Novel seam welder rotary head device

A technology of rolling welding machine and rotating head, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of low walking and positioning accuracy, complex structure design, and low production efficiency, and achieve high walking and positioning accuracy, Stable and reliable work operation, the effect of improving work accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

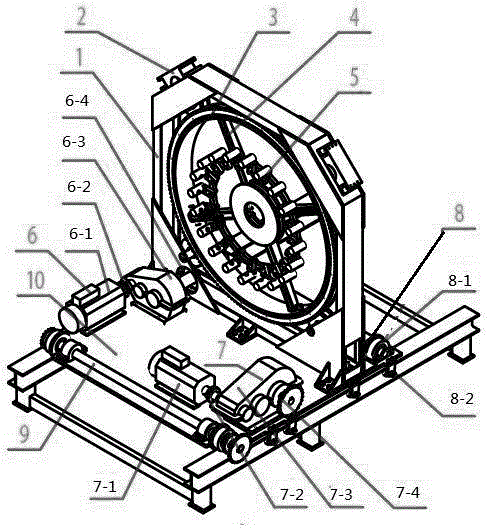

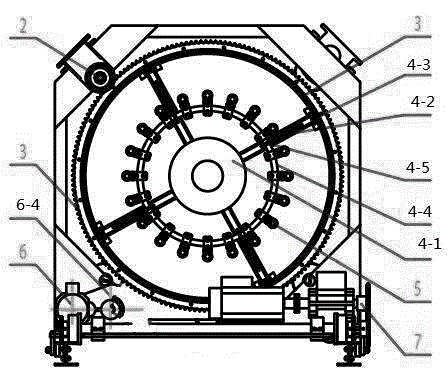

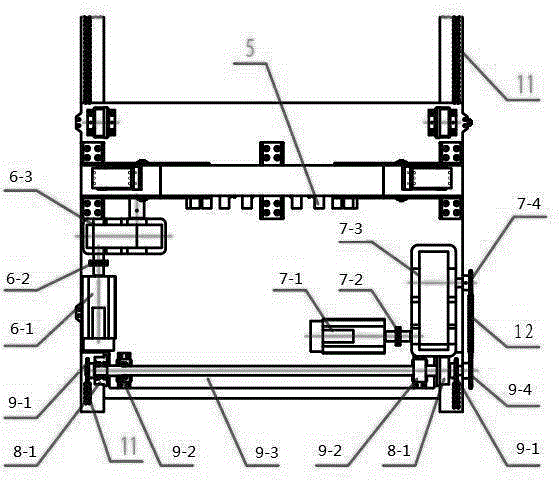

[0024] Such as figure 1 As shown, the present invention relates to a new type of rotary head device for a seam welding machine, including a moving head frame 1, a supporting wheel mechanism 2 is respectively fixed at four corners of the moving head frame 1, and a rotor 3 is fixed on the moving head frame at four corners 1, the rotor 3 has a moving head connecting plate 4 to reinforce the rotor mechanism 3, and the connecting plate 4 is surrounded by a plurality of steel bar fixing devices 5; the moving head frame 1 is fixed on the moving head base plate 10, and the moving head base plate 10 is installed Rotating power mechanism 6 and walking power mechanism 7 are arranged, and guide wheel mechanism 8 is installed on the movable head base plate 10, and its power can drive whole device to reciprocate on the guide rail by transmission mechanism 9.

[0025] Such as figure 2 As shown, the moving head frame 1 adopts a hexagonal design, that is, on the basis of the domestic general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com