System for adjusting resonance frequencies in a linear compressor

a linear compressor and resonance frequency technology, applied in the direction of positive displacement liquid engine, piston pump, pump parameter, etc., can solve the problems of loss of motor efficiency, unbalance between mechanical resonance frequency and electrical supply frequency of the power system and achieve adequate volumetric yield, high cost, and high energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

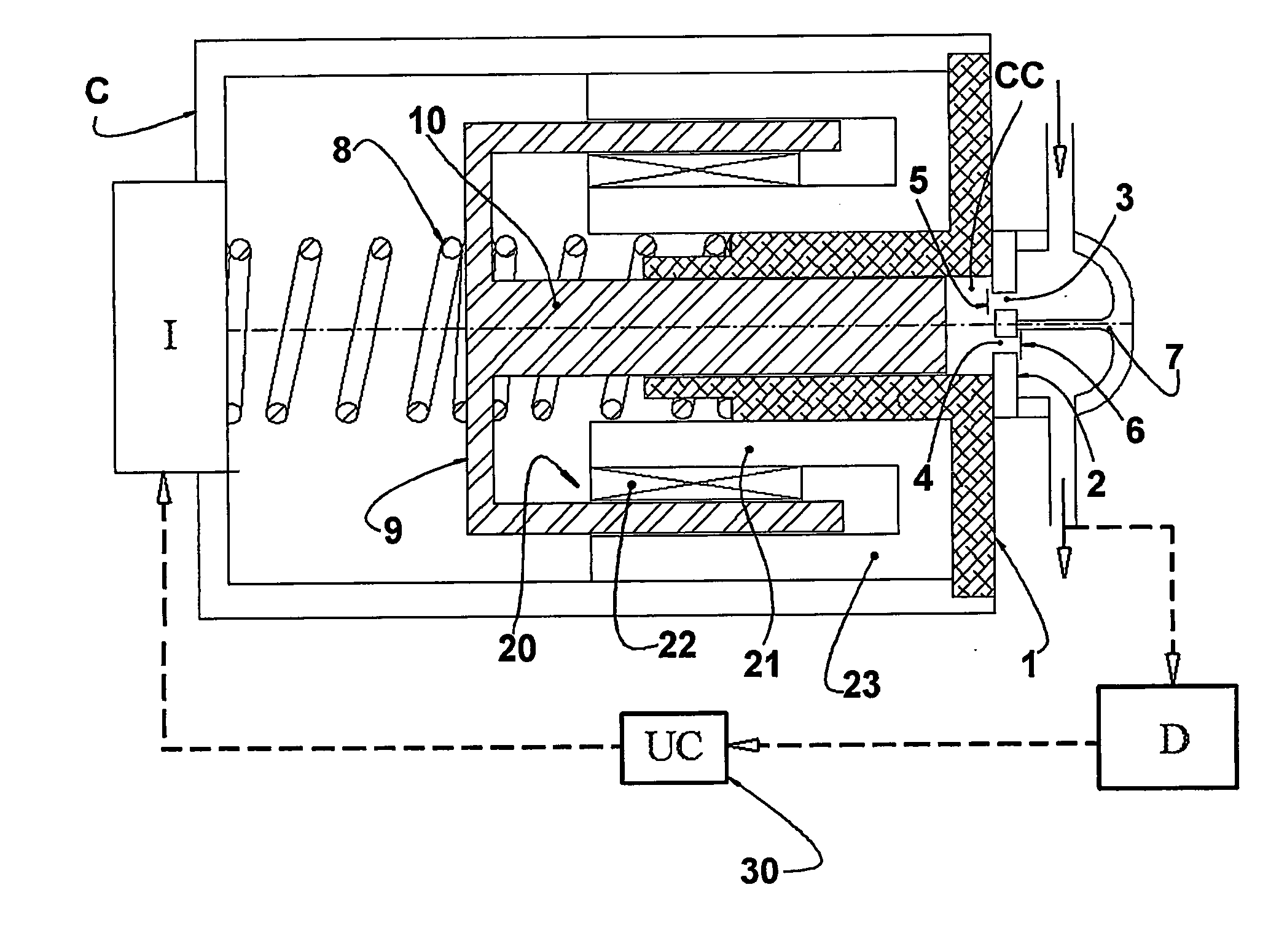

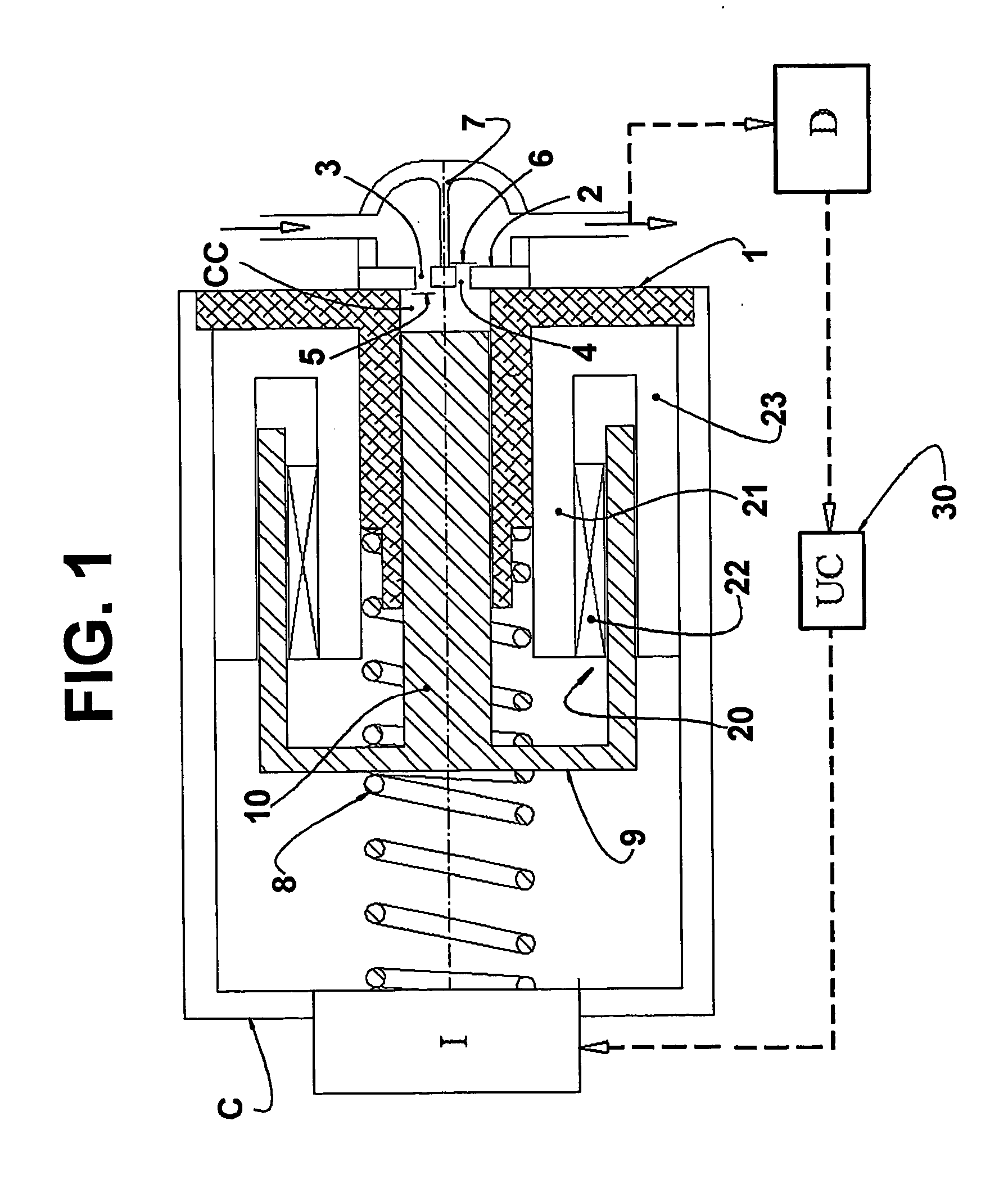

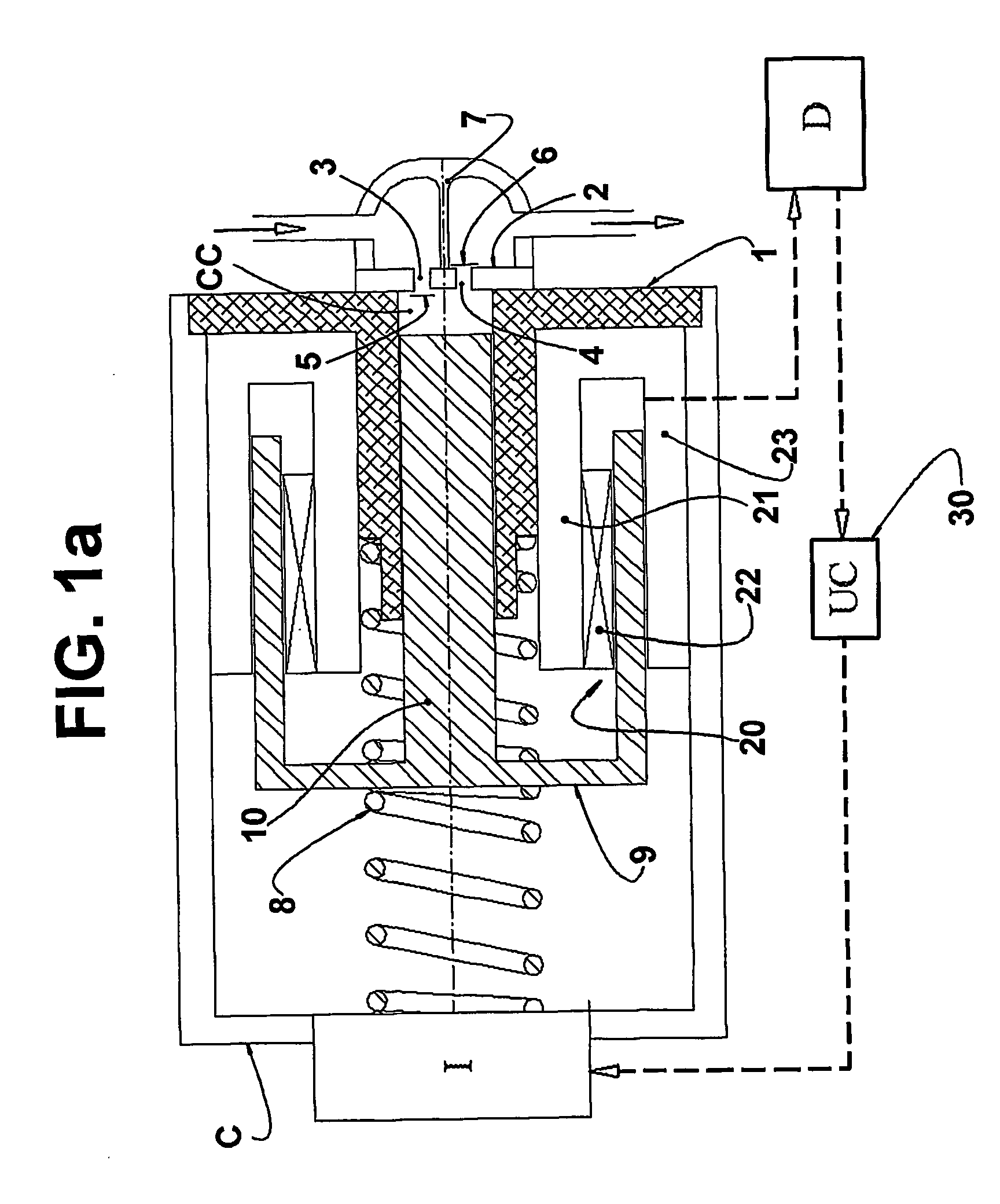

[0031] The present invention will be described in relation to a reciprocating compressor driven by a linear motor of the type used in refrigeration systems and comprising, within a hermetic shell (not illustrated), a motor-compressor assembly including a cylinder 1, which is closed, at one of the ends thereof, by a valve plate 2, and inside which is provided a piston 10 reciprocating in consecutive suction and compression strokes.

[0032] In conventional constructions, an internal lower portion of the shell defines a reservoir for the lubricant oil of the compressor.

[0033] In the valve plate 2 there are defined a suction orifice 3 and a discharge orifice 4 of the compressor, which are respectively and selectively closed by a suction valve 5 and by a discharge valve 6, in order to allow the selective fluid communication between a compression chamber CC, which is defined within the cylinder 1 between a top portion of the piston 10 and the valve plate 2, and respective internal portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com