Patents

Literature

53results about How to "Minimum energy loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

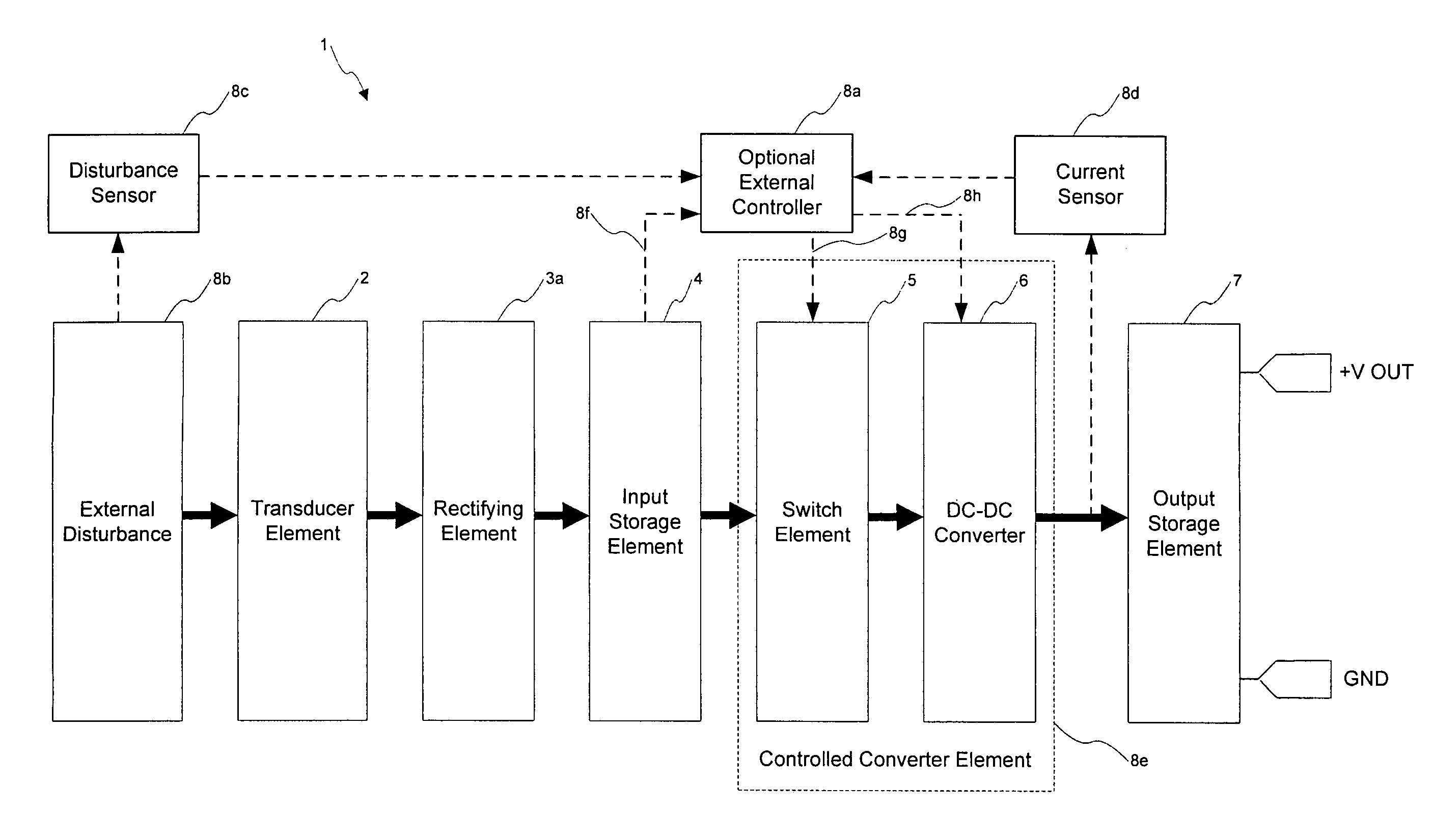

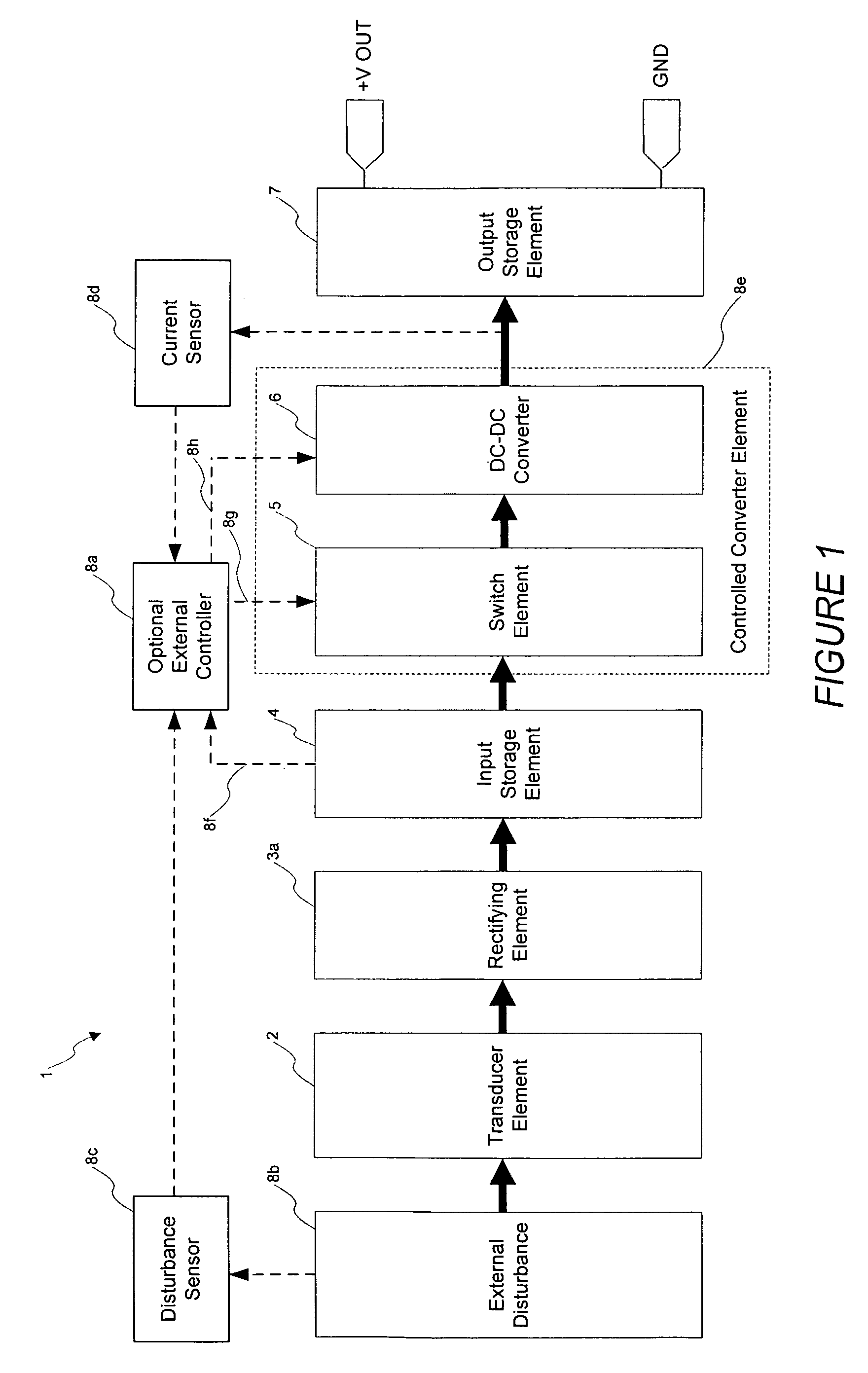

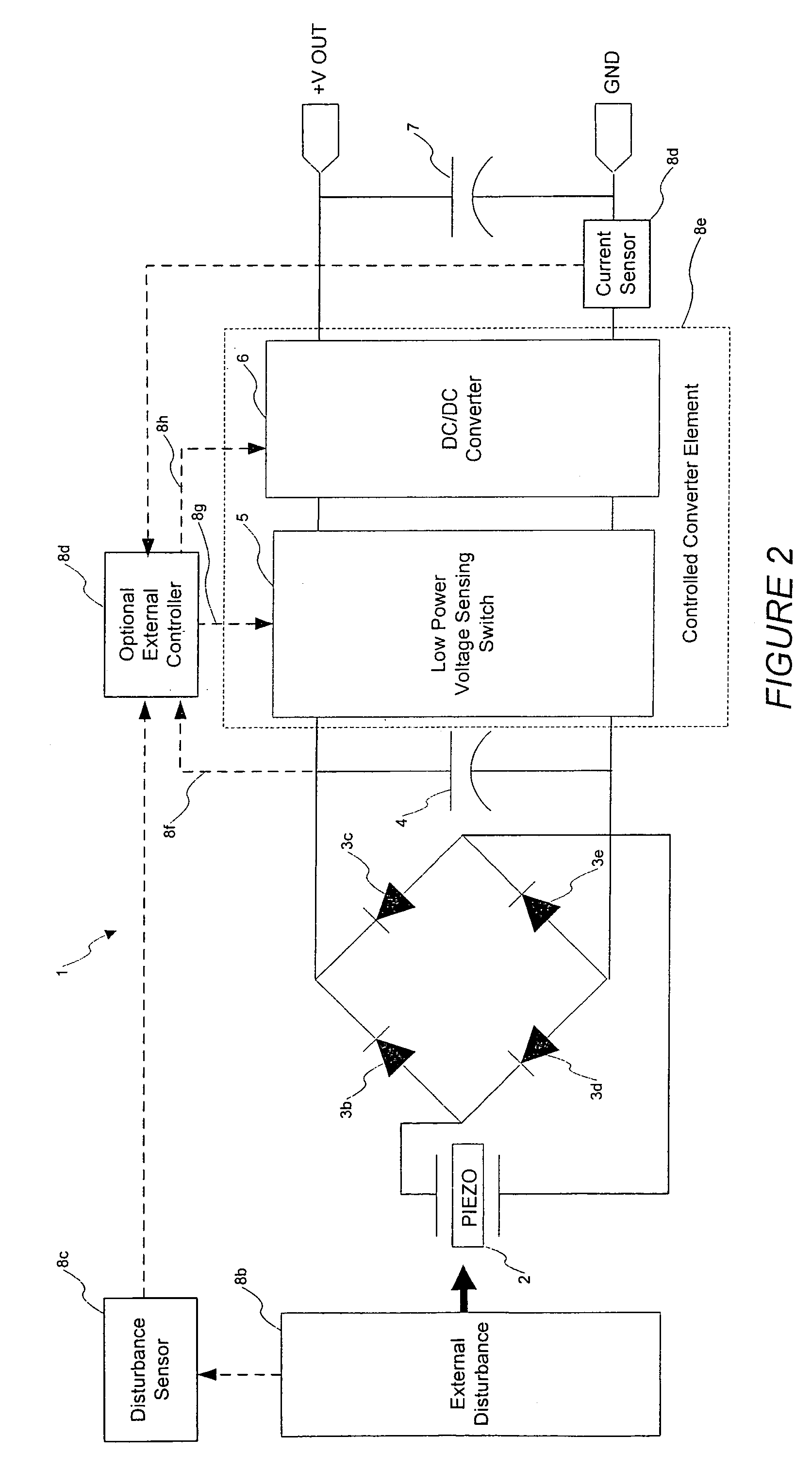

System for optimal energy harvesting and storage from an electromechanical transducer

ActiveUS7105982B1Efficient HarvestingEfficient storagePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesStored energyMechanical energy

A device for collection of energy from mechanical disturbances and distribution of that energy to an electrical load. A transducer converts mechanical energy in the form of forces and displacements into electrical energy in the form of charge pulses. The charge pulses are rectified into a Direct Current (DC) power signal and accumulated and stored in an input storage element. A controlled conversion circuit assures that the voltage on the storage element is maintained within a predetermined optimal range for energy harvesting from the transducer, avoiding the application of peak voltages. The controlled conversion circuit can be hard wired and / or controllably adjustable to match a given disturbance characteristic. Only when the voltage is within the optimal range for a given type of disturbance will the controlled conversion circuit enable a DC / DC converter to further convert the stored energy to a voltage that is coupled to an output storage element. This technique optimizes power conversion by controlling the high voltage to low version conversion process by, for example, sensing the disturbance with external sensor or internal voltage of the system, and then using this information about the disturbance to control how and when the electrical conversion process will occur.

Owner:POLATIS PHOTONICS INC

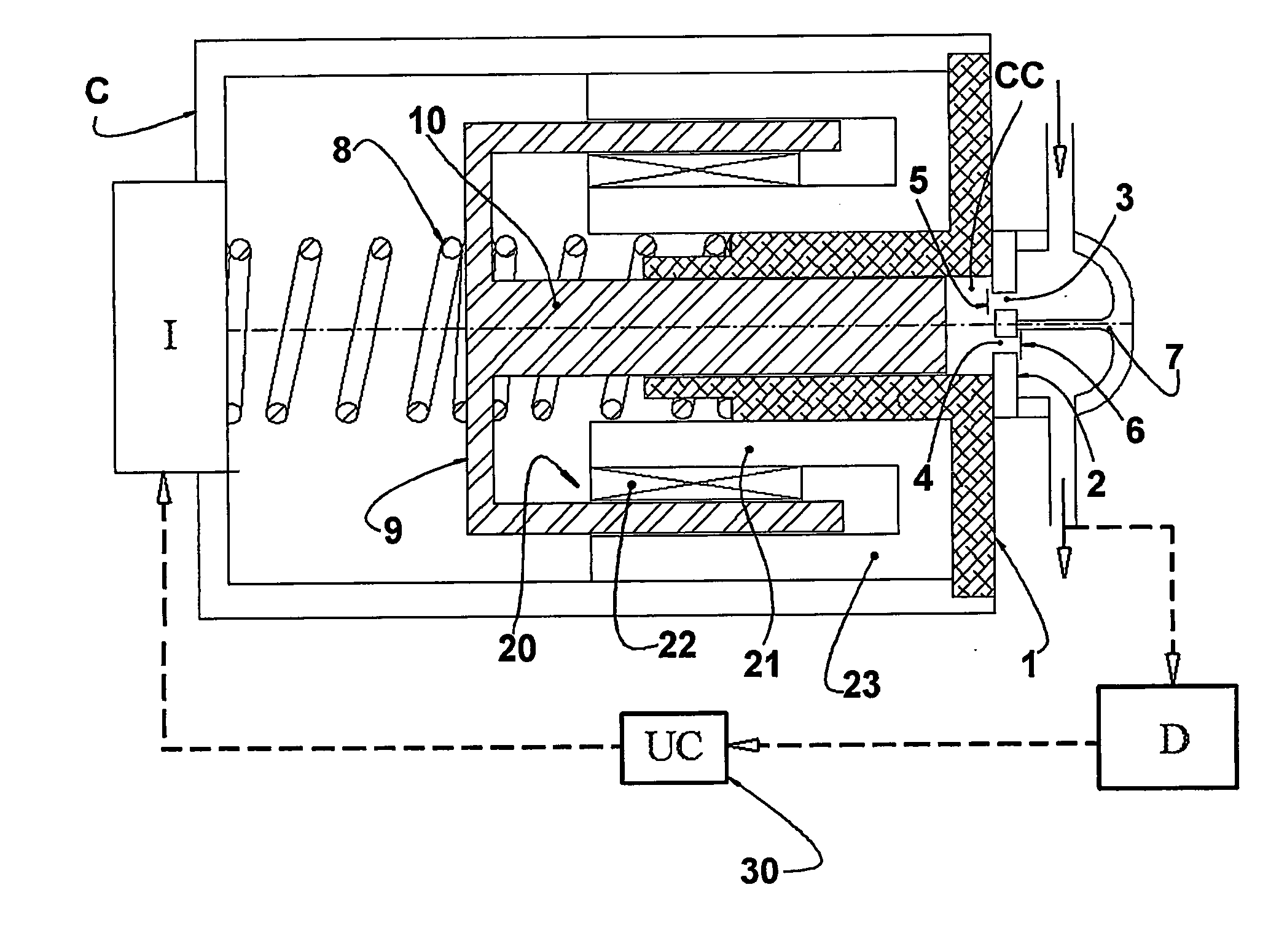

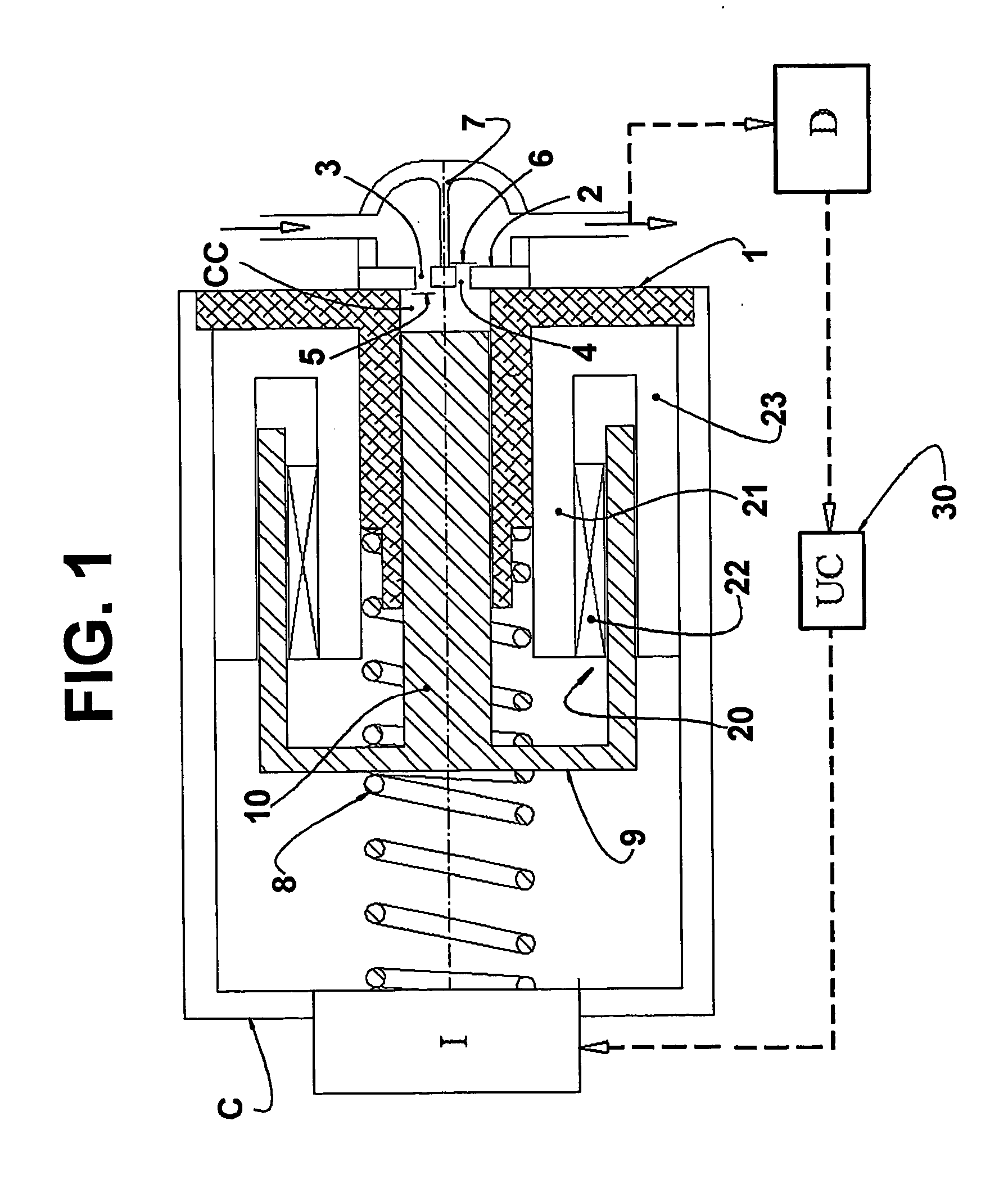

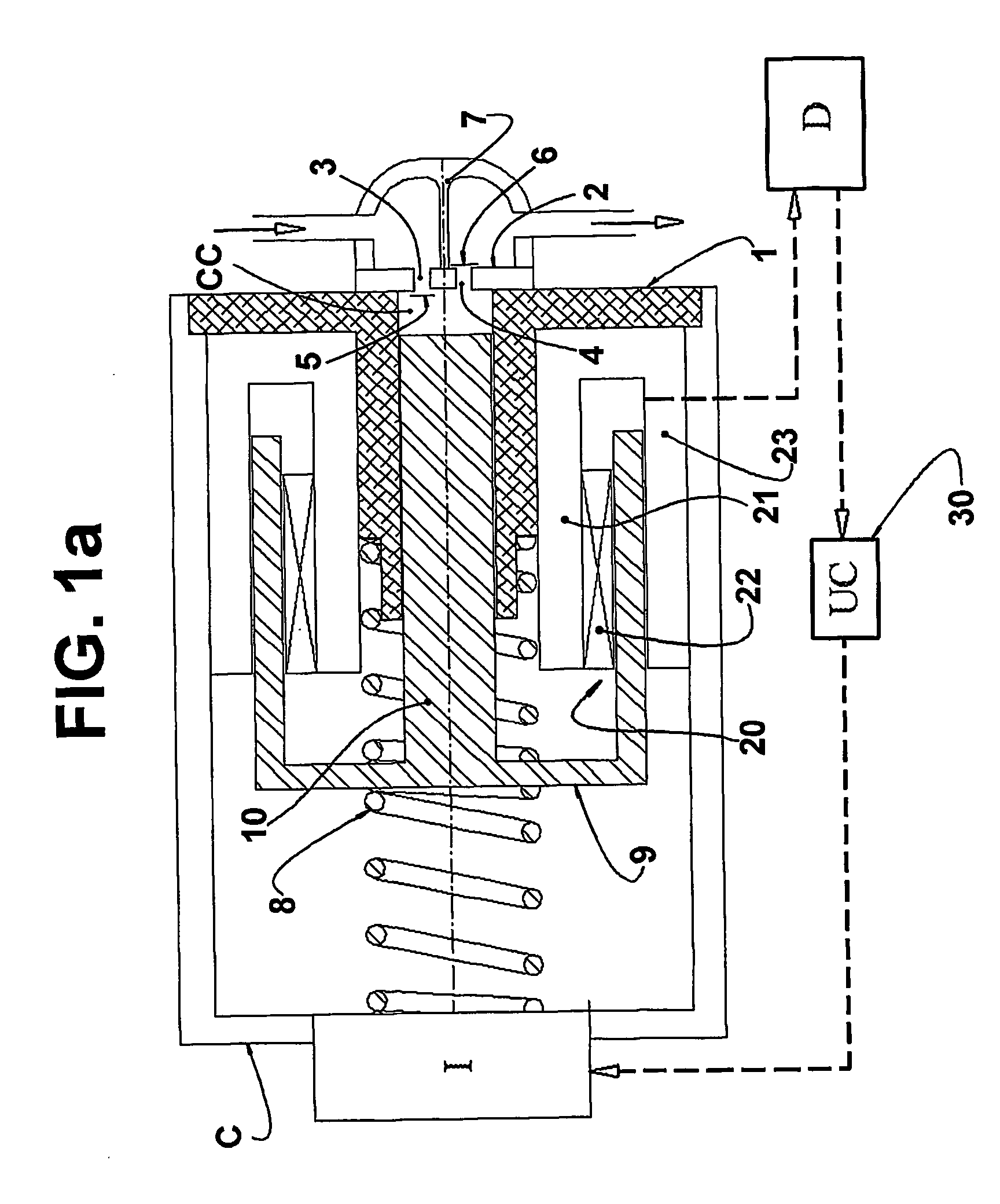

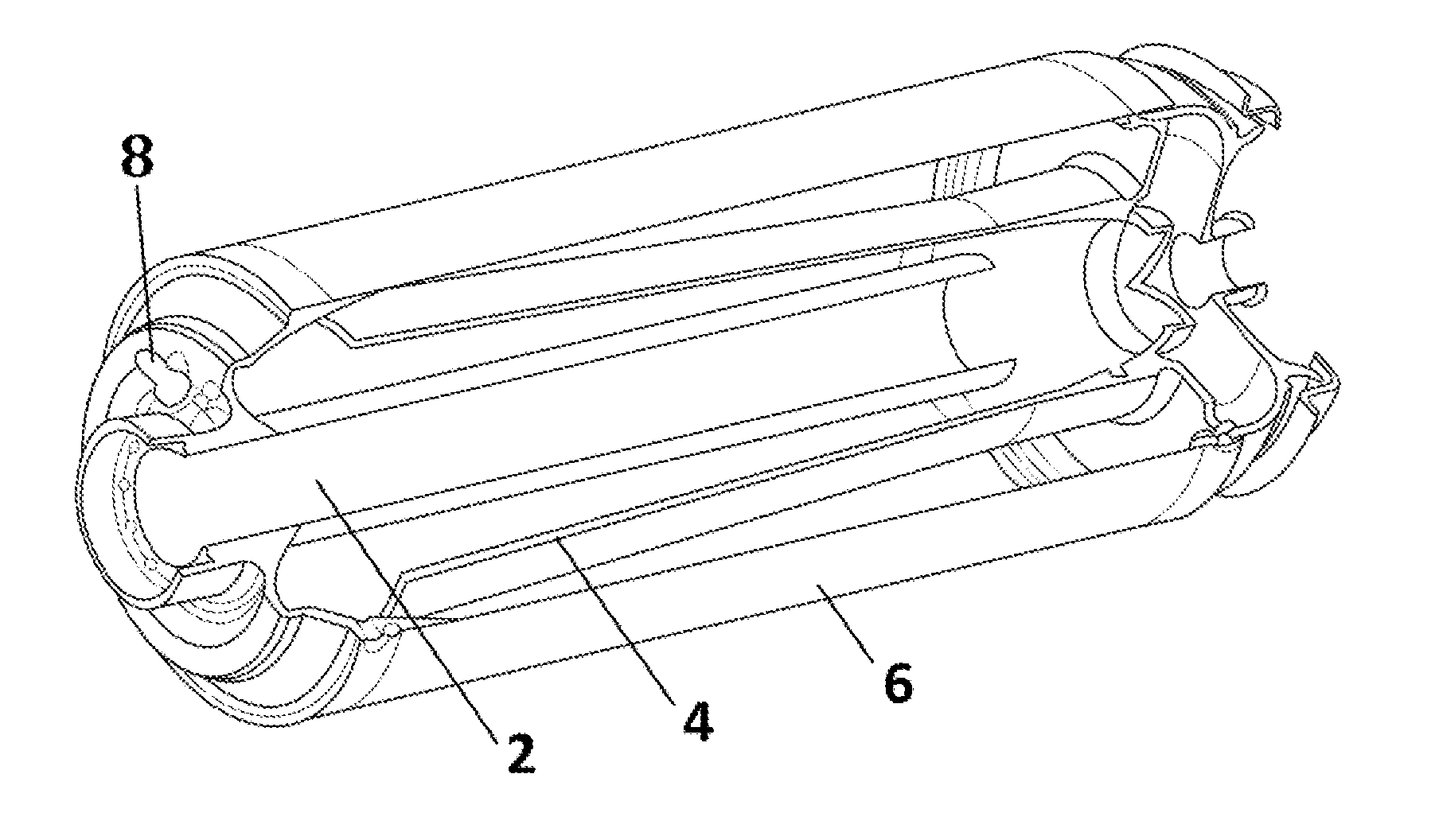

System for adjusting resonance frequencies in a linear compressor

InactiveUS20060110259A1Low costIncreased energy lossFluid parameterPositive displacement pump componentsReciprocating motionLinear compressor

A system for adjusting resonant frequencies in a linear compressor comprising, in the interior of a shell: a linear motor: a cylinder; a piston reciprocating inside the cylinder; and an actuating means operatively coupling the piston to the linear motor, said system comprising: a detecting means to detect a load imposed to the linear motor, in an operational condition of the latter related to the gas pressure in the discharge thereof; and a frequency adjusting means operatively associated with the detecting means and with the resonant assembly, in order to define, as a function of said operational condition, a frequency adjustment, by varying at least one of the values related to the mass of the resonant assembly and to the average stroke of the piston, to a value of the mechanical resonance frequency corresponding to the electrical supply frequency.

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

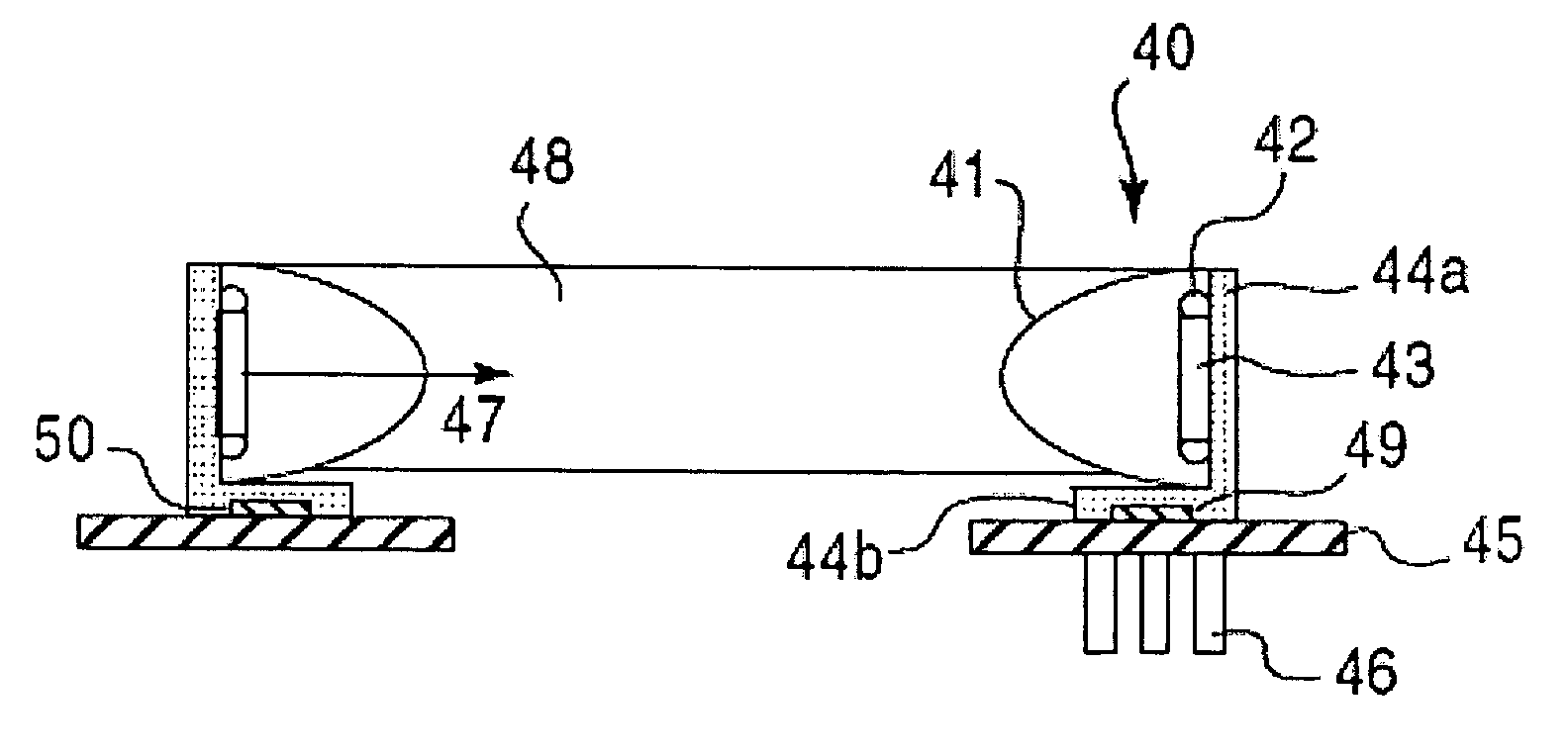

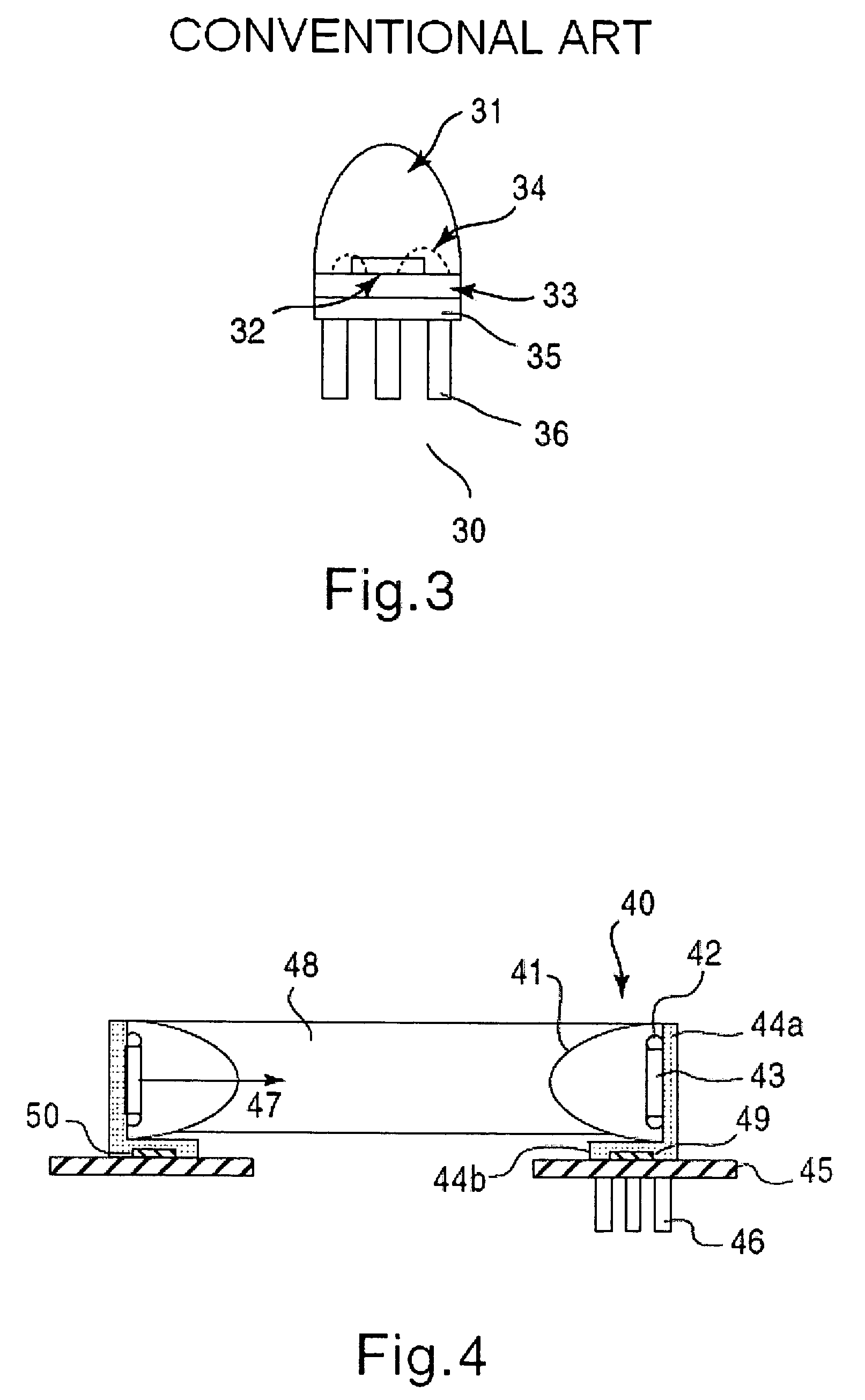

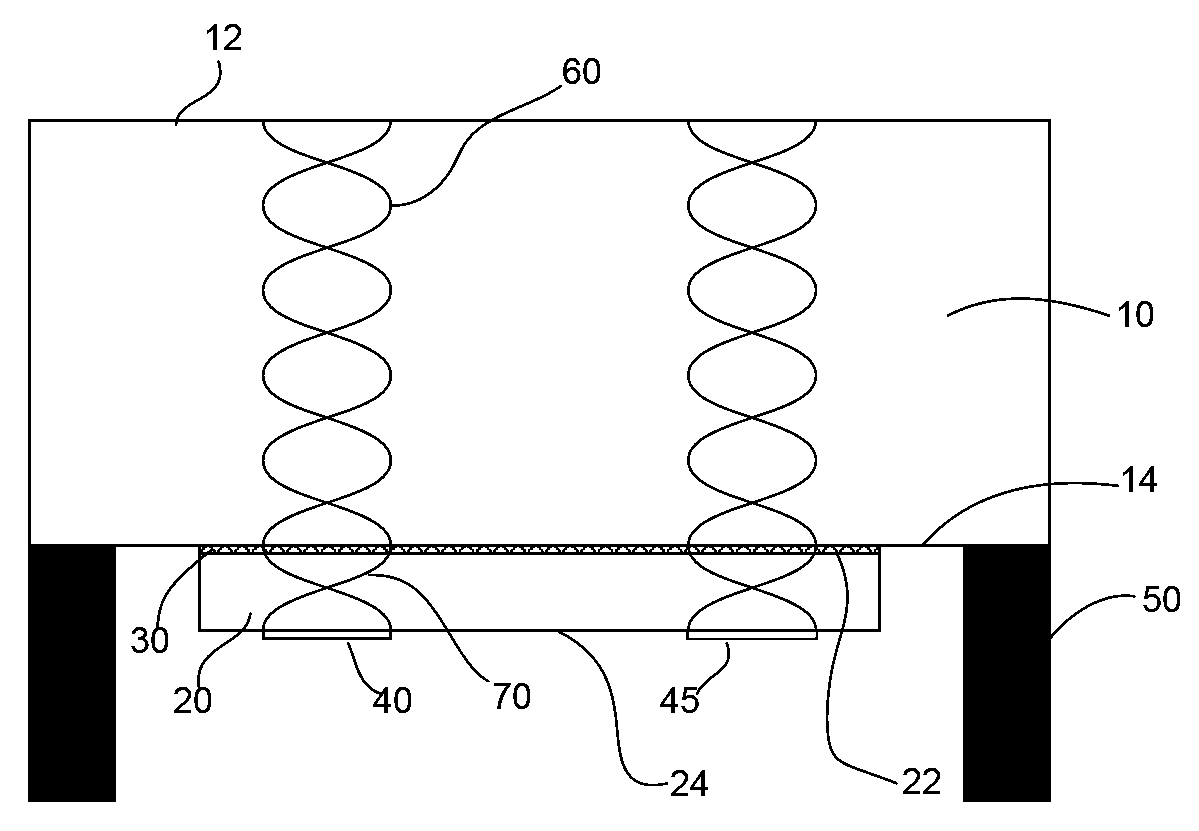

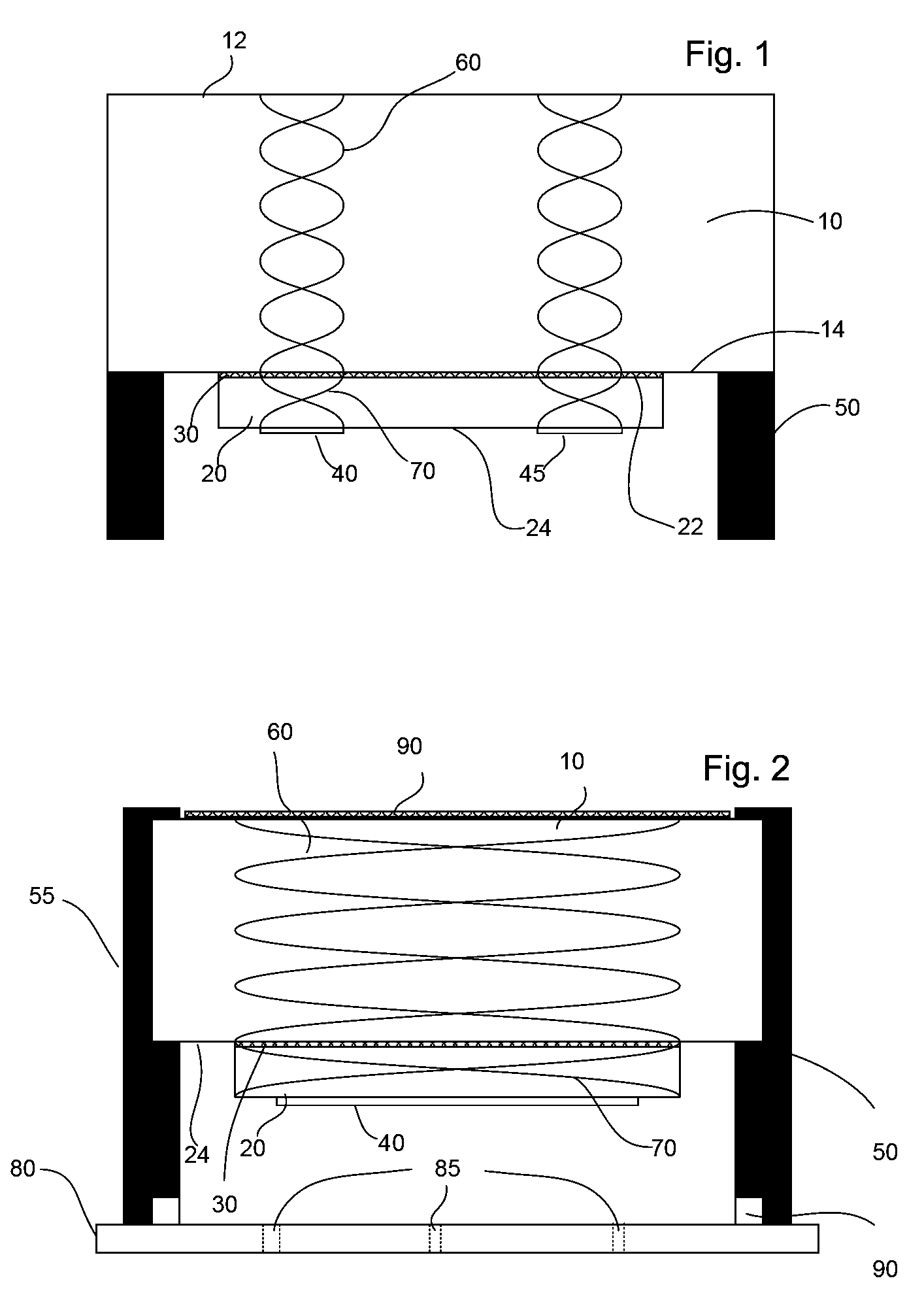

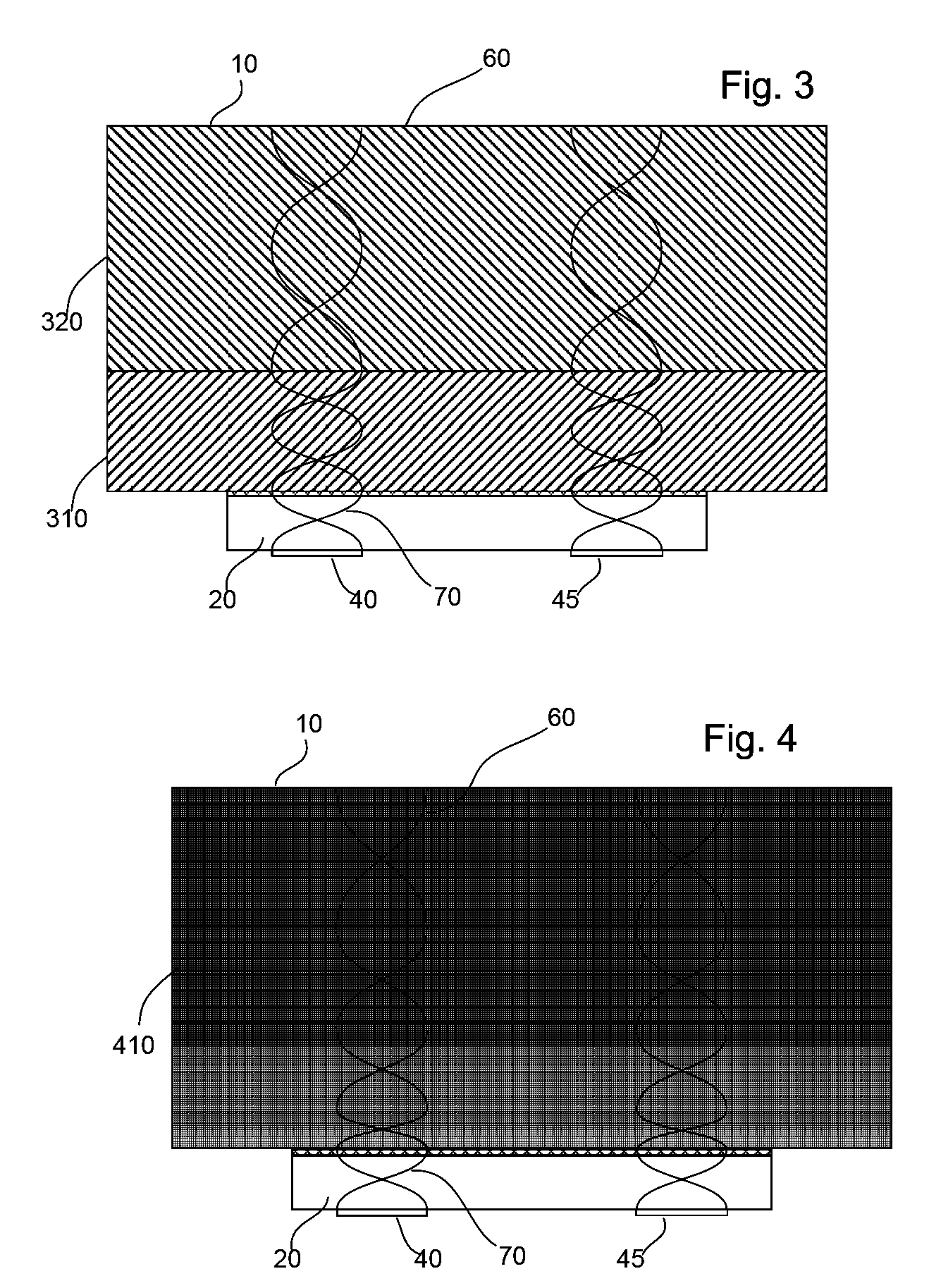

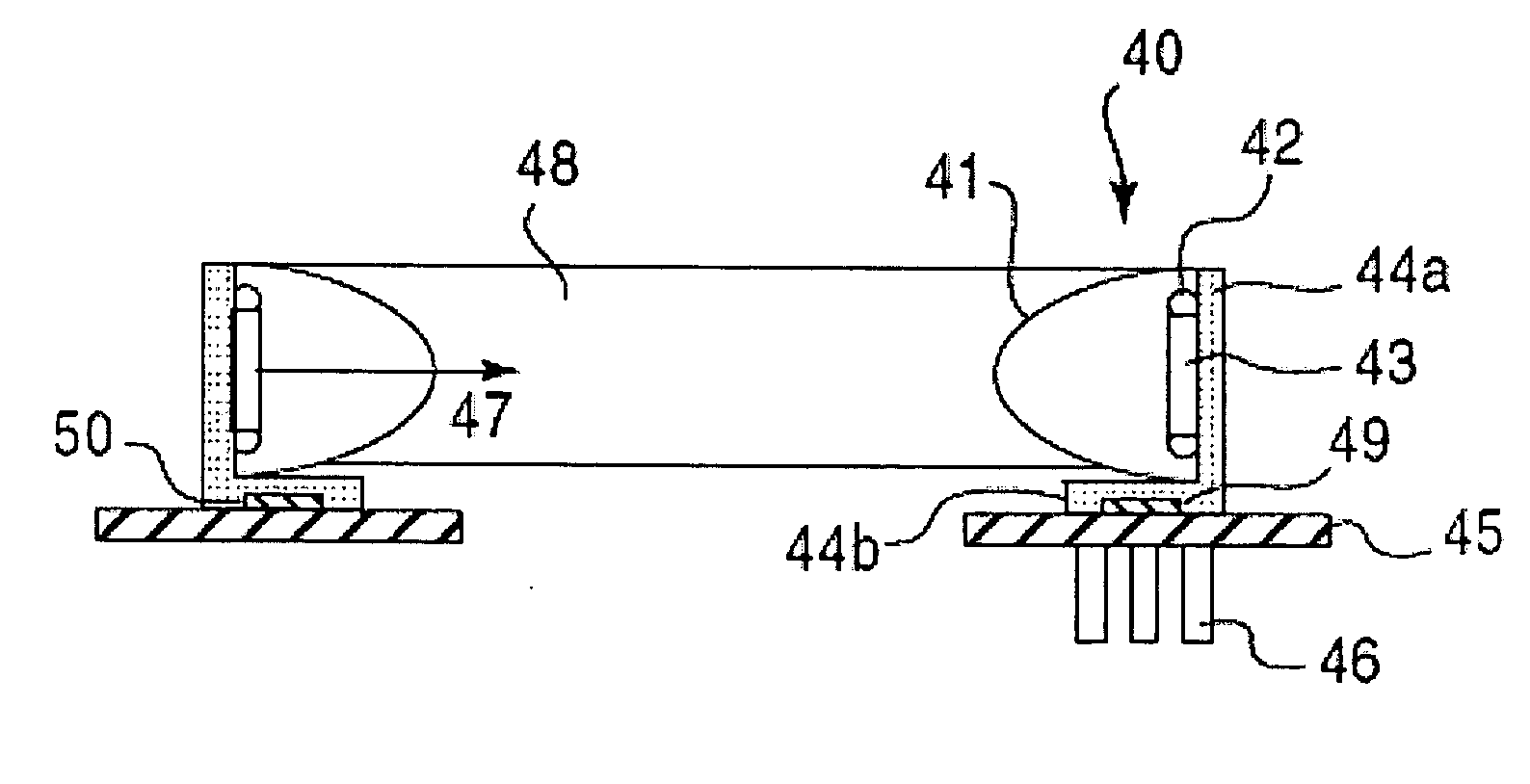

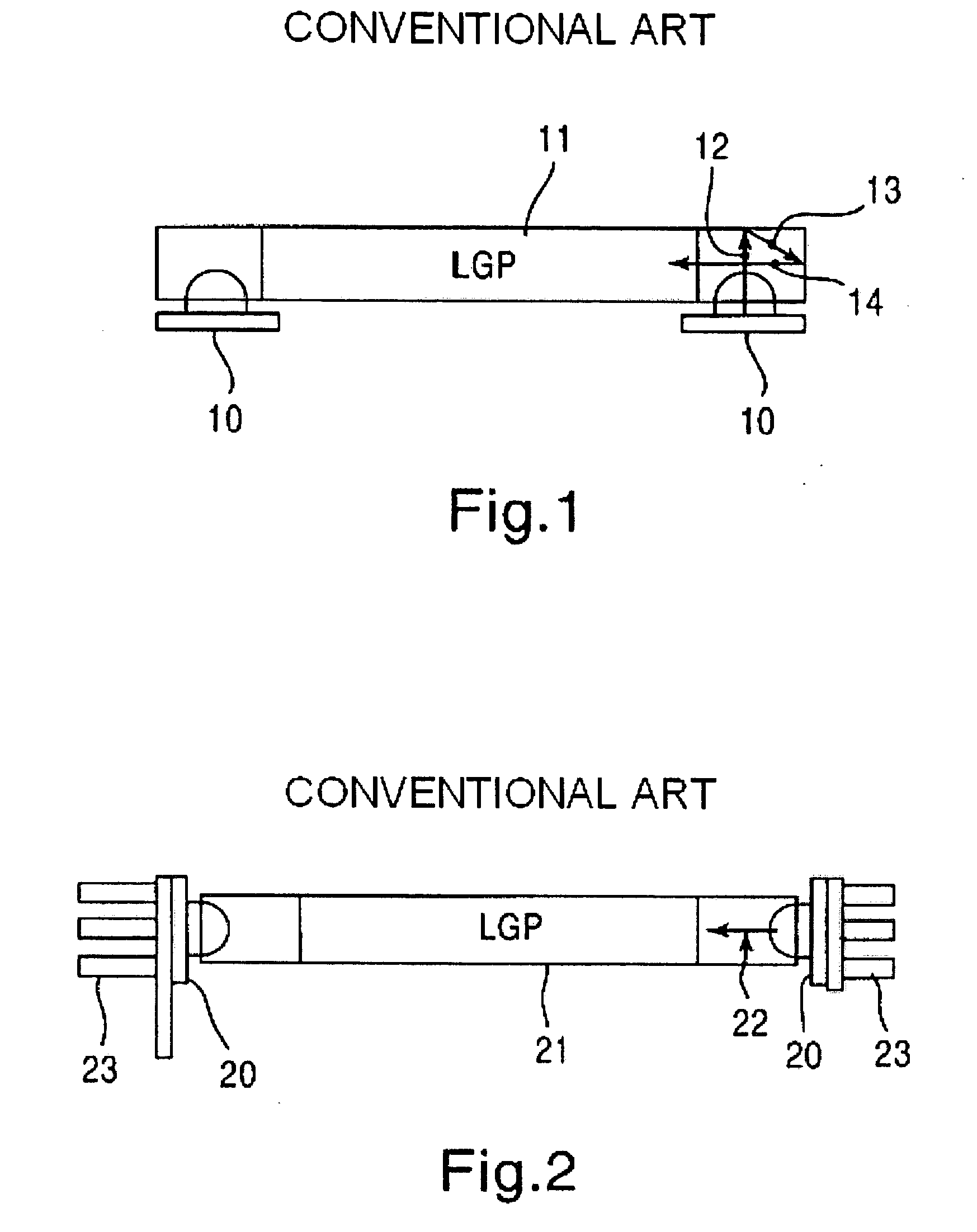

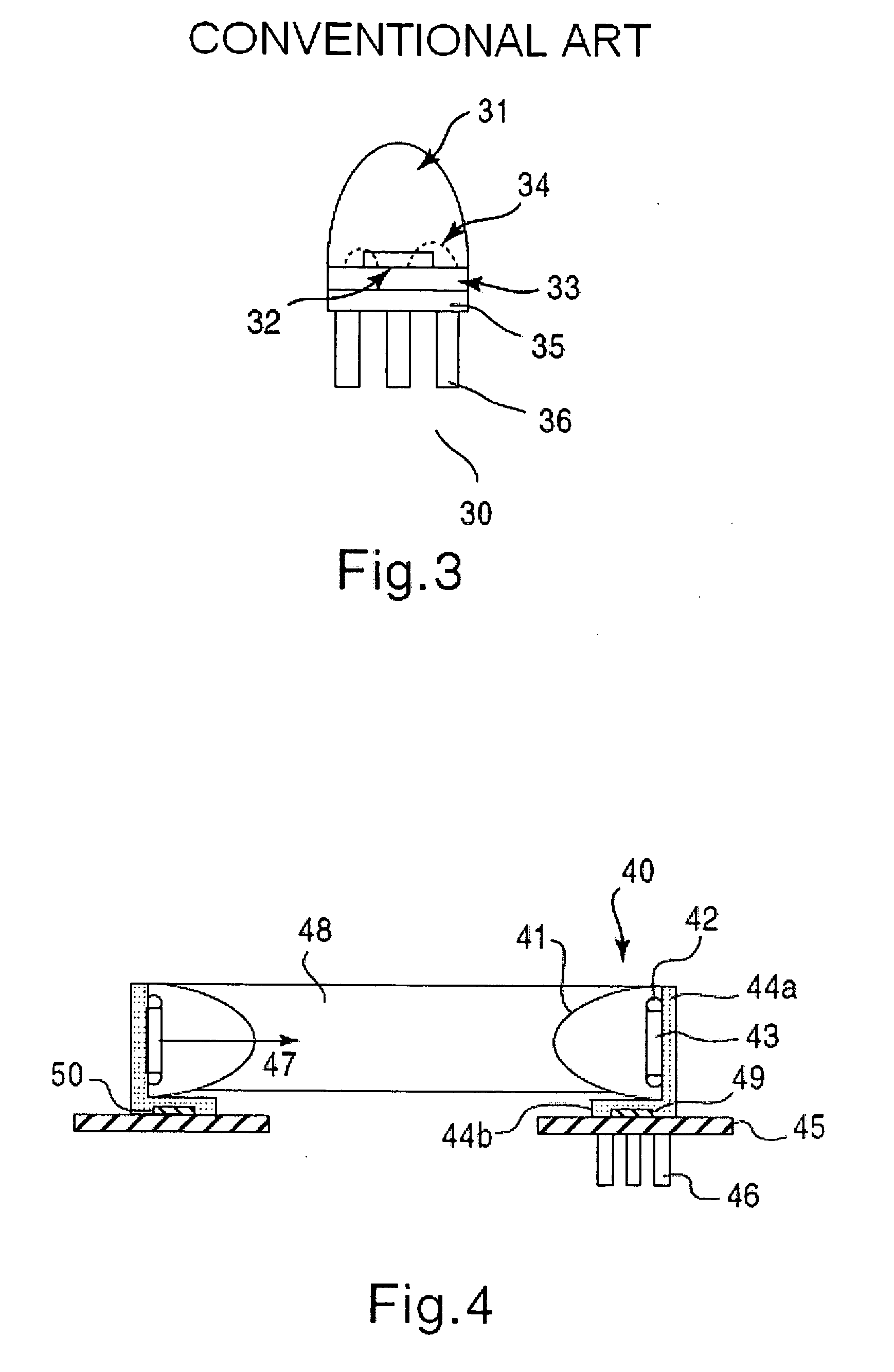

Light emitting diode backlight package

ActiveUS7168842B2Minimum energy lossOptimizing travel pathLighting heating/cooling arrangementsSolid-state devicesLight guideEngineering

In a light emitting device including a transparent covering, a fastener having a vertical member and a horizontal member, a light-emitting chip disposed on one face of the vertical member and encased by the transparent covering, a circuit board disposed on one face of the horizontal member, at least one conductive means connecting the light-emitting chip to the circuit board, and at least one heat-dissipating plate perpendicularly disposed on the other face of the horizontal member, light may be emitted longitudinally along a light-guiding plate, thus optimizing the travel path of the emitted light, while maintaining a compact shape by enabling placement of the printed circuit board and heat dissipating plates away from a longitudinal axis of the light-guiding plate.

Owner:OPTRONIC SCI LLC

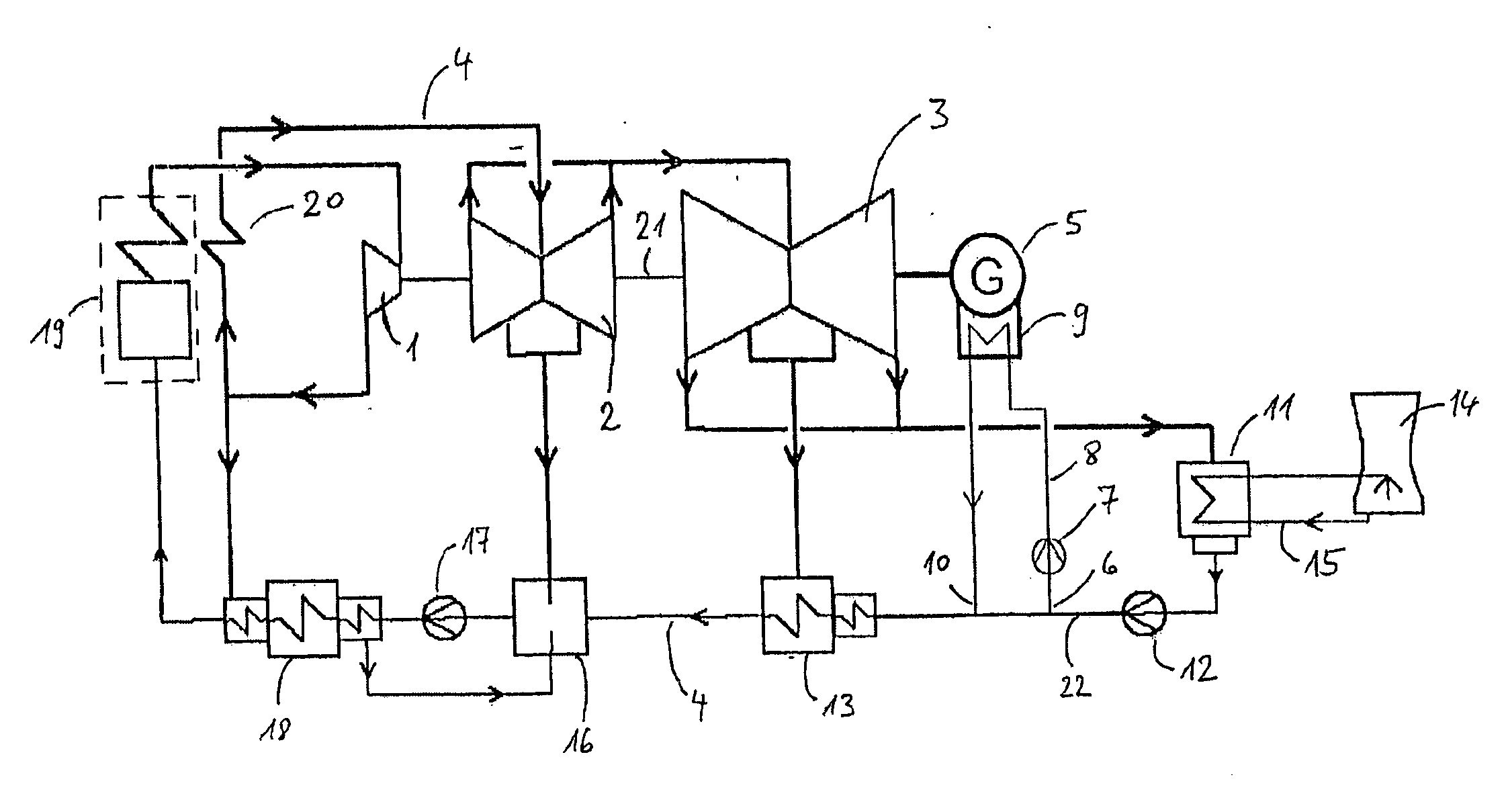

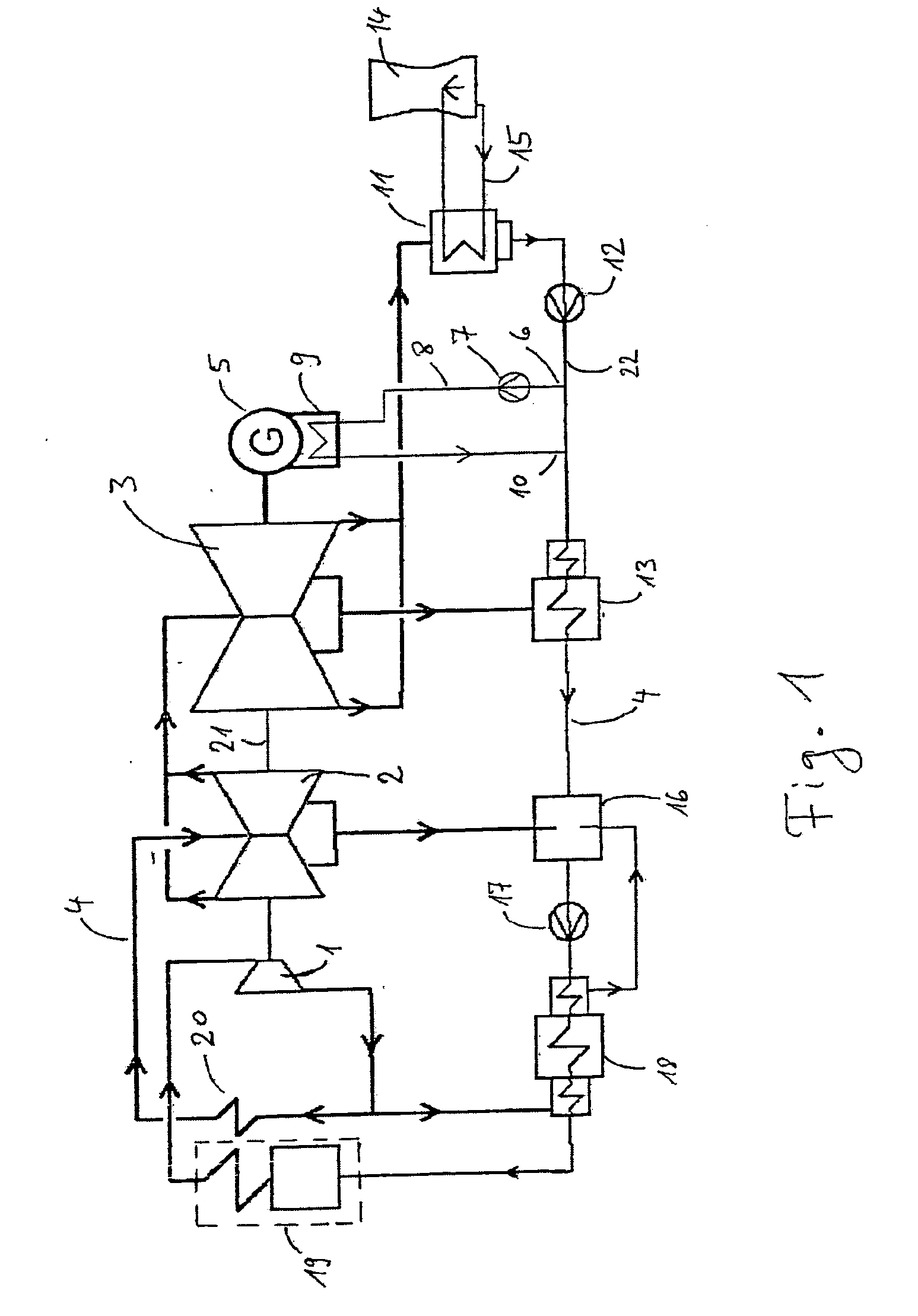

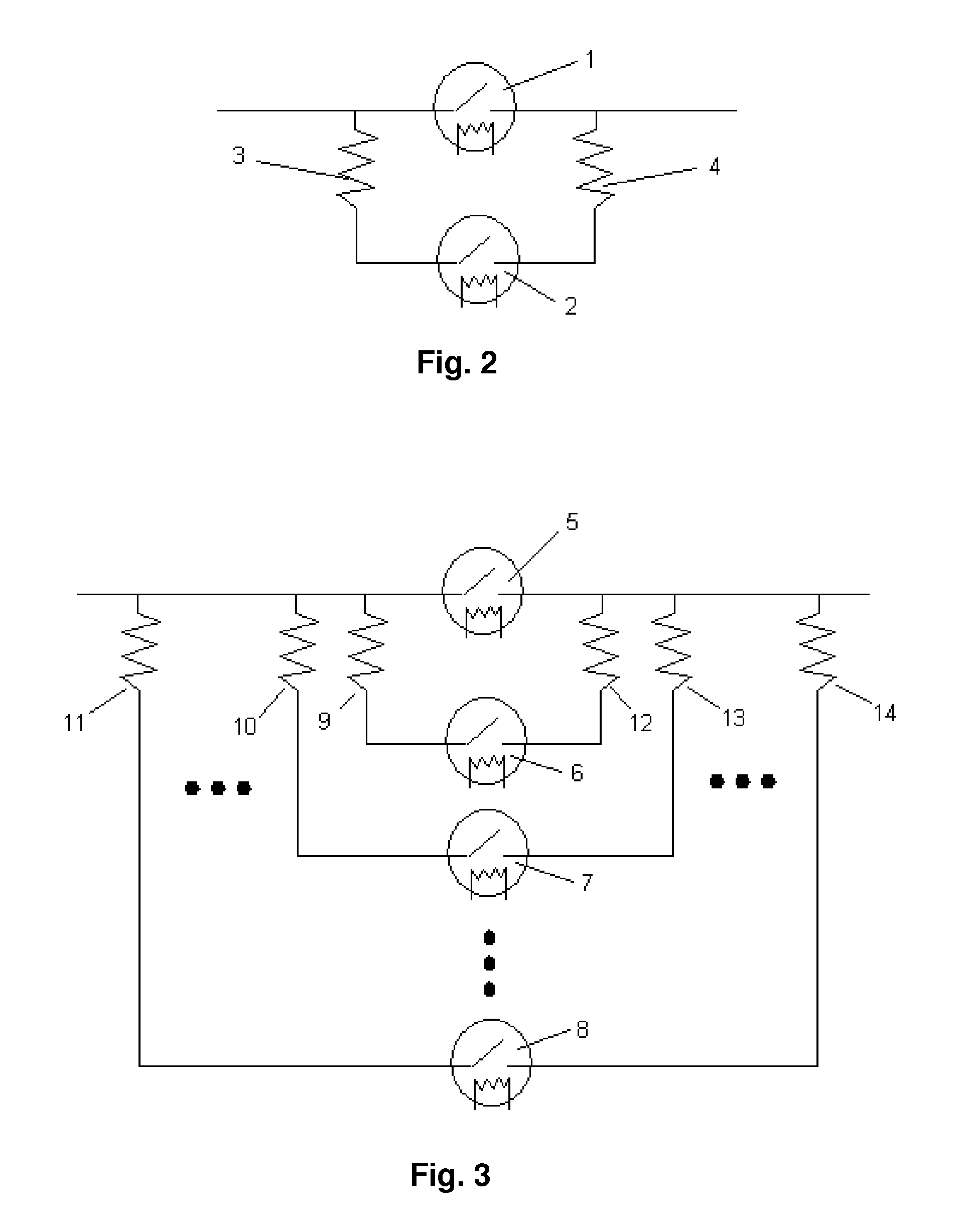

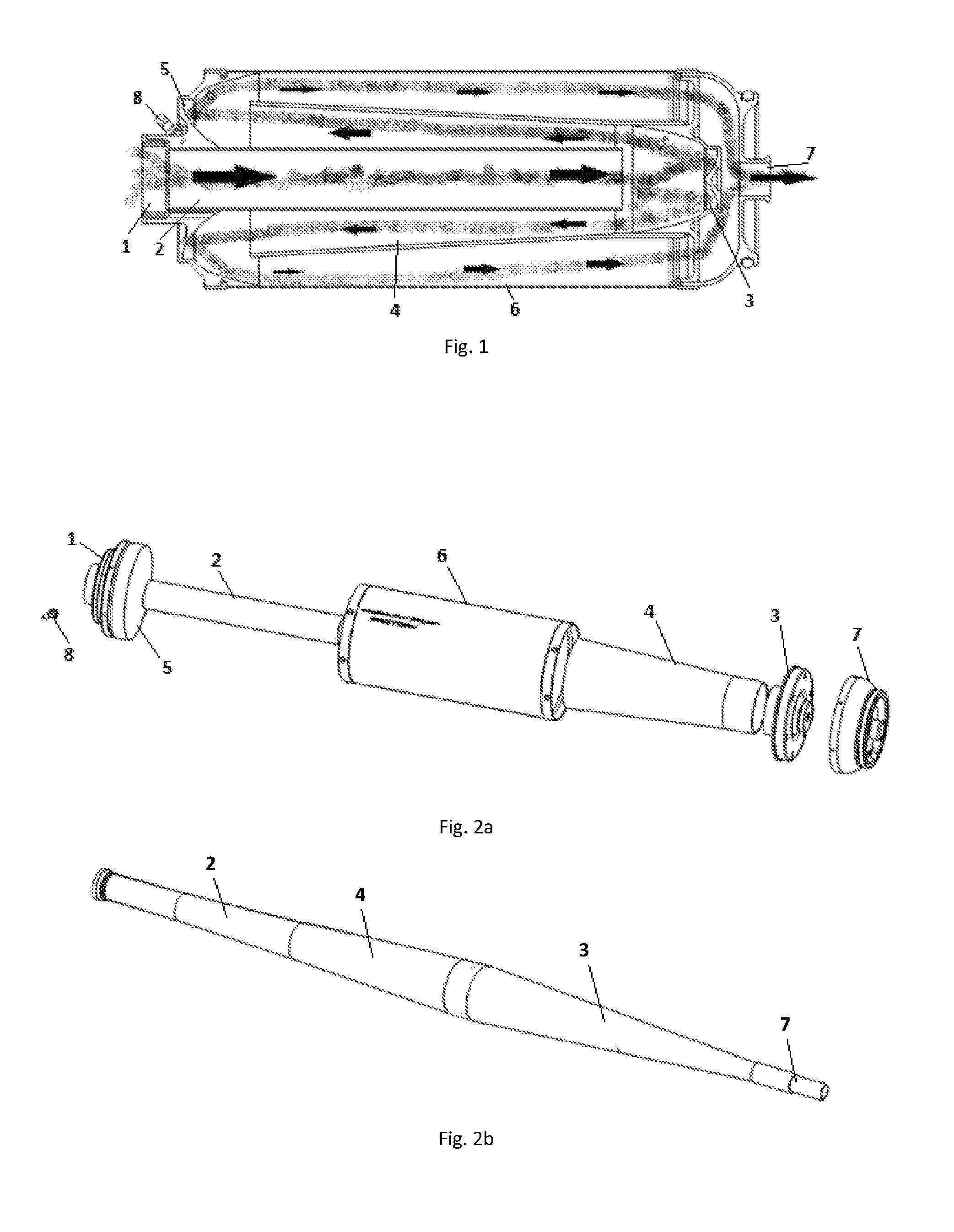

Thermal power plant

InactiveUS20060185366A1Improve thermal efficiencyMinimum energy lossSteam engine plantsAutomotive engineeringElectric generator

The invention relates to a thermal power plant including a turbine (1, 2, 3) operated using at least one water-steam-loop (4), and a generator (5) driven by said turbine (1, 2, 3). According to the present invention, means (6, 7, 8, 9, 10) for cooling said generator (5) are provided, which means (6, 7, 8, 9, 10) are de signed for extracting condensate from said water-steam-loop (4), transporting it to said generator (5) and returning it into said water-steam-loop (4).

Owner:SIEMENS AG

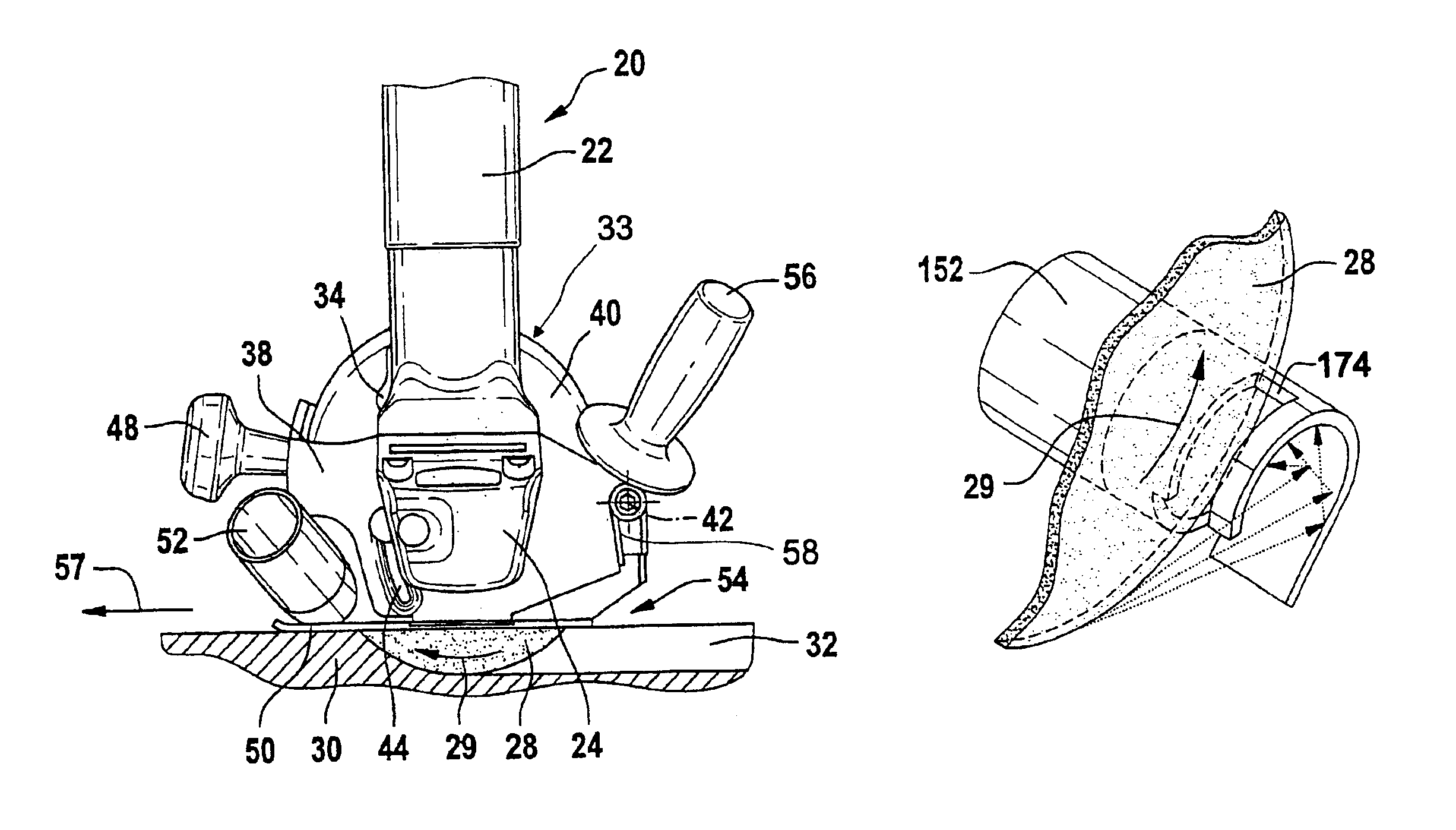

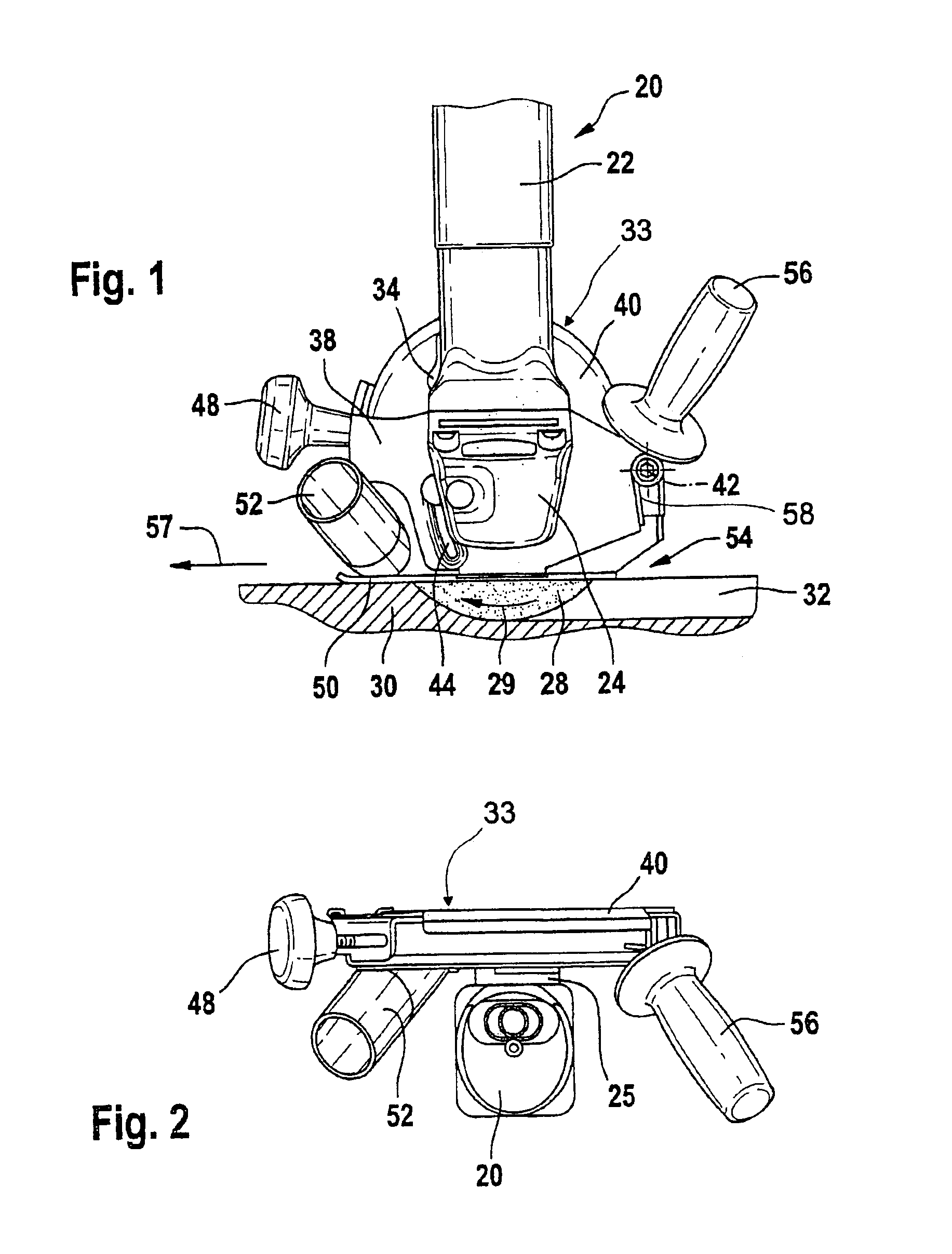

Protective device for a hand machine tool

InactiveUS6878050B2Cross sectionFacilitate entryPortable grinding machinesMaintainance and safety accessoriesPower toolEngineering

The invention is based on a guard device (33) for a power tool, in particular for a sanding power tool, having a protective cover (40) that is provided to at least partially encompass a disk-shaped, rotating tool, and having a dust removal tube (52), the longitudinal axis of which is located at an angle of up to 80° to the axis of rotation of the tool.It is proposed that part of the dust removal tube (52) passes through the plane of a flat side of the tool.

Owner:ROBERT BOSCH GMBH

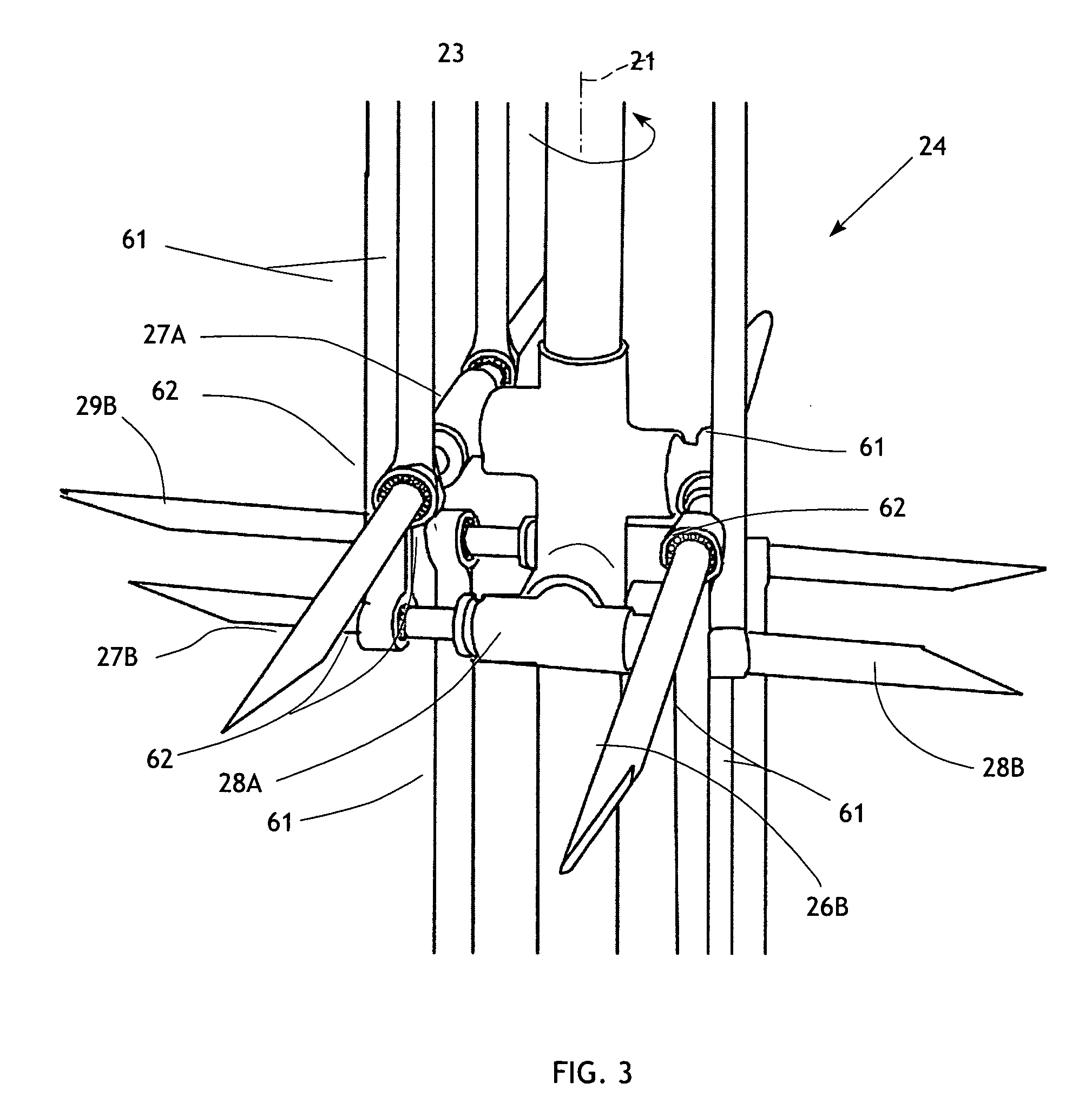

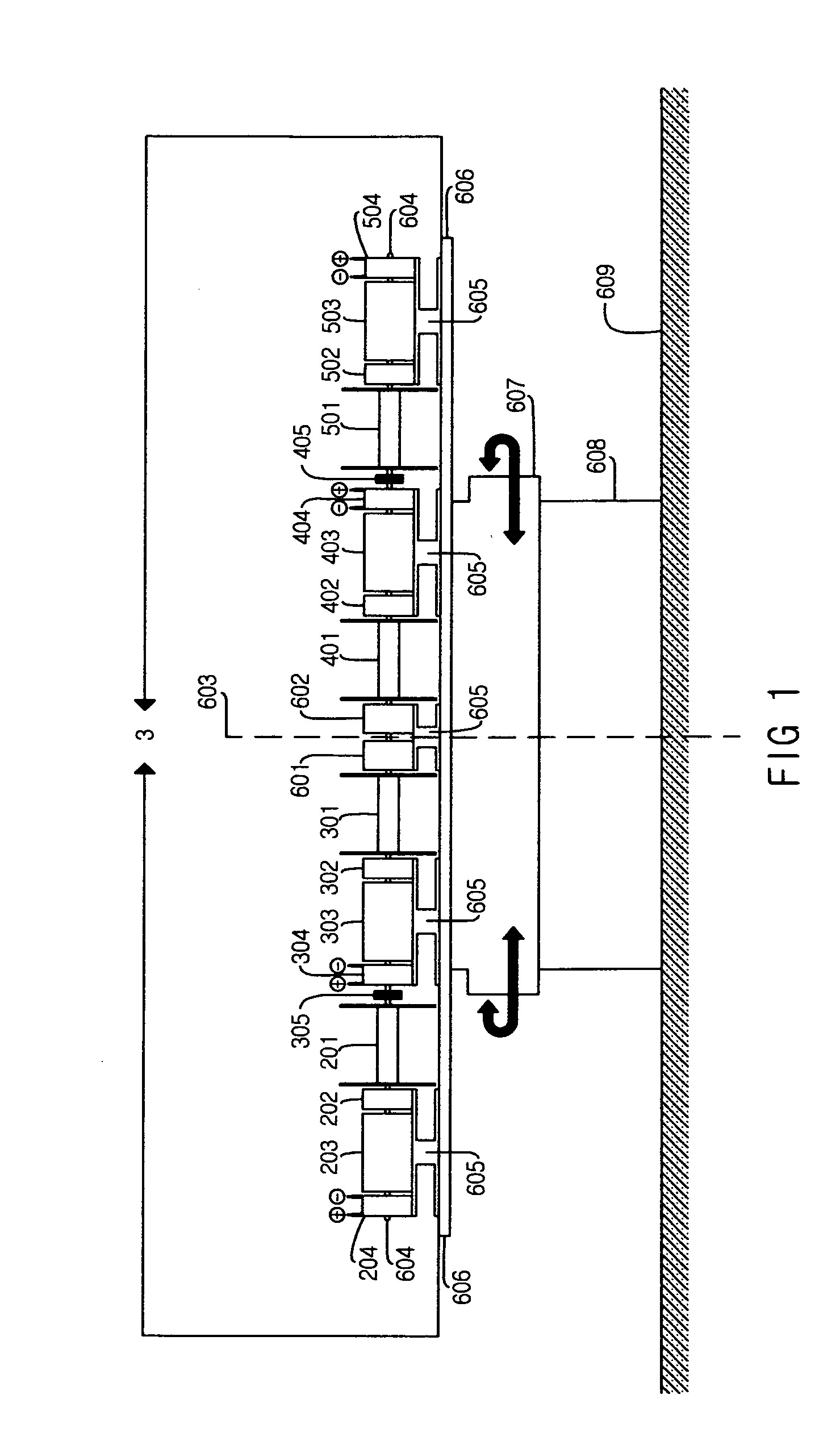

Wind turbine generator and motor

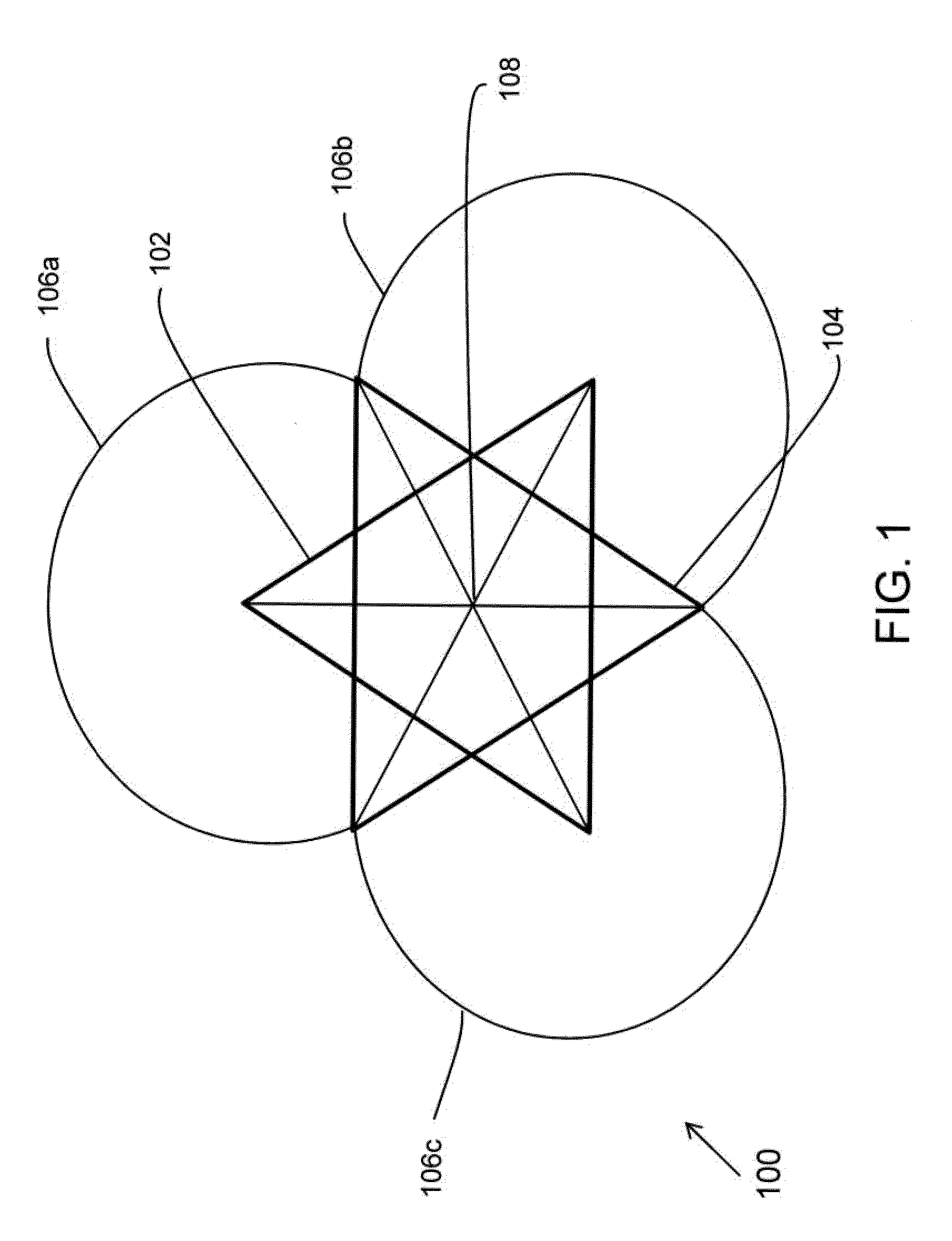

ActiveUS20100181777A1Minimum energy lossEasy to repositionPropellersPump componentsIn planeDrive shaft

A wind turbine includes a quartet of pivot shafts that are in paired parallel relationship and transversely mounted on a central drive shaft. each pivot shaft supports a pair of wings at opposed ends thereof, the wings offset by 90°. Each pivot shaft rotates cyclically through 90° to move each wing from a wind-engaging orientation (drive position) in which the wing presents a flat surface approximately transverse to the incident wind, to a minimum drag position (glide position). In addition, the two wings of each pair on a shaft are disposed in planes that are offset by approximately 90° about their pivot shaft, so that one is in the drive position while the other is in the glide position. The wings of each pair of pivot shafts have wings at the ends thereof that open into the drive position at the same time and rotational angle of the turbine. A backstop at the site of each drive position supports the wind load and transfers its force to the central drive shaft.

Owner:GRIGG CHARLES

Asymmetric Composite Acoustic Wave Sensor

InactiveUS20100052470A1Easy to operateImprove dynamic rangePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersAcoustic wavePeak value

A composite acoustic wave device provides improved protection from environmental factors while maintaining high electrical characteristics and dynamic range is provided. The device comprises a rigid protector plate having high quality acoustical characteristics and a thickness which is a multiple of half wavelength of the resonant frequency. A piezoelectric plate is coupled to the protector plate, is supported therefrom, and forms an energy interface therewith. The piezoelectric and protector plates are dimensioned such that a wave of resonant frequency traveling between the excitation face and the loaded / sensing face, forms a substantially continuous-phase wave, at substantially peak amplitude, at the energy interface. By doing so the device decouples the electrical thickness of the wave device from the mechanical thickness thereof.

Owner:MICROSEMI CORP HIGH PERFORMANCE TIMING

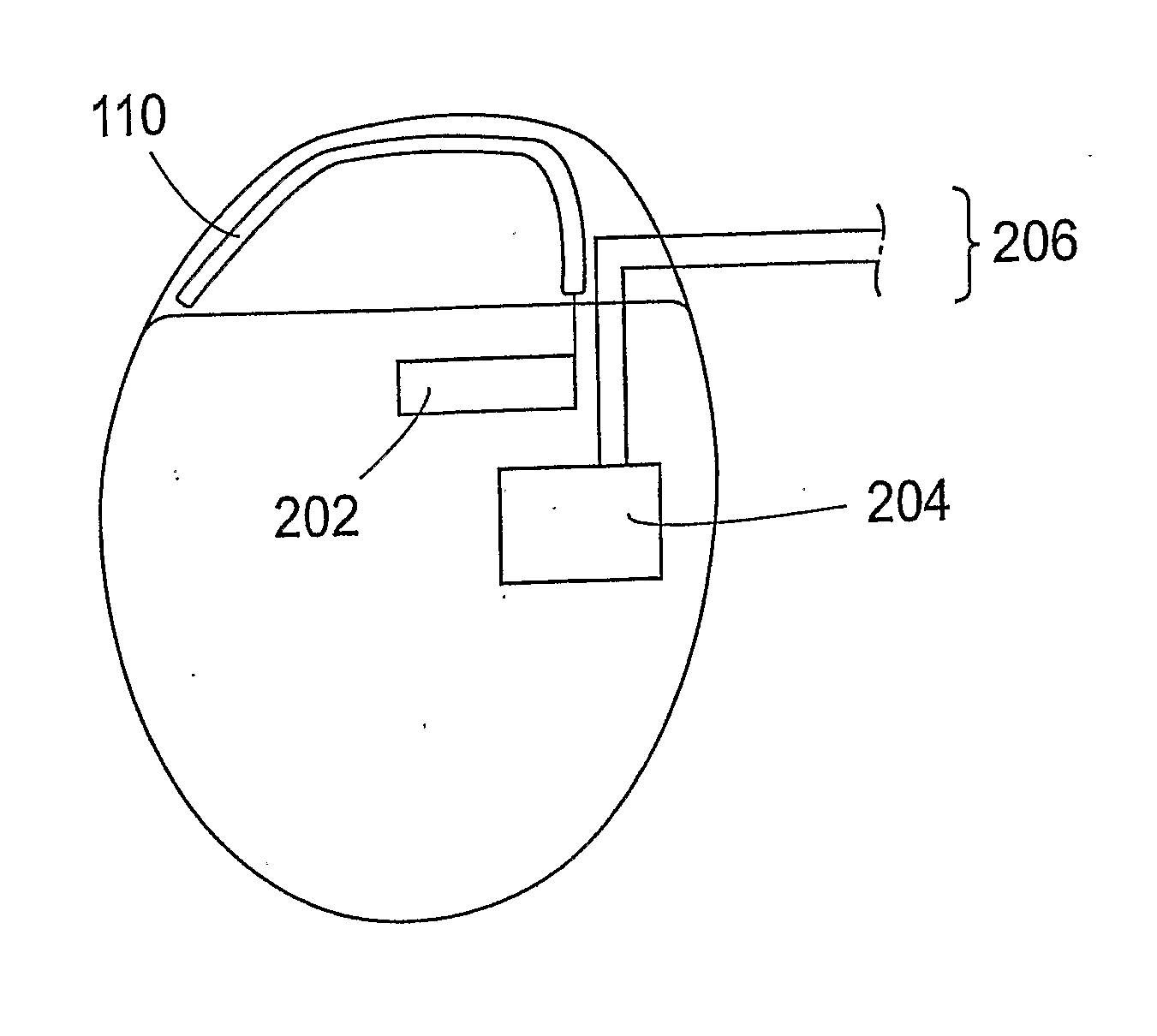

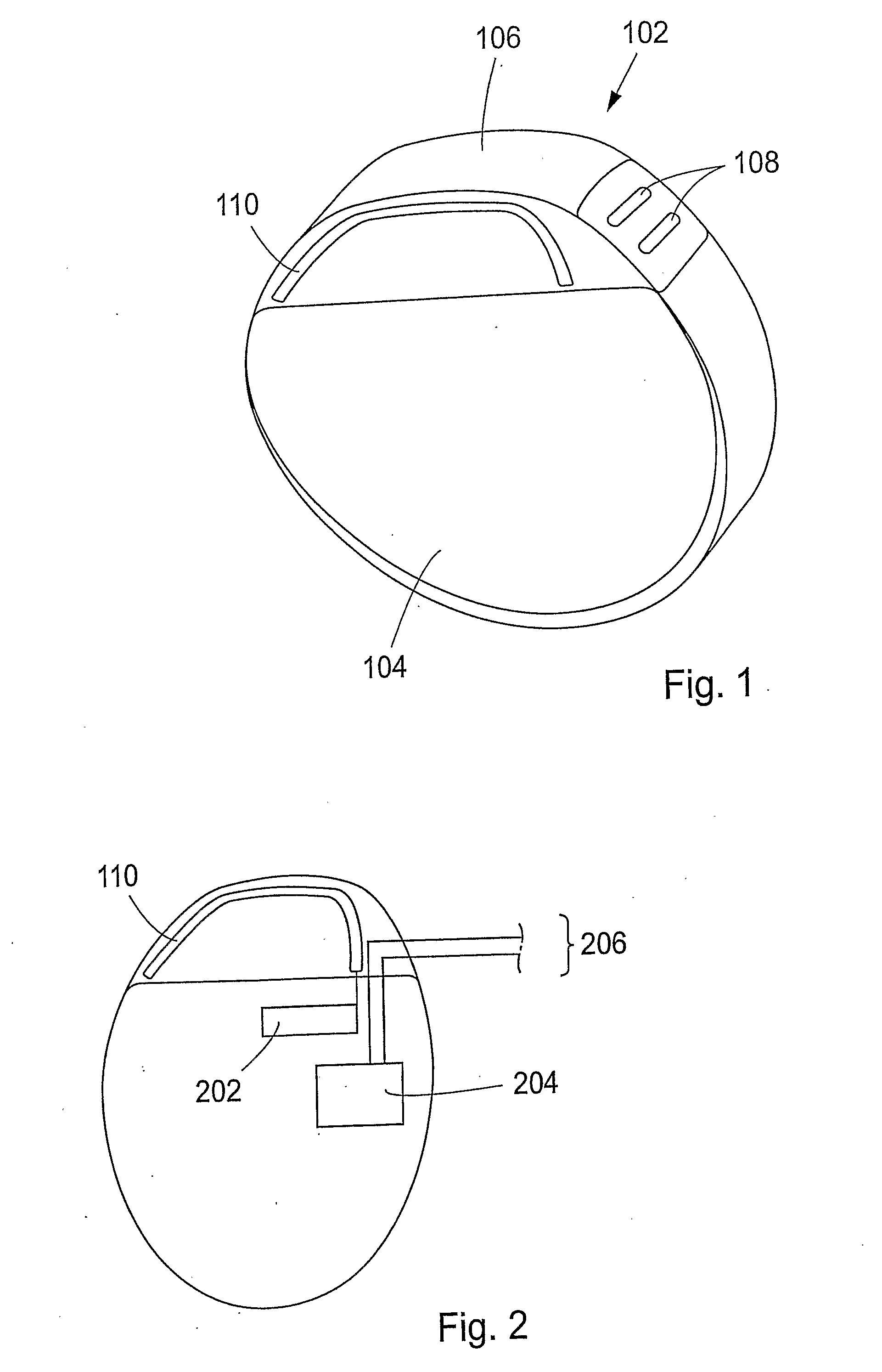

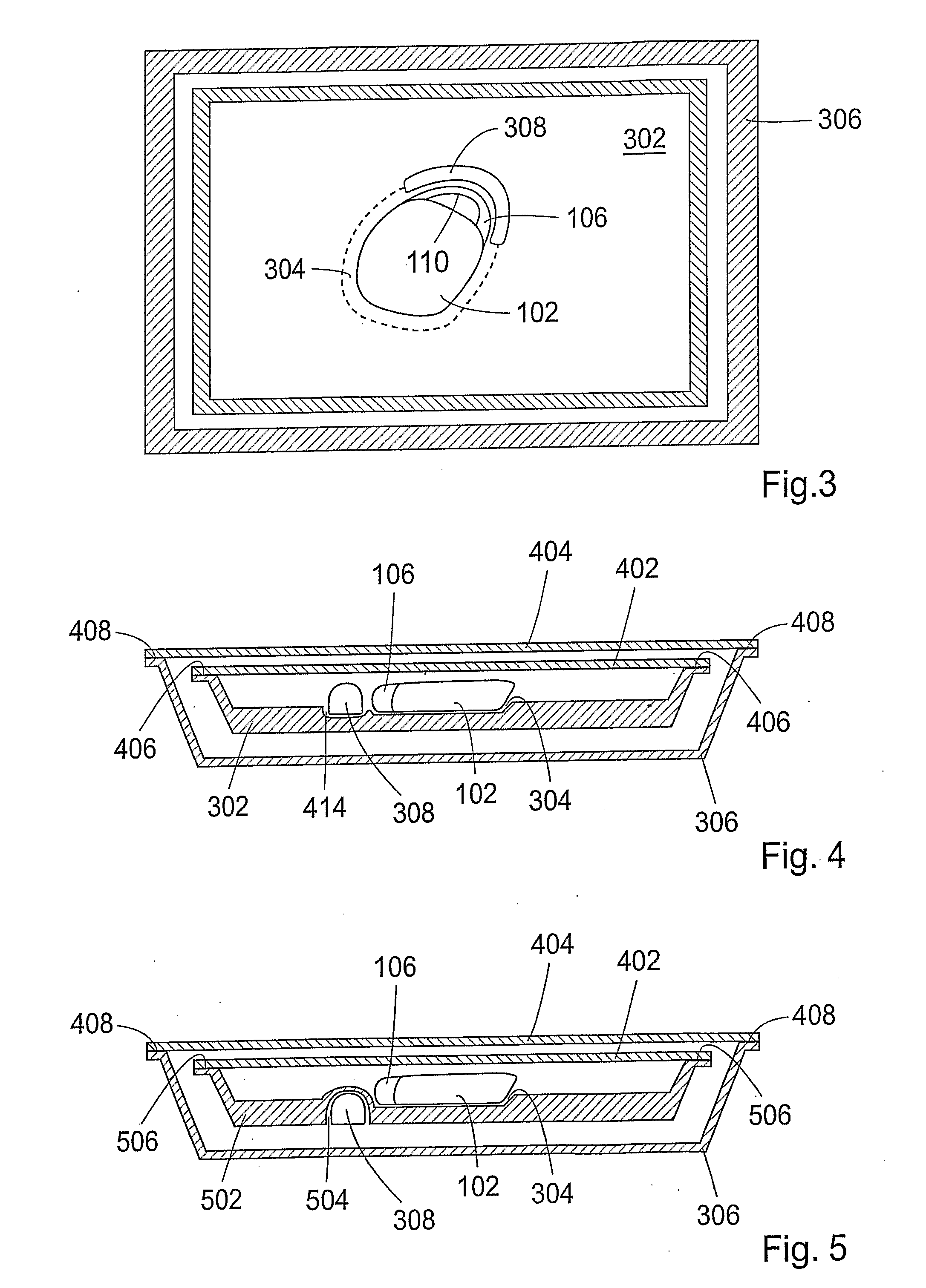

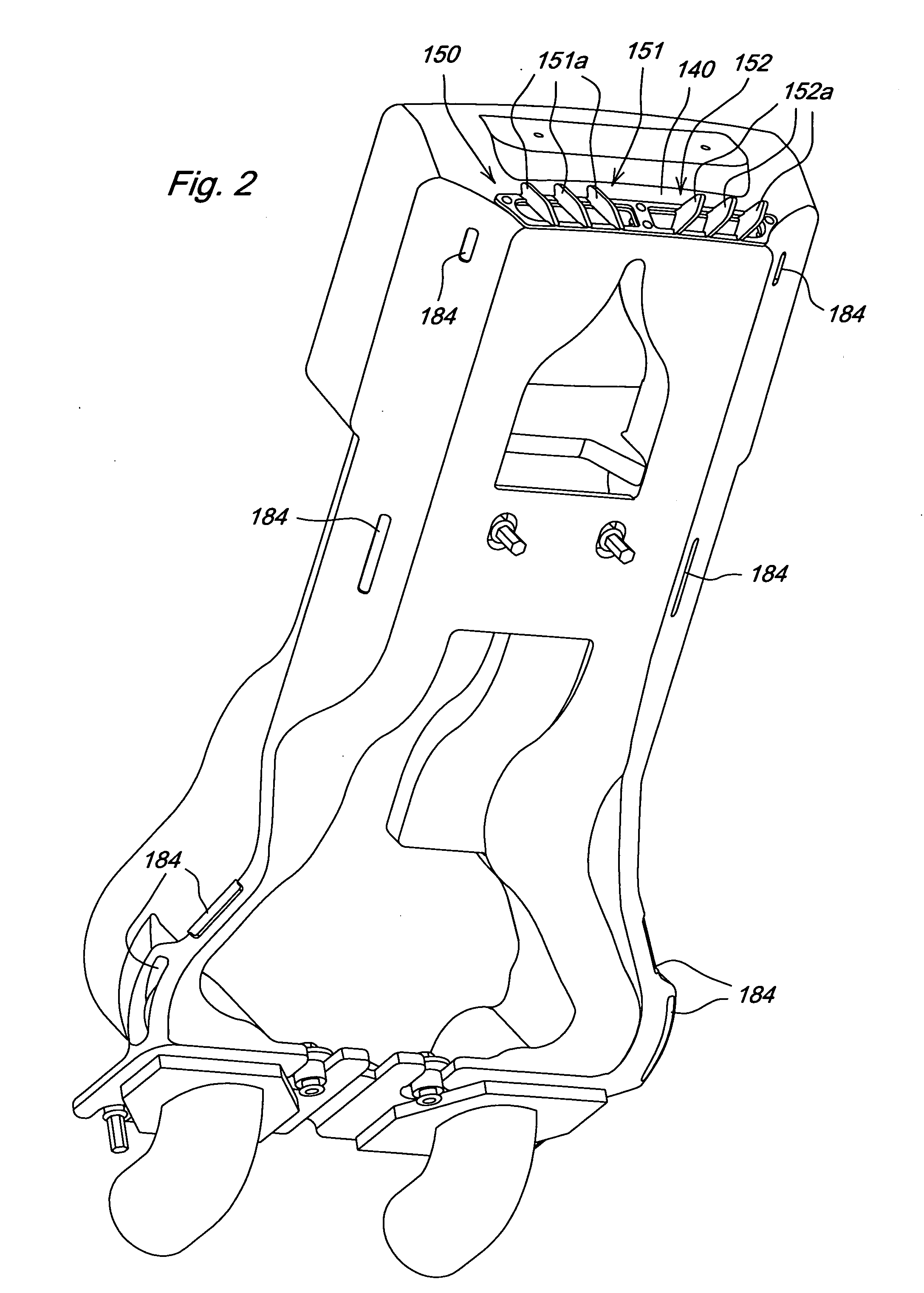

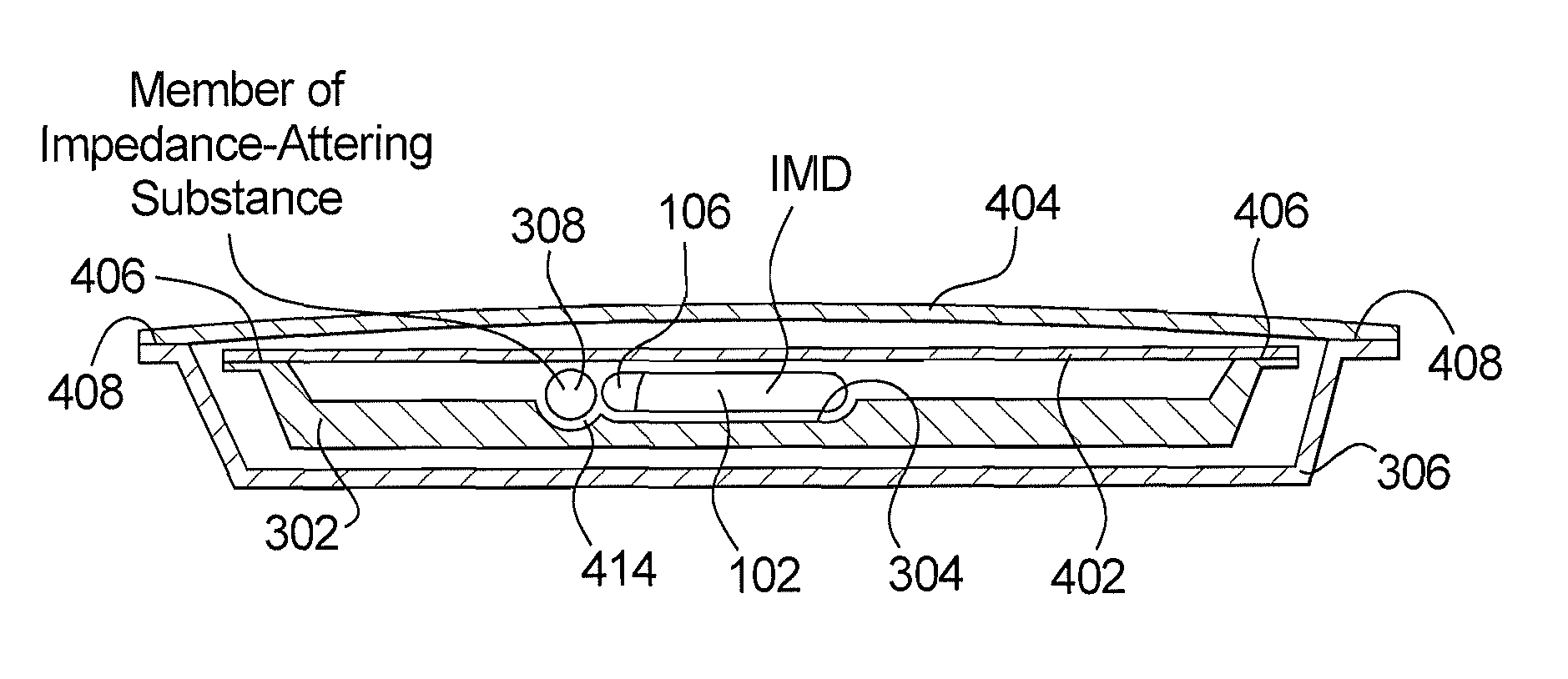

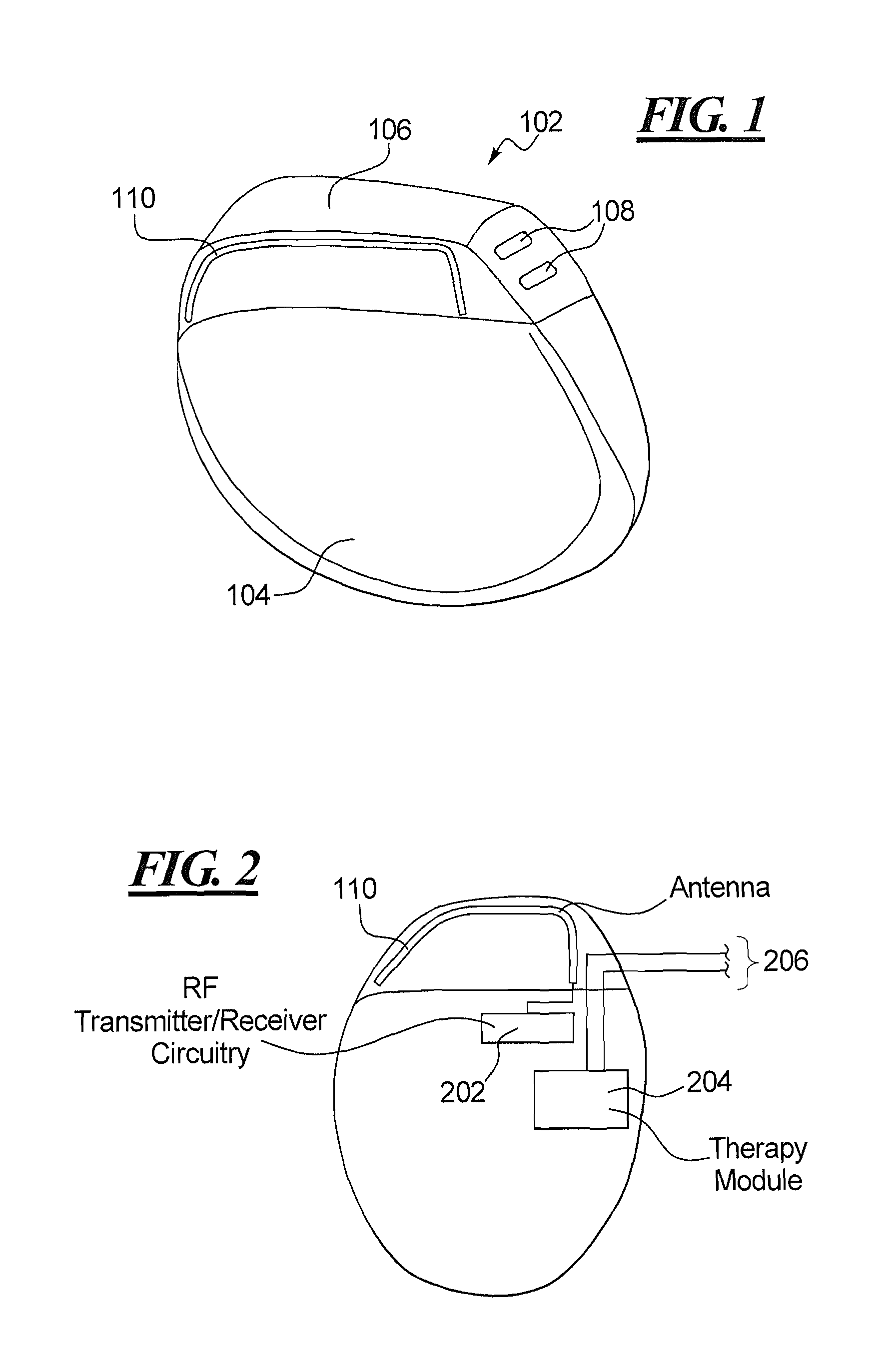

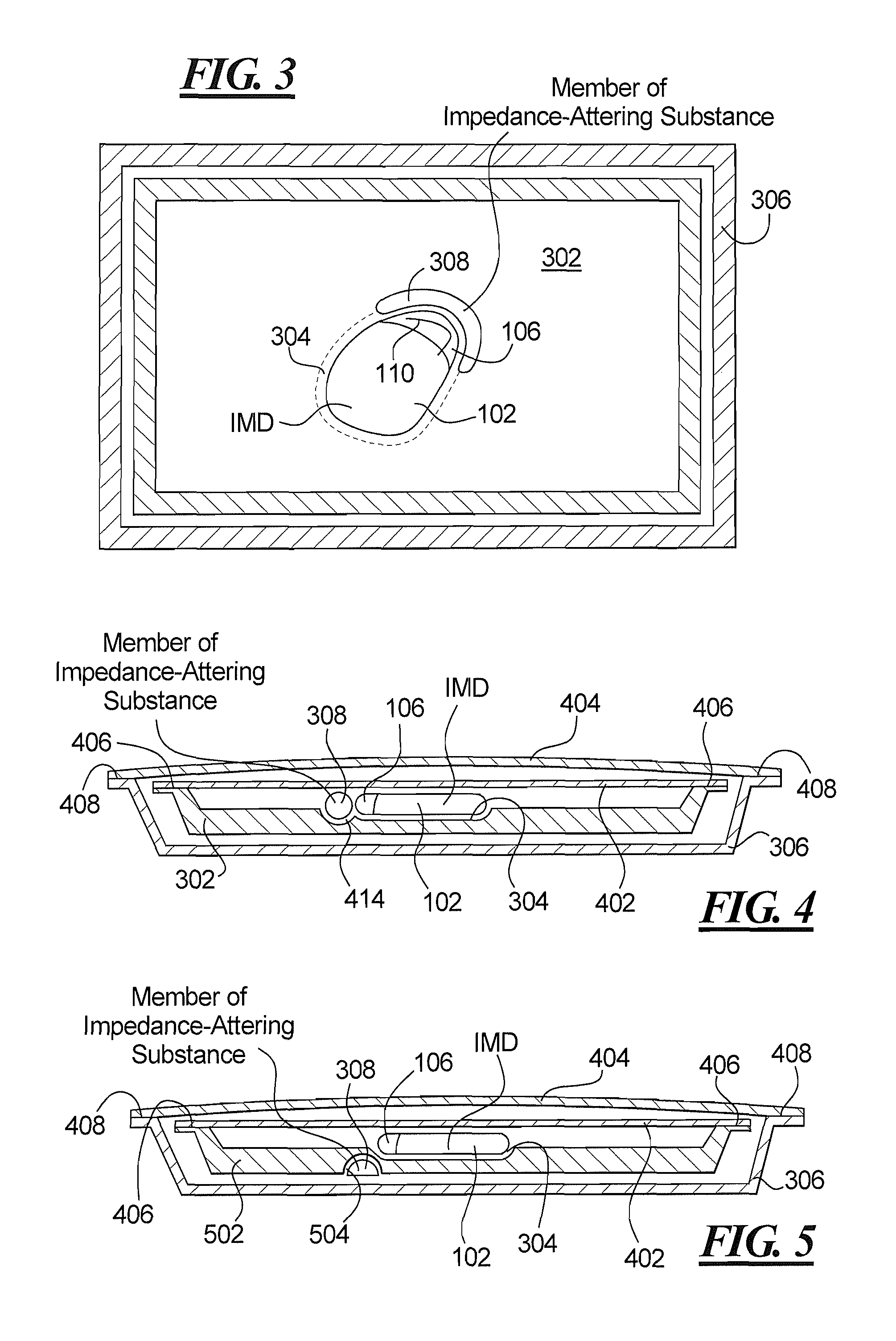

System, an apparatus and a container for storing an implantable medical device, and a method for packaging such a device

ActiveUS20100114247A1Improve propertiesEasy to receiveElectrotherapyDiagnosticsInput impedanceMedical device

An implantable medical device is stored in a container prior to implantation in body tissue. The, IMD includes transmitter / receiver circuitry and at least one antenna. The storage container (packaging) includes an impedance altering substance positioned in proximity to the IMD when stored in the container, the substance having electrical material properties that alter the input impedance of the antenna to improve receive and transmit properties of the antenna when the IMD is stored in the container. A container for storing an IMD having an antenna has a packaging tray for housing the IMD, the packaging tray having a support for supporting the IMD and the container includes a substance positioned in proximity to the support that has electrical material properties that after the input impedance of the antenna of the IMD supported by the support, so as to improve receive and transmit properties of the antenna. A method for packaging an IMD prior to implantation in body tissue includes the step of providing such an impedance altering substance in the pre-implantation IMD packaging, in proximity to the packaged IMD.

Owner:ST JUDE MEDICAL

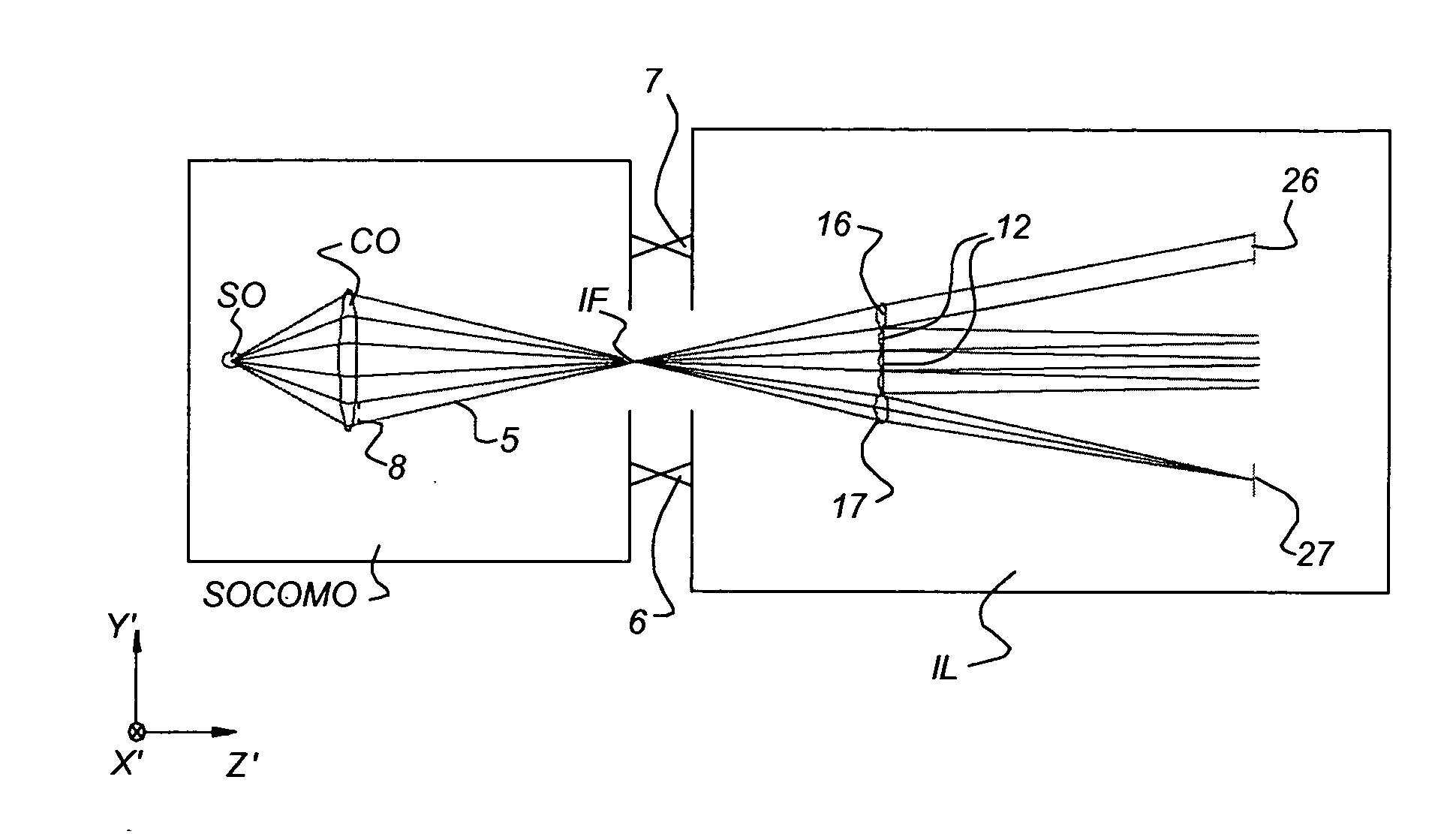

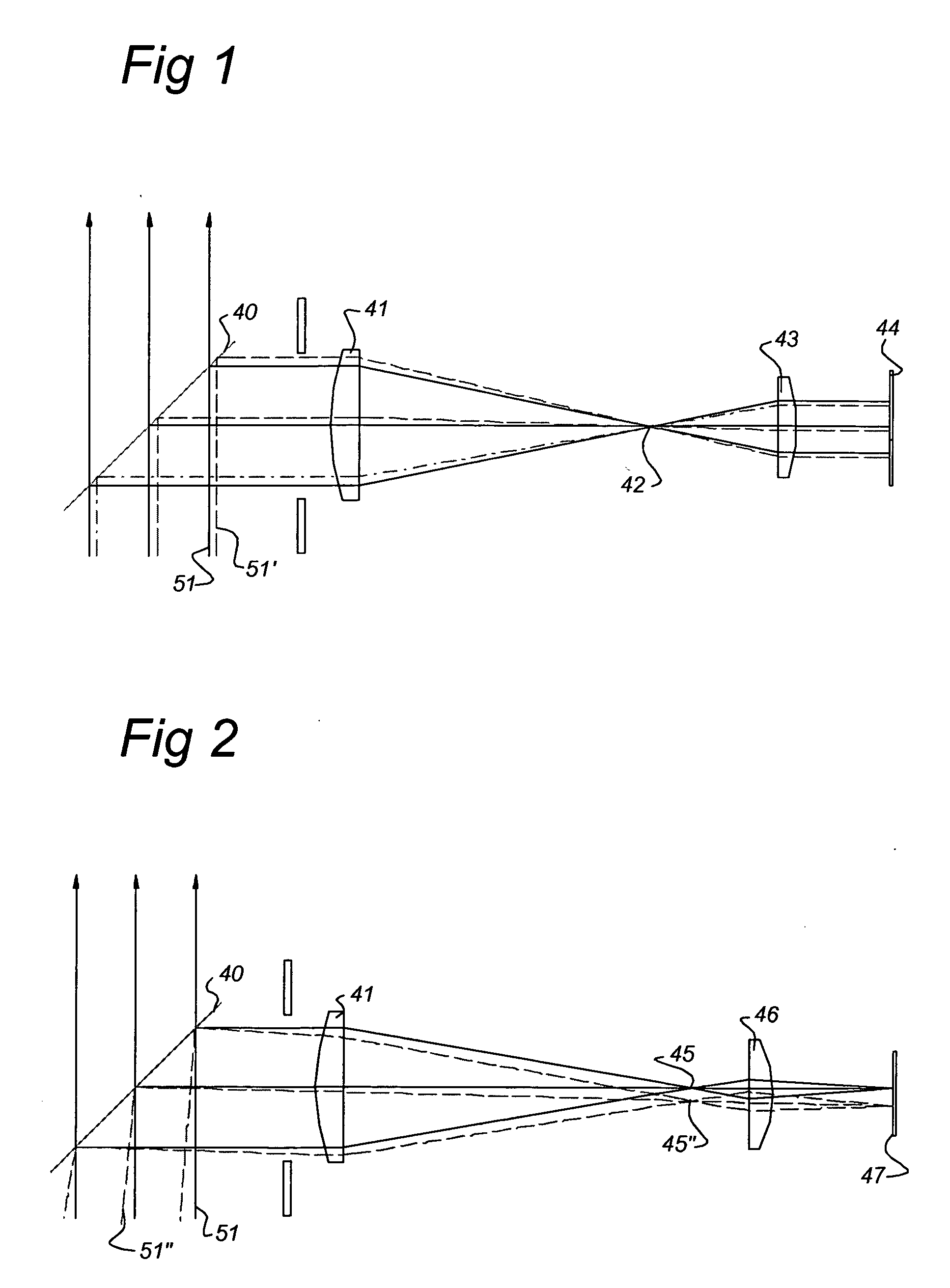

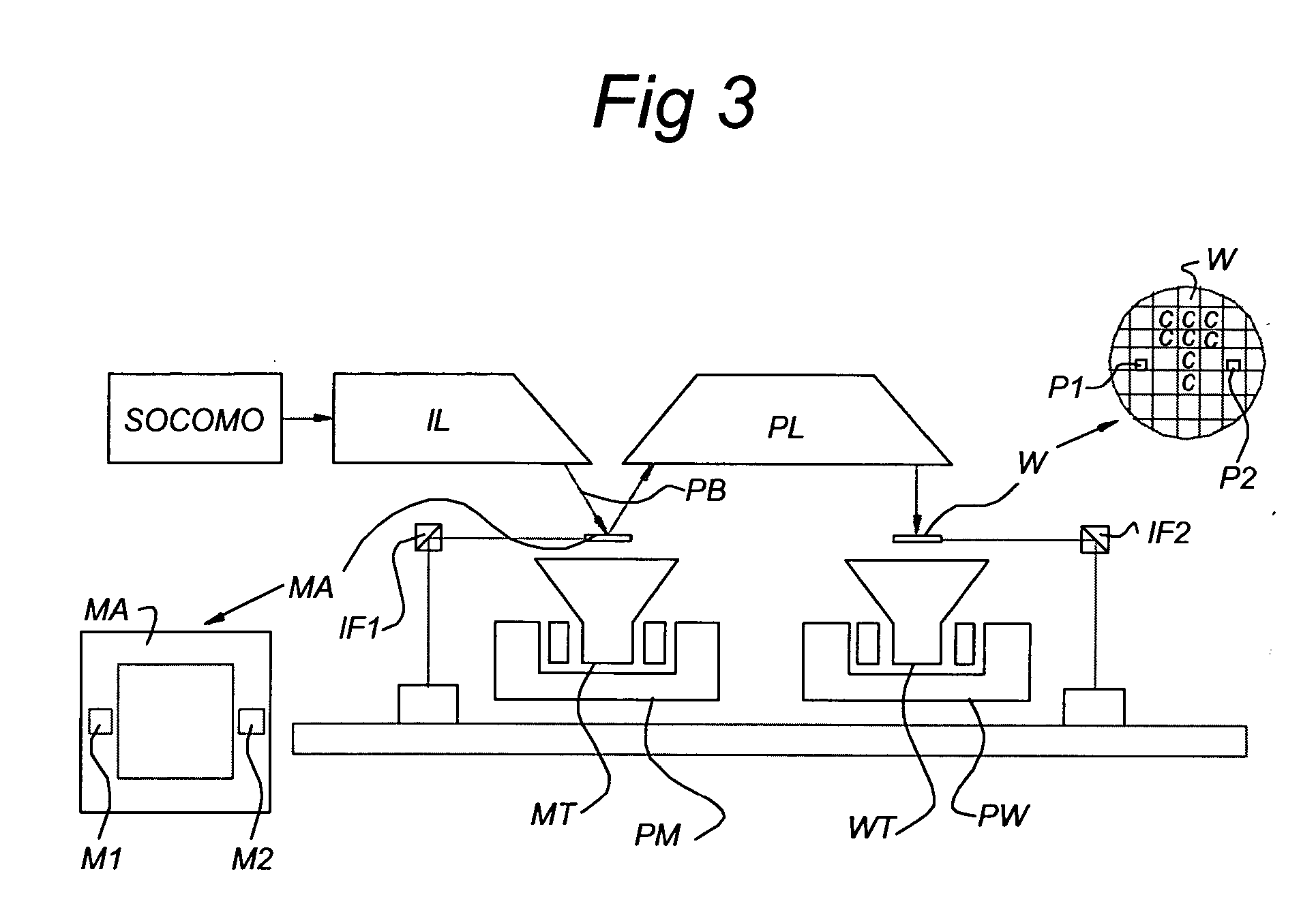

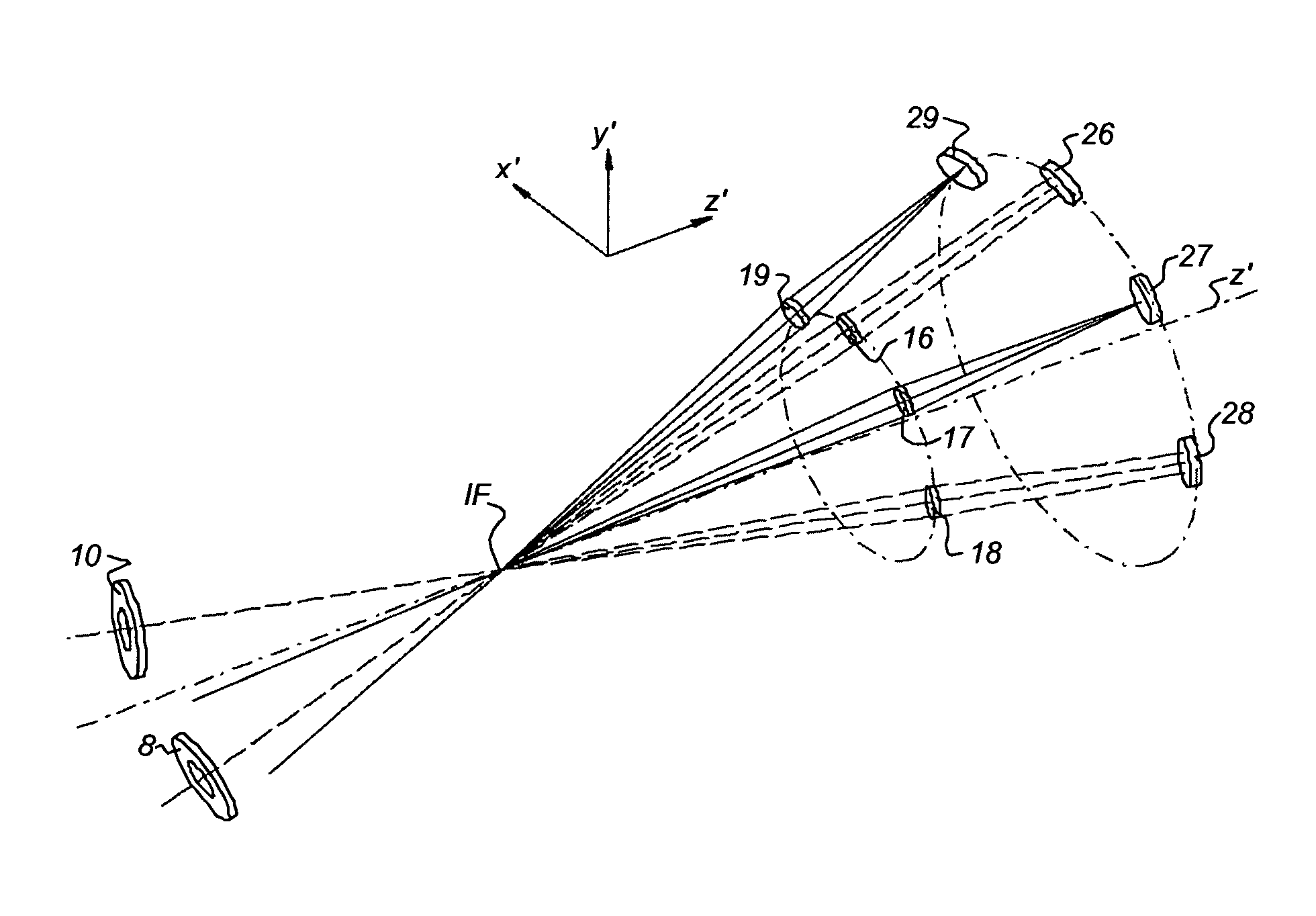

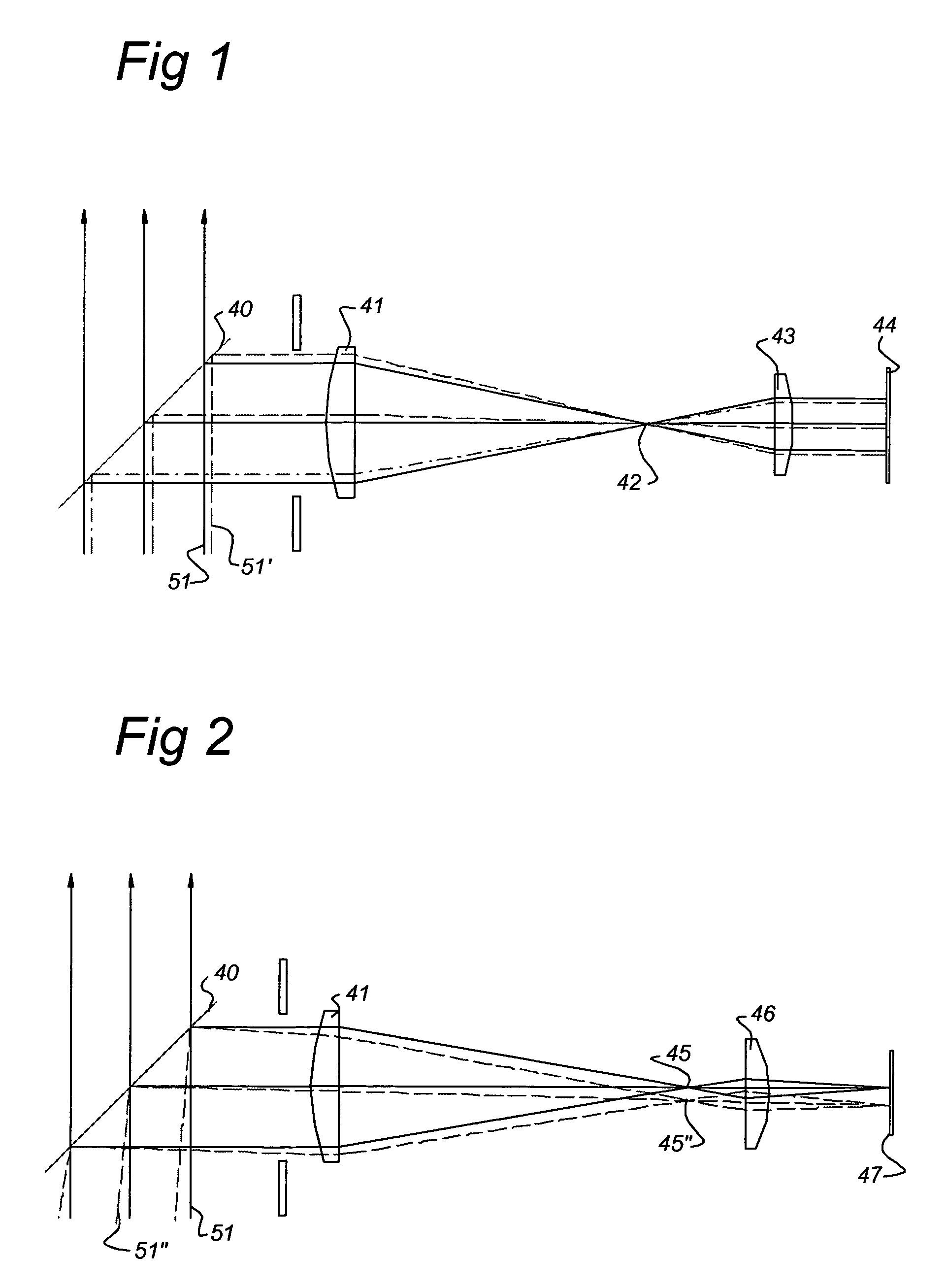

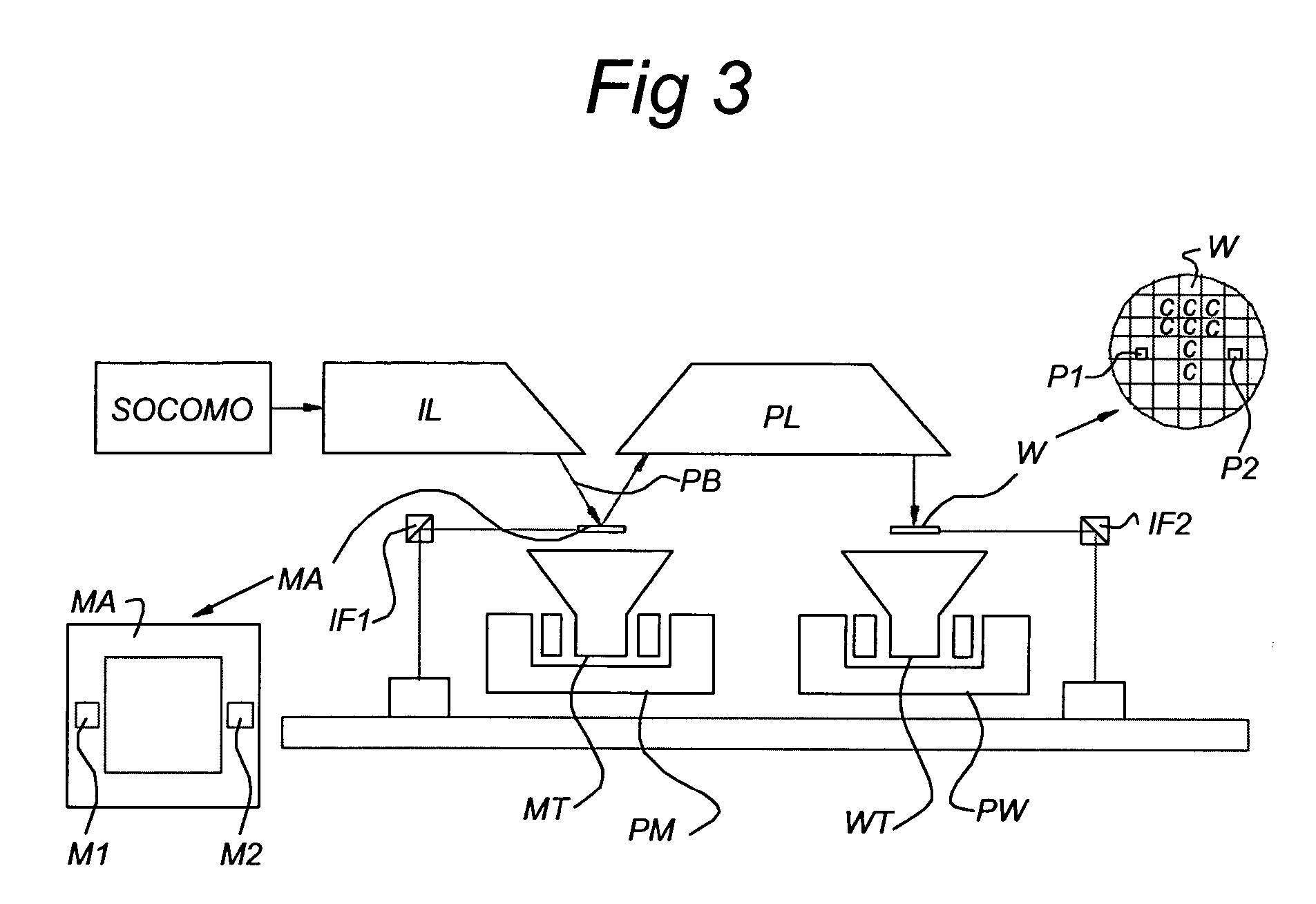

Radiation system, lithographic apparatus, device manufacturing method and device manufactured thereby

ActiveUS20050270511A1Minimum energy lossMirrorsSemiconductor/solid-state device manufacturingLight beamLighting system

A radiation system includes a radiation generator to generate a beam of radiation, a source, and an illumination system configured to receive the beam of radiation and provide a projection beam of radiation. The illumination system includes a beam measuring system configured measure at least one of position and tilt of the beam of radiation relative to the illumination system and a projecting device configured to redirect only a part of a cross section of the beam of radiation to the beam measuring system. The beam measuring system may include several position sensors, the readouts of which can be used to determine incorrect alignment of the radiation source with respect to the illumination system. Diaphragms are connected to the collector of the radiation generator, so that in addition to X, Y, and Z corrections, Rx, Ry and Rz corrections are possible.

Owner:ASML NETHERLANDS BV

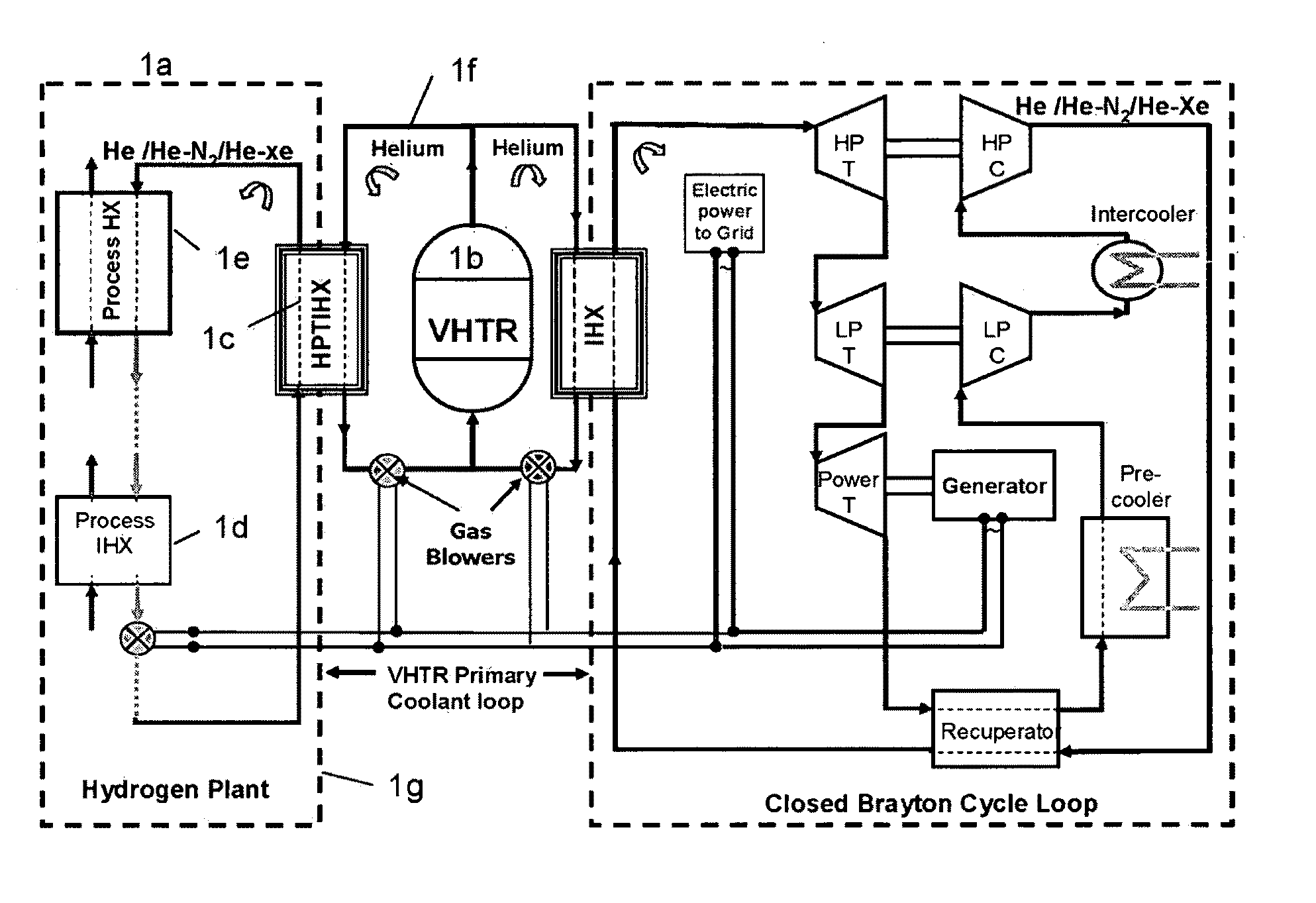

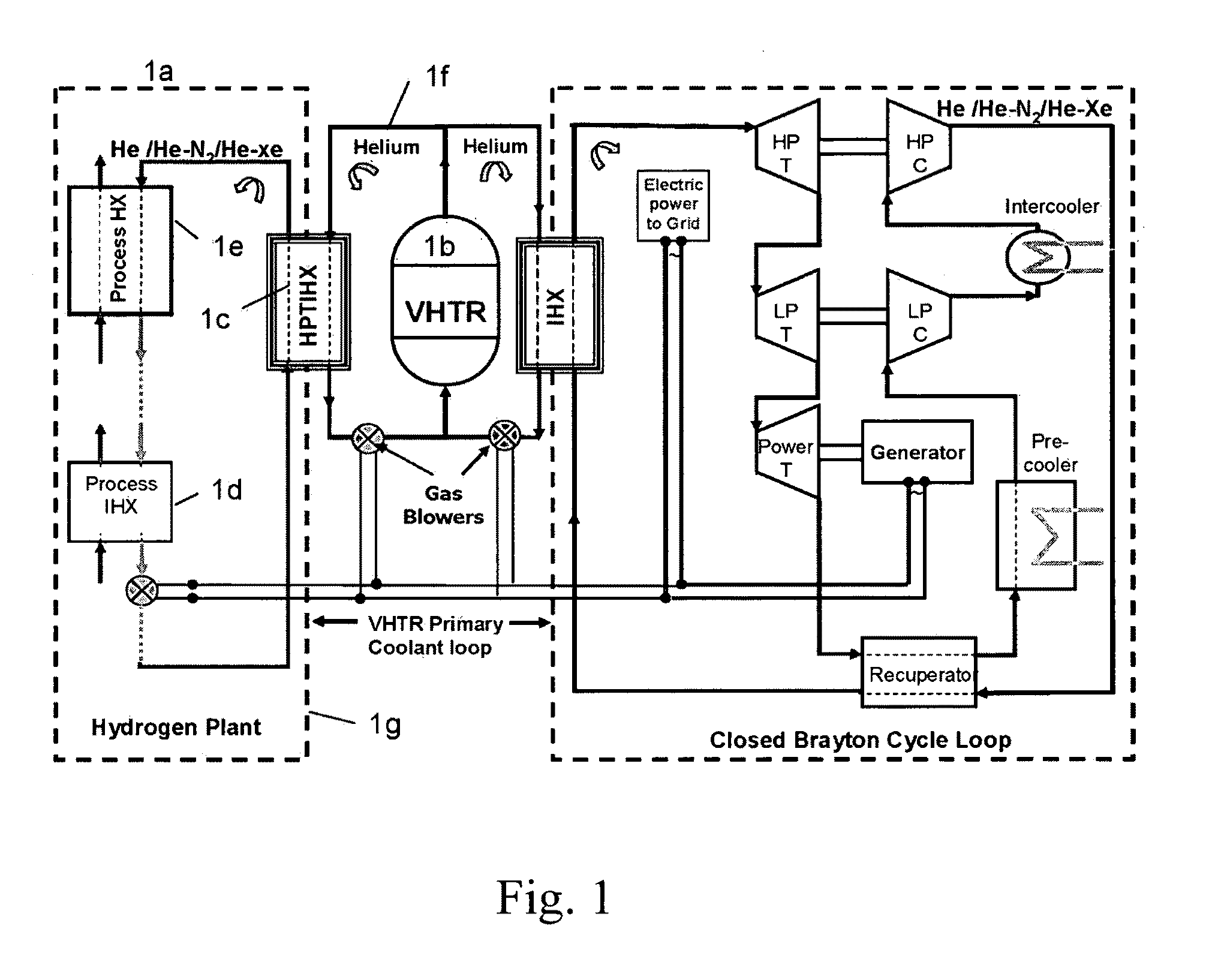

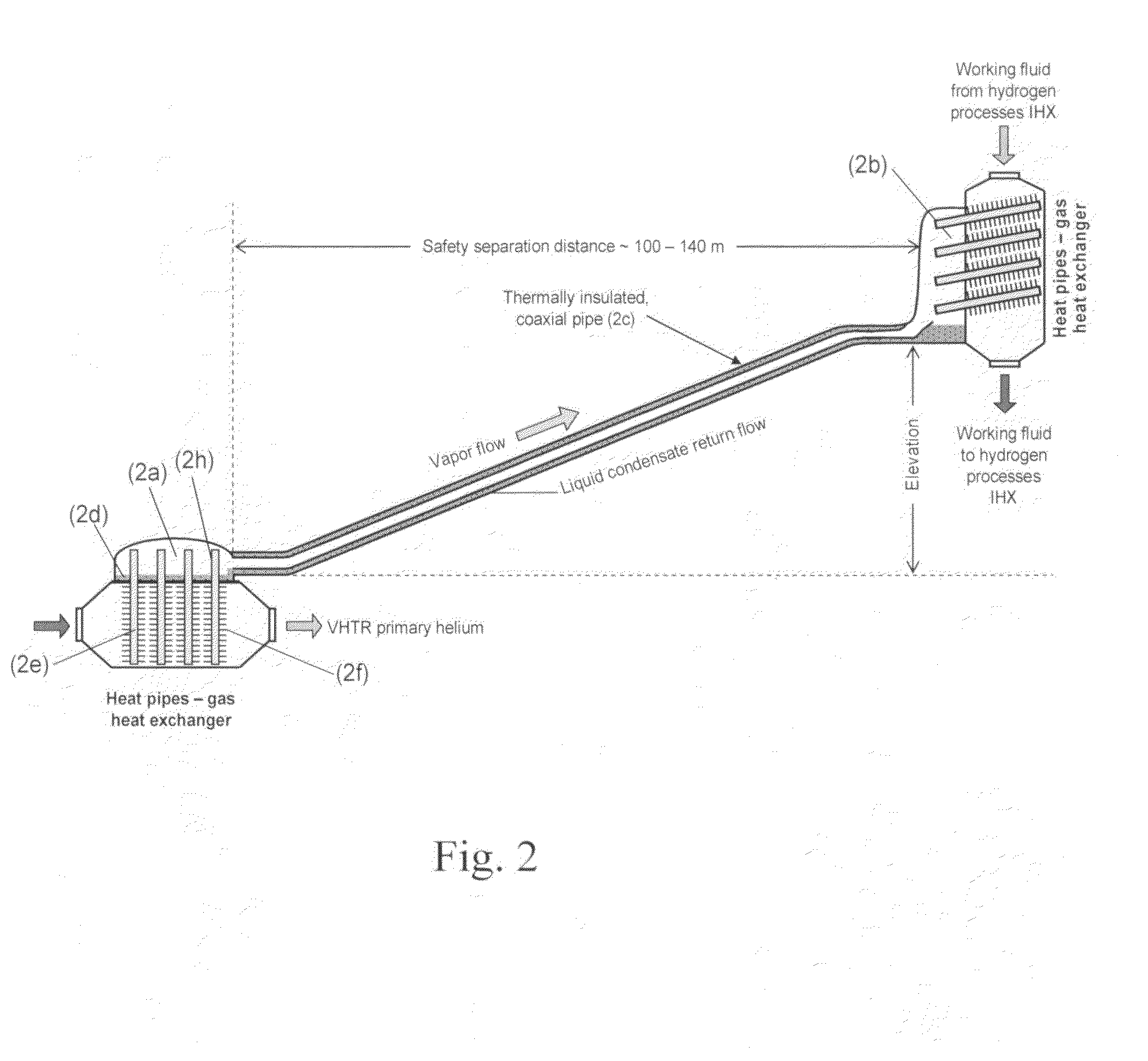

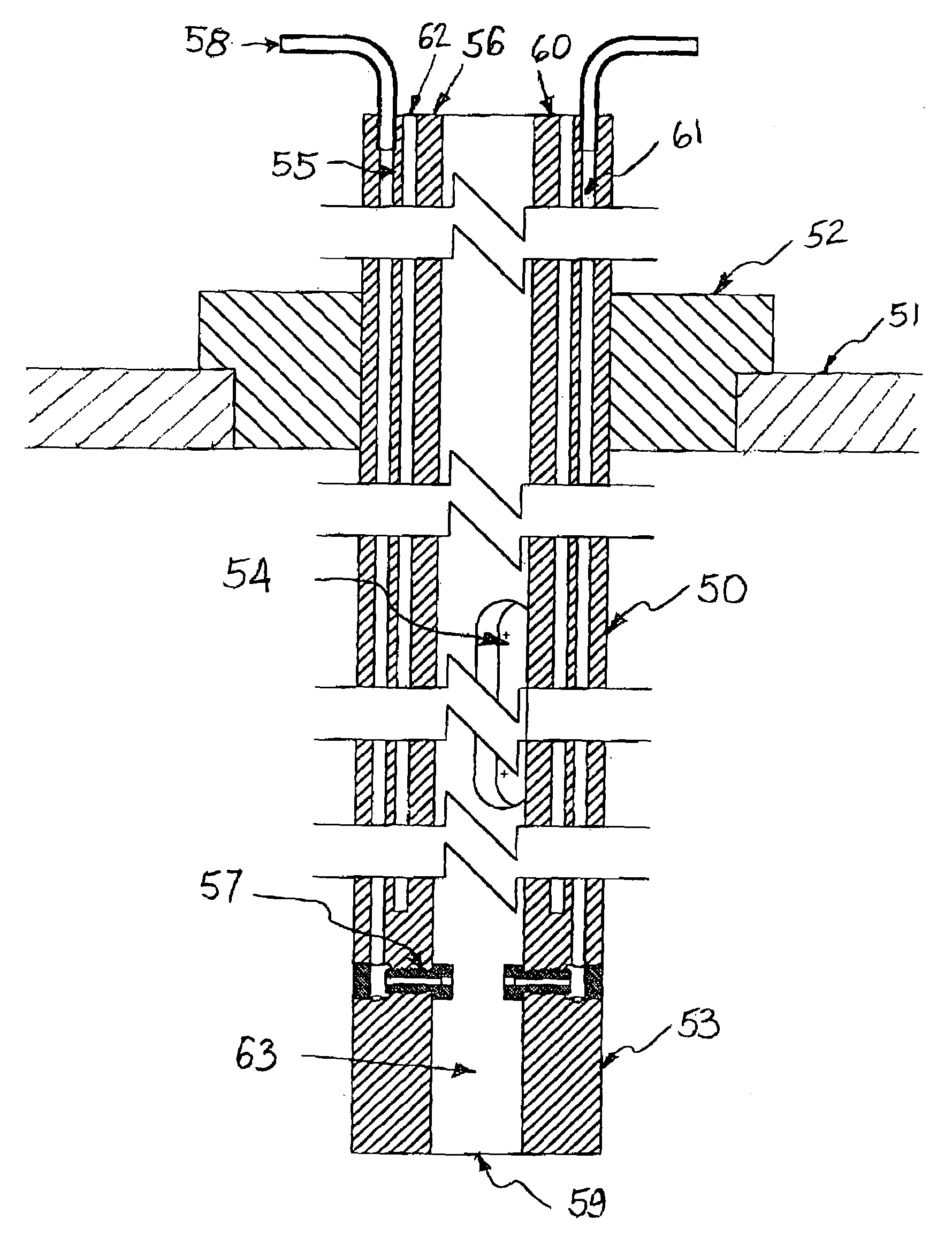

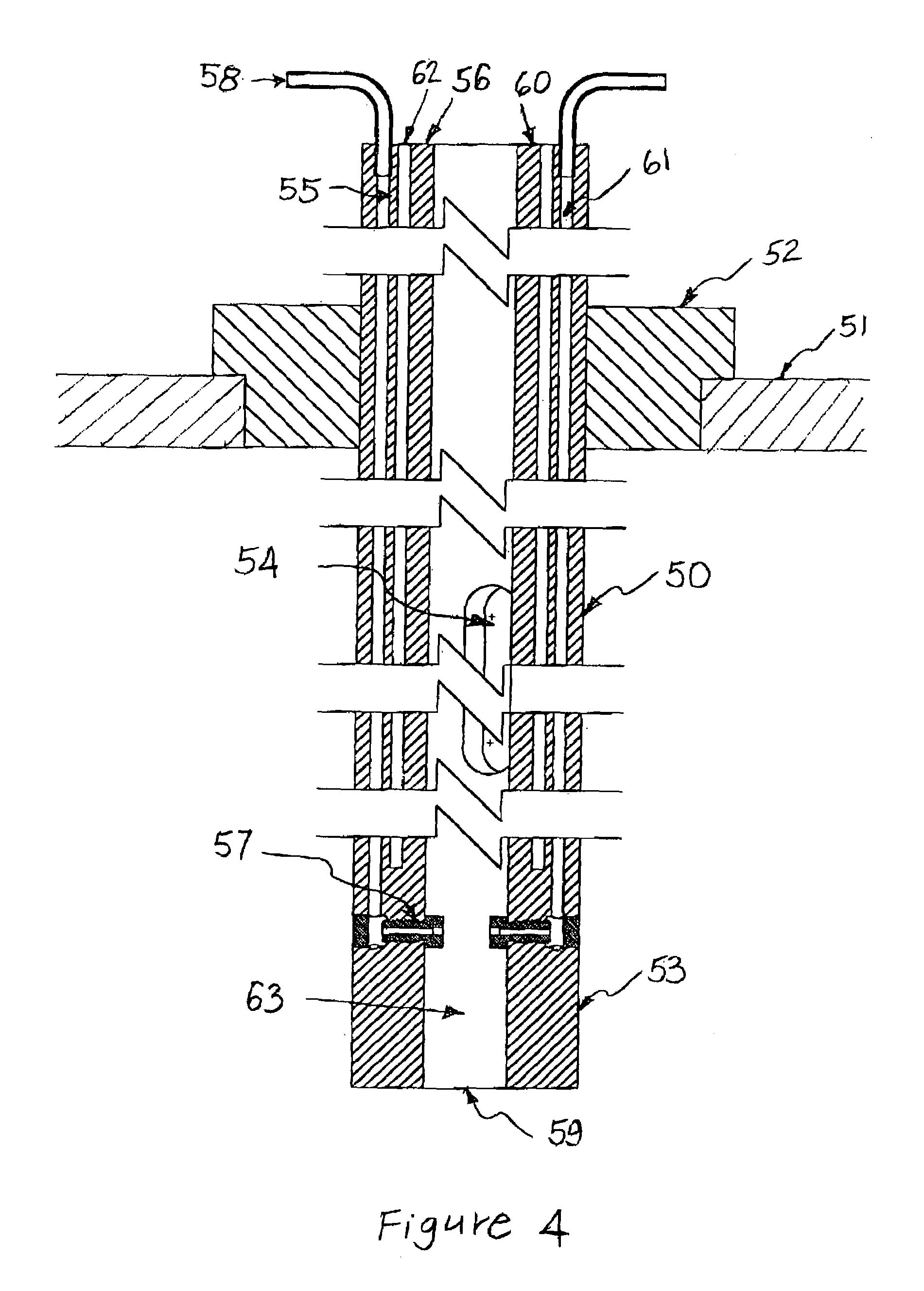

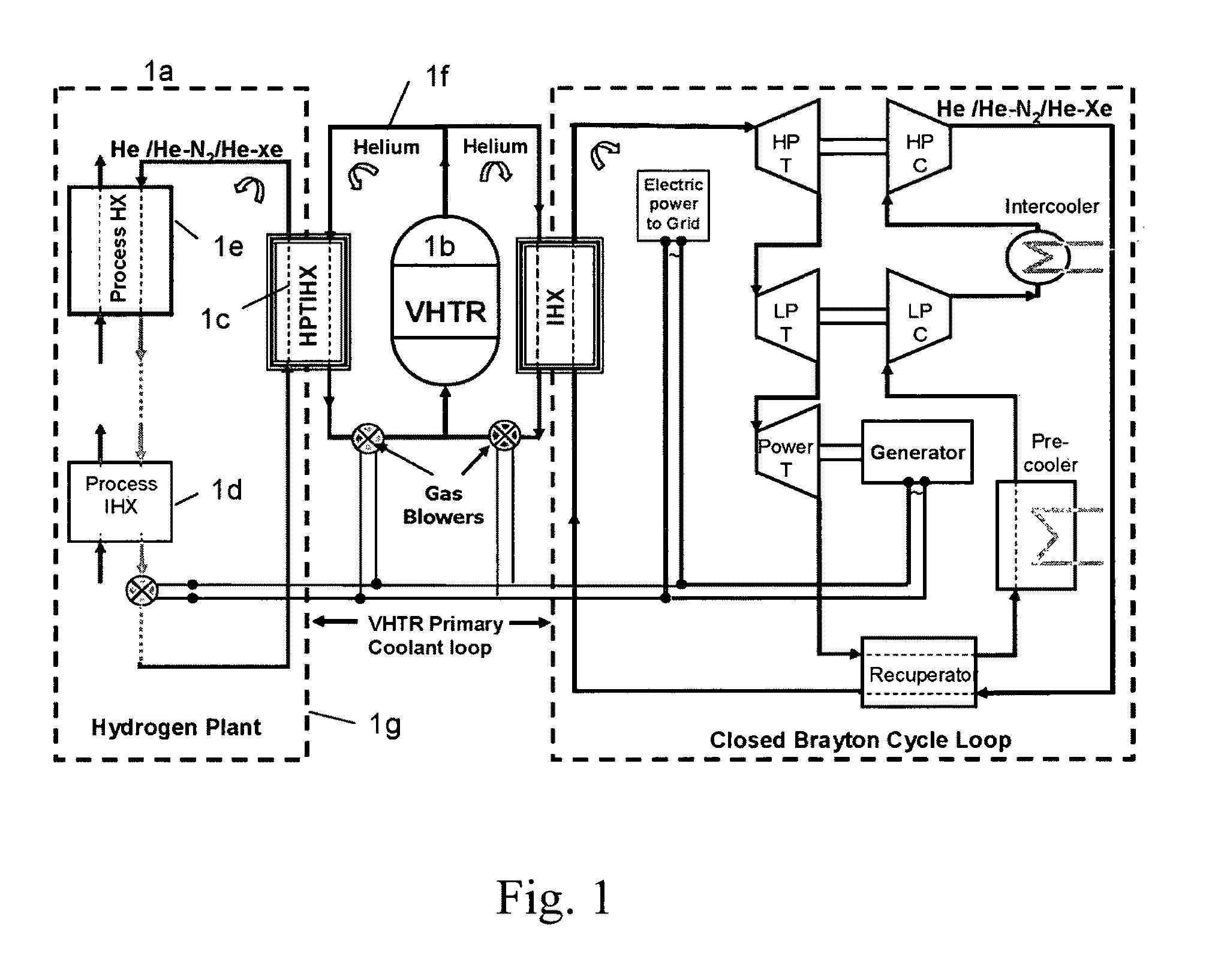

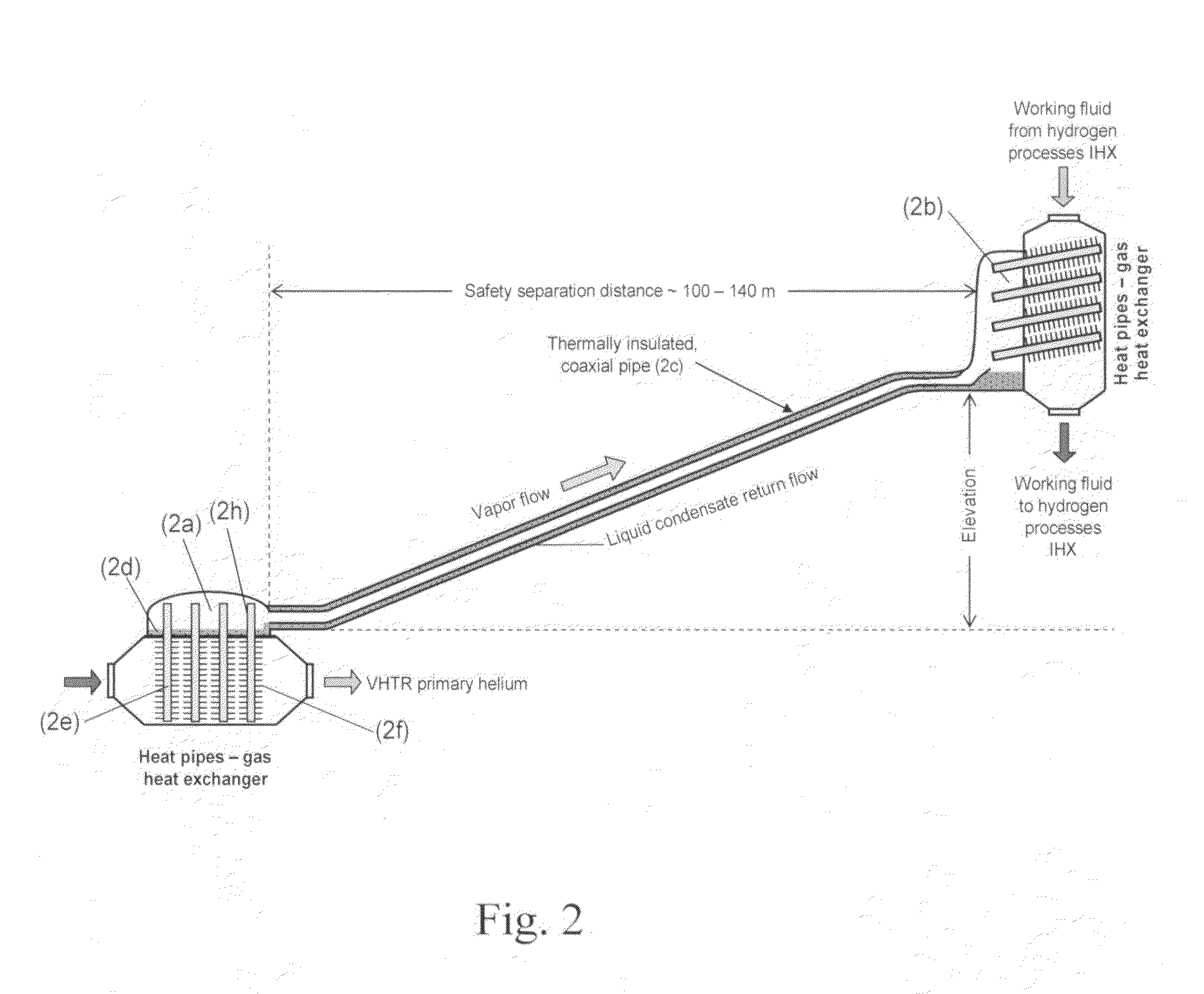

Methods and apparatuses for removal and transport of thermal energy

ActiveUS20090323886A1Minimum energy lossAir heatersIndirect heat exchangersThermochemical cycleThermal energy

Methods and apparatuses are provided for the removal and transportation of thermal energy from a heat source to a distant complex for use in thermochemical cycles or other processes. In one embodiment, an apparatus includes a hybrid heat pipes / thermosyphon intermediate heat exchanger (HPTIHX) system that is divided into three distinct sections, namely: an evaporation chamber, a condensation chamber, and a working fluid transport section of liquid and vapor counter-current flows.

Owner:STC UNM

Wind turbine generator and motor

A wind turbine includes a quartet of pivot shafts in paired parallel relationship and transversely mounted on a central drive shaft, each pivot shaft supporting a pair of wings at opposed ends thereof, the wings offset by 90°. Each pivot shaft rotates cyclically through 90° to move each wing from a wind-engaging orientation (drive position) in which the wing presents a flat surface approximately transverse to the incident wind, to a minimum drag position (glide position). The wings of each pair of pivot shafts open into the drive position at the same time and rotational angle of the turbine. A backstop at the site of each drive position transfers force from each wing to the central drive shaft.

Owner:GRIGG CHARLES

Light emitting diode backlight package

ActiveUS20060114693A1Minimum energy lossOptimizing travel pathSolid-state devicesPlanar/plate-like light guidesLight guideEngineering

In a light emitting device including a transparent covering, a fastener having a vertical member and a horizontal member, a light-emitting chip disposed on one face of the vertical member and encased by the transparent covering, a circuit board disposed on one face of the horizontal member, at least one conductive means connecting the light-emitting chip to the circuit board, and at least one heat-dissipating plate perpendicularly disposed on the other face of the horizontal member, light may be emitted longitudinally along a light-guiding plate, thus optimizing the travel path of the emitted light, while maintaining a compact shape by enabling placement of the printed circuit board and heat dissipating plates away from a longitudinal axis of the light-guiding plate.

Owner:OPTRONIC SCI LLC

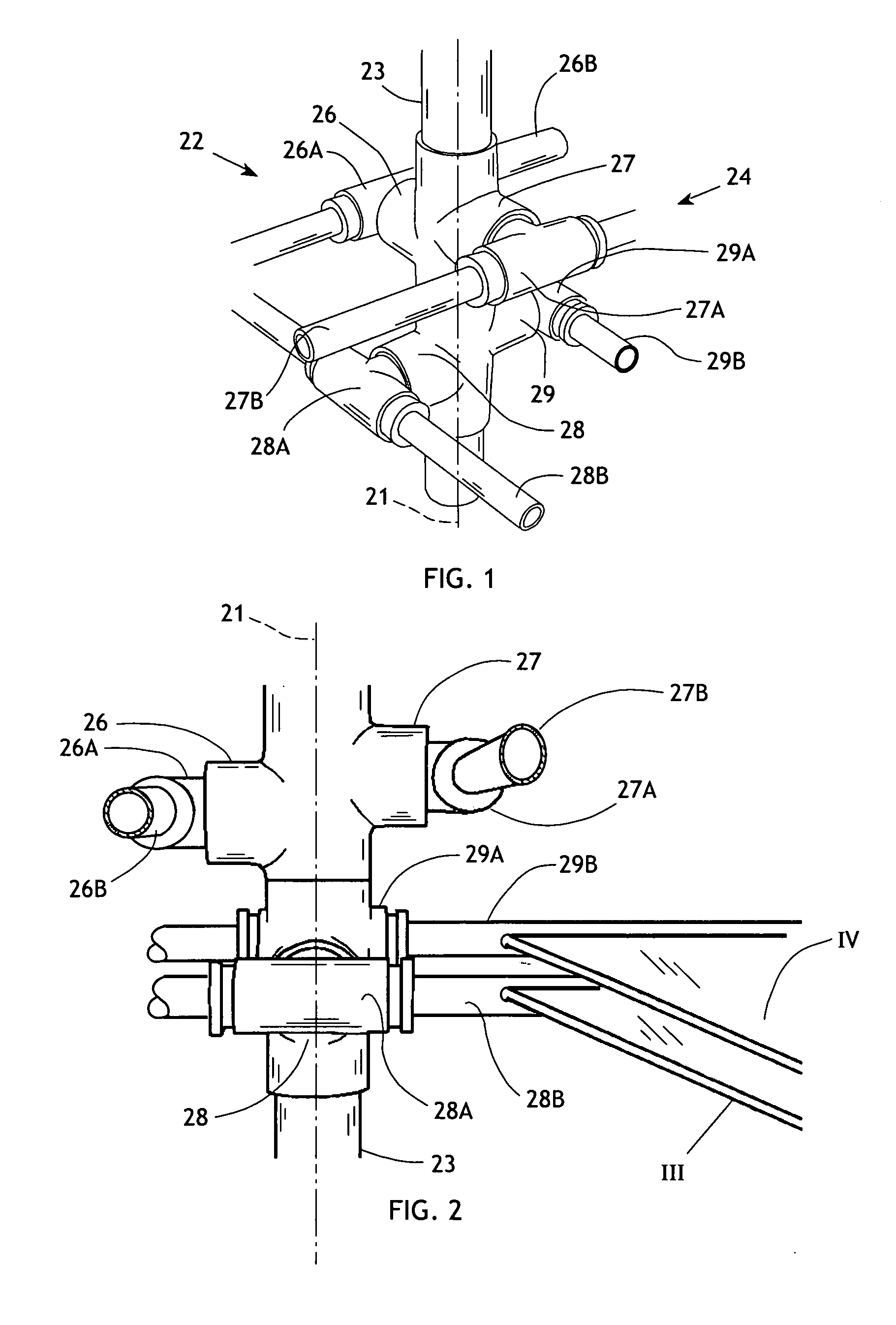

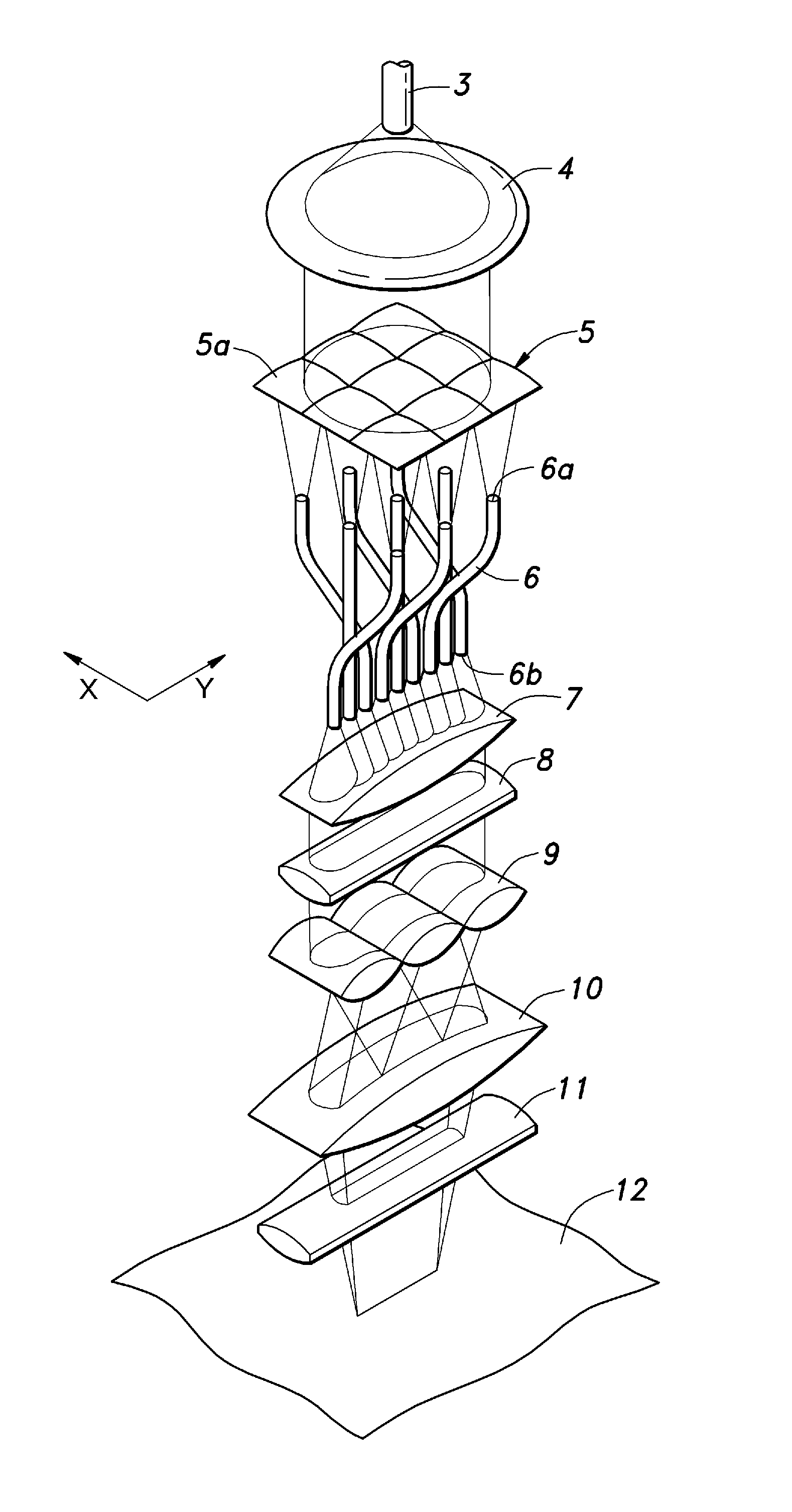

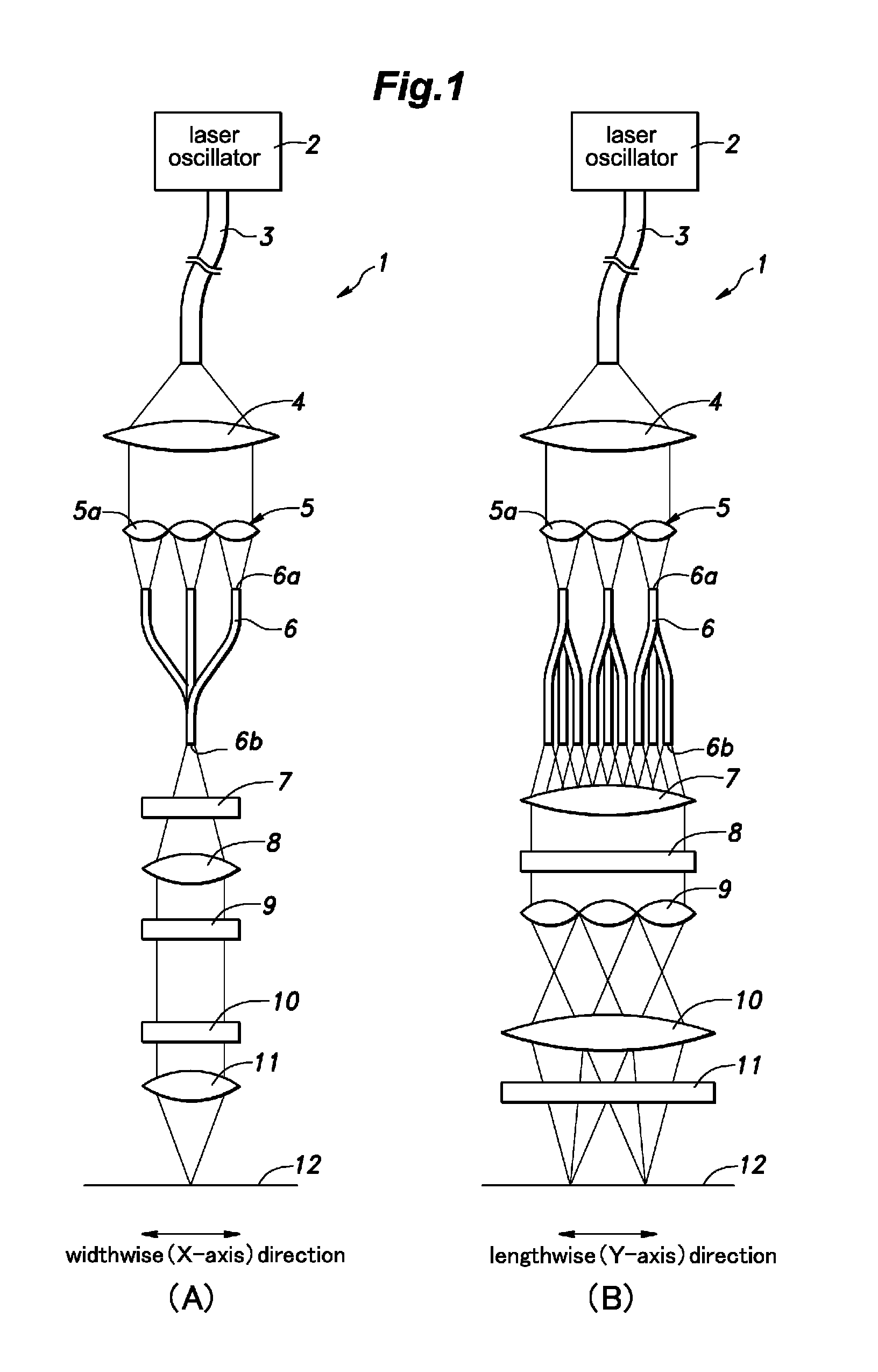

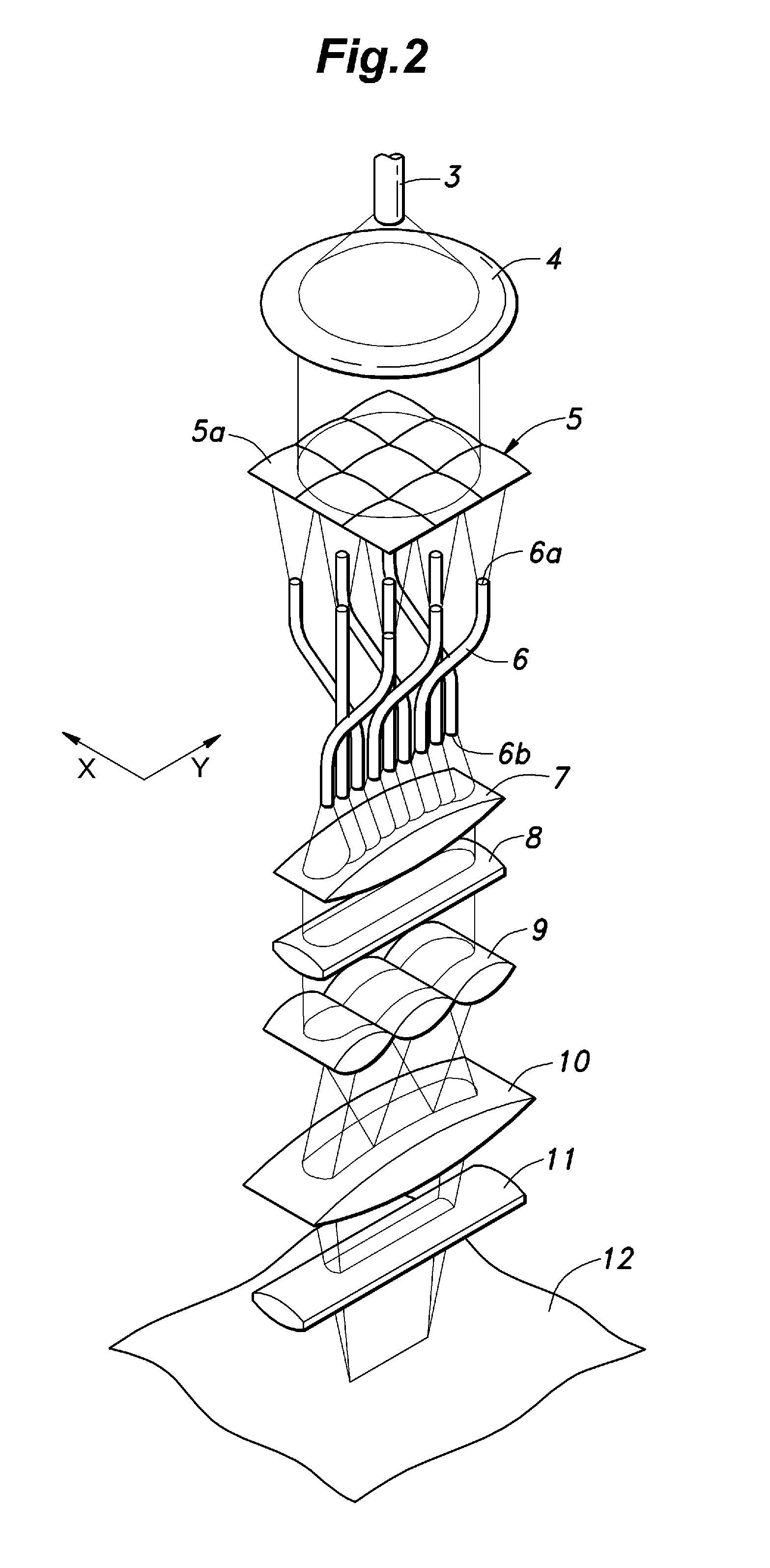

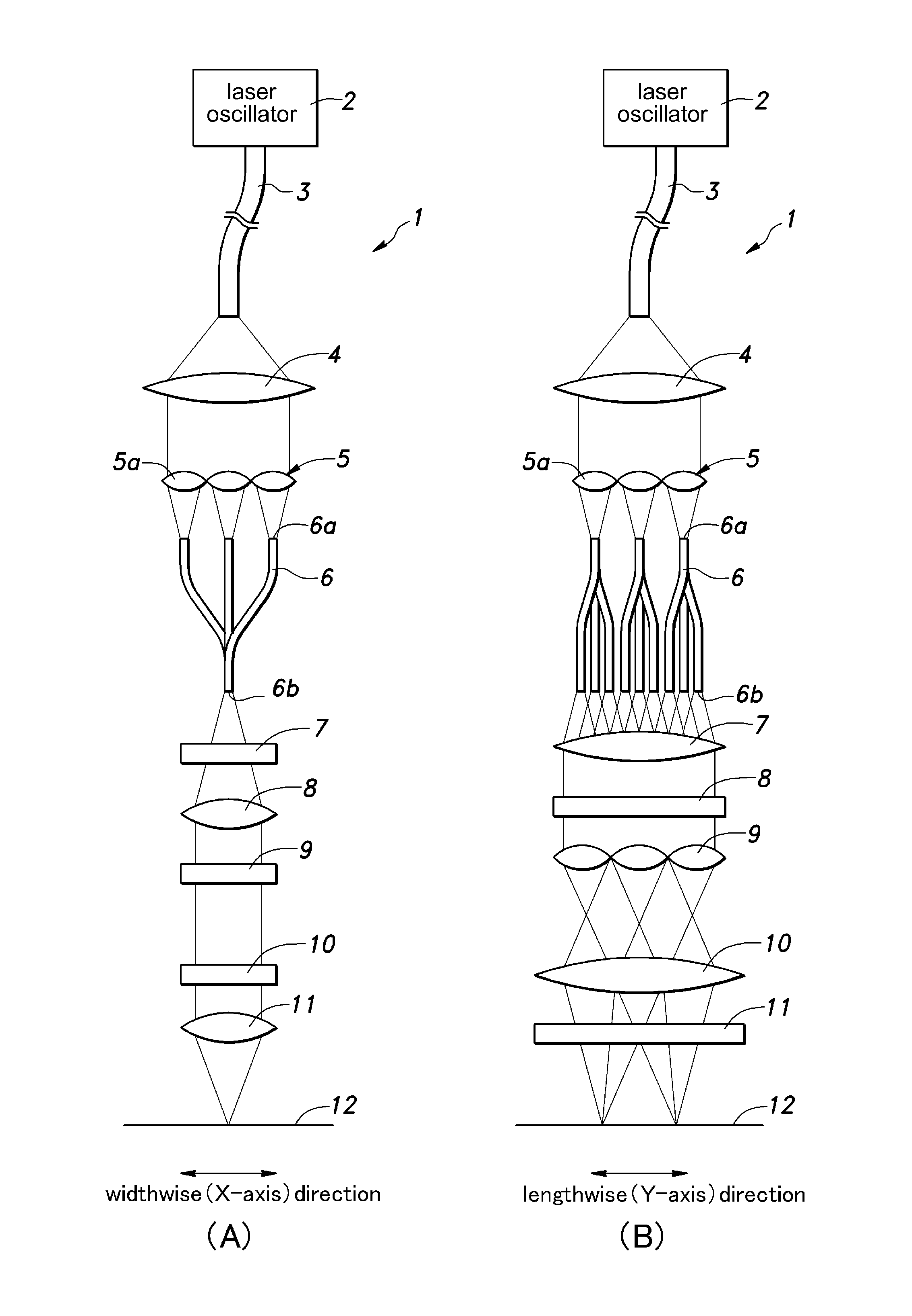

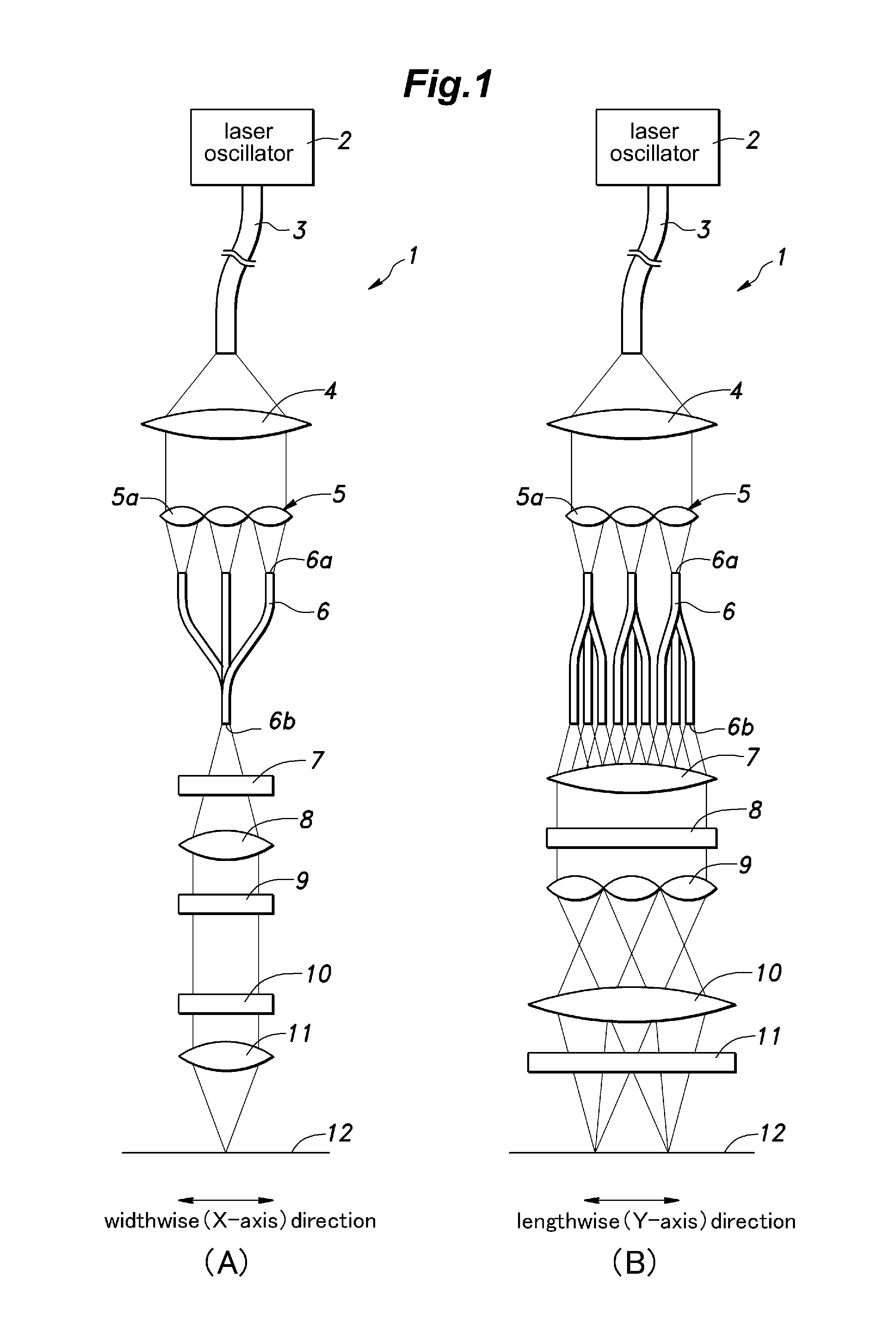

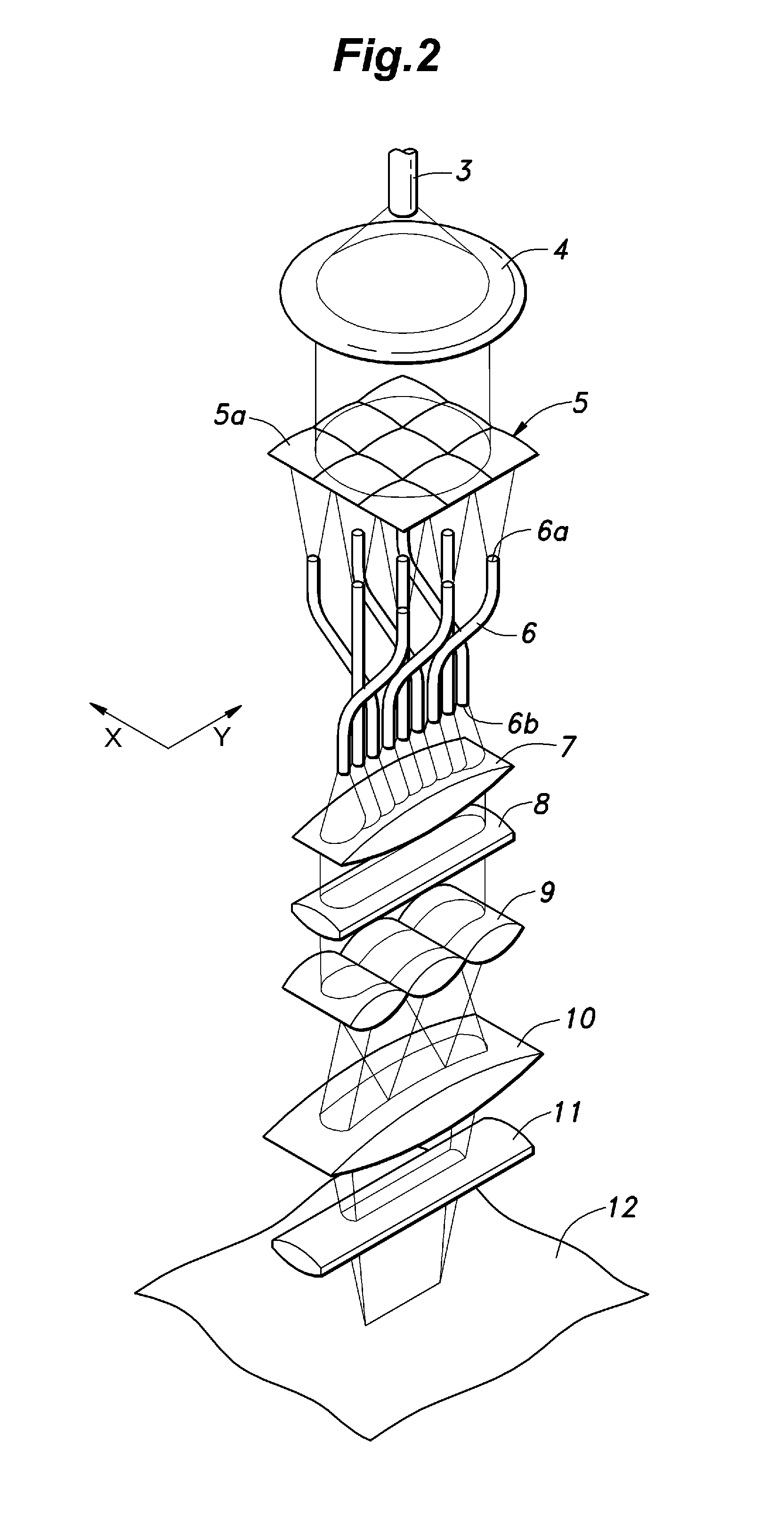

Laser optical system using optical fiber transmission

ActiveUS8662761B2Improve performanceIncrease productionSemiconductor/solid-state device manufacturingFibre light guidesLaser lightOptical fiber cable

A laser optical system using optical fiber transmission, includes a first optical fiber for transmitting laser light emitted from a laser oscillator, a collimator lens for collimating laser light emitted from the first optical fiber, a spherical array lens including a plurality of cells for converging laser light emitted from the collimator lens into a plurality of spots, a plurality of second optical fibers each having a smaller core diameter than the first optical fiber and configured to admit the laser light converged into the corresponding spot by the spherical array lens, the second optical fibers having output ends that have mutually parallel axial lines and are arranged linearly in a single row, and a linearization optical unit for shaping laser light emitted from the second optical fibers into laser light having a linear cross section at an illuminated surface.

Owner:THE JAPAN STEEL WORKS LTD +1

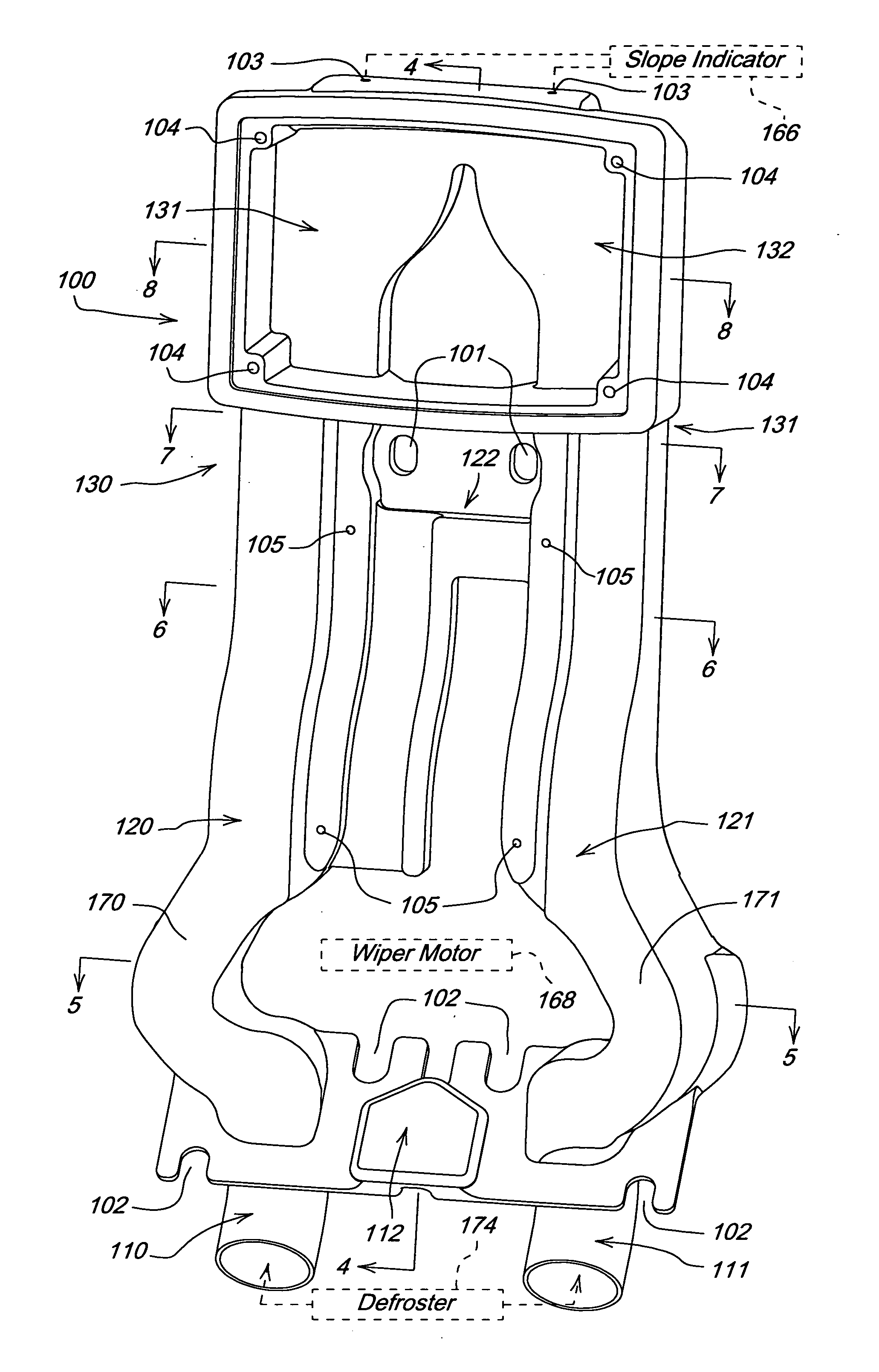

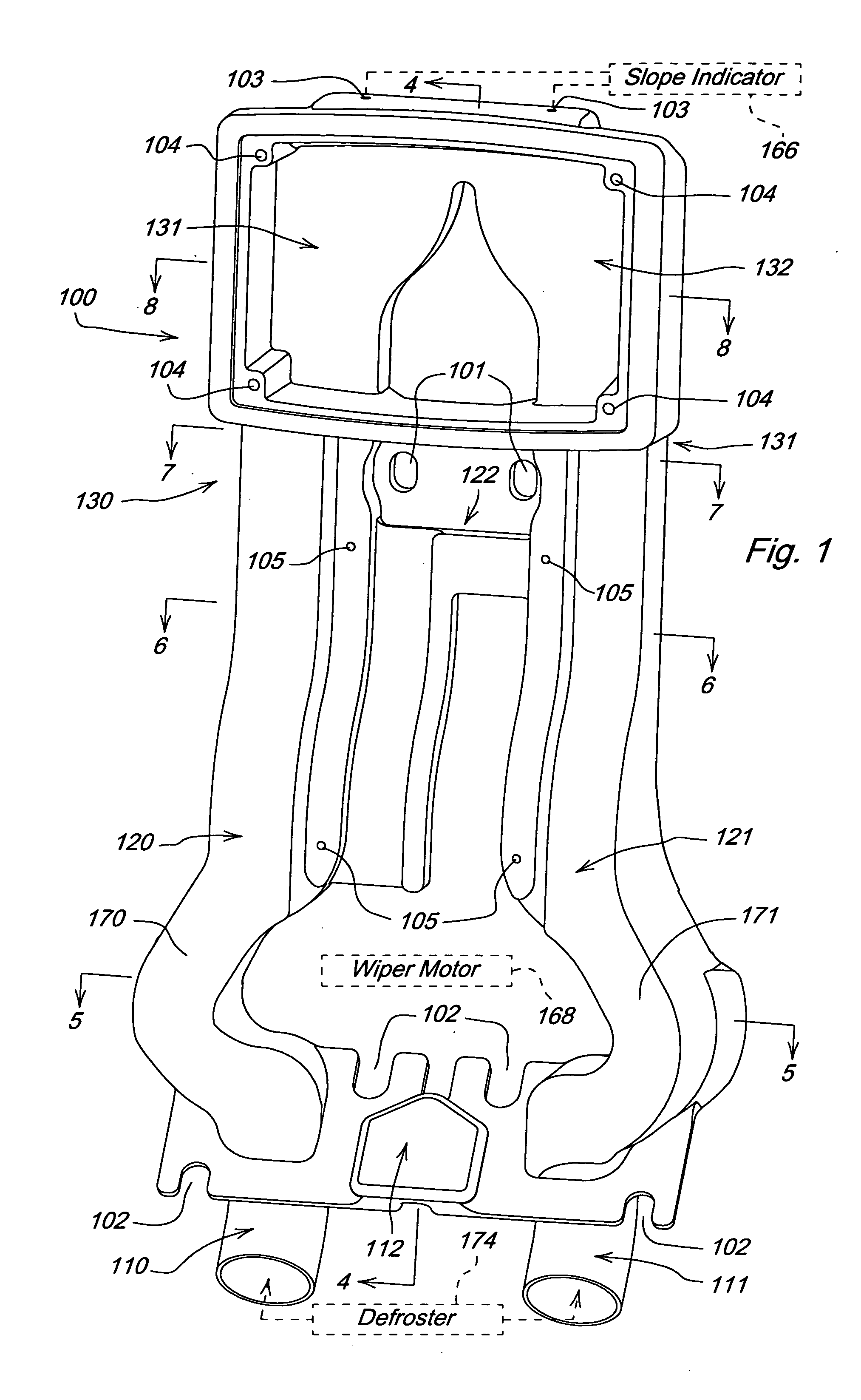

Integrated duct and monitor housing

InactiveUS20060211358A1Space saveCost reductionAir-treating devicesRailway heating/coolingDisplay deviceWaste management

Owner:DEERE & CO

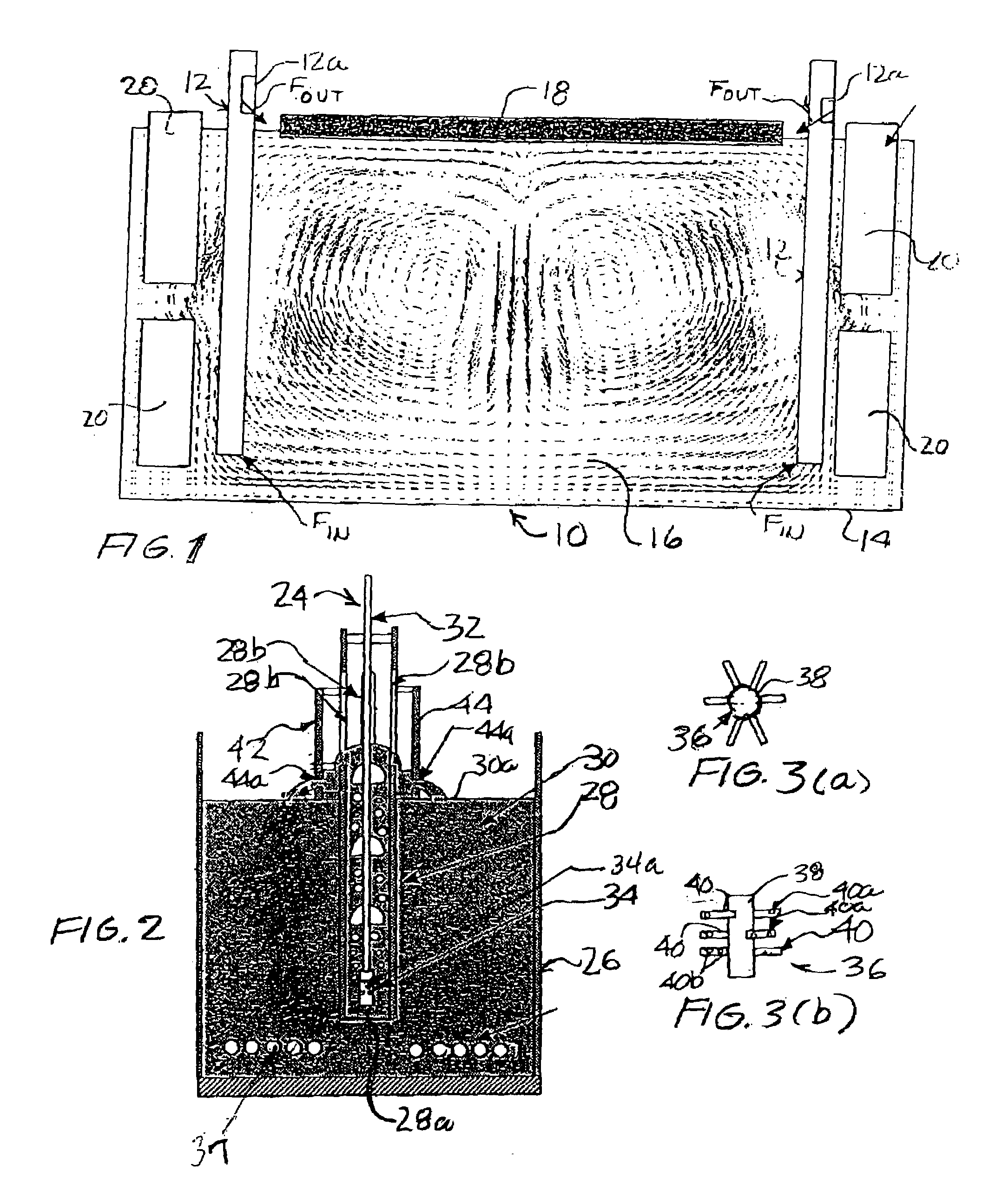

Recirculation bubbler for glass melter apparatus

InactiveUS7225643B1Minimum energy lossEffective distributionTransportation and packagingGlass furnace apparatusGas bubblerGas bubble

A gas bubbler device provides enhanced recirculation of molten glass within a glass melter apparatus. The bubbler device includes a tube member disposed within a pool of molten glass contained in the melter. The tube member includes a lower opening through which the molten glass enters and upper slots disposed close to (above or below) the upper surface of the pool of molten glass and from which the glass exits. A gas (air) line is disposed within the tube member and extends longitudinally thereof. A gas bubble distribution device, which is located adjacent to the lower end of the tube member and is connected to the lower end of the gas line, releases gas through openings therein so as to produce gas bubbles of a desired size in the molten glass and in a distributed pattern across the tube member.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Radiation system, lithographic apparatus, device manufacturing method and device manufactured thereby

ActiveUS7113261B2Minimum energy lossMirrorsSemiconductor/solid-state device manufacturingLight beamLighting system

Owner:ASML NETHERLANDS BV

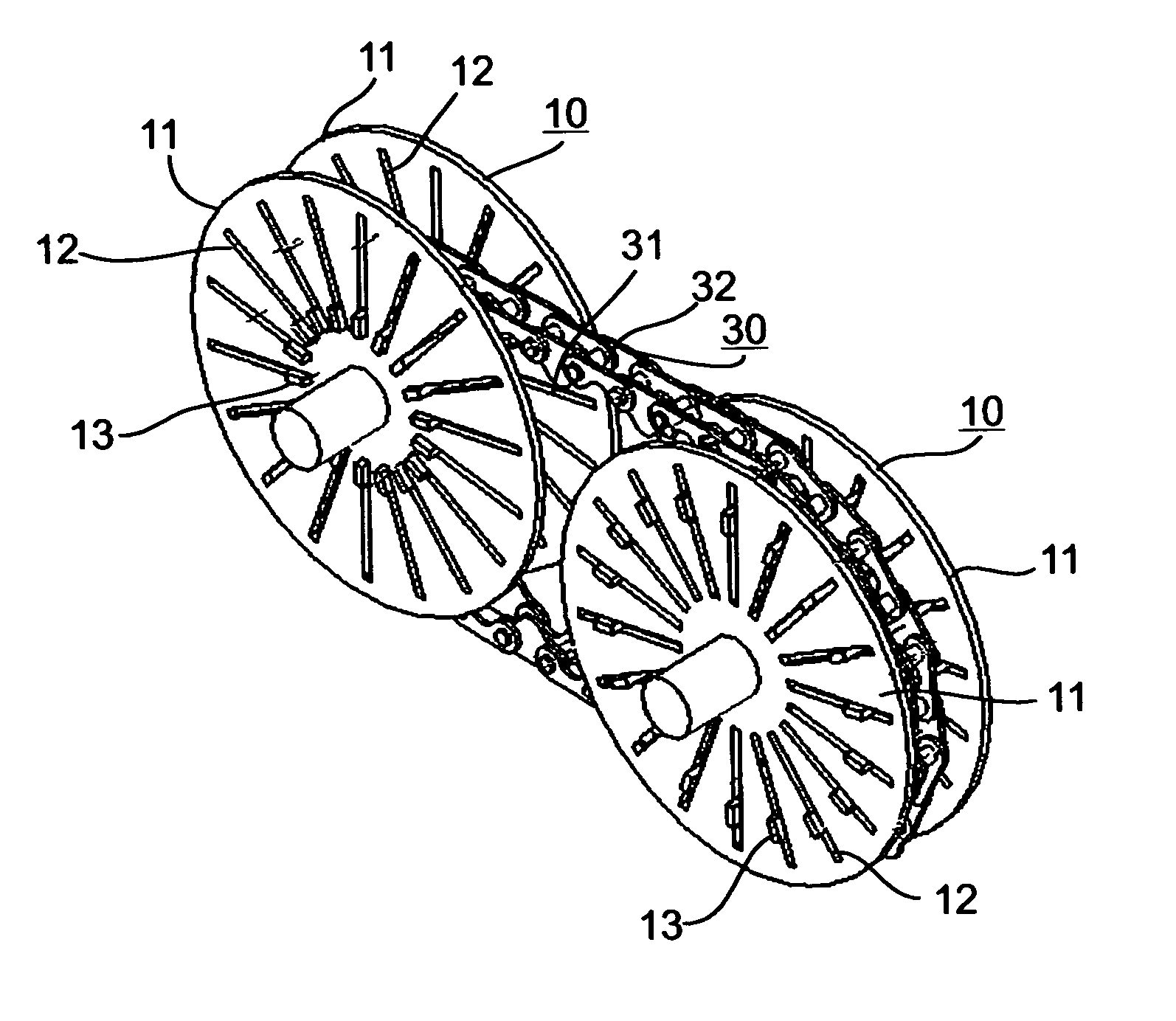

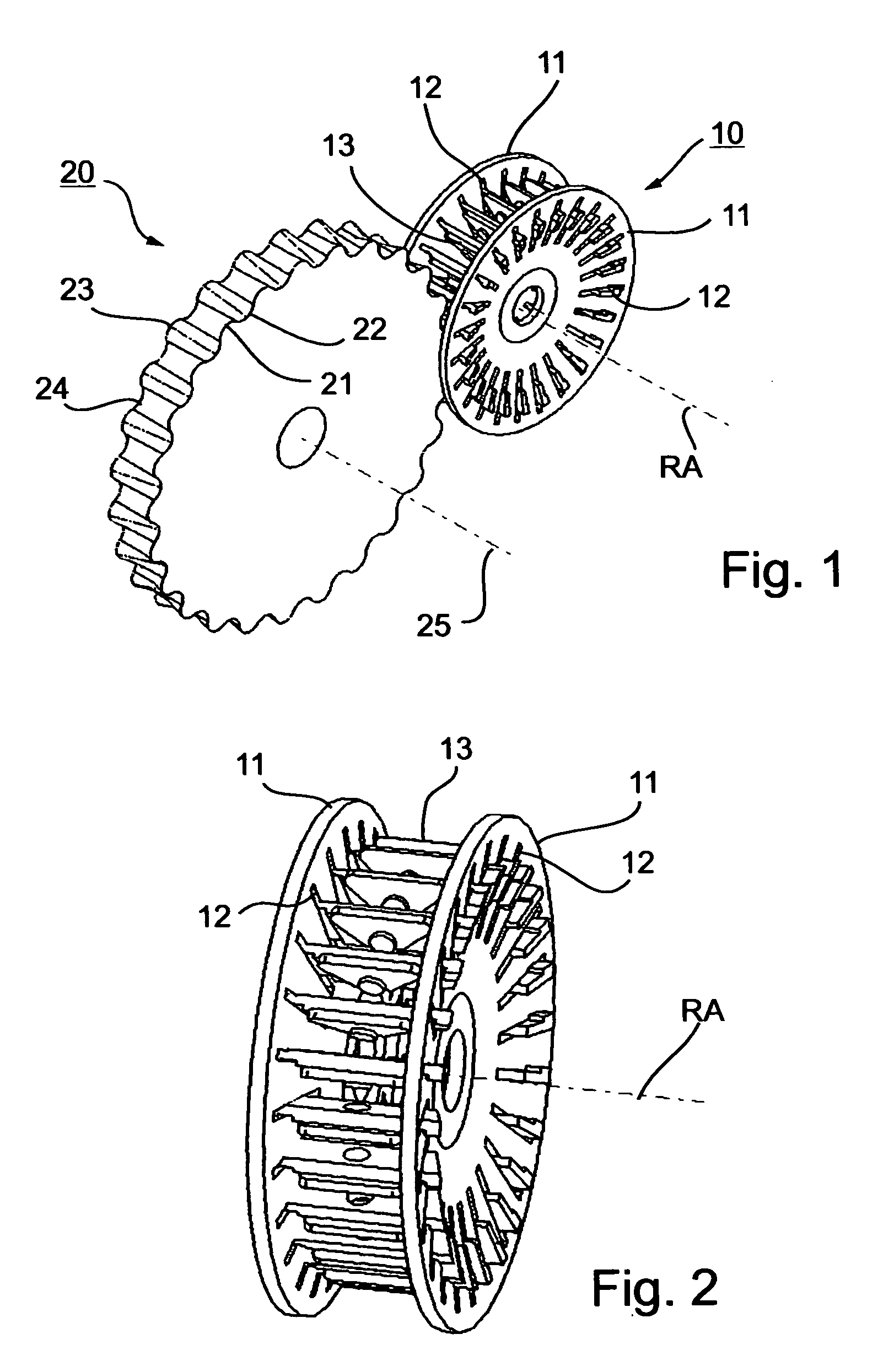

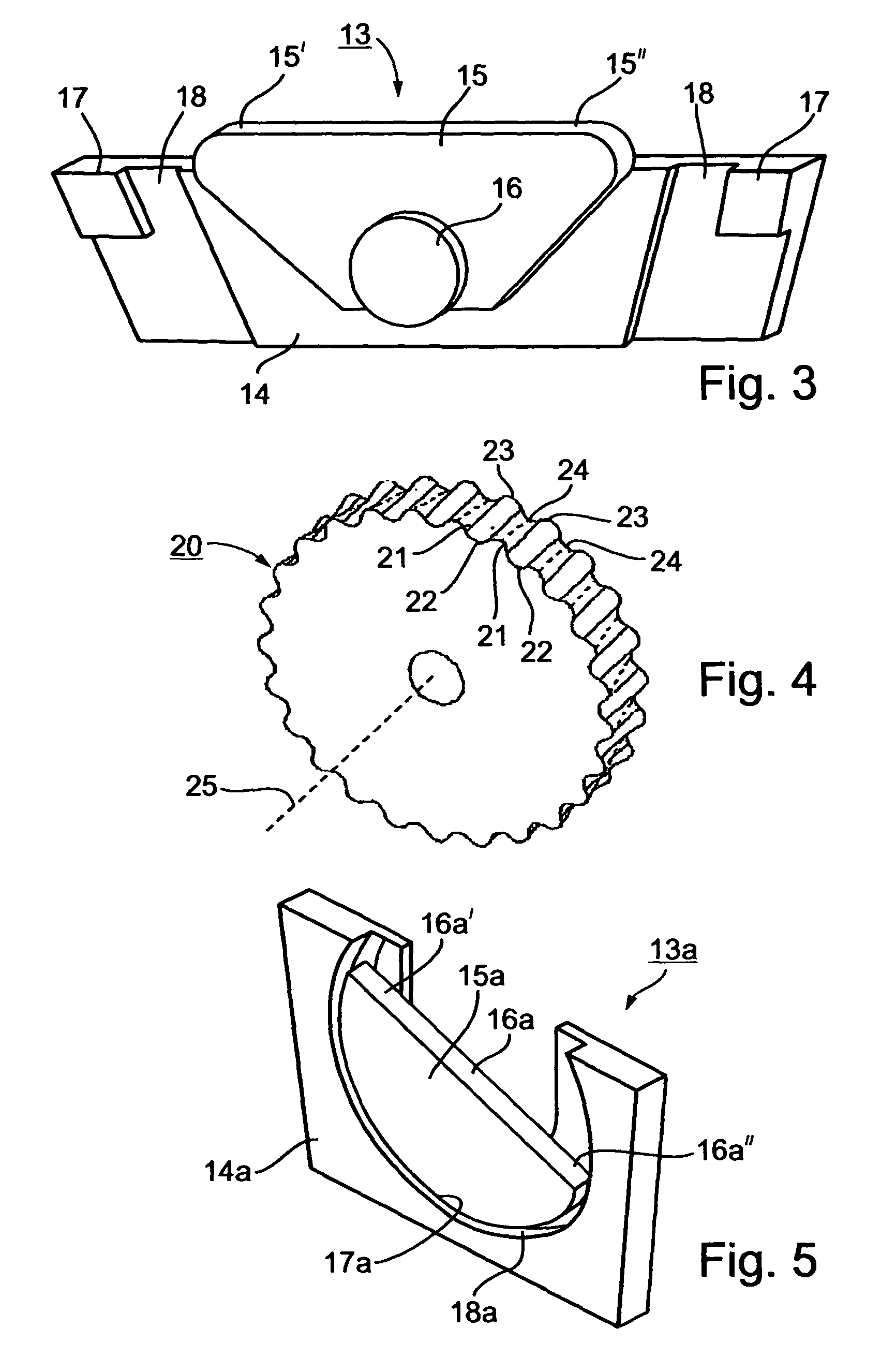

Non-slip transmissions particularly useful as continuously-variable transmissions and transmission members thereof

InactiveUS7955203B2Eliminate slippageReduce friction lossToothed gearingsPortable liftingRotational axisCoupling

A continuously-variable transmission includes two transmission members each having coupling elements engageable to couple the transmission members for movement together. At least one of the transmission members is a rotary member rotatable about a rotary axis; and at least one of the groups of coupling elements is radially displaceable towards and away from the rotary axis to change the conversion ratio of the transmission. The coupling elements of one group on one transmission member are of a fixed configuration defining projections alternating with depressions each of a fixed configuration formed on a surface of the transmission member between opposite side faces and having the same pitch for every cross section of the surface perpendicular to the mentioned rotary axis. The coupling elements of the other group are of a self-adaptive configuration, each movable in opposite directions to adapt itself to the configuration of the fixed-configuration coupling elements in all displacement positions of the radially-displaceable coupling elements and to effect a non-slip coupling therewith.

Owner:CVTRON LTD

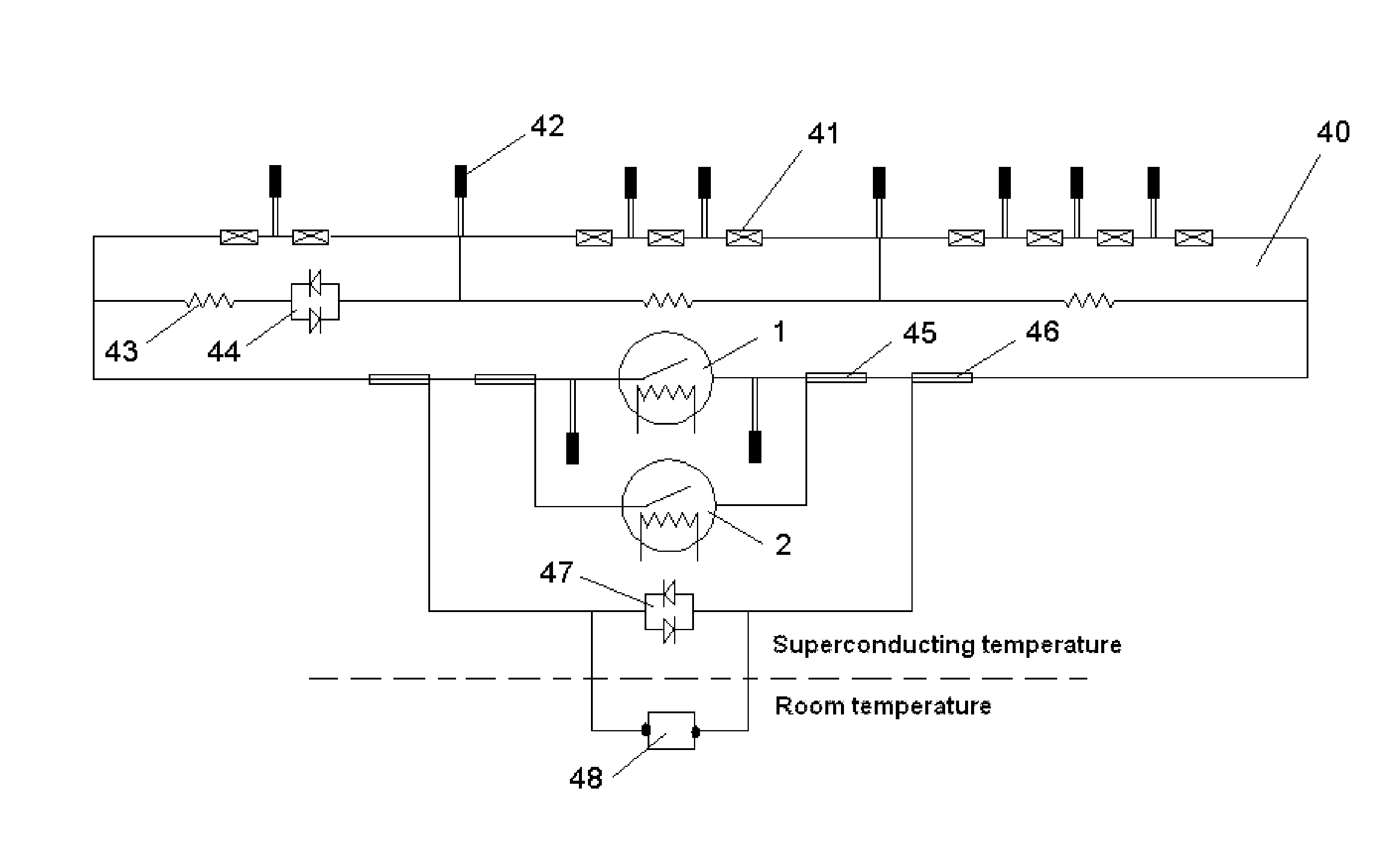

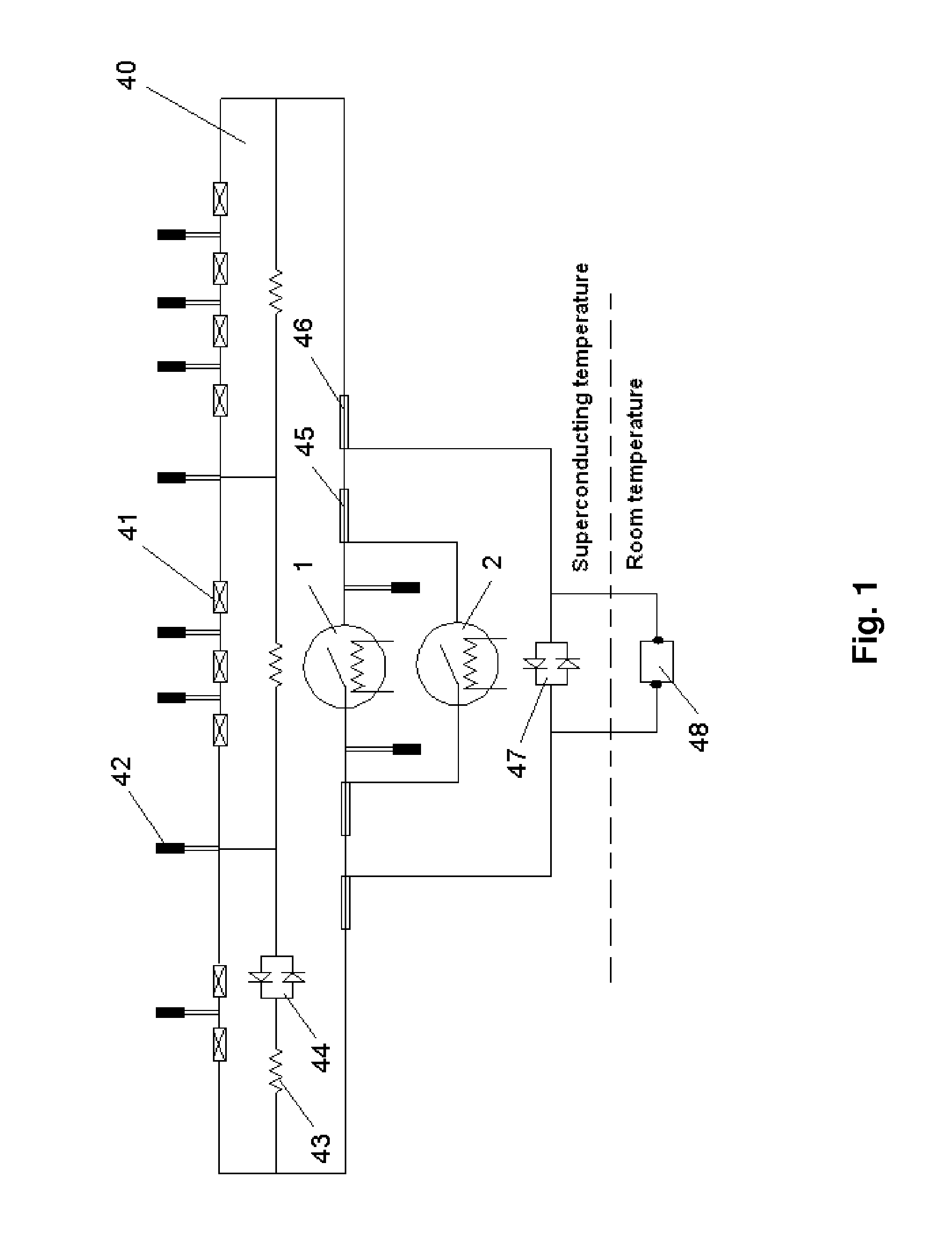

Superconducting switch operation

InactiveUS20100213772A1Reduce power consumptionMinimum energy lossBoards/switchyards circuit arrangementsEmergency protective circuit arrangementsElectrical resistance and conductanceSuperconducting Coils

A method of operating a superconducting switch system to protect against quenching in a superconducting magnet circuit is provided. The system comprises a magnet circuit, a main superconducting switch and an auxiliary superconducting switch connected in parallel thereto by low resistance connecting parts. In an initial magnet energisation procedure, after establishing superconducting flow in the circuit, the main and auxiliary switches are closed to cause current to persist in the circuit without further power input. If the main switch quenches, the current will transfer to the auxiliary switch through the resistive connecting parts. Upon restoring the main switch to the superconducting state, the voltage drop through the resistive connecting parts will drive the current back through the main switch. A preconditioning procedure is carried out as part of the magnet energisation procedure to ensure that opening the main switch will establish superconducting current through the auxiliary switch.

Owner:AGILENT TECH INC

Methods and apparatuses for removal and transport of thermal energy

ActiveUS8073096B2Minimum energy lossAir heatersIndirect heat exchangersThermal energyThermochemical cycle

Methods and apparatuses are provided for the removal and transportation of thermal energy from a heat source to a distant complex for use in thermochemical cycles or other processes. In one embodiment, an apparatus includes a hybrid heat pipes / thermosyphon intermediate heat exchanger (HPTIHX) system that is divided into three distinct sections, namely: an evaporation chamber, a condensation chamber, and a working fluid transport section of liquid and vapor counter-current flows.

Owner:STC UNM

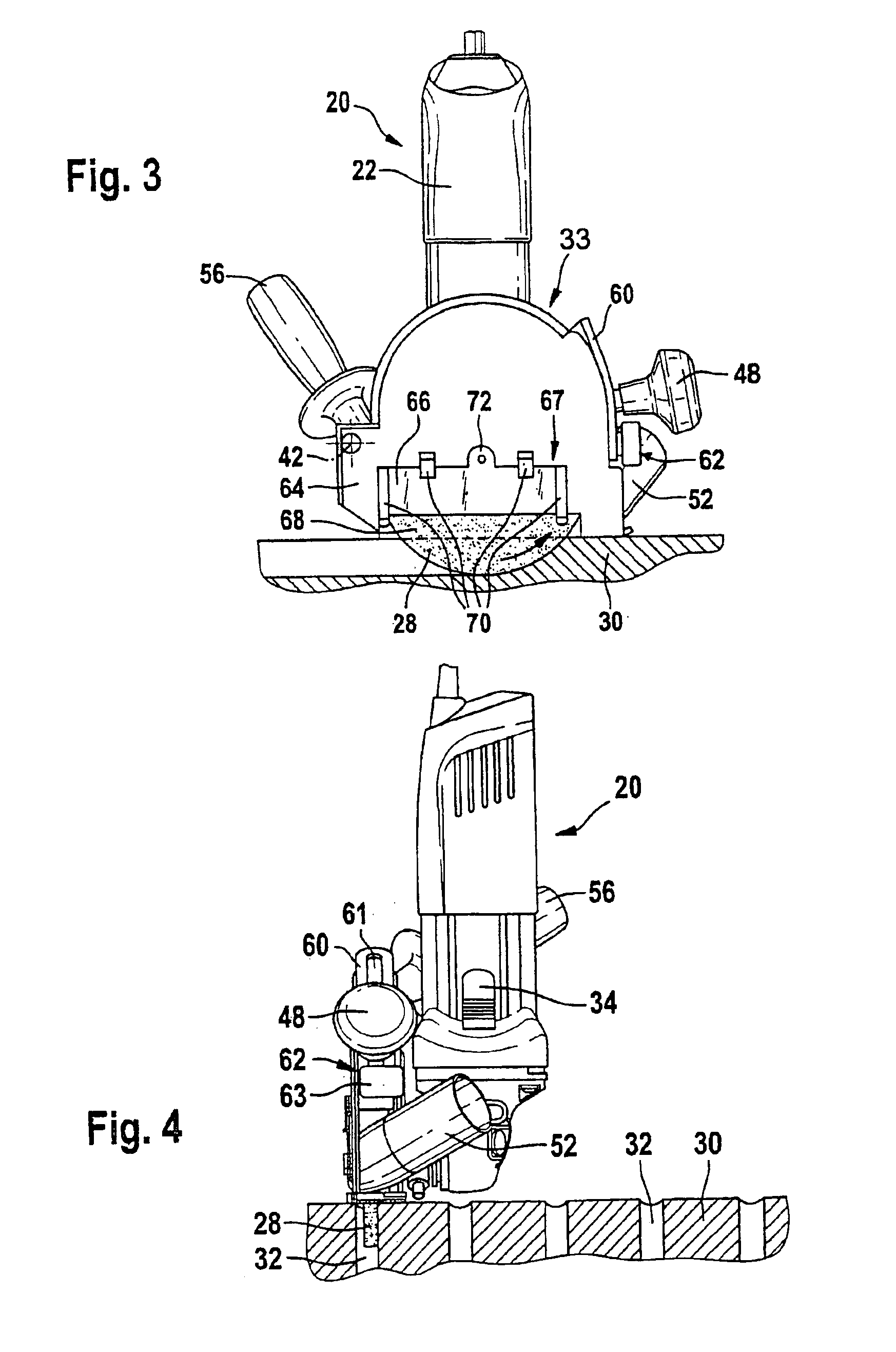

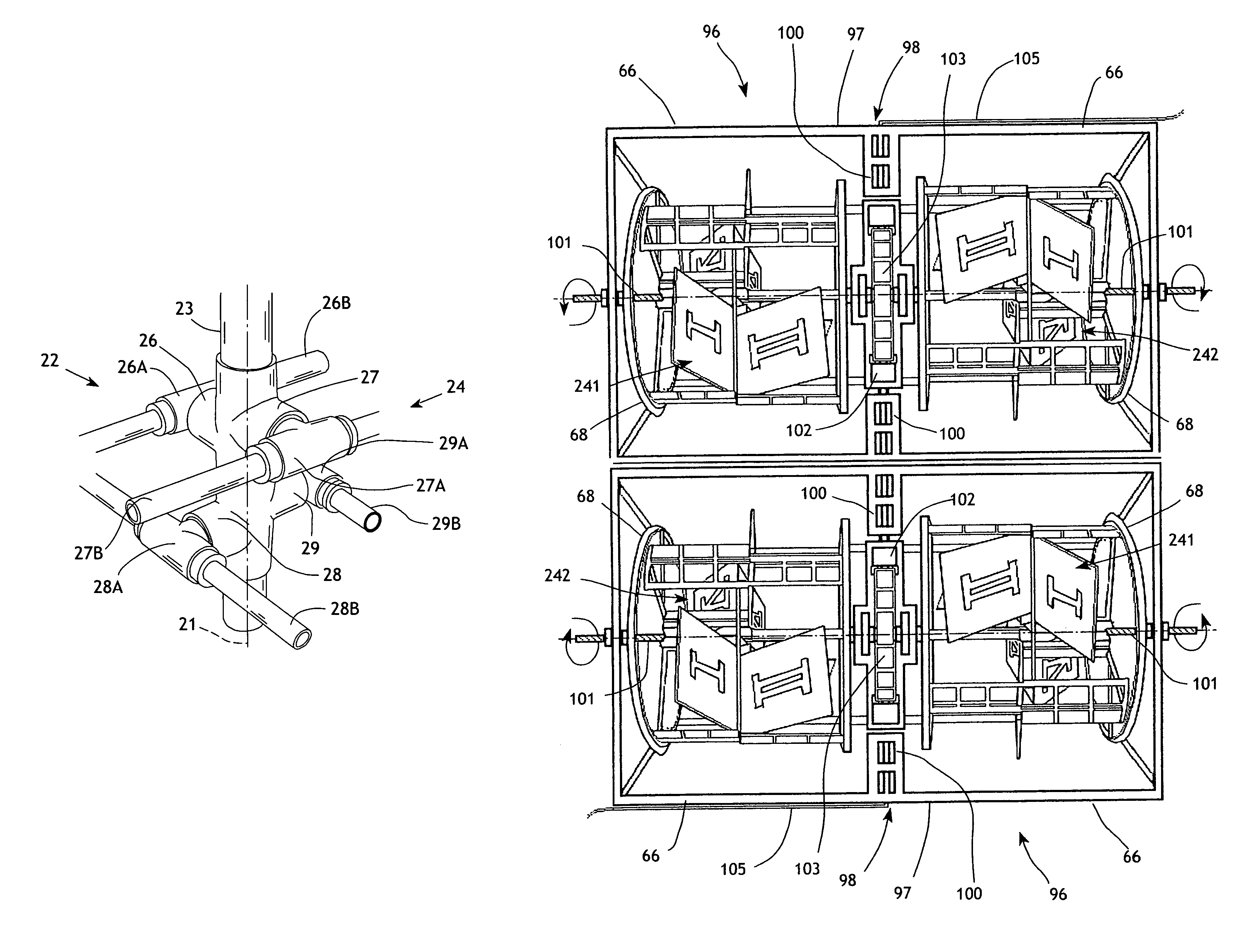

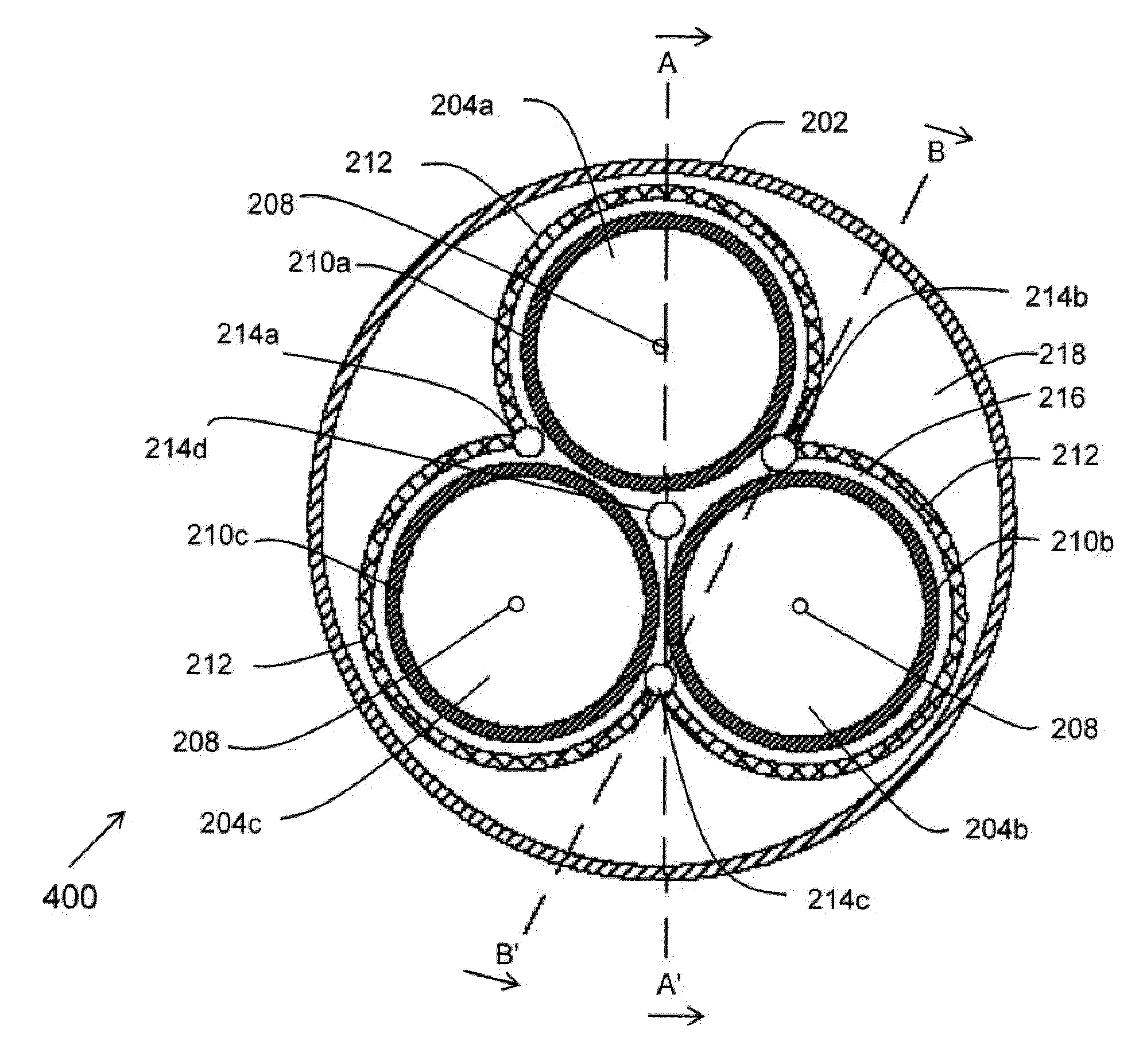

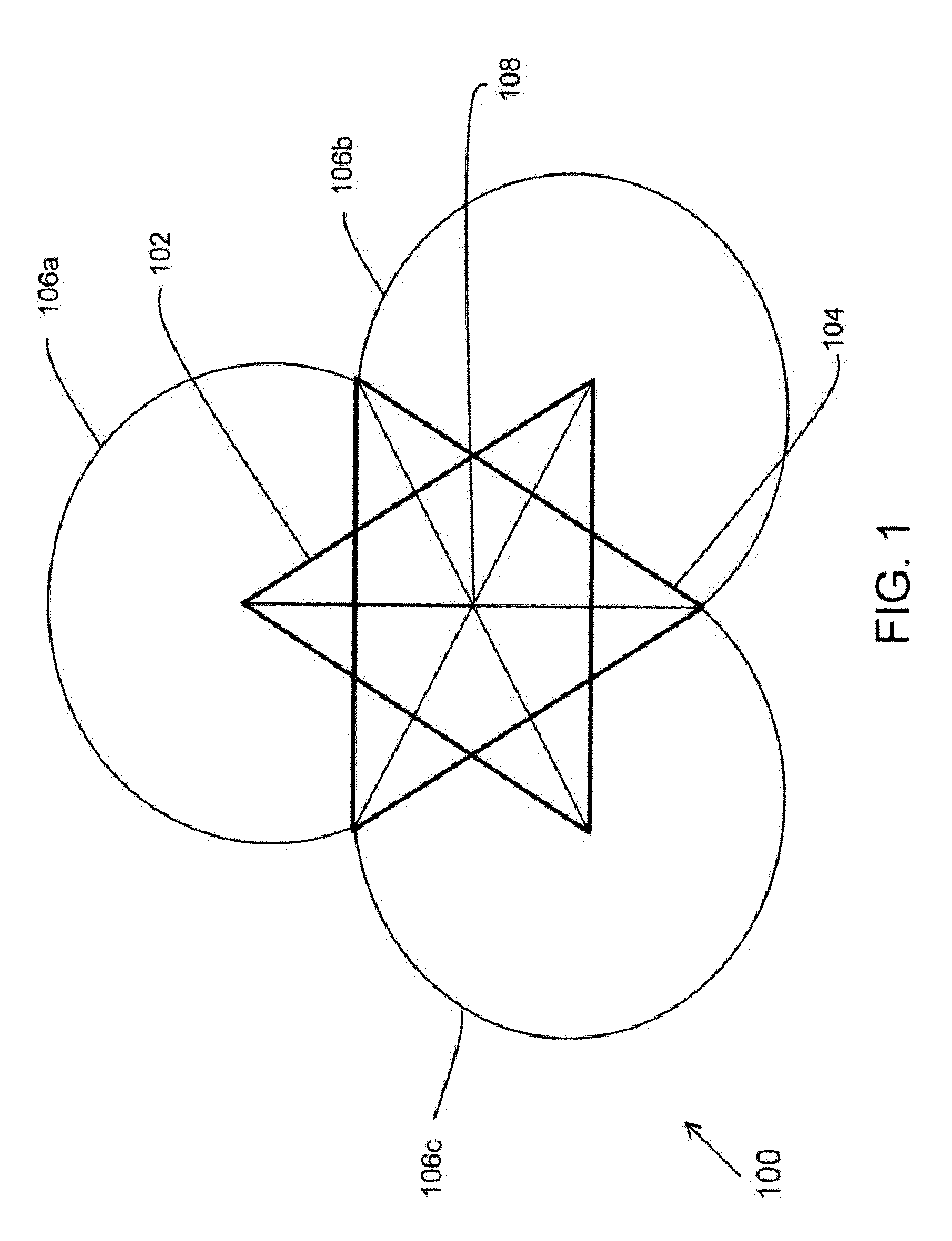

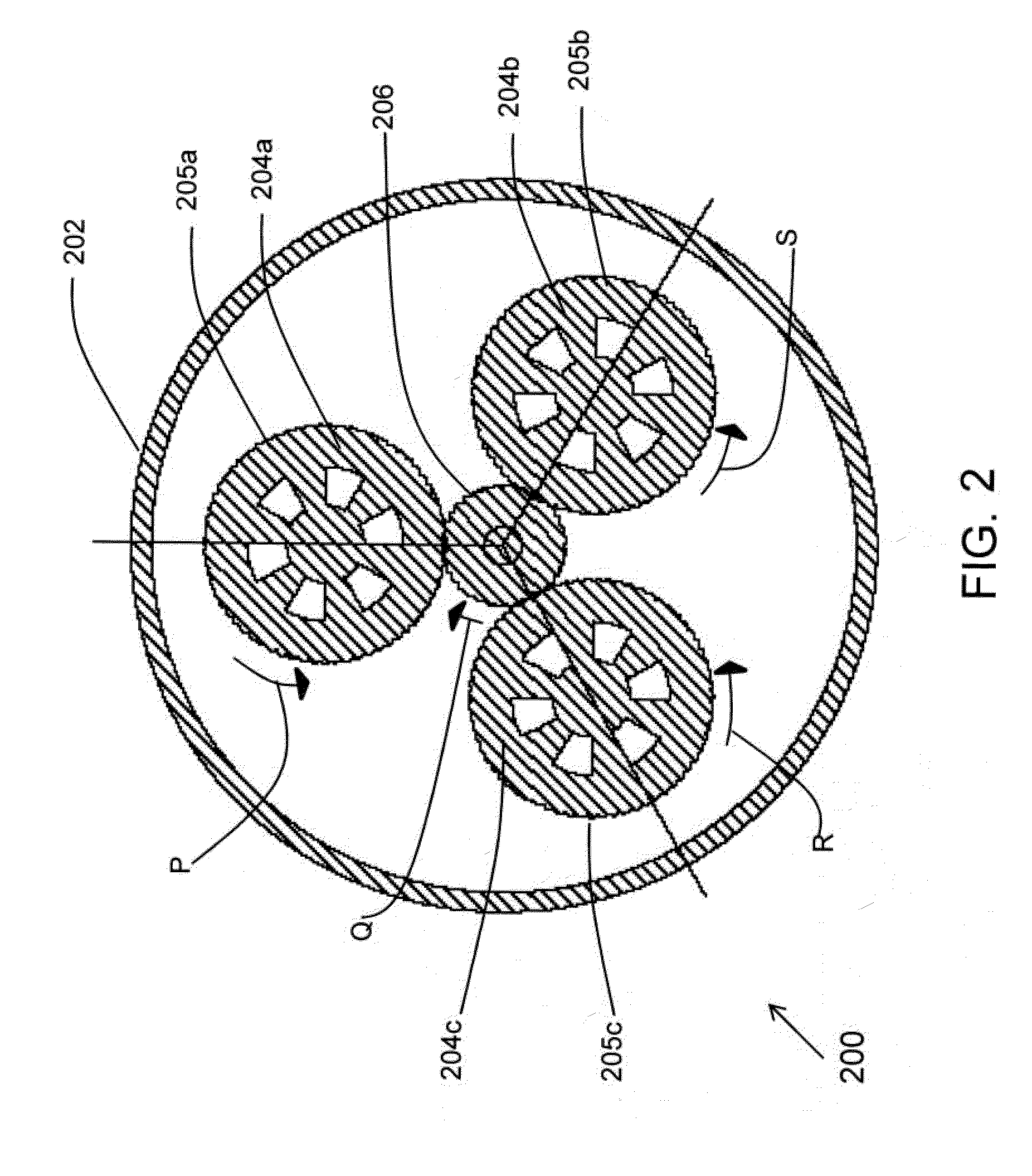

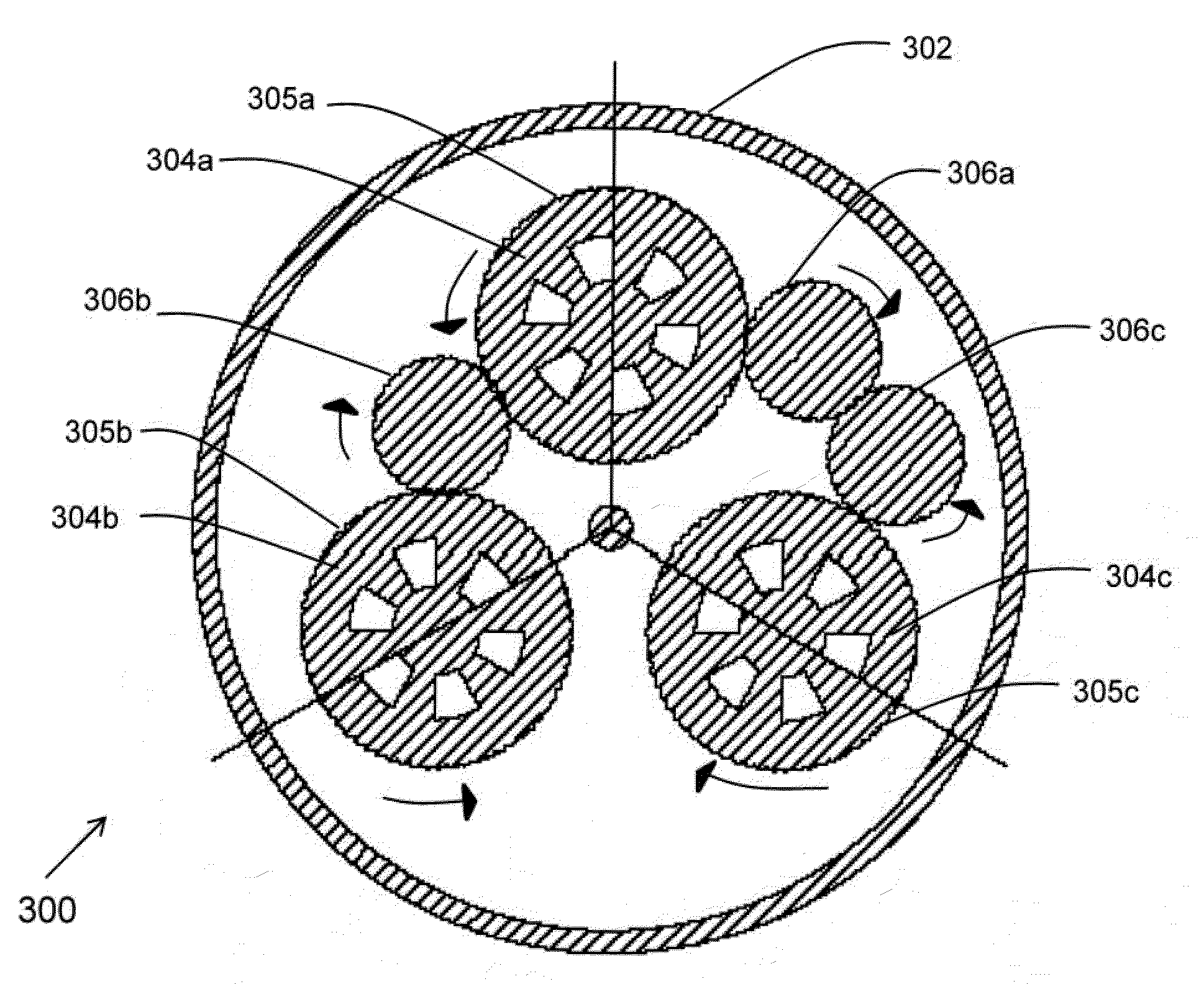

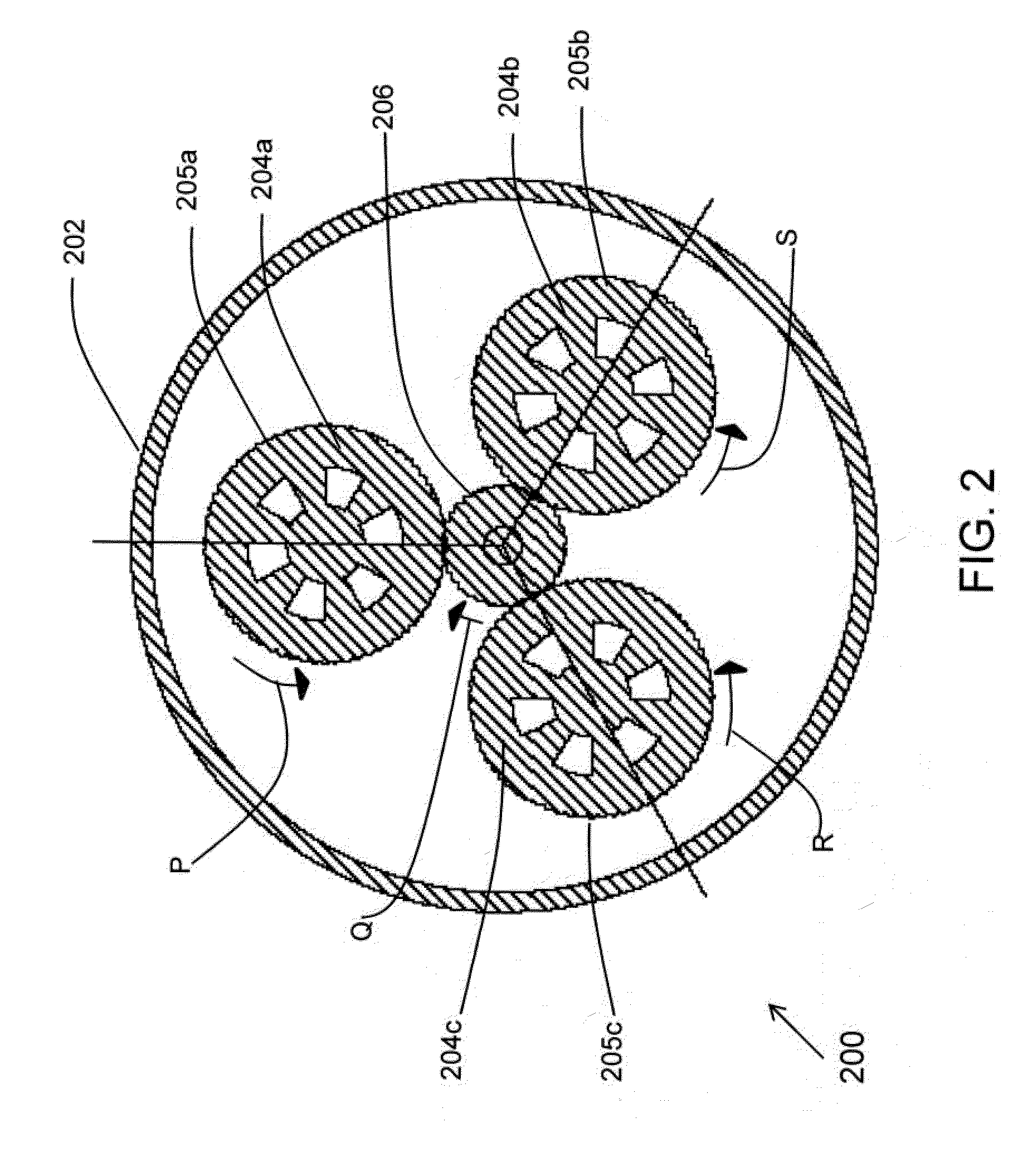

Three dimensional motor generator system

InactiveUS7965007B2Keep for a long timeReduces/eliminates requirementSynchronous generatorsAsynchronous induction motorsEngineeringThree-phase

A universal three dimensional motor generator system is provided with magnets and permanent magnetic and / or electromagnetic windings on rotors and stator for compounding and multiplying the order of voltage or potential to or from a machine. Three rotating rotors mechanically interconnected through gears and coils are strategically positioned within a housing that allows the multiple input and / or output of single and / or three phases A / C, D / C or in combination. When input power is supplied to rotor one, rotor two and rotor three start rotating along with rotor one due to gear arrangement to generate / produce power which is fed back to rotor one. This generated / produced power can / will be utilize to supplement the input power to maintain the synchronous speed across the designed load or combined to increase the output rating of machine. The system allows multiple wiring configurations allowing each section of a rotor and stator configuration to operate independently or separately as a motor or generator, or in combination.

Owner:DAHLEN HERBERT CAREY

Three dimensional motor generator system

InactiveUS20100201217A1Keep for a long timeReduces/eliminates requirementSynchronous generatorsAsynchronous induction motorsThree-phaseDesign load

A universal three dimensional motor generator system is provided with magnets and permanent magnetic and / or electromagnetic windings on rotors and stator for compounding and multiplying the order of voltage or potential to or from a machine. Three rotating rotors mechanically interconnected through gears and coils are strategically positioned within a housing that allows the multiple input and / or output of single and / or three phases A / C, D / C or in combination. When input power is supplied to rotor one, rotor two and rotor three start rotating along with rotor one due to gear arrangement to generate / produce power which is fed back to rotor one. This generated / produced power can / will be utilize to supplement the input power to maintain the synchronous speed across the designed load or combined to increase the output rating of machine. The system allows multiple wiring configurations allowing each section of a rotor and stator configuration to operate independently or separately as a motor or generator, or in combination.

Owner:DAHLEN HERBERT CAREY

Laser optical system using optical fiber transmission

ActiveUS20130084046A1Increase productionImprove performanceSemiconductor/solid-state device manufacturingFibre light guidesLaser lightLaser optics

A laser optical system using optical fiber transmission, includes a first optical fiber for transmitting laser light emitted from a laser oscillator, a collimator lens for collimating laser light emitted from the first optical fiber, a spherical array lens including a plurality of cells for converging laser light emitted from the collimator lens into a plurality of spots, a plurality of second optical fibers each having a smaller core diameter than the first optical fiber and configured to admit the laser light converged into the corresponding spot by the spherical array lens, the second optical fibers having output ends that have mutually parallel axial lines and are arranged linearly in a single row, and a linearization optical unit for shaping laser light emitted from the second optical fibers into laser light having a linear cross section at an illuminated surface.

Owner:JAPAN STEEL WORKS LTD +1

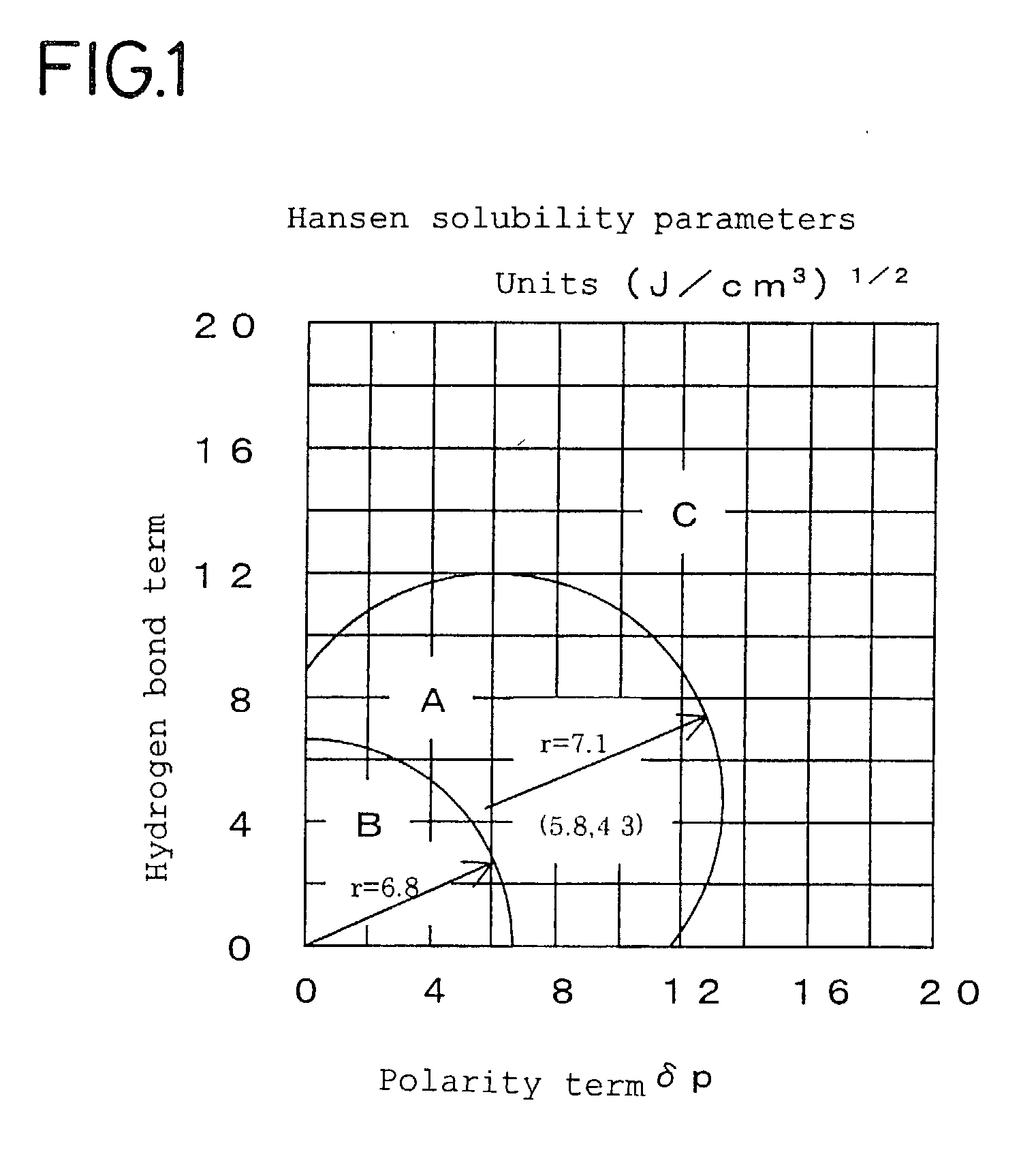

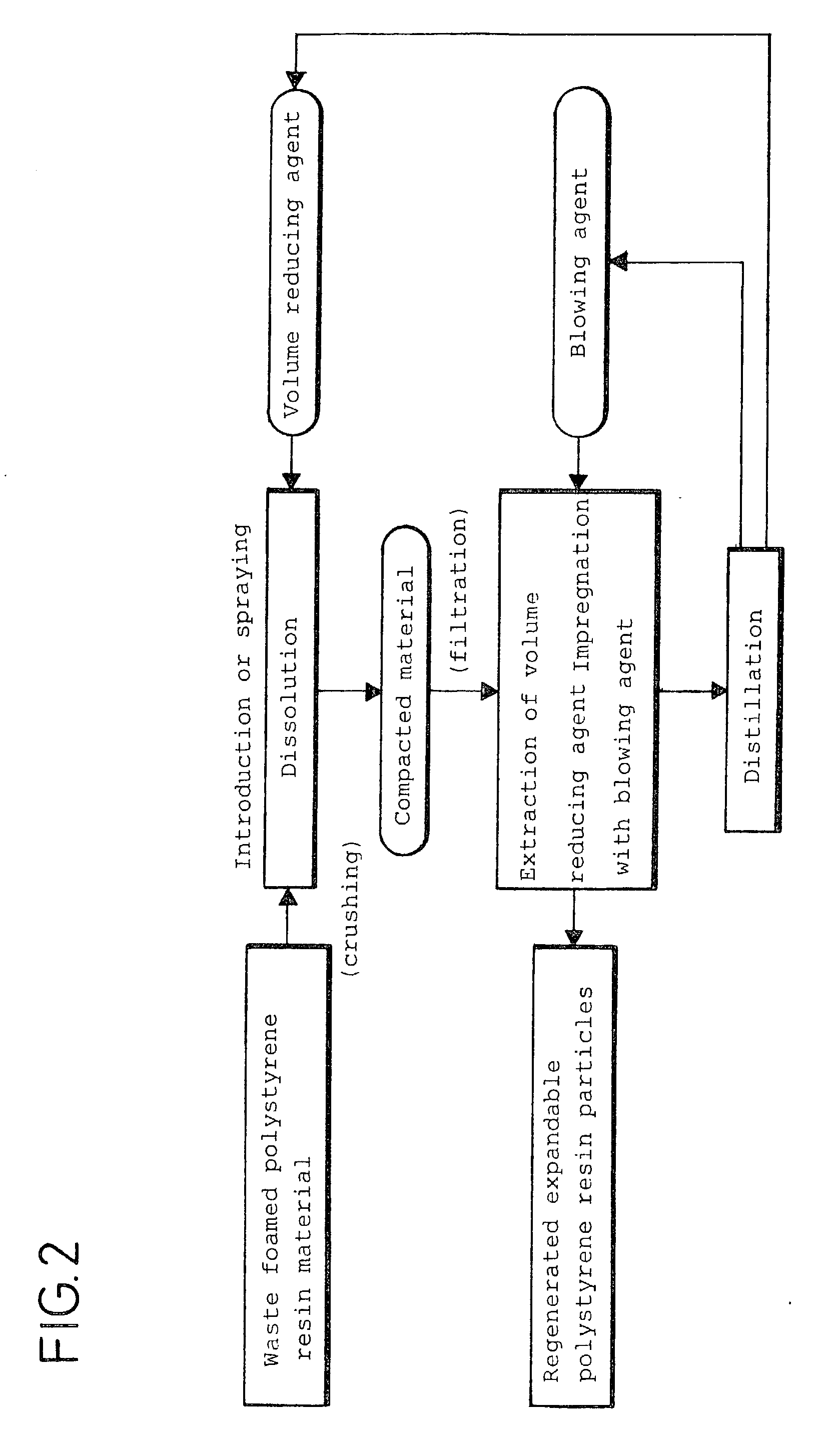

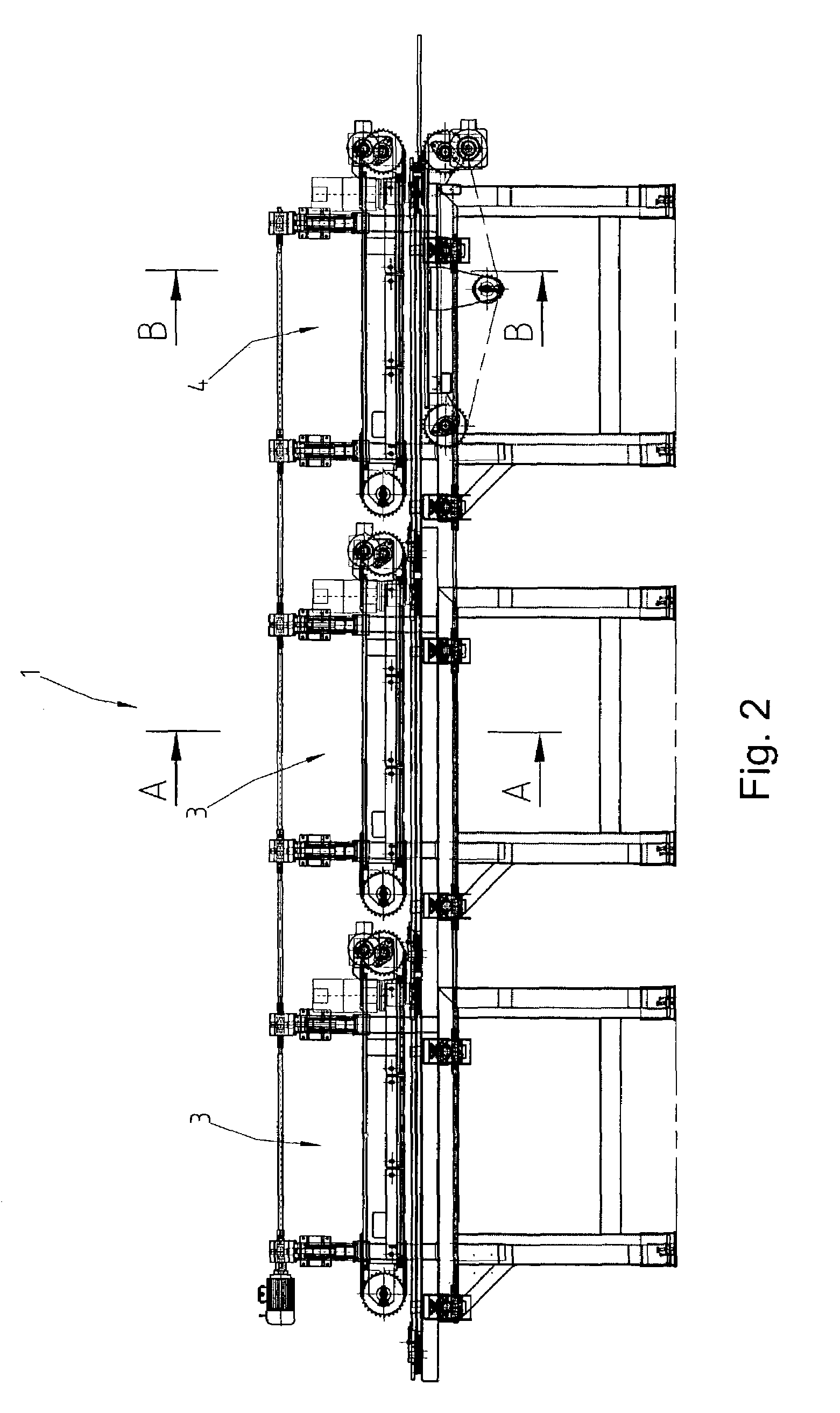

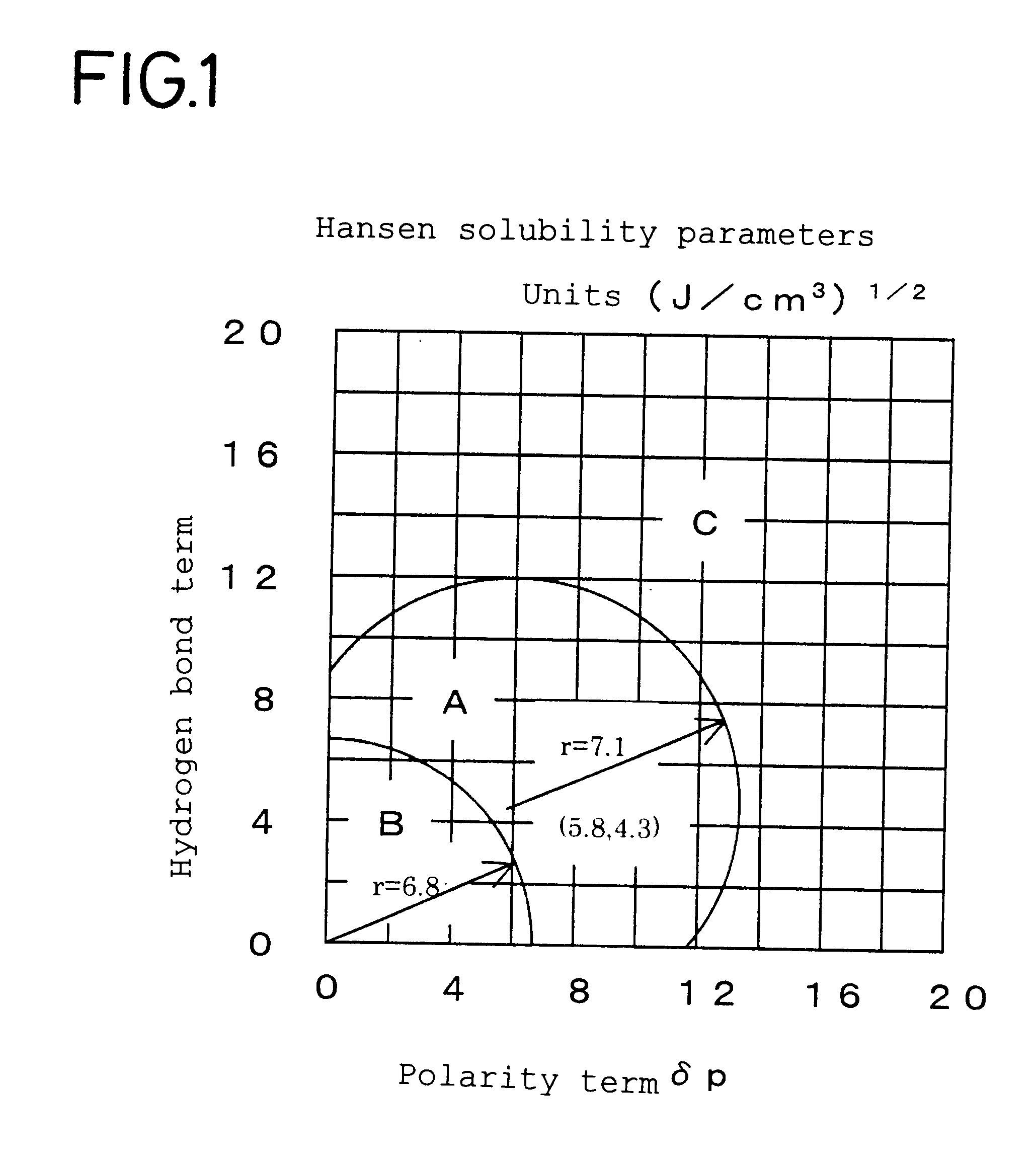

Process for producing reclaimed expandable polystyrene resin particle

It is possible to recover a volume reducing agent from a waste foamed polystyrene resin material compacted with the volume reducing agent and to impregnate a blowing agent into the compacted material at ordinary room temperature. The volume reducing agent is preferably a polar solvent having solubility with respect to the polystyrene resin and exhibiting a mutual solubility with the blowing agent, which is one whose hydrogen bond term deltah and polarity term deltap of the Hansen solubility parameters satisfy the following conditions:<paragraph lvl="0"><in-line-formula>(deltap-5.8)2+(deltah-4.3)2<50 and deltap2+deltah2>46 [units :(J / cm3)½]< / in-line-formula>The solvent used as the volume reducing agent is preferably at least one solvent selected from the group consisting of ketones, esters, polyhydric alcohol ether acetates, ethers, halogenated hydrocarbons, nitro compounds, and amines. The solvent may be a mixed solvent consisting essentially of at least one solvent selected from the above-described group and at least one solvent selected from the group consisting of aliphatic hydrocarbons and aromatic hydrocarbons.

Owner:KAGOSHIMAKEN

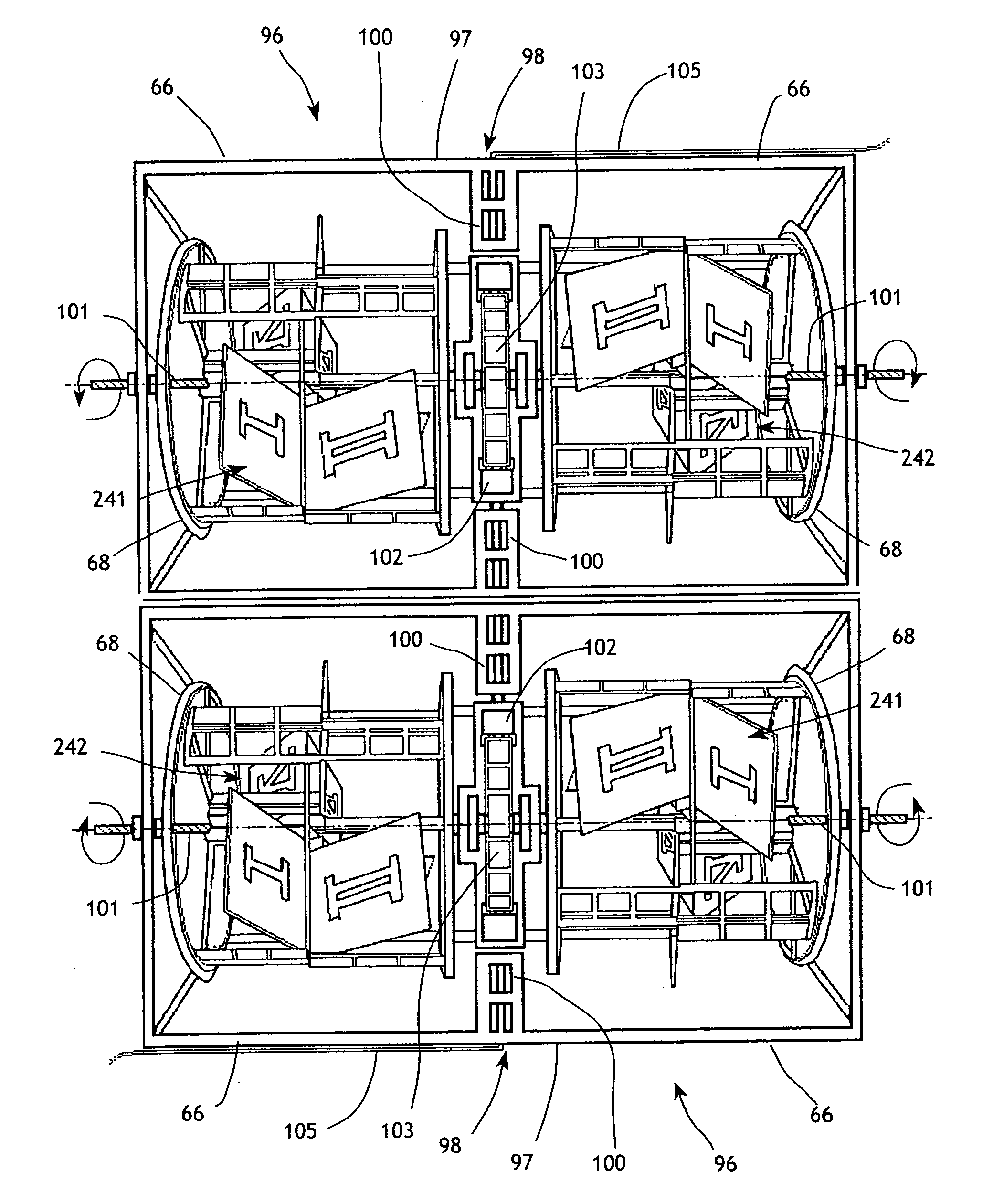

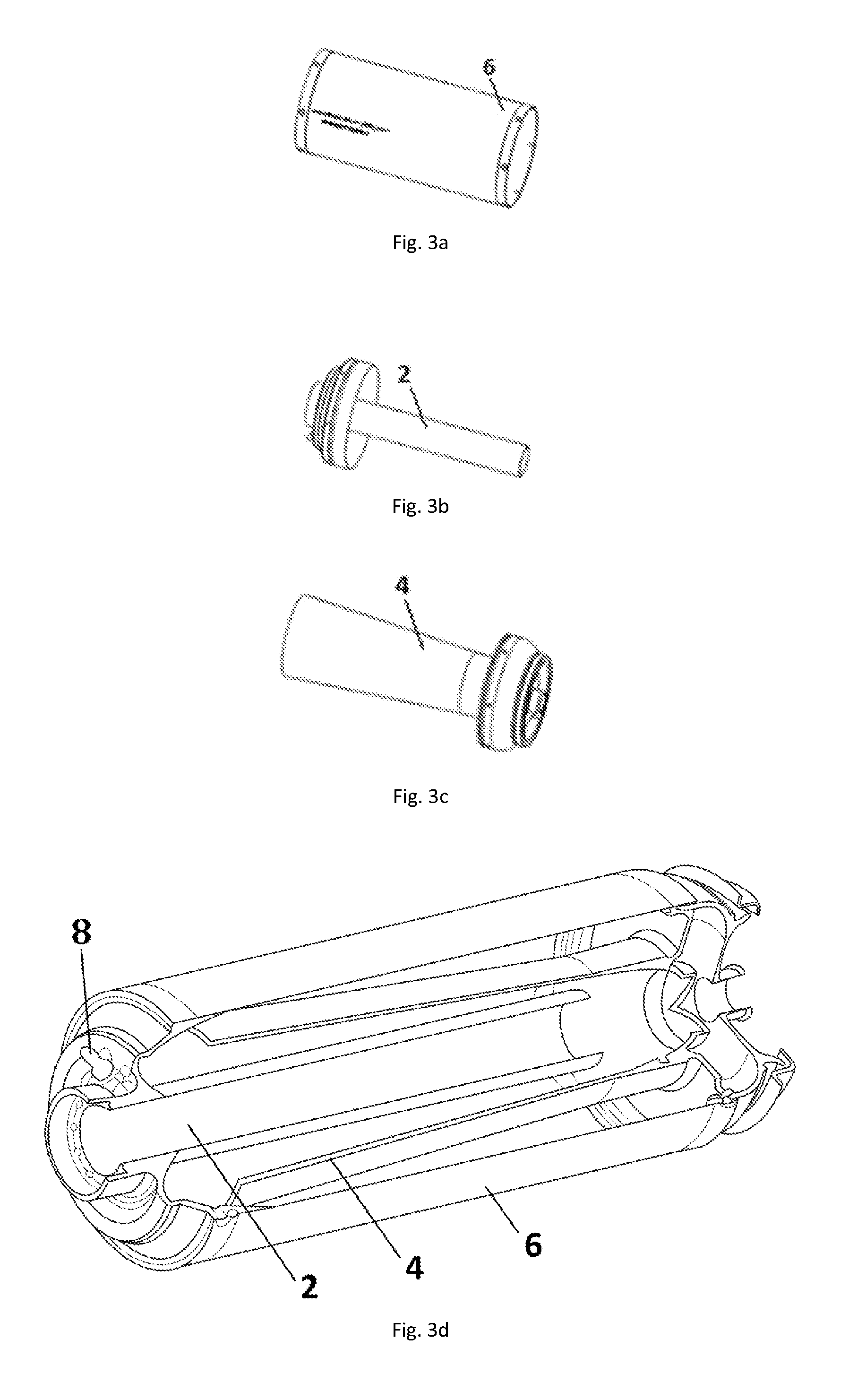

Exhaust resonator for a two-stroke engine for use in a motorized float

InactiveUS20160376952A1Increase volumePressure wave is generatedInternal combustion piston enginesExhaust apparatusFour-stroke engineEngineering

An exhaust resonator comprises a first cover having an inlet. A first end of a stabilizer tube is connected to the inlet. A second end of the stabilizer tube aims at a primary reflection surface at a first end of an expansion cone surrounding the stabilizer tube to define a first expansion space. A second end of the expansion cone aims at a secondary reflection surface inwardly of a first cover. A first end of an outer case surrounds the expansion cone. A second end of the outer case connects to a second cover that is provided with the outlet. A second expansion space is defined by the expansion cone and the outer case. The second expansion space is terminated by a baffle with an opening on an interface between the outer case and the second cover. The first cover is provided with at least one coolant liquid opening.

Owner:SULA MARTIN

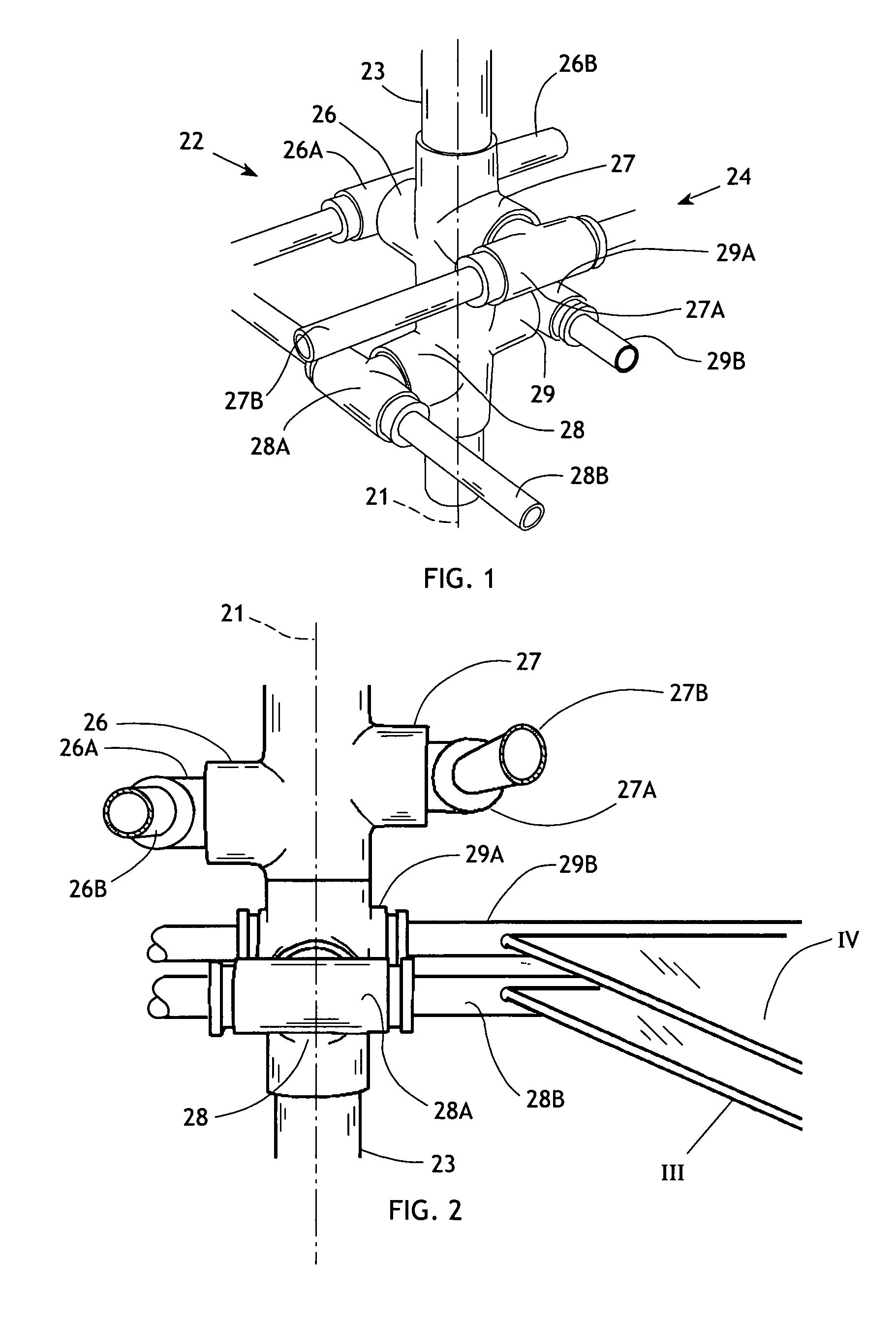

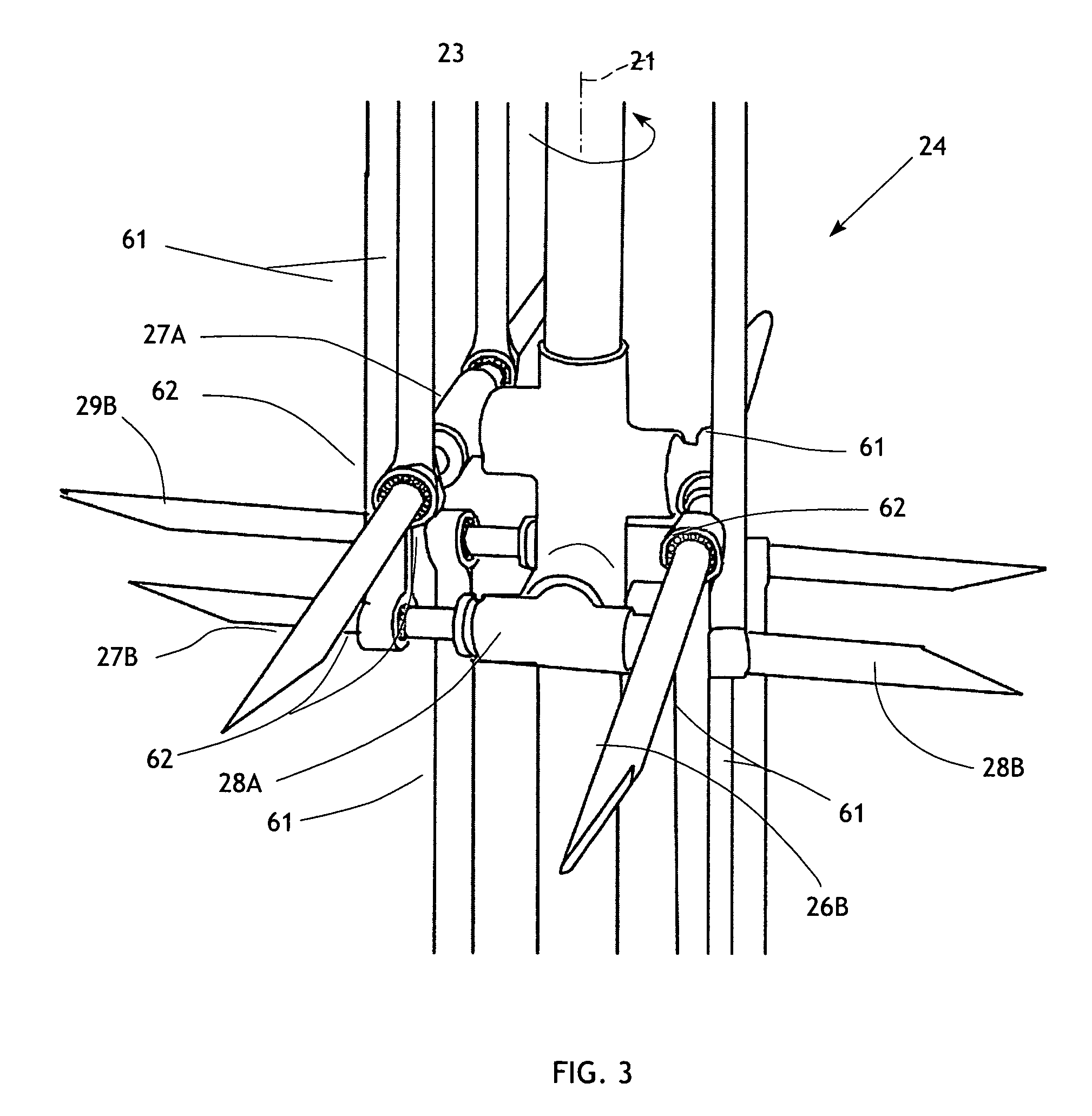

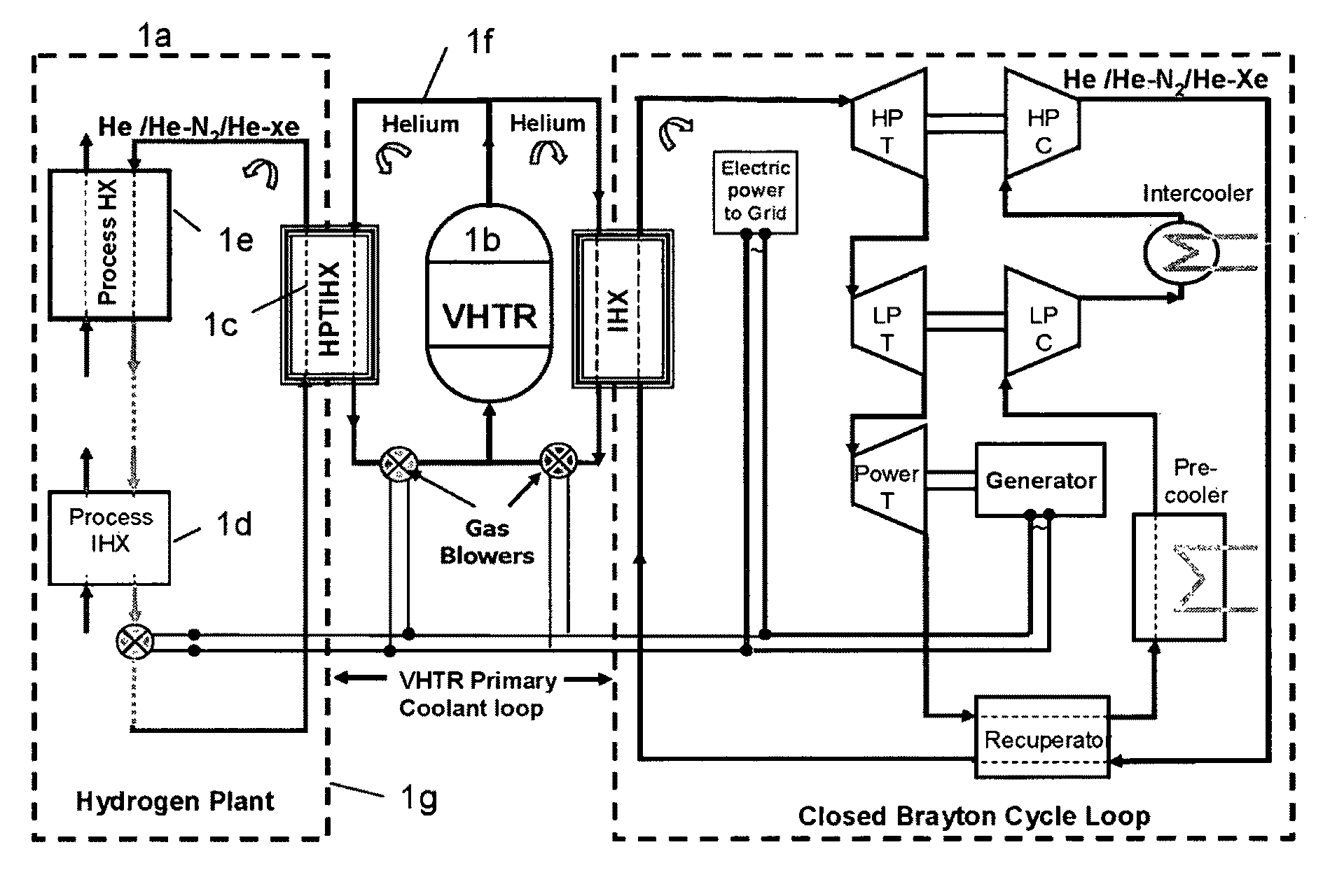

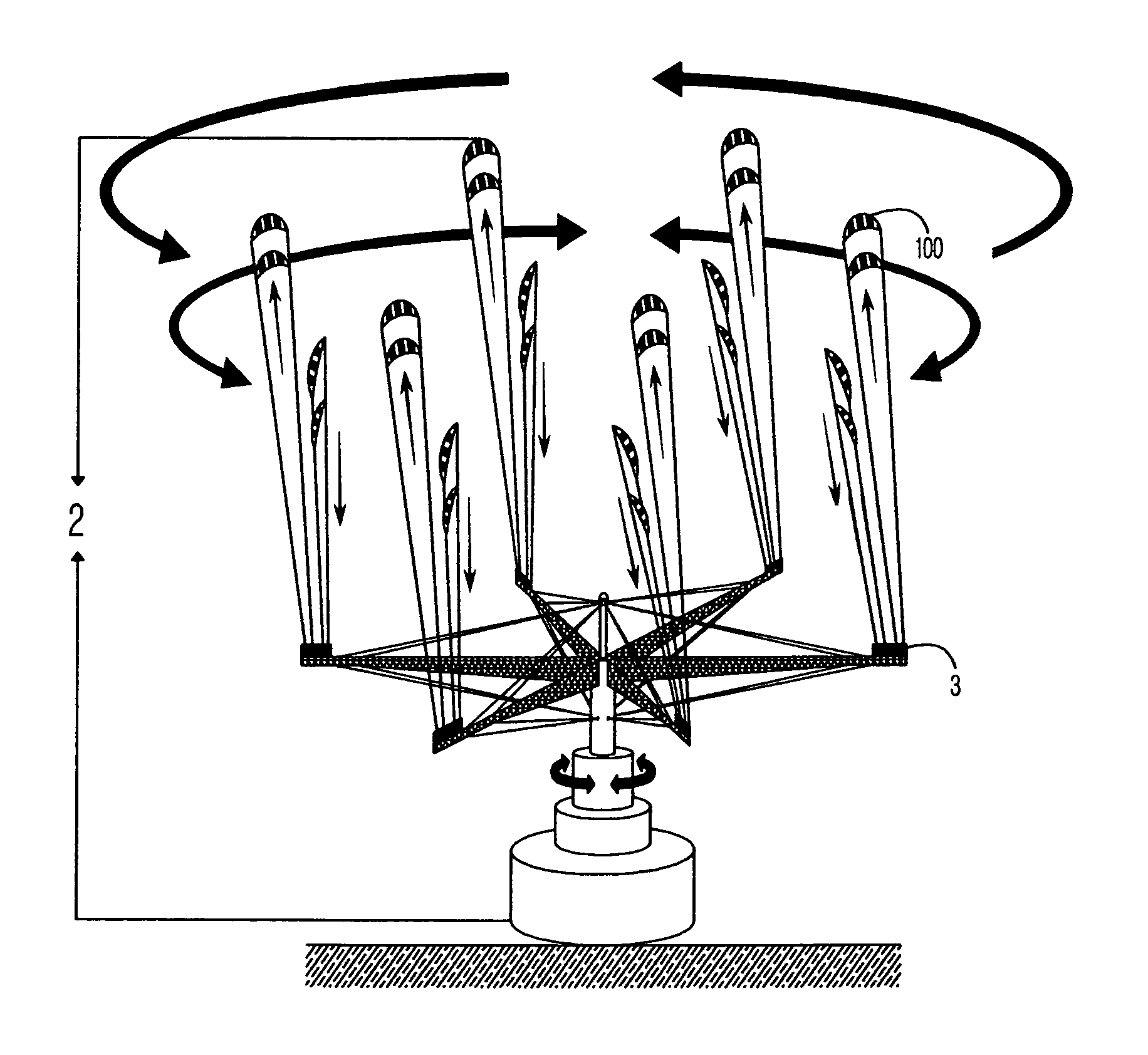

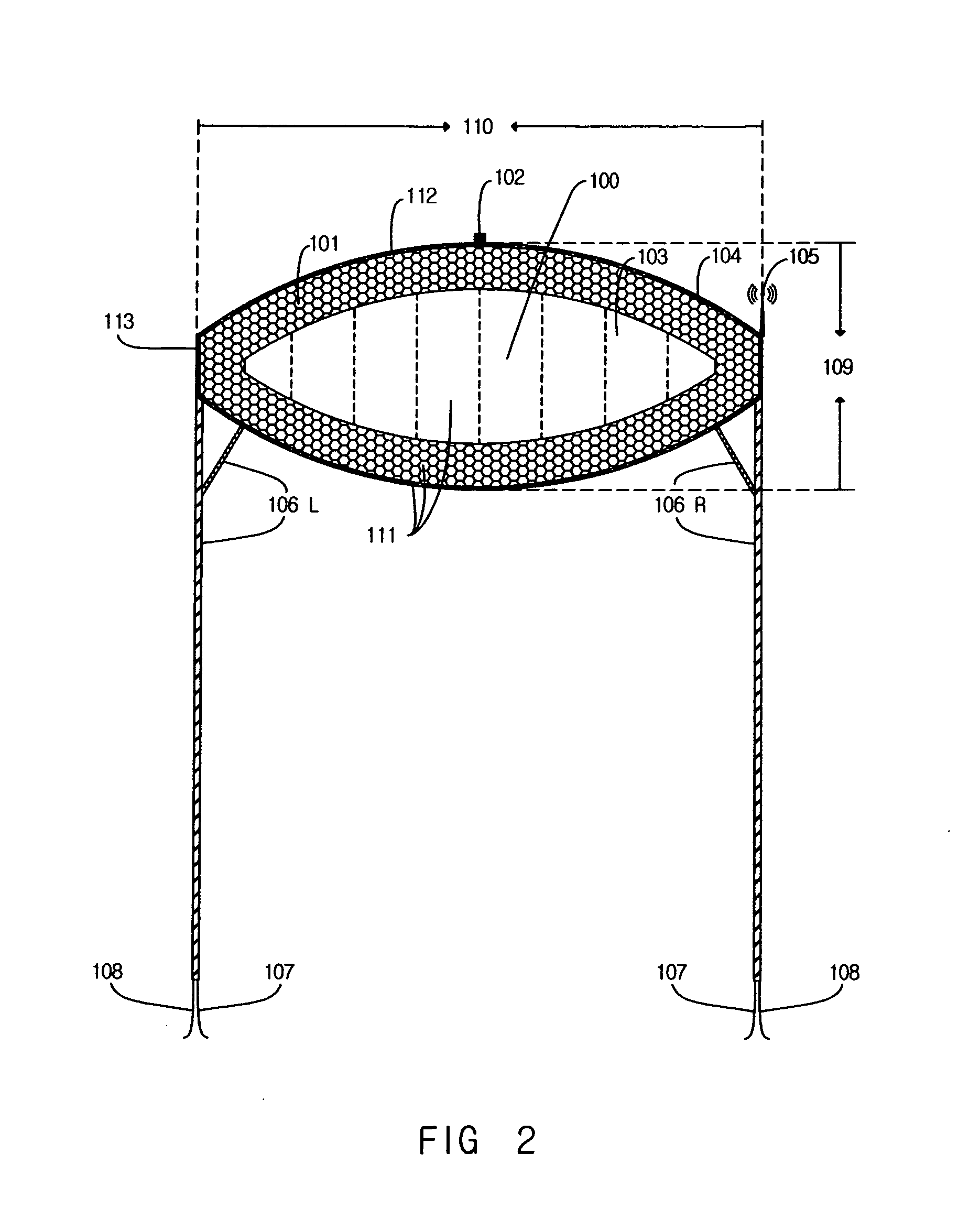

Medium/Large Electricity Generator Equipped with Automatically Winding and Un-winding Kite Cable Mechanism for minimum energy loss

InactiveUS20150330366A1Minimum energy lossMaximal power generationWind motor combinationsMachines/enginesElectricityFree rotation

A medium / large electricity generator equipped with automatically winding and un-winding kite cable mechanism for minimum energy loss is provided. The electricity generation system of the current invention comprises of pluralities of medium size electricity generators, multiplying gears, ampere transfers, cable shafts, automatic clutches, automatic breaks, and auto gear transformers mounted on one medium generator supporting frame, which is mounted on one large power generator system that rotates 360 degrees freely in counter clockwise and counter clockwise. The large power generator system is mounted on a round supporting frame firmly installed on a ground. Each kite is connected to two neighboring cable shafts via one kite cable on one cable shaft. The electricity generator uses negligible energy to wind the kite compared to all other prior arts that use kite for power generation.

Owner:WOO YOUNG SUK +1

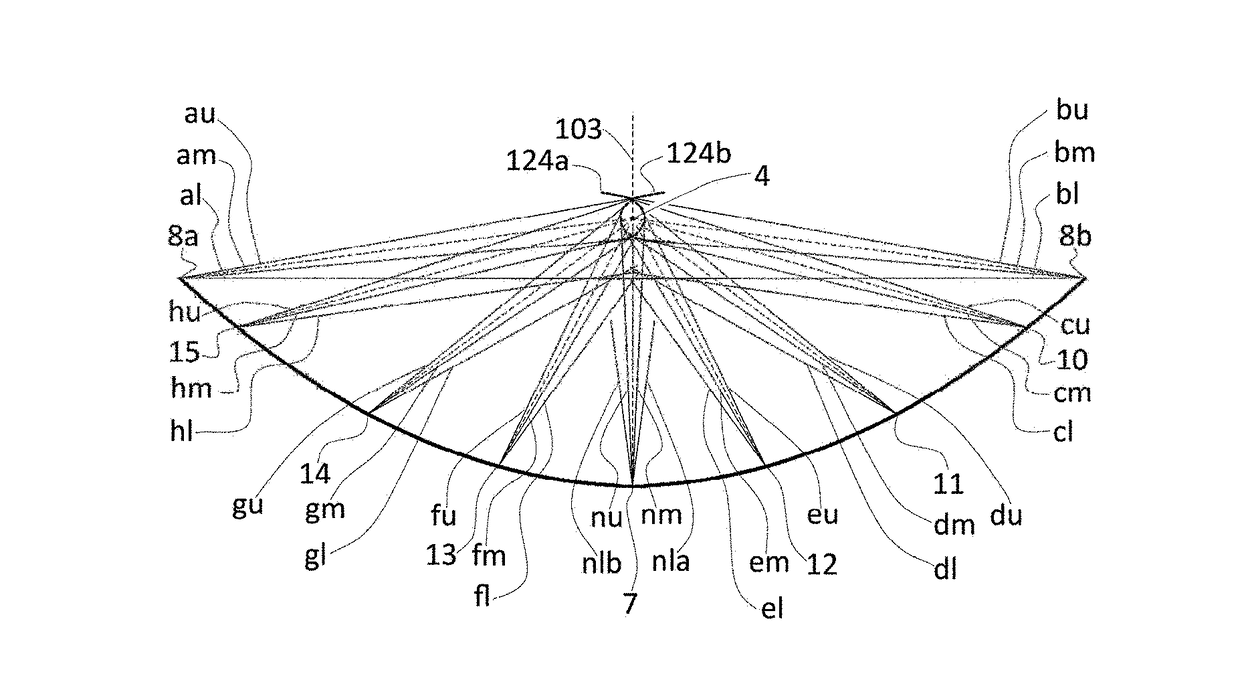

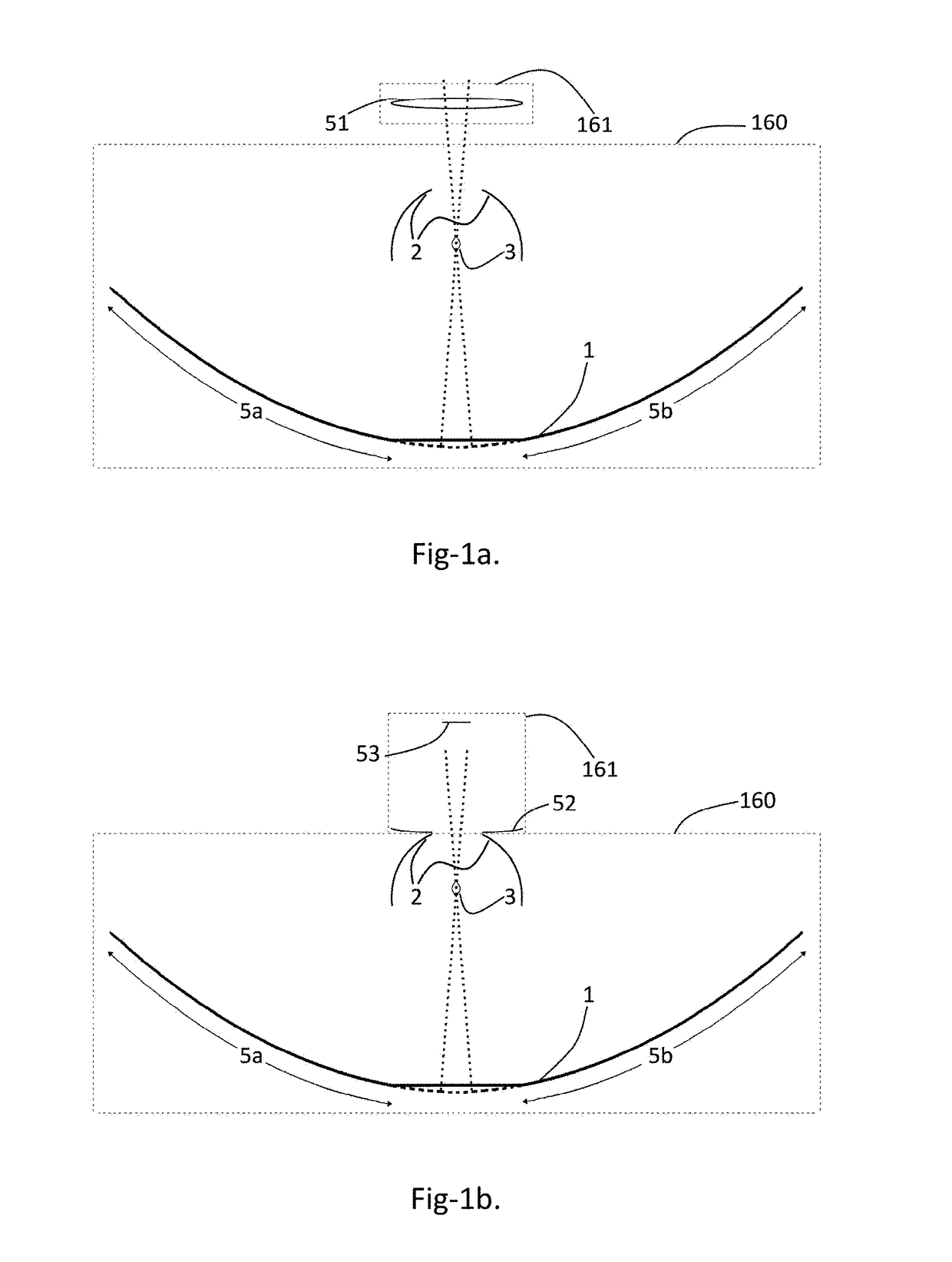

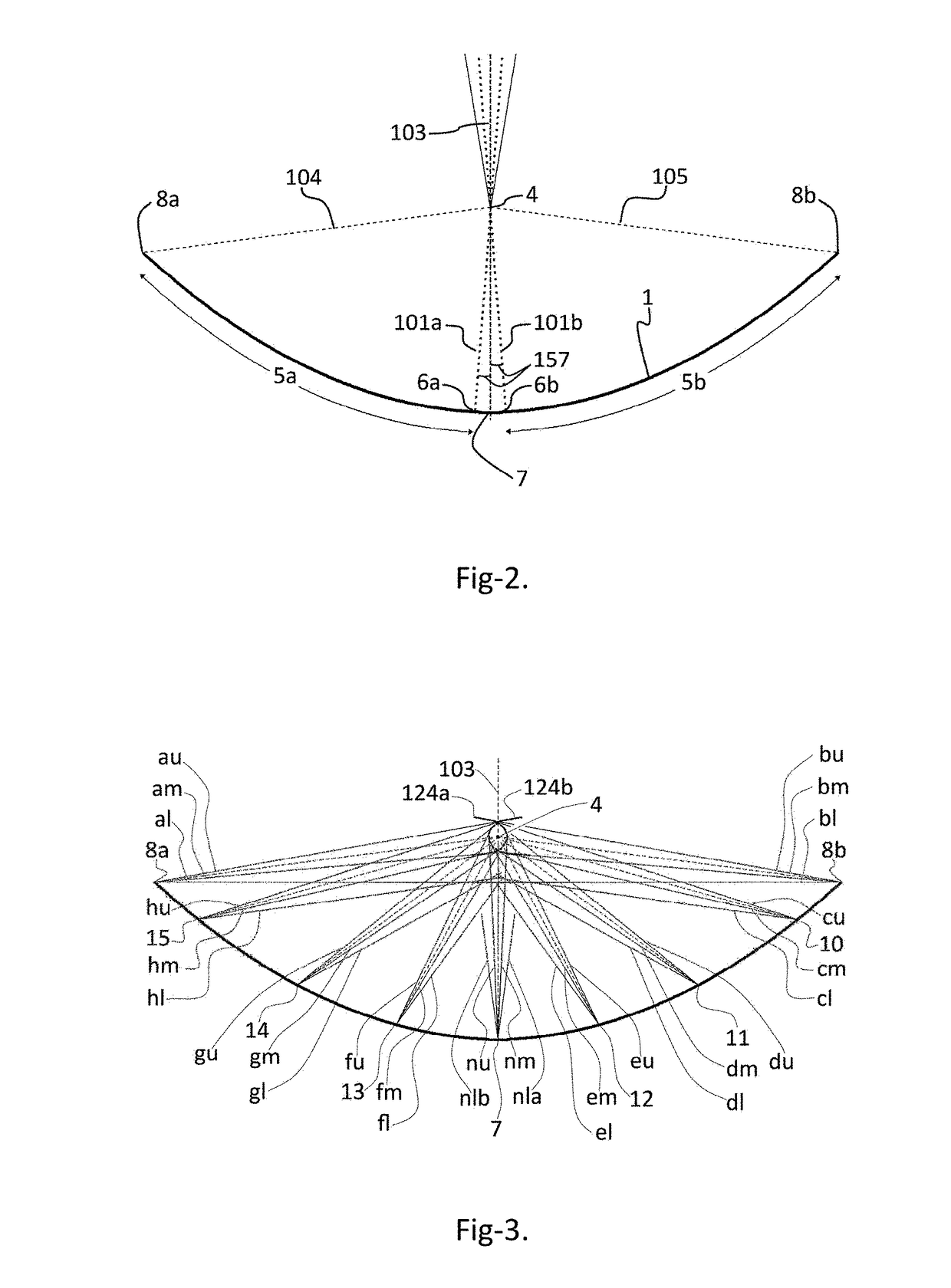

Radiation concentrator incorporating compound confocal uneven parabolic primary reflector, tailored secondary reflector and tailored receiver

A radiation concentrator incorporating a main radiation concentrator (160) and an auxiliary radiation concentrator (161) that concentrates the incident radiation to the common receiver (3) is presented. The primary reflector (1) of the main concentrator (160) consists of two confocal parabolic reflectors (5a &5b) on either side of the axial plane in such a way that their parabolic axes points at the centers of the diagonally opposite halves of the radiation source. The main concentrator (160) is configured in such a way that a part of the radiation reflected from every point on its primary reflector (1) is absorbed by the receiver (3) directly and its secondary reflector (2) reflects the other part of the radiation to the receiver (3). The auxiliary concentrator (161) concentrates a substantial part of the incident radiation, which would have been blocked by the secondary reflector (2), to the receiver (3).

Owner:NOBLE NEVIN

Container for storing an implantable medical device and a method for packaging such a device

ActiveUS8457755B2Improve propertiesEasy to receiveElectrotherapyDiagnosticsInput impedanceEngineering

An implantable medical device is stored in a container prior to implantation in body tissue. The IMD includes transmitter / receiver circuitry and at least one antenna. The storage container (packaging) includes an impedance altering substance positioned in proximity to the IMD when stored in the container, the substance having electrical material properties that alter the input impedance of the antenna to improve the reception and transmission properties of the antenna when the IMD is stored in the container. A container for storing an IMD having an antenna has a packaging tray for housing the IMD, the packaging tray having a support for supporting the IMD and the container including a substance positioned in proximity to the support that has electrical material properties that after the input impedance of the antenna of the IMD supported by the support, so as to improve the reception and transmission properties of the antenna. A method for packaging an IMD prior to implantation in body tissue includes the step of providing such an impedance altering substance in the pre-implantation IMD packaging, in proximity to the packaged IMD.

Owner:ST JUDE MEDICAL

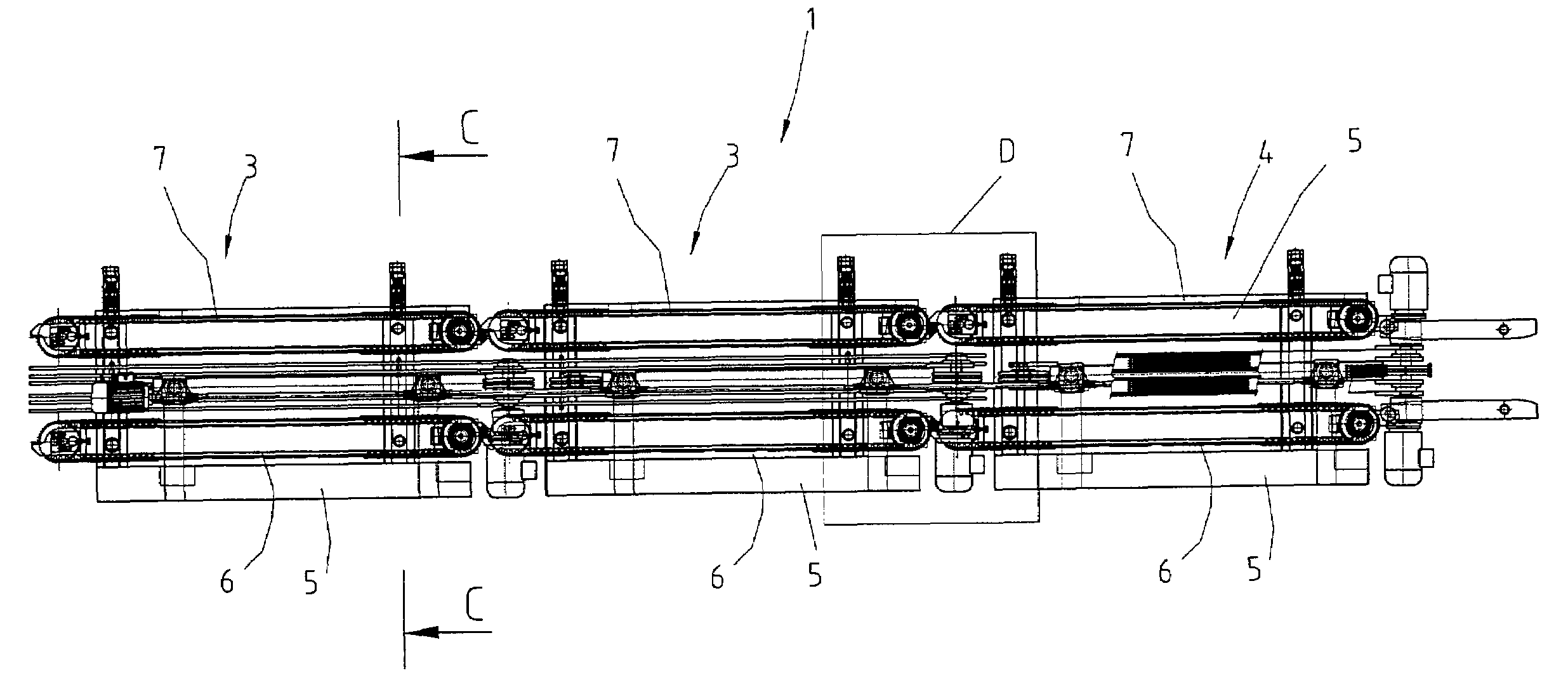

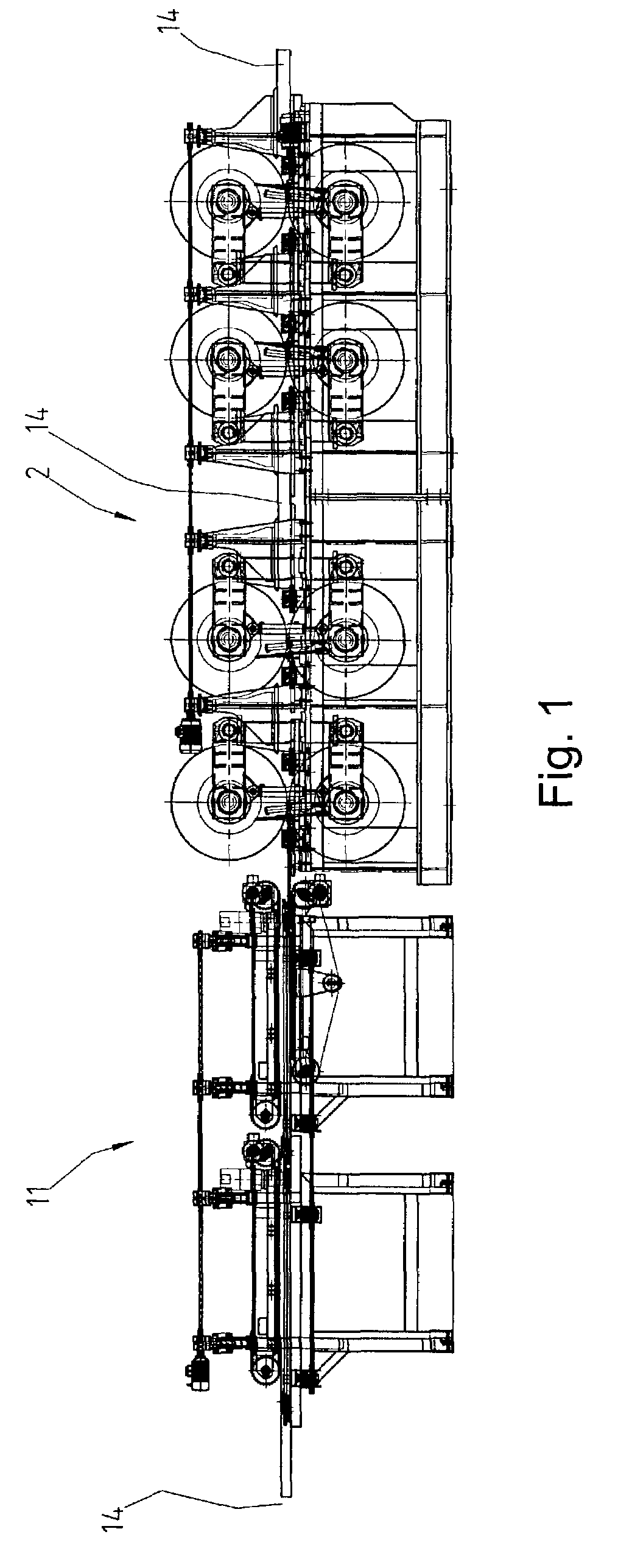

Machine for front joining and sticking of oblong wood workpieces by toothed front joints and referential procedure

ActiveUS7654385B2Minimum interactive frictionMinimum loss of energyWood feeding arangementsMetal sawing accessoriesSide chainMachine press

Owner:LEDINEK GREGOR +1

Process for producing reclaimed expandable polystyrene resin particle

It is possible to recover a volume reducing agent from a waste foamed polystyrene resin material compacted with the volume reducing agent and to impregnate a blowing agent into the compacted material at ordinary room temperature. The volume reducing agent is preferably a polar solvent having solubility with respect to the polystyrene resin and exhibiting a mutual solubility with the blowing agent, which is one whose hydrogen bond term deltah and polarity term deltap of the Hansen solubility parameters satisfy the following conditions:The solvent used as the volume reducing agent is preferably at least one solvent selected from the group consisting of ketones, esters, polyhydric alcohol ether acetates, ethers, halogenated hydrocarbons, nitro compounds, and amines. The solvent may be a mixed solvent consisting essentially of at least one solvent selected from the above-described group and at least one solvent selected from the group consisting of aliphatic hydrocarbons and aromatic hydrocarbons.

Owner:KAGOSHIMAKEN

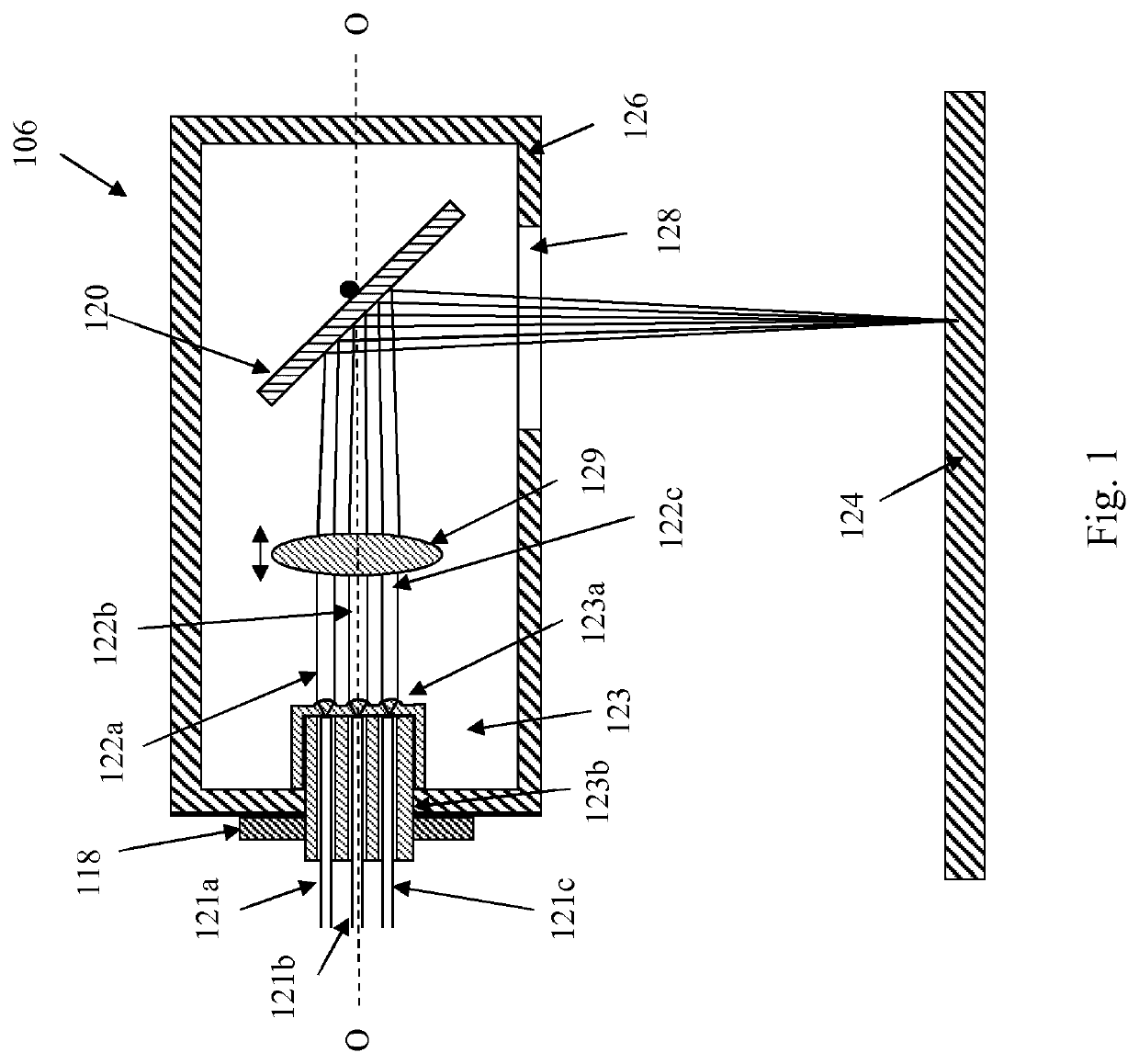

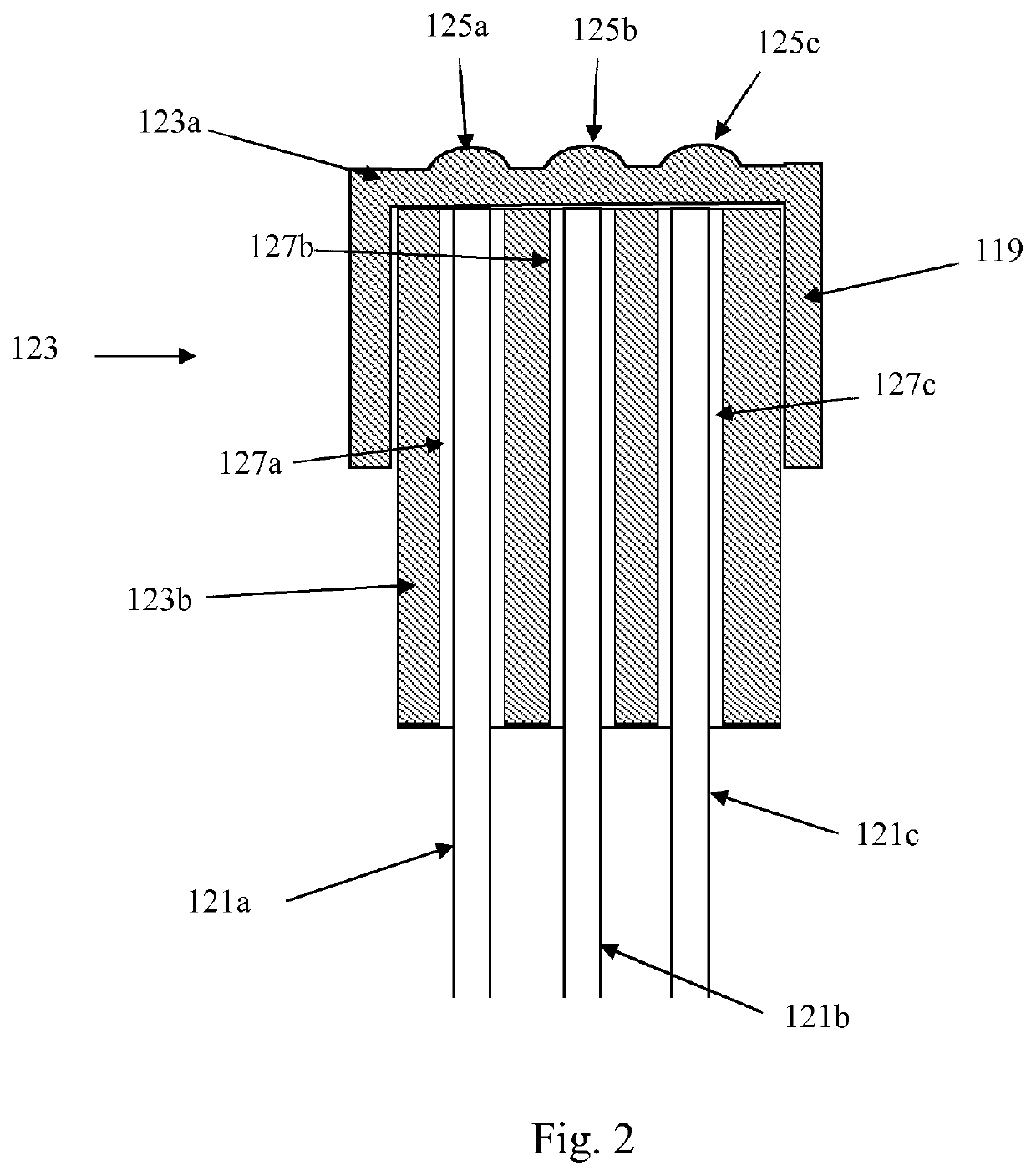

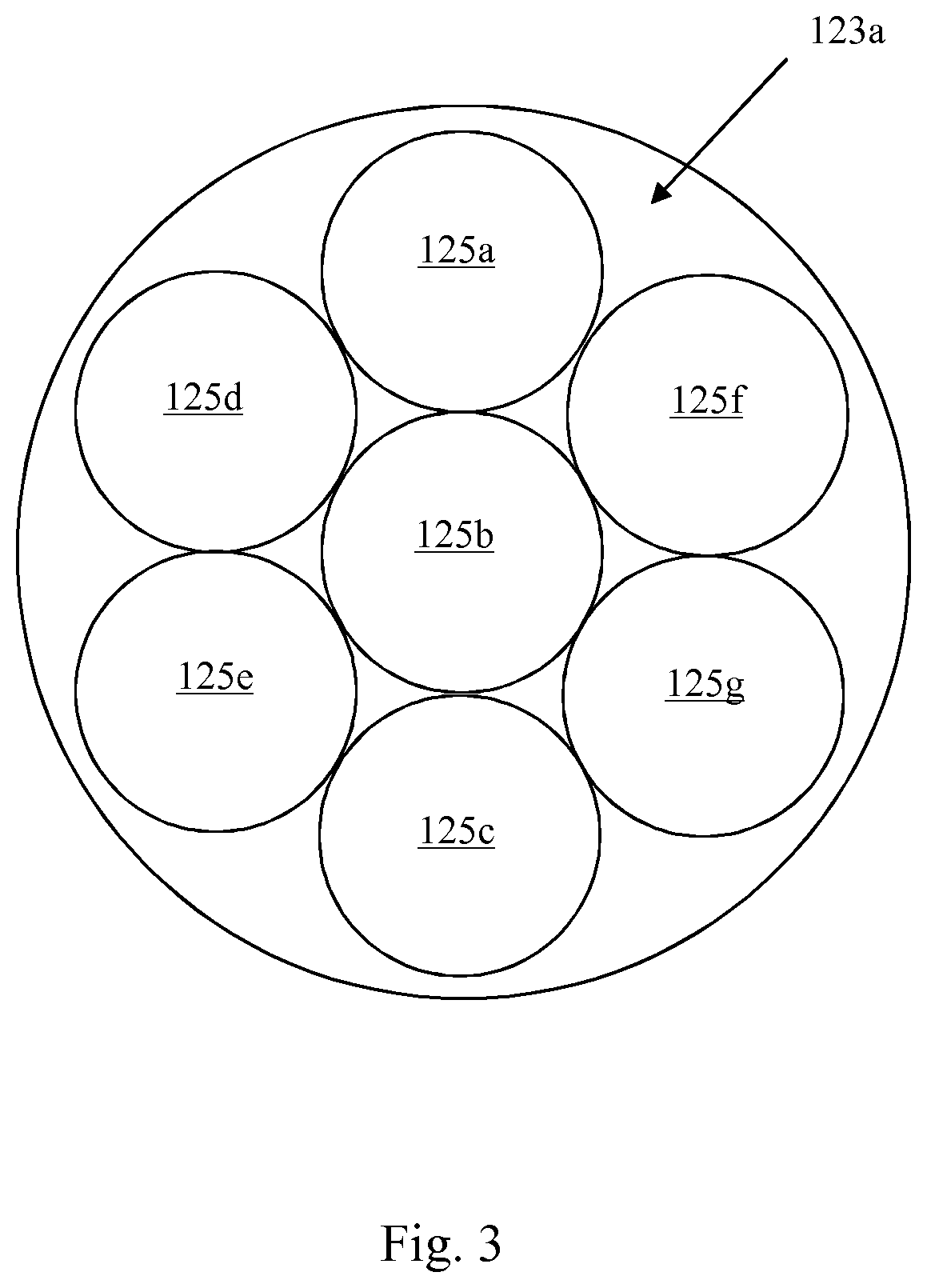

Laser beam scanner

PendingUS20210229215A1Keep the distanceImprove punctualityAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringBeam scanning

A laser beam scanner including a laser beams positioning optic, a plurality of optical fibres for delivering a plurality of laser beams and a fibre termination optic aligned to direct the laser beams from output ends of the plurality of optical fibres to the laser beams positioning optic. The laser beams positioning optic is movable relative to the fibre termination optic to scan the laser beams across a working surface.

Owner:RENISHAW PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com