Y-direction assembly of numerical control carving machine

A CNC engraving machine and assembly technology, applied in the field of Y-direction assembly, can solve the problems of guide rail torsion, improve driving accuracy, Y-direction jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment is applied to a 3D three-dimensional multifunctional numerical control engraving machine.

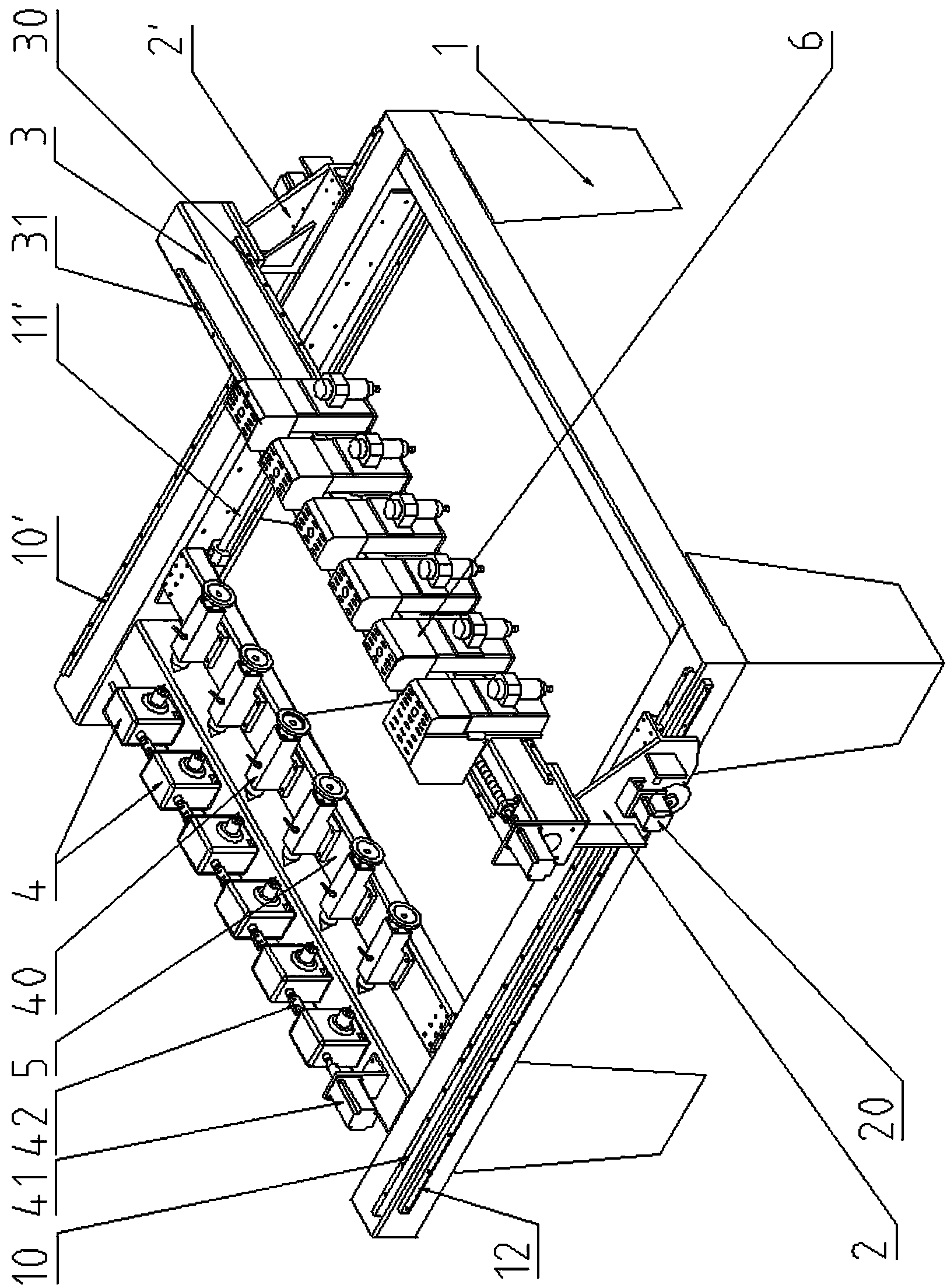

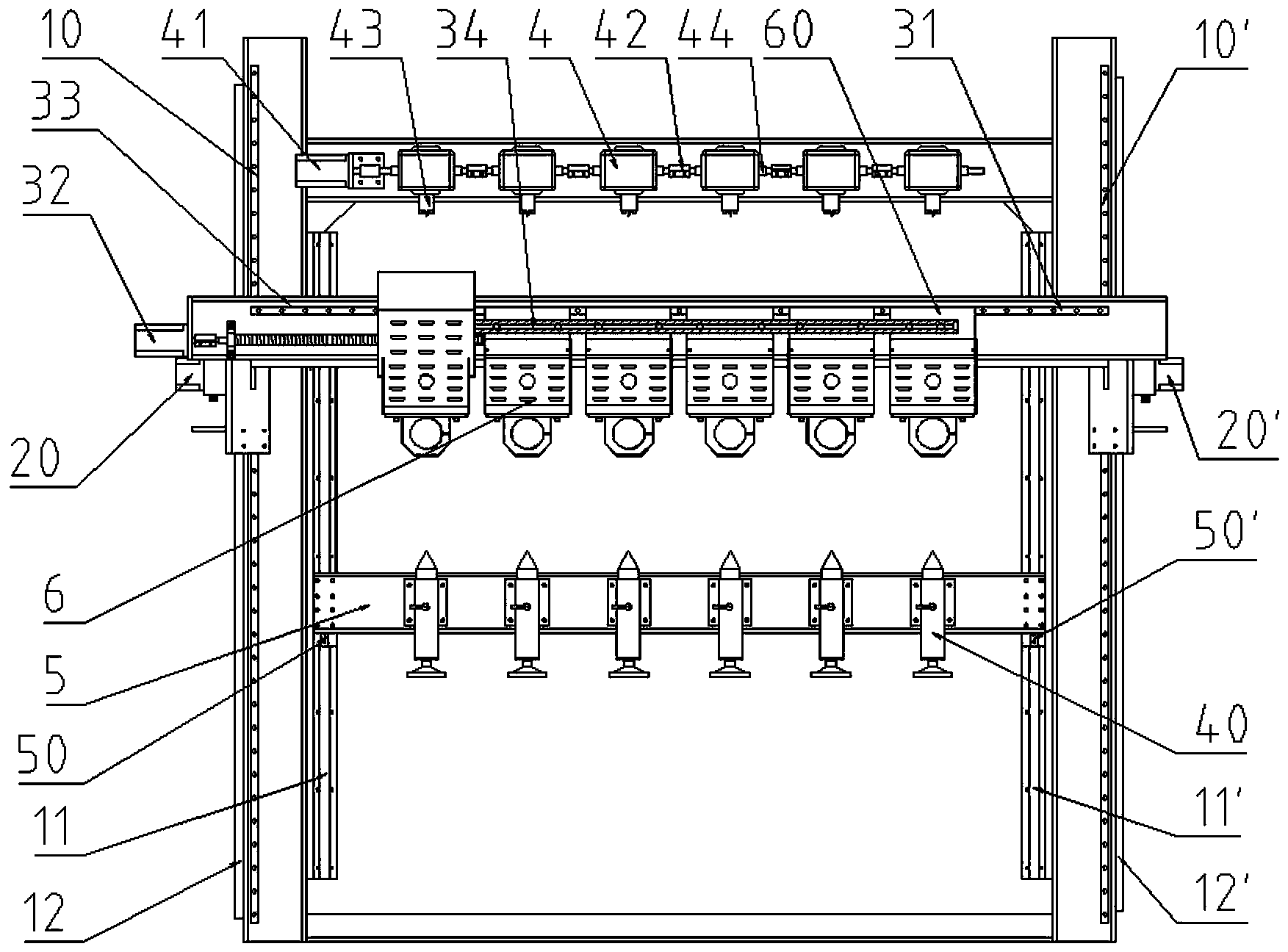

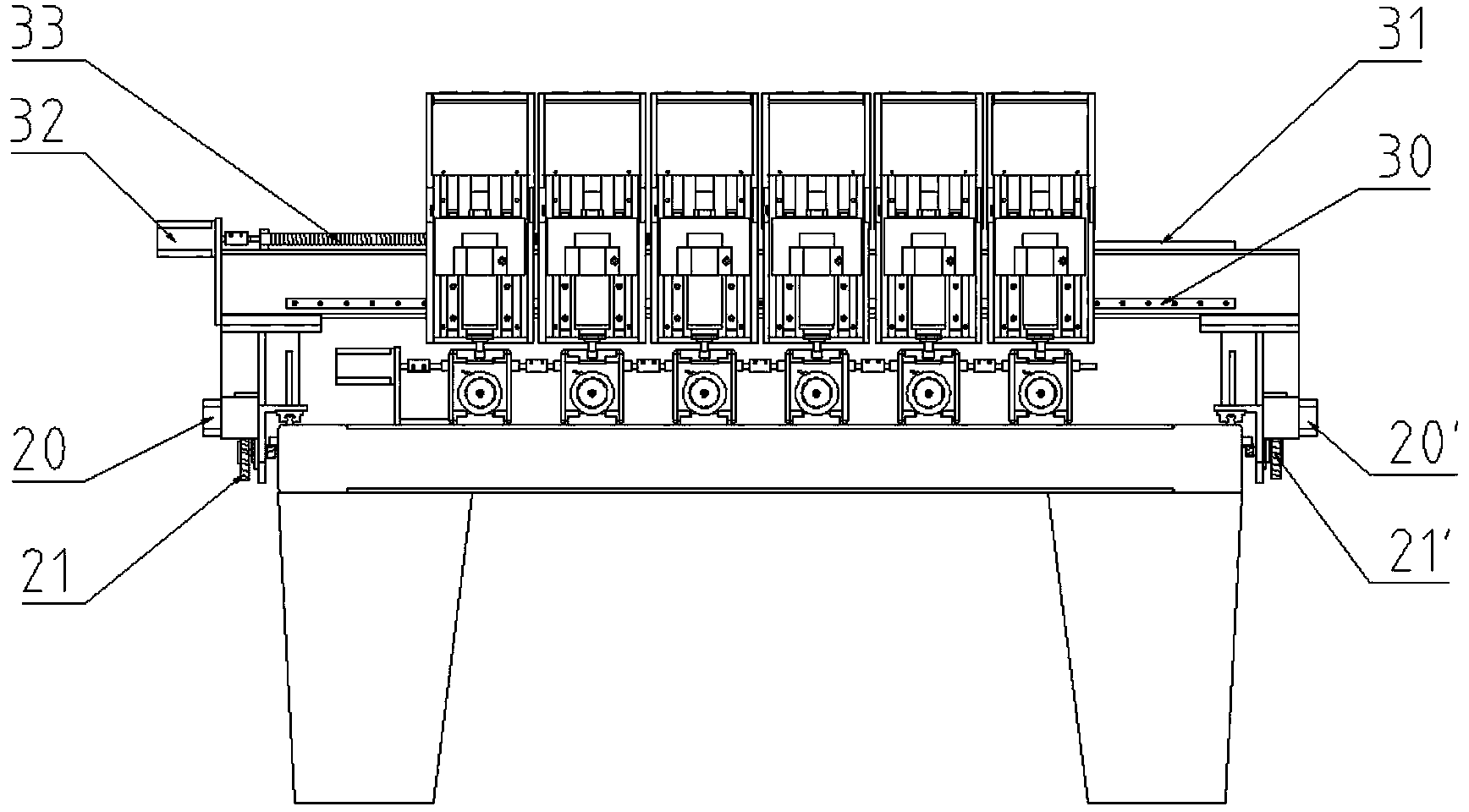

[0022] The 3D three-dimensional multifunctional numerical control engraving machine includes a bed body 1, and a left column 2 and a right column 2' are movably connected to the bed body 1 through the left guide rail 10 and the right guide rail 10'. The left column 2. There is also a Y-direction drive device between the right column 2' and the bed body 1, and a gantry 3 is set above the left column 2 and the right column 2', and a plurality of U is set on the bed body 1 below the gantry 3 Shaft clamping device; the U-axis clamping device includes a plurality of tailstocks 4 arranged at the end of the bed body 1, and a chuck 43 that can rotate by itself is arranged in the tailstock 4, and a plurality of chucks 43 that match the The thimble 40; the main shaft of the chuck 43 is in transmission connection with the chuck driving device; the inner side of the bed body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com