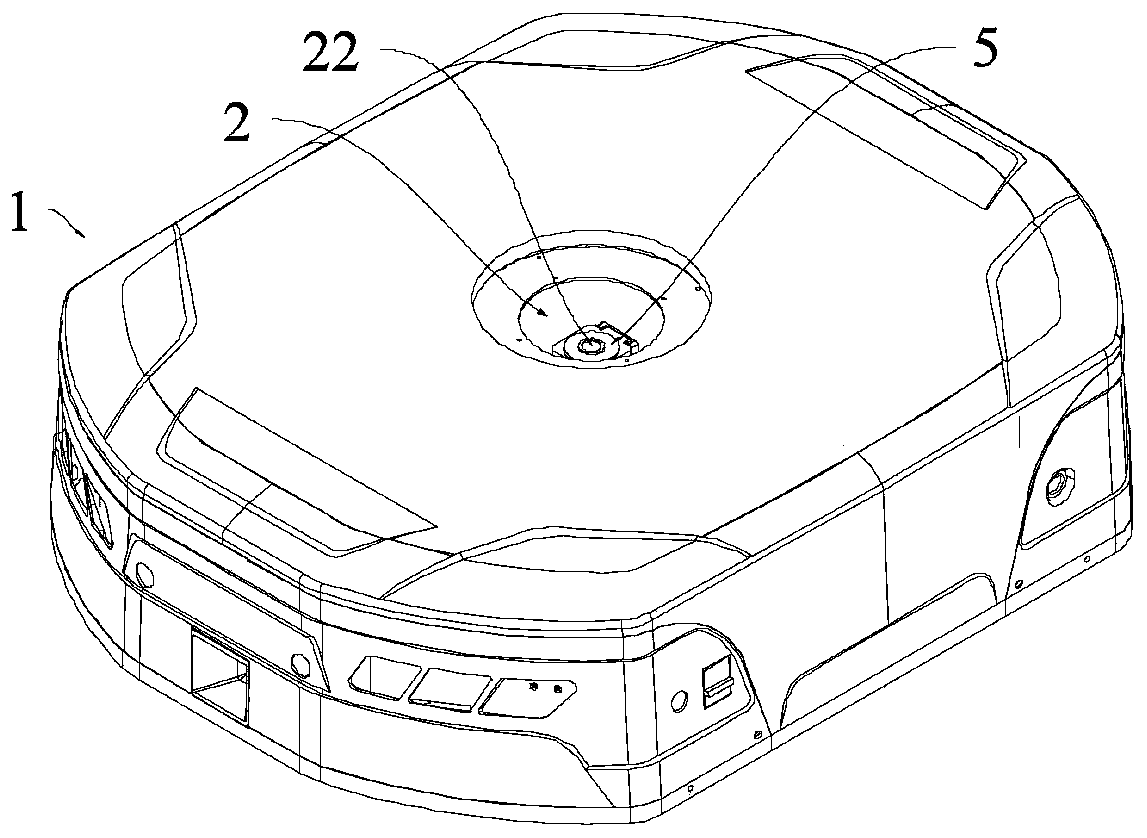

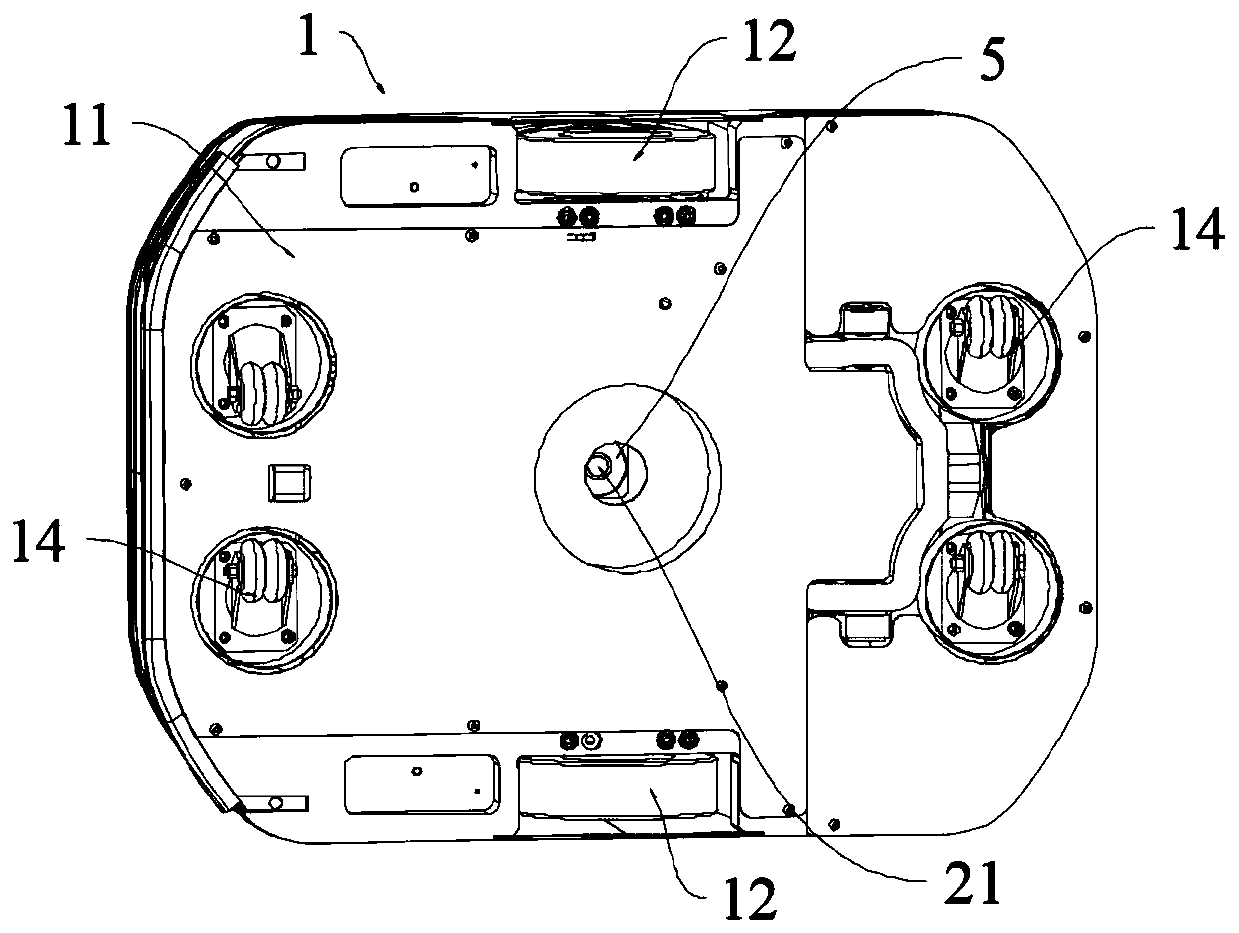

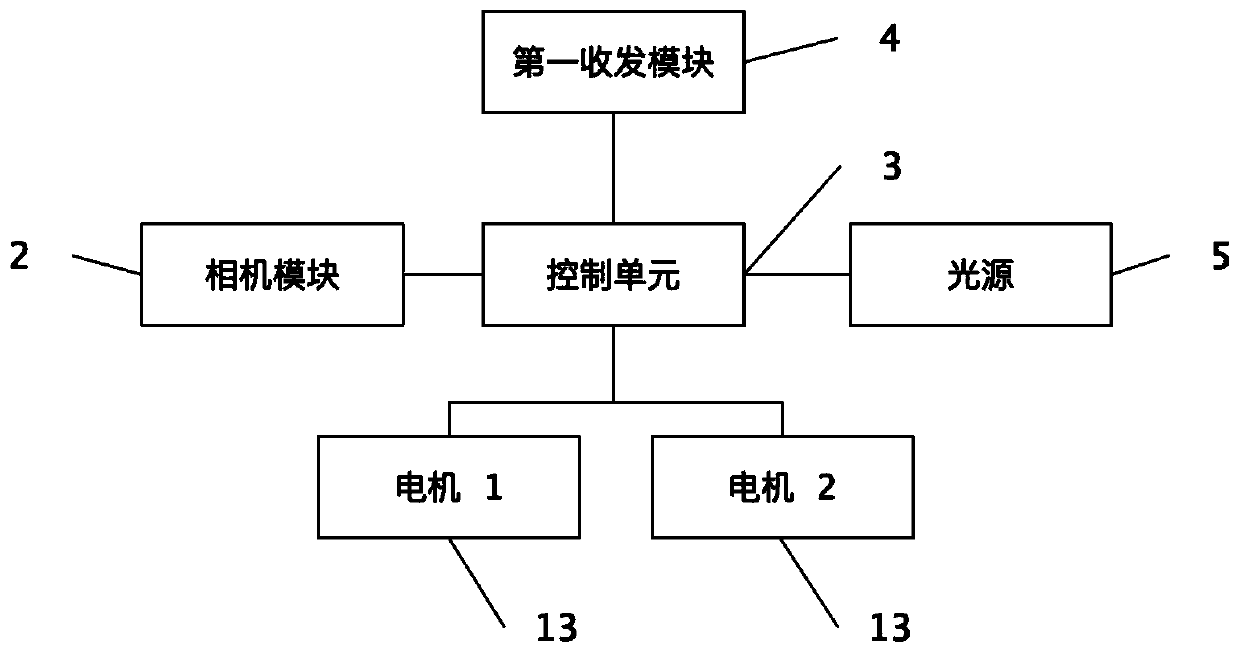

PendingCN110509297AHigh walking accuracyProgramme-controlled manipulatorNavigation instrumentsElectricityComputer module

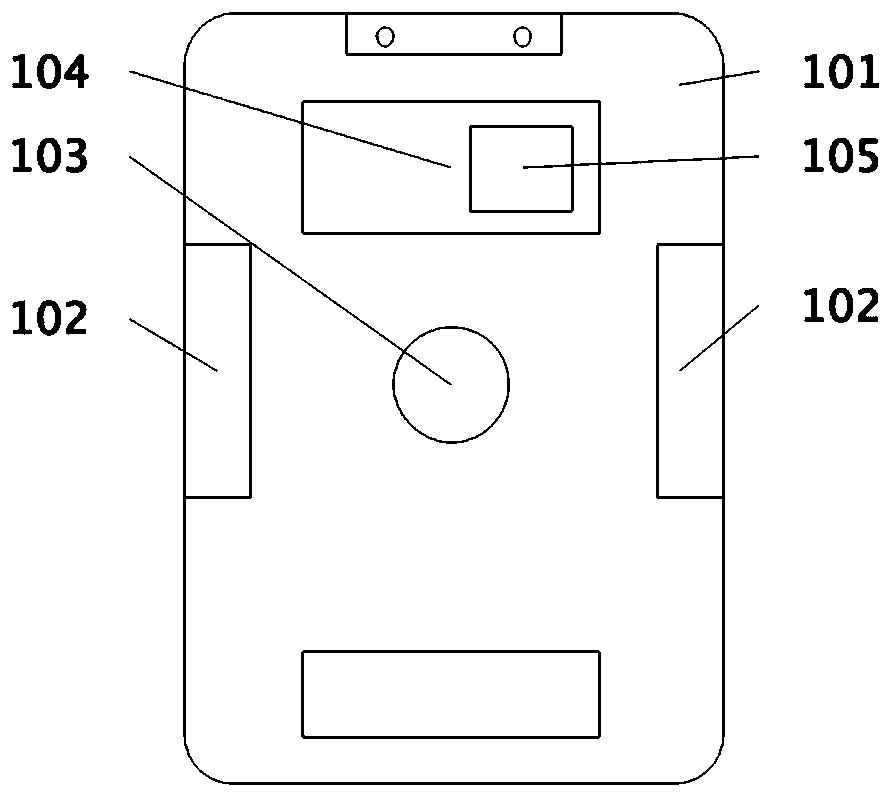

The invention discloses a two-dimensional code detecting robot, system and method. The detecting robot comprises a robot body, a camera module, a control unit and a first receiving and transmitting module; the robot body can comprise a power assembly capable of driving the whole of the robot body to move controllably; the camera module is installed on the robot body, and comprises the previous oneor both of a first camera and a second camera; the control unit is electrically connected with the power assembly and the camera module; and the first receiving and transmitting module is electrically connected with the control unit and used for receiving and transmitting data. According to the two-dimensional code detecting robot, system and method, the robot body moves along a preset path, so that the cameral module acquires an image of a position where each two-dimensional code is located in an operation area; by processing the images, the position deviation of the two-dimensional codes can be obtained, and therefore a basis is provided for subsequent manual correcting or automatic correcting during robot travelling, and it is guaranteed that the intelligent robot has high travelling precision when subsequently performing two-dimensional code navigation in the operation area.

Owner:SUZHOU MUSHINY INTELLIGENCE TECH CO LTD

Novel seam welder rotary head device

InactiveCN105269226AGuaranteed stabilityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesProgrammable logic controllerReciprocating motion

The invention relates to a novel seam welder rotary head device. The novel seam welder rotary head device comprises a movable head frame. Supporting wheel mechanisms are fixed to the four corners of the movable head frame respectively. A rotor mechanism is fixed in the movable head frame through the four corners. A movable head connecting disc reinforcing a rotor is arranged in the rotor mechanism. A plurality of reinforcing steel bar fixing sleeves are arranged around the connecting disc. The movable head frame is fixed to a movable head bottom plate. A rotary power mechanism and a running power mechanism are installed on the movable head bottom plate. A guide wheel mechanism capable of moving reciprocally in a guide rail is installed on the movable head bottom plate. The novel seam welder rotary head device has the beneficial effects that the running power mechanism controls the position of the whole device on the guide rail in the whole operation process, and the rotary power mechanism controls the rotation speed of the rotor to operate; all the operations are controlled through a programmable logic controller (PLC) program; the working labor intensity is low; the automation degree is high; the working operation is stable and reliable; the production efficiency is improved; the quality is more reliable.

Owner:王金鹤

Integrated vertical numerical control edge caving machine

InactiveCN103522812ARealize surface engraving functionRealize functionModel makingNumerical controlEngineering

The invention provides an integrated vertical numerical control edge caving machine. The integrated vertical numerical control edge caving machine has the advantages that multiple usages are achieved, relief carving can be conducted on the surface of a large workpiece, all surfaces of a polyhedron can also be carved, carving precision is high and the service life is long. The integrated vertical numerical control edge caving machine comprises a machine tool body. A left stand column and a right stand column are connected to the machine tool body through a left guide rail and a right guide rail respectively. A Y-direction drive device is also arranged between the left stand column, the right stand column and the machine tool body. A gantry is arranged above the left stand column and the right stand column. The integrated vertical numerical control edge caving machine is characterized in that a movable base is connected to the gantry through an X-direction guide rail device and an X-direction drive device. A carving head fixing board is movably arranged on the movable base through a left base guide rail and a right base guide rail. A Z-direction drive device is arranged between the movable base and the carving head fixing board. The carving head fixing board is provided with a plurality of carving heads. A plurality of Y-direction beams matched with the carving heads respectively are arranged on the machine tool body in the Y-axis direction in a rotatable mode.

Owner:安庆市宏大涛业精啄数控科技有限公司

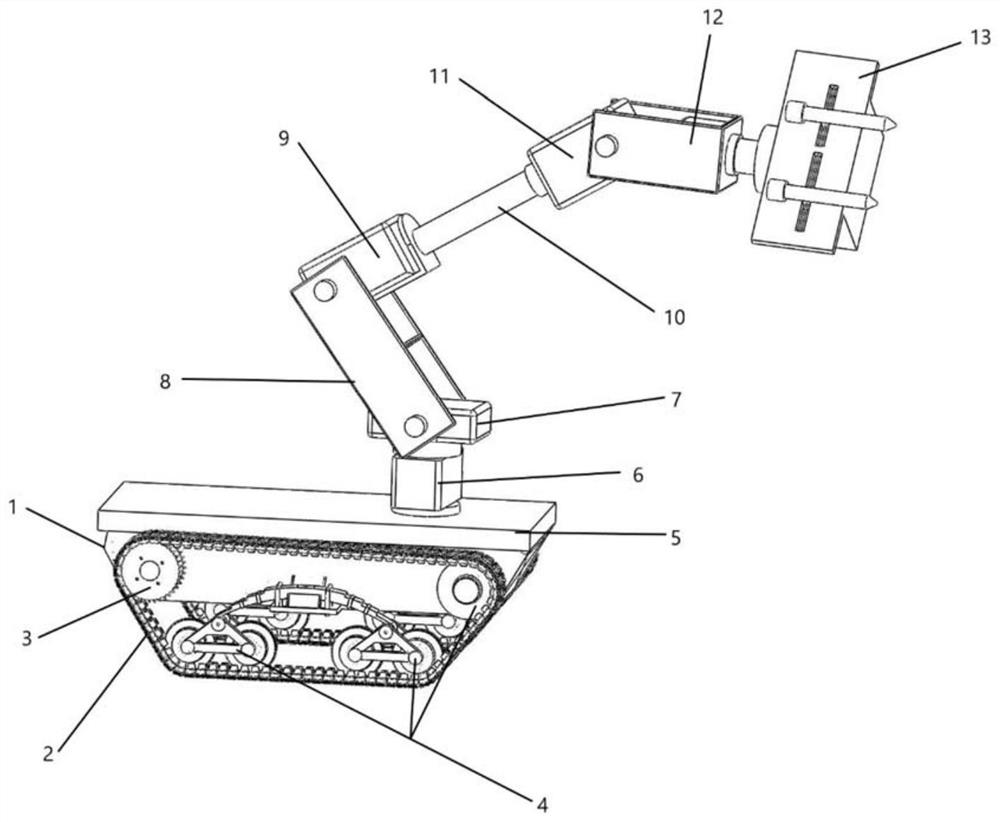

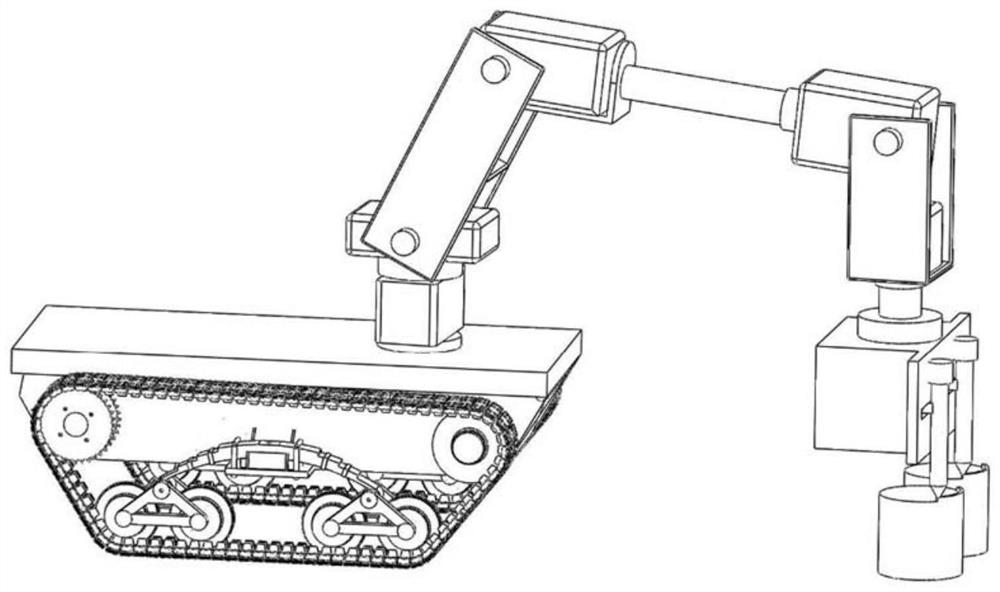

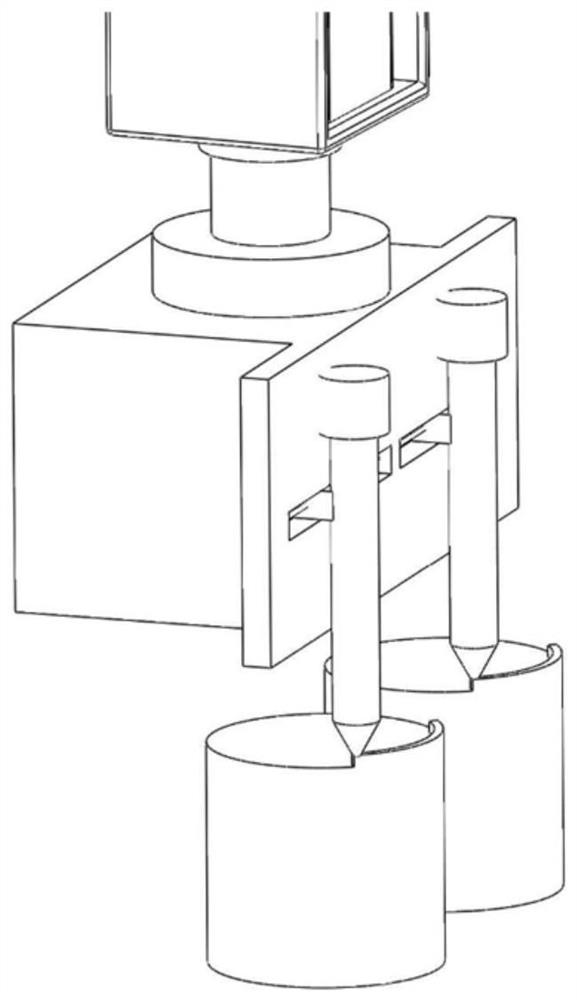

Multi-degree-of-freedom double-nozzle crawler belt moving type 3D printing device

PendingCN114407354AHigh walking accuracyNot easy to slideManufacturing driving means3D object support structures3d printColor printing

The invention discloses a multi-degree-of-freedom double-nozzle crawler moving type 3D printing device which comprises a crawler base, a multi-degree-of-freedom mechanical arm, a moving guide rail and a 3D printing nozzle. A round hole is formed in an upper shell of the crawler base, a steering engine output shaft is reserved on the multi-degree-of-freedom mechanical arm, and a steering engine is fixedly connected with the round hole. A steering engine at the other end of the multi-degree-of-freedom mechanical arm is fixedly connected with the two movable guide rails; the two moving guide rails are connected with the two 3D printing nozzles correspondingly. The movable guide rail is used for moving the printing spray head, the moving precision is high, meanwhile, due to the existence of a fifth steering engine, printing can be conducted like compasses during circle printing, and compared with traditional 3D printing equipment, the circular arc printing precision is higher; double-nozzle printing is adopted, the double nozzles can collaboratively print the same product, the printing speed is increased, two same products can be synchronously printed, meanwhile, two-color printing can be achieved through materials of two colors, and 3D printing of two different materials can be achieved by replacing the printing nozzles.

Owner:TIANJIN UNIV

Intelligent running robot

InactiveCN108819959AReasonable structureCompact structureMonorailsClosed circuit television systemsRolloverDrive motor

An intelligent running robot comprises a single-row track and a sliding table mechanism, wherein the single-row track is placed on a production field according to a preset trajectory; an intelligent robot is mounted on the sliding table mechanism; the sliding table mechanism is mounted on the single-row track to automatically run; the single-row track comprises metal tracks which are suspended onthe top surface in sections and laterally mounted on the wall surfaces in sections, and track surfaces symmetrically extend outwards from the two sides of the lower parts of the metal tracks; the sliding table mechanism comprises a longitudinal sliding table housing which is arranged in the middle of the upper part of the sliding table mechanism and used for the metal tracks to be embedded in; a driving motor and driving running wheel mechanisms are mounted in the sliding table housing, and the driving running wheel mechanisms are erected on the track surfaces on the two sides of the metal tracks; and the whole sliding table mechanism and the intelligent robot mounted on the sliding table mechanism are inversely suspended under the metal tracks. The intelligent running robot has the characteristics that the structure is reasonable and compact, the use operation is convenient, the placing is easy, the mounting is easy, the intelligent running robot is safe and reliable, rollover torquecan be effectively controlled, the running accuracy can be improved and so on.

Owner:DEQING HUAMENG WOODWORK

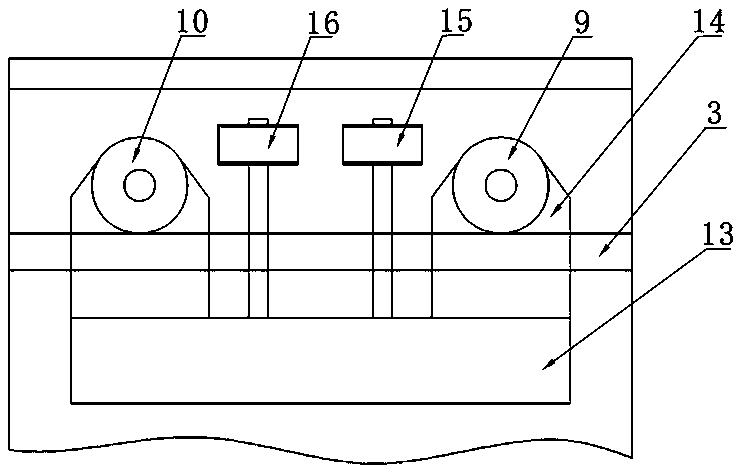

Integrated tool-setting type numerical-control engraving machine portal frame assembly

InactiveCN103538405AHigh walking accuracyImprove engraving accuracyModel makingEngravingNumerical controlPortal frame

The invention provides an integrated tool-setting type numerical-control engraving machine portal frame assembly which is high in travelling precision, good in engraving effect, long in service life and flexible in mounting mode and comprises a portal frame and an X-direction driving device arranged on the portal frame. An X-direction vertical guide rail is arranged on a vertical surface of the portal frame, an X-direction horizontal guide rail is arranged on a horizontal surface of the portal frame, a moving base is arranged on the portal frame through the X-direction vertical guide rail and the X-direction horizontal guide rail, the moving base is composed of a transverse plate and a vertical plate which are mutually perpendicular, an engraving head fixing plate is movably arranged on the moving base through a left base guide rail and a right base guide rail, a Z-direction driving device is arranged between the moving base and the engraving head fixing plate, and a plurality of engraving heads are arranged on the engraving head fixing plate.

Owner:安庆市宏大涛业精啄数控科技有限公司

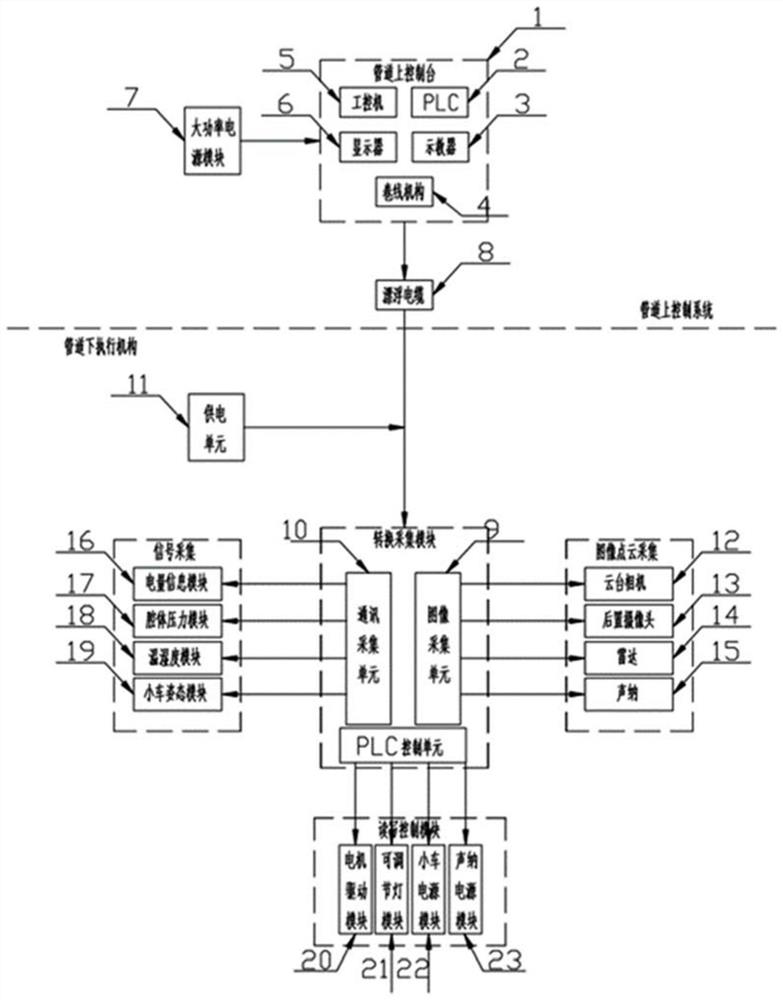

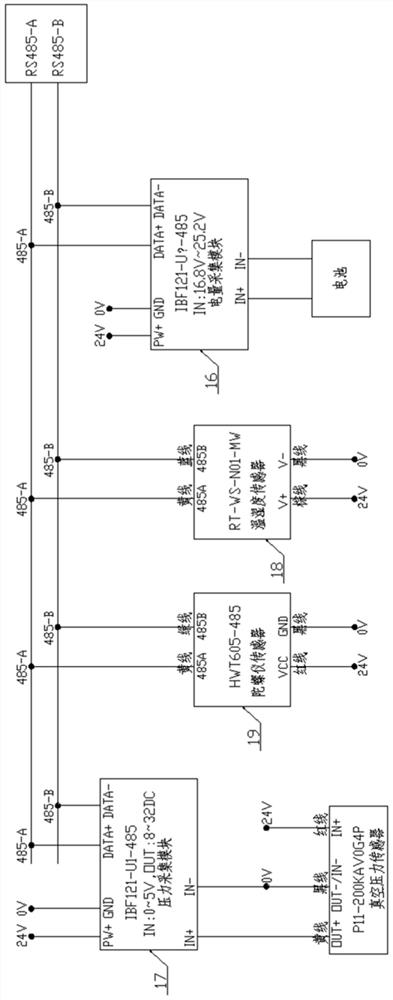

Control system of pipeline water-carrying detection robot

ActiveCN114738597ADegree of relaxationGood anti-interferenceTotal factory controlPigs/molesControl systemSimulation

The invention discloses a control system of a pipeline water detection robot, which comprises an upper pipeline control system and a lower pipeline execution mechanism, the upper pipeline control system is connected with the lower pipeline execution mechanism through a cable, and the upper pipeline control system is used for receiving information and transmitting the information to an industrial personal computer; the pipeline lower execution mechanism is arranged on the robot, is used for collecting information and transmitting the information to the pipeline upper control system, and is also used for sending a control instruction to control the robot and control the start and stop of a power supply; the content of controlling the robot comprises robot linear walking control and matching control between the pay-off speed of a control system on a pipeline and the running speed of the robot; the trolley has the advantages that the anti-interference, shockproof and moistureproof effects are better, the trolley is not prone to colliding with the pipe wall, the walking precision is high, the stability is good, in the trolley walking process, the cable is flexible in relaxation and free in take-up and pay-off, the occurrence of wire twisting accidents caused by trolley slipping is avoided, and manual take-up and pay-off intervention treatment is not needed.

Owner:HRG INT INST FOR RES & INNOVATION

Automatic pipeline crack scanning device

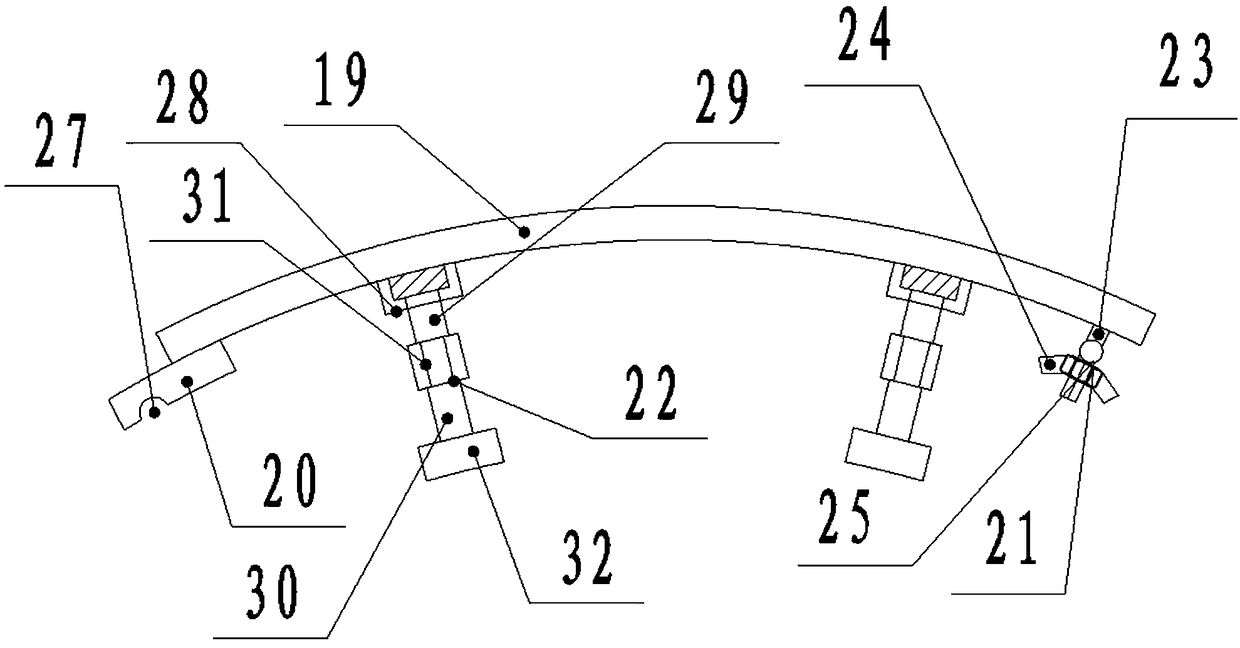

PendingCN110657354AImplement automatic detectionFacilitates automatic detectionPipeline systemsStructural engineeringMechanical engineering

The invention discloses an automatic pipeline crack scanning device for automatically scanning cracks on outer walls of fuel pipelines. The automatic pipeline crack scanning device is characterized bycomprising an axial scanning mechanism, an adjustment limiting mechanism and an adjustment rotating mechanism, wherein the adjustment limiting mechanism is mounted on the adjustment rotating mechanism, such that the automatic pipeline crack scanning device can clamp and fix pipelines with different pipe diameters and slide axially. The axial scanning mechanism is mounted on the adjustment rotating mechanism, such that the automatic pipeline crack scanning device can scan the cracks on the outer walls of the pipelines. The automatic pipeline crack scanning device is an automatic scanning device based on eddy-current nondestructive detection, which is automatic in detection, high in accuracy and comprehensive in detection of the outer walls of the pipelines. The automatic pipeline crack scanning device eliminates errors caused by the fact that a constructor needs to hold an eddy-current sensing probe by hand to scan the outer walls of the pipelines, solves the problems of low scanning efficiency and accurate detection result and can comprehensively detect the outer walls of the pipelines with high accuracy and efficiency.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Independent-tool-setting type numerical control edge carving machine

InactiveCN103522815ARealize surface engraving functionRealize functionModel makingNumerical controlEngineering

The invention provides an independent-tool-setting type numerical control edge carving machine which is high in walking precision, good in carving effect, long in service life and flexible in installation mode. A left stand column and a right stand column are movably connected to a machine tool body through a left guide rail and a right guide rail, a Y-direction drive device is further arranged among the left stand column, the right stand column and the machine tool body, and a gantry is arranged above the left stand column and the right stand column. The independent-tool-setting type numerical control edge carving machine is characterized in that an X-direction perpendicular guide rail is arranged on the perpendicular surface of the gantry, and an X-direction horizontal guide rail is arranged on the horizontal surface. Multiple carving head bases are movably arranged on the gantry through the X-direction perpendicular guide rail and the X-direction horizontal guide rail, each carving head base is composed of a vertical plate and a transverse plate which are mutually connected, carving heads are fixed to the carving head bases, and the carving head bases are mutually connected through an X-direction connecting rod. The independent-tool-setting type numerical control edge carving machine further comprises an X-direction drive device connected with the carving heads, and the carving heads are provided with Z-direction independent vertical structures.

Owner:安庆市宏大涛业精啄数控科技有限公司

Mobile robot navigation system and mobile robot

PendingCN111522344AHigh walking accuracyReduce use costNavigation instrumentsElectromagnetic wave reradiationControl systemSimulation

The invention relates to the technical field of robots, and discloses a mobile robot navigation system and a mobile robot. The mobile robot navigation system comprises a mobile robot and a target board. The mobile robot comprises a body, a walking mechanism, a navigation sensor set, a position sensor set and a control system. The navigation sensor set, the position sensor set and the walking mechanism are all in signal connection with the control system, the navigation sensor set comprises a center laser sensor and a deviation rectifying laser sensor, the deviation rectifying laser sensor is assembled on the body in a swinging mode in the horizontal direction, and a heading target is arranged on the target board. When the deviation rectification laser sensor receives a laser signal reflected by the heading target, the mobile robot deviates from a straight line; whether the mobile robot deviates leftwards or rightwards is determined according to the received position of the deviation rectification laser sensor, so that the walking direction of the walking mechanism is changed by the control system, the walking precision of the mobile robot is improved, special auxiliary equipment and algorithms are omitted, and the use cost of the mobile robot is reduced.

Owner:内蒙古锦泰明科技集团有限公司

Array magnetic navigation sensor

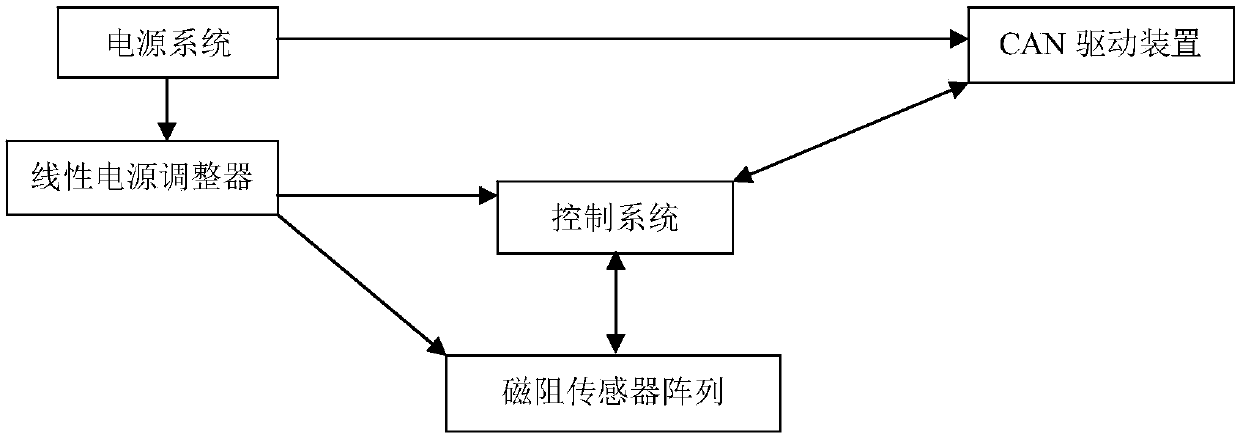

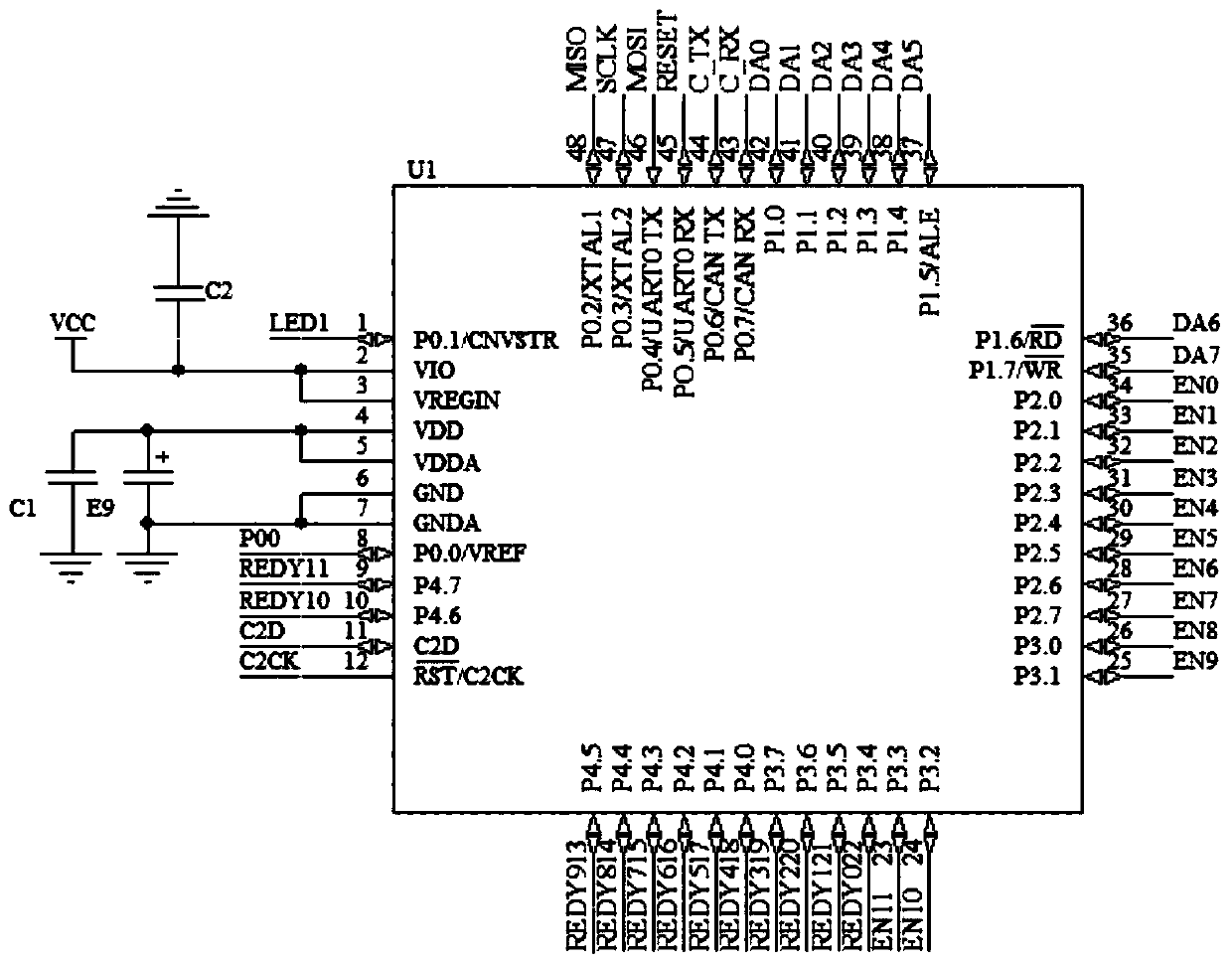

PendingCN109945862AImprove detection accuracyHigh walking accuracyMagnetic measurementsNavigational calculation instrumentsControl systemElectromagnetic field

The invention relates to an array magnetic navigation sensor, and the sensor comprises a magnetoresistive sensor array which is connected with a control system, collects a magnetic field signal and sends the magnetic field signal to the control system; the control system which is connected with a CAN driving device and used for converting the magnetic field signal into two-dimensional position information and sending the two-dimensional position information to the CAN driving device; the CAN driving device which is connected with an upper computer through a CAN bus and sends the two-dimensional position information to the upper computer; and a power supply system which is connected with the CAN driving device to supply power to the CAN driving device, and is connected with the control system and the magnetoresistive sensor array through a linear power supply adjuster to supply power to the CAN driving device. The sensor can improve the detection precision of the magnetic field, can detect the deviation in the left-right direction, also can detect the deviation in the front-back direction, improves the walking precision of the AGV, and reduces the interference of an external electromagnetic field on signals. The wiring structure is more flexible and convenient.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Driving device and driving method of a four-way shuttle trolley

ActiveCN109928132BEliminate cumulative errorsPrecise positioningStorage devicesData matchingTrackway

The invention relates to a walking device and a walking method for a four-way shuttle trolley, comprising a walking device for a four-way shuttle trolley, which includes a controller for controlling the walking of the four-way shuttle trolley; The track is set sequentially in units of grids, and there is a counting piece in each grid; the counting piece is used to calculate the number of grids that the four-way shuttle trolley runs, and sends the relevant pulse information to the controller; the four-way shuttle trolley also has An RFID reader is provided, and a corresponding RFID chip is provided in each grid of the running track, and the data matching the grid is provided in the RFID chip; the present invention eliminates the The cumulative error of the four-way shuttle car in the process of walking is reduced to make the positioning of the car more accurate; at the same time, an RFID reader and an RFID chip are added to judge whether the number of walking steps of the four-way shuttle car is counted correctly, further increasing the four-way shuttle. The walking accuracy of the trolley.

Owner:牛眼智能物流设备(苏州)有限公司

CNC gantry milling machine milling power head

ActiveCN103056675BMove up and down flexiblyStrong heavy cutting abilityLarge fixed membersMaintainance and safety accessoriesNumerical controlReflux

Owner:青岛欧普特精工机床有限公司

Load controllable active type follow-up force-applying linear guide rail pair test bed

InactiveCN102692320BEasy to controlAccurate assessmentMachine part testingEngineeringMechanical engineering

The invention relates to a load controllable active type follow-up force-applying linear guide rail pair test bed. Force-applying heads (force-applying points) of a transverse loading mechanism and a vertical loading mechanism independently use or share a lead screw driving mechanism so that the transverse loading mechanism and the vertical loading mechanism move synchronously along with a stressed sliding table and the force-applying points are relatively stationary with four guide rail sliding blocks. Therefore, loads applied by a force-applying device can be uniformly and invariably acted on the four guide rail sliding blocks. The load born by each guide rail sliding block is 1 / 4 of that applied by the fore-applying device, namely, change curves of the loads born by the guide rail sliding blocks are completely consistent with the change curves of force applied by the force-applying device, only the amplitude is reduced to 1 / 4. Therefore, when the load controllable active type follow-up force-applying linear guide rail pair test bed is used for carrying out a performance and service life test on the linear guide rail pair, the load applied can be conveniently, precisely and reliably controlled so as to relatively accurately and reliably evaluate a relationship among the load, the performance and service life of the linear guide rail pair, thus providing a relatively reliable test basis for design and maintenance of the guide rail pair.

Owner:SOUTHWEST JIAOTONG UNIV

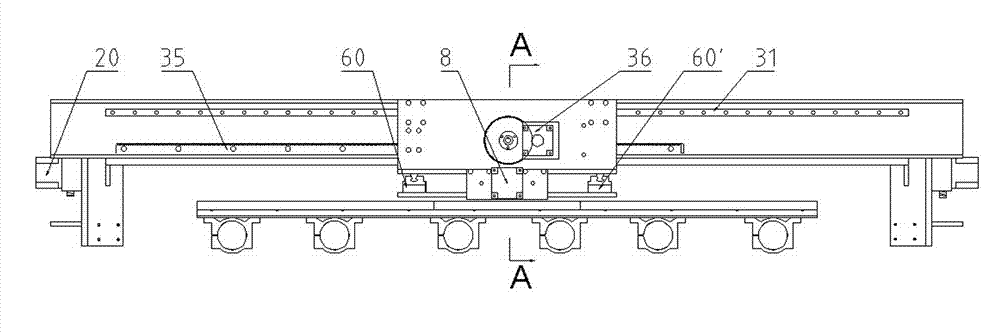

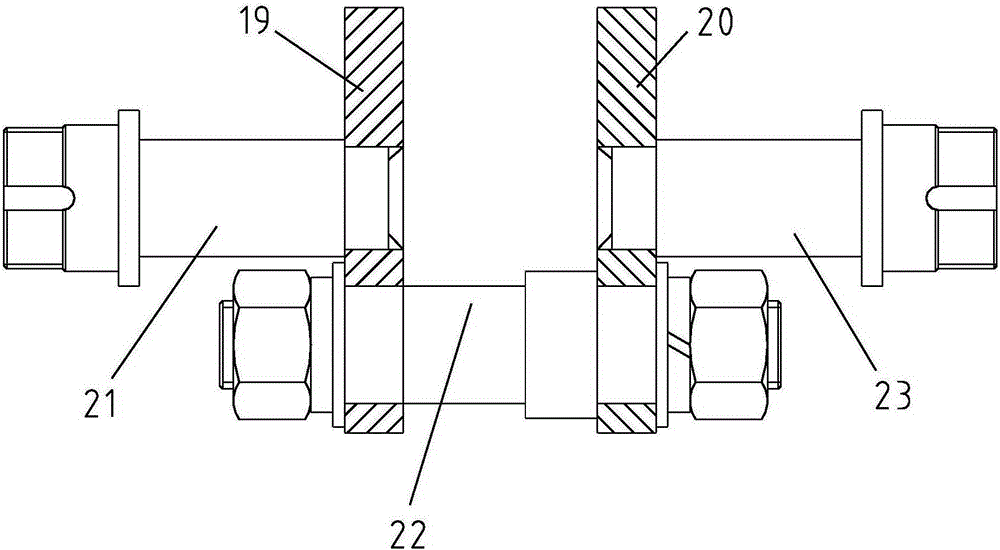

Petroleum pipeline weld seam trolley automatic walking method

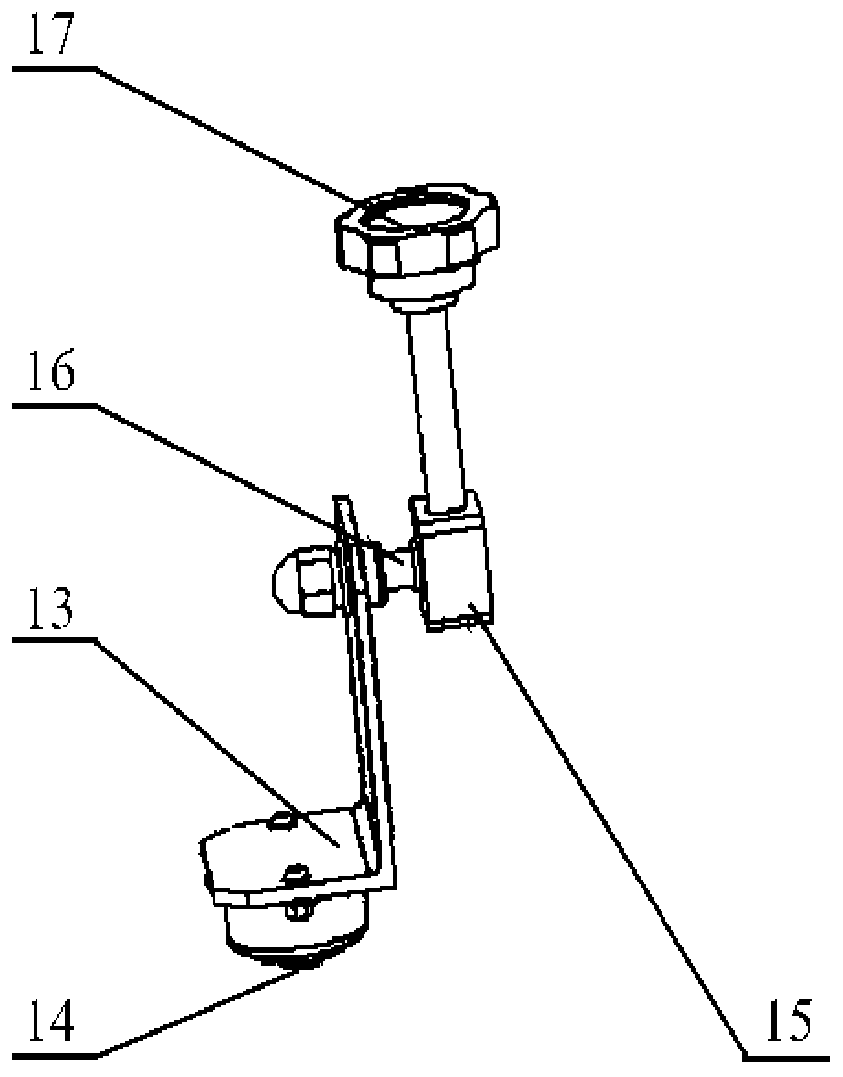

InactiveCN108274170AWalking smoothlyHigh walking accuracyWelding/cutting auxillary devicesAuxillary welding devicesLower limitDrive wheel

The invention discloses a petroleum pipeline weld seam trolley automatic walking method. Two driving wheels are arranged on the bottom face of a welding trolley frame and connected through a wheel axle; the wheel axle is mounted on the welding trolley frame through a suspension frame; a wheel axle bevel gear is arranged on the wheel axle; a transmission shaft for vertical transmission is arrangedon the part, corresponding to the welding trolley frame, of the bevel gear; a lower transmission shaft bevel gear engaged with the wheel axle bevel gear is arranged at the lower end of the transmission shaft; an upper transmission shaft bevel gear is arranged at the upper end of the transmission shaft; a driving motor is arranged on the welding trolley frame; a rotary shaft bevel gear is arrangedon a rotary shaft of the driving motor and is in engagement transmission with the transmission shaft bevel gear; guide rail clamping devices are arranged on the two sides of the welding trolley framecorrespondingly; each guide rail clamping device comprises an adjusting screw, an L-shaped sliding frame, a lower limiting wheel and an upper limiting wheel; the adjusting screws are connected with the upper ends of the L-shaped sliding frames; the L-shaped sliding frames are enabled to move left and right by rotating the adjusting screws; and the lower limiting wheels and the upper limiting wheels which are clamped on guide rails are arranged on the L-shaped sliding frames.

Owner:CHENGDU KESHENG PETROLEUM TECH

A mesh trimmer

InactiveCN103600118BHigh positioning accuracyHigh walking accuracyShearing machinesEngineeringFriction force

The invention discloses a mesh trimmer. The mesh trimmer comprises a support seat, a frame arranged on the upper side of the support seat, a blade holder connecting plate arranged on the front side of the frame, a driving device arranged on the left side of the frame, a transmission device arranged on the upper portion of the frame and driving the blade holder connecting plate to move up and down, an upper blade mounted on the lower side of the blade holder connecting plate, and a lower blade arranged below the upper blade. The mesh trimmer has the advantages that the whole mesh trimmer is small in friction force, low in energy consumption, small in size, compact in structure, reasonable in layout, convenient and safe to operate, low in cost and high in production efficiency. Without being powered off, the whole mesh trimmer can be timely controlled in operation through two foot switches conveniently, rapidly and efficiently.

Owner:安平县赫鹏五金网业有限公司

Double-lead-screw loading horizontal movement measuring mechanism

PendingCN112547839AWith three-dimensional motion functionCompact structureMeasurement devicesMetal working apparatusReciprocating motionElectric machinery

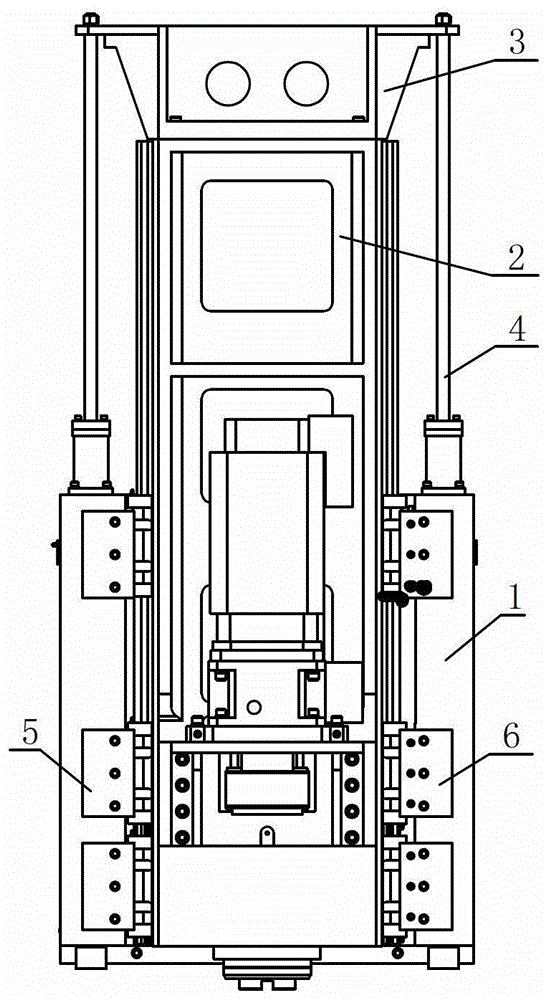

The invention discloses a double-lead-screw loading horizontal movement measuring mechanism. The double-lead-screw loading horizontal movement measuring mechanism comprises two first guide rails oppositely arranged at the top of a main machine, a supporting mechanism arranged on the guide rails in a matched mode, a cylinder which is fixedly arranged at the top of the main machine at one end and connected to the bottom of the supporting mechanism at the other end, and can drive the supporting mechanism to reciprocate on the first guide rails, a first driving motor arranged at the top of the supporting mechanism, a first lead screw mechanism connected to the output end of the first driving motor at one end, a second lead screw mechanism arranged opposite to the first lead screw mechanism, asynchronization mechanism, a lower cross beam, a loading cross beam, two second guide rails, two slide block connecting mechanisms, a second driving motor arranged at one side of the supporting mechanism, a moving mechanism arranged on the lower cross beam, and a measuring mechanism. The measuring mechanism has the movement functions in the X-axis direction, the Y-axis direction and the Z-axis direction, and has the straightness scanning function of a radial run-out measuring machine.

Owner:中机试验装备股份有限公司

Axial-direction positioning device with dust cover and used on manipulator

InactiveCN103465273ABig work scheduleNo need for frequent lubricationProgramme-controlled manipulatorReciprocating motionEngineering

The invention discloses an axial-direction positioning device with a dust cover and used on a manipulator. The axial-direction positioning device comprises a rectangular base made of an aluminum alloy plate. A workbench in straight reciprocating motion is mounted above the base. Dust caps are mounted at two ends of the base. A shield is in bridge connection between the upper ends of the dust caps. A motor supporting plate is mounted in the inner side of the dust cap at the left end of the base. A motor is mounted on the motor supporting plate. Through the technical scheme, working stroke of the manipulator is increased; due to the dust cover and the dust caps, influences of dust particles to accuracy are avoided, frequent lubrication is not needed, and high travelling accuracy and positioning accuracy are realized accordingly.

Owner:苏州凯欧机械科技有限公司

Portable pipeline automatic circumferential walking device and pipeline processing method

ActiveCN102000928BGuaranteed coincidenceHigh walking accuracyWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention discloses a portable pipeline automatic circumferential walking device and a pipeline processing method, which belong to the technical field of pipeline processing and construction. The portable pipeline automatic circumferential walking device consists of a circular rail, a walking mechanism and a control part. The circular rail consists of a rail and a grab for mounting the rail. The portable pipeline automatic circumferential walking device has the characteristics that one type of rail is adaptable to a plurality of types of pipe diameters, and a plurality of types of rails is adaptable to more pipe diameters in a matching mode. The walking mechanism consists of a machine frame, wheels, a chain tensioning mechanism, a driving motor system and a chain. The control part consists of a local controller and a remote controller. The local controller can adjust positive rotation and negative rotation of a motor, and can adjust the walking mechanism to perform clockwise rotation or counterclockwise rotation around a pipeline. The remote controller can control the walking mechanism at a distant place, and is compact and convenient. The portable pipeline automatic circumferential walking device is convenient to mount, has high walking accuracy, is not affected by whether the pipeline has a coating layer or not, and is suitable for meeting requirements on circumferential construction of an onsite pipeline.

Owner:宣邦机器人(苏州)有限公司

Layered feeding structure of PET fabric

PendingCN111186076AEnsure the effect of absorbing fabricImprove adsorption capacityCoatingsStructural engineeringInjection molding process

The invention discloses a layered feeding structure of a PET fabric. The layered feeding structure comprises a positioning mechanism, a stepping mechanism, an adsorption mechanism, and a counterweight, wherein the positioning mechanism comprises a bearing plate, positioning needles fixed on the bearing plate, limiting baffles fixed on the edge of the bearing plate, and a mistake-proof shifting plate fixed on the bearing plate, the stepping mechanism comprises a stand column and a forward extension frame fixed on the stand column, the front end of the forward extension frame is fixedly providedwith a guide rod air cylinder, the upper end of one side of the forward extension frame is fixed with a pressure reducing valve, the pressure reducing valve and the guide rod air cylinder are pneumatically connected, the adsorption mechanism comprises a connecting frame, four sucking devices fixed on the two sides of the connecting frame and an induction switch mounted at the front end of the connecting frame, the extending rod end of the guide rod air cylinder is fixed on the connecting frame to drive the adsorption mechanism to move up and down, and the counterweight is fixed on the stand column and is opposite to the fixing direction of the forward extension frame. According to the layered feeding structure of the PET fabric, for a damascene material used in an inlaid injection moldingmanufacturing process and process requirements, a single-layer fabric material can be provided through the structure, so that the full-automatic inlaid injection molding process is further realized,the repeated precision is high, the cost is low, and repair and maintenance are simple.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

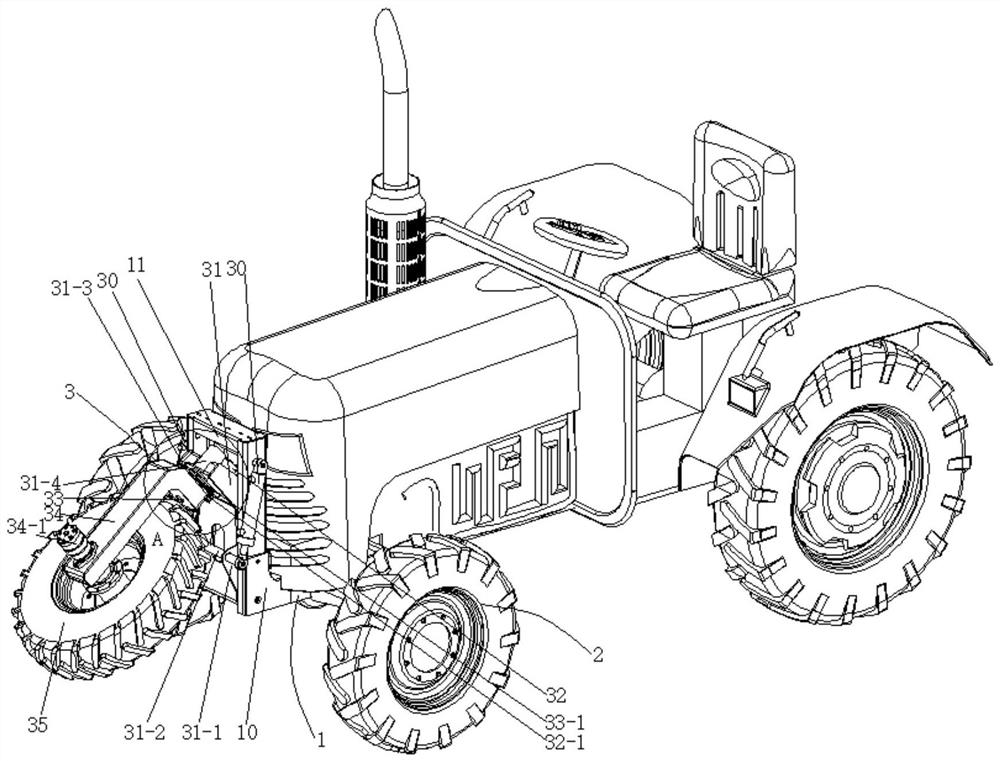

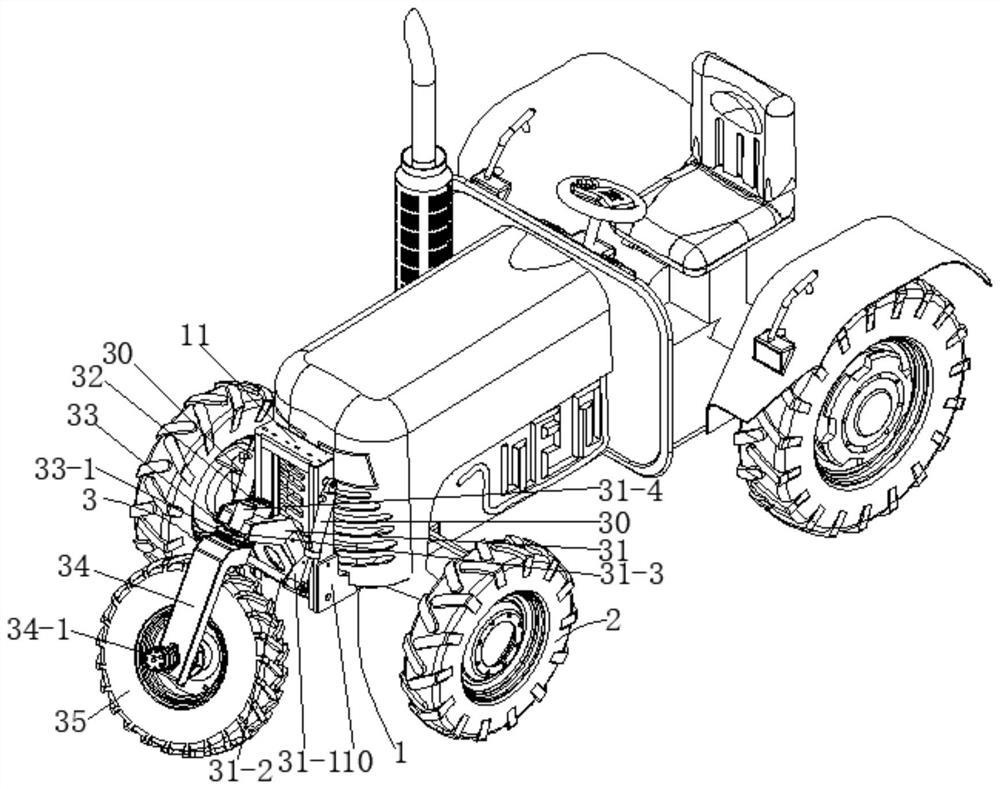

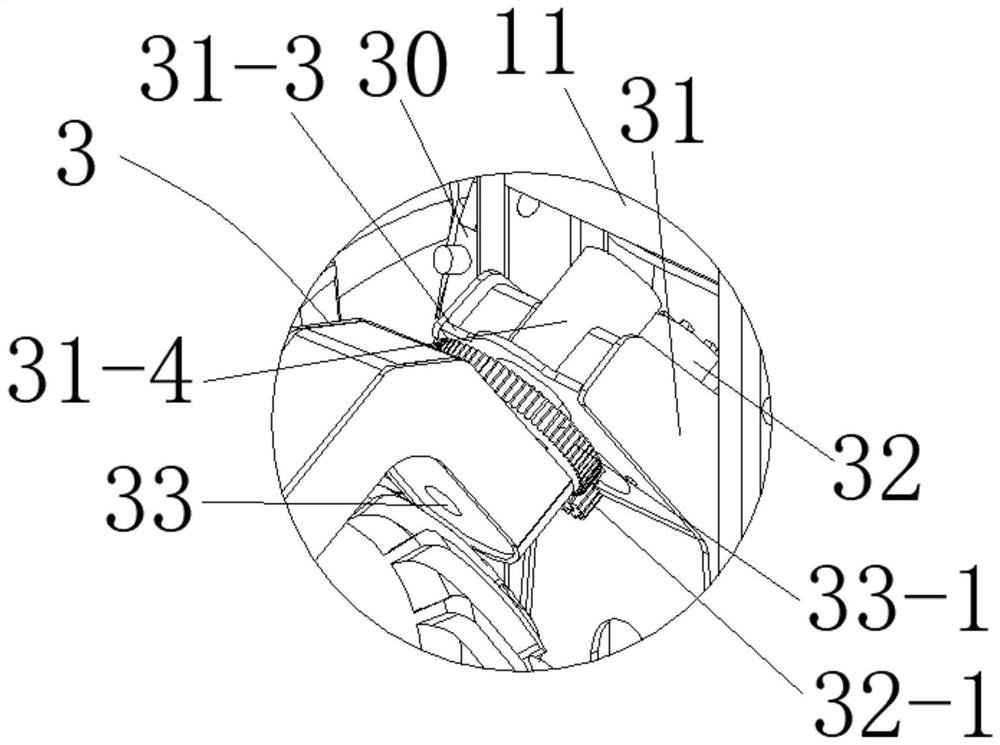

Composite steering system of tractor

PendingCN113799873AHigh walking accuracyRealize fully automated operationFluid steeringVehiclesSteering wheelVehicle frame

The invention discloses a tractor composite steering system which comprises a frame, a traditional steering system and a folding steering system, the traditional steering system is connected with the frame, and the folding steering system is connected with the front end of the frame in a storable mode, so that the walking precision of a tractor is high when the tractor cooperatively works along with equipment such as agricultural cultivation and harvesting equipment, and the full-automatic operation is achieved; and meanwhile, an independent steering wheel can be stored as a spare tire.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Robot RGV meter hanging system

PendingCN114474014AIngenious designImprove stabilityProgramme-controlled manipulatorFrequency changerElectric machinery

A robot RGV meter hanging system comprises a robot, a rack welding frame, a driving motor, a frequency converter and a current collecting arm, the current collecting arm is fixed below the rack welding frame, the robot and the driving motor are fixed on the rack welding frame, the frequency converter is fixed on the driving motor, and the robot RGV meter hanging system is characterized by further comprising a driving assembly, a guide wheel assembly and a visual code reader, and the two guide rails are fixed below the rack welding frame. The system is simple and ingenious in design, safe, reliable and high in stability, and the walking precision is greatly improved through a bar code positioning system.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD MARKETING SERVICE CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com