Driven Vane Compressor

a compressor and driven technology, applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of increased fluid flow pressure loss in the inlet and outlet region, affecting the operation affecting the efficiency of such machines, so as to reduce the side load acting, less power consumption, and longer life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

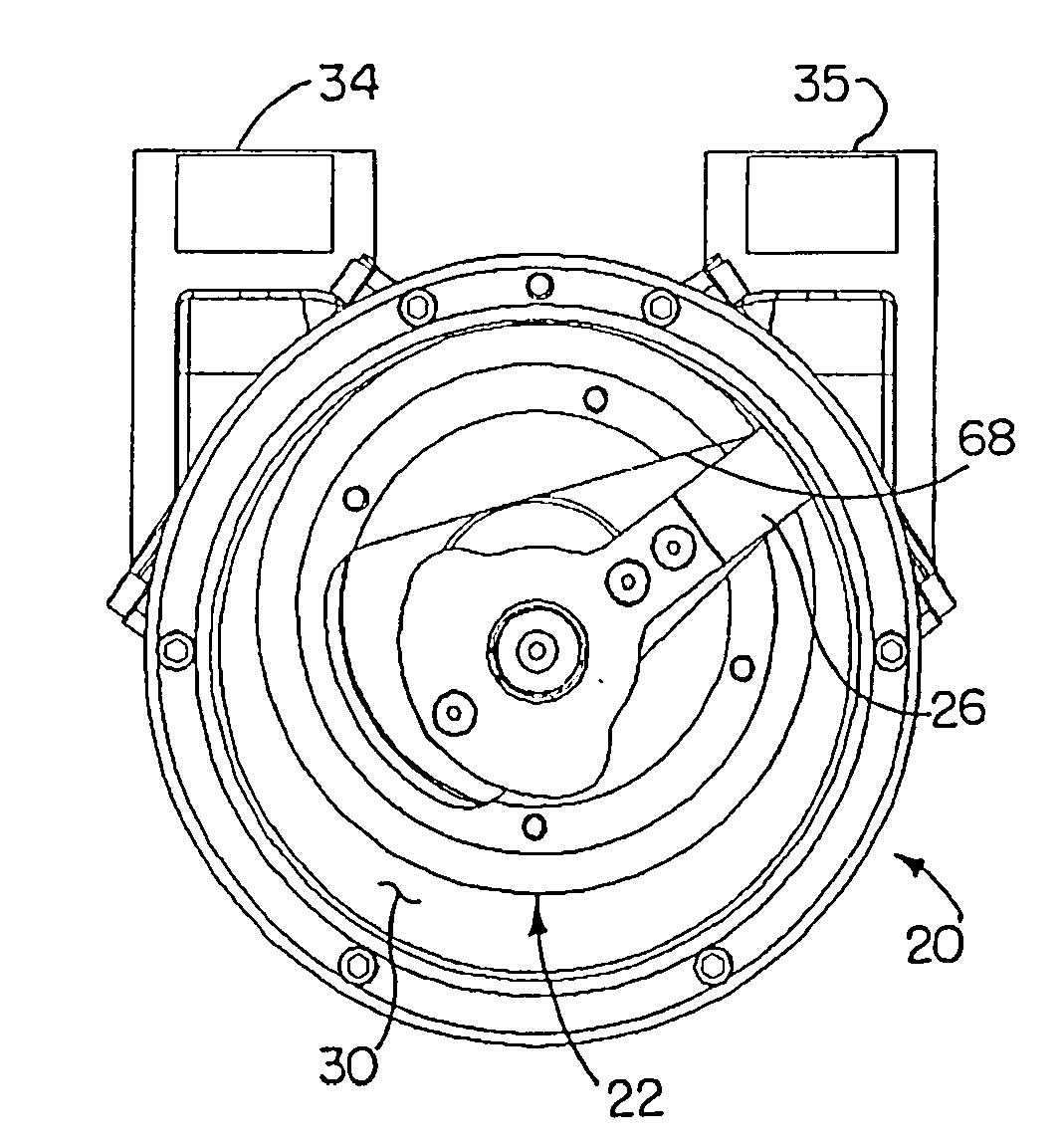

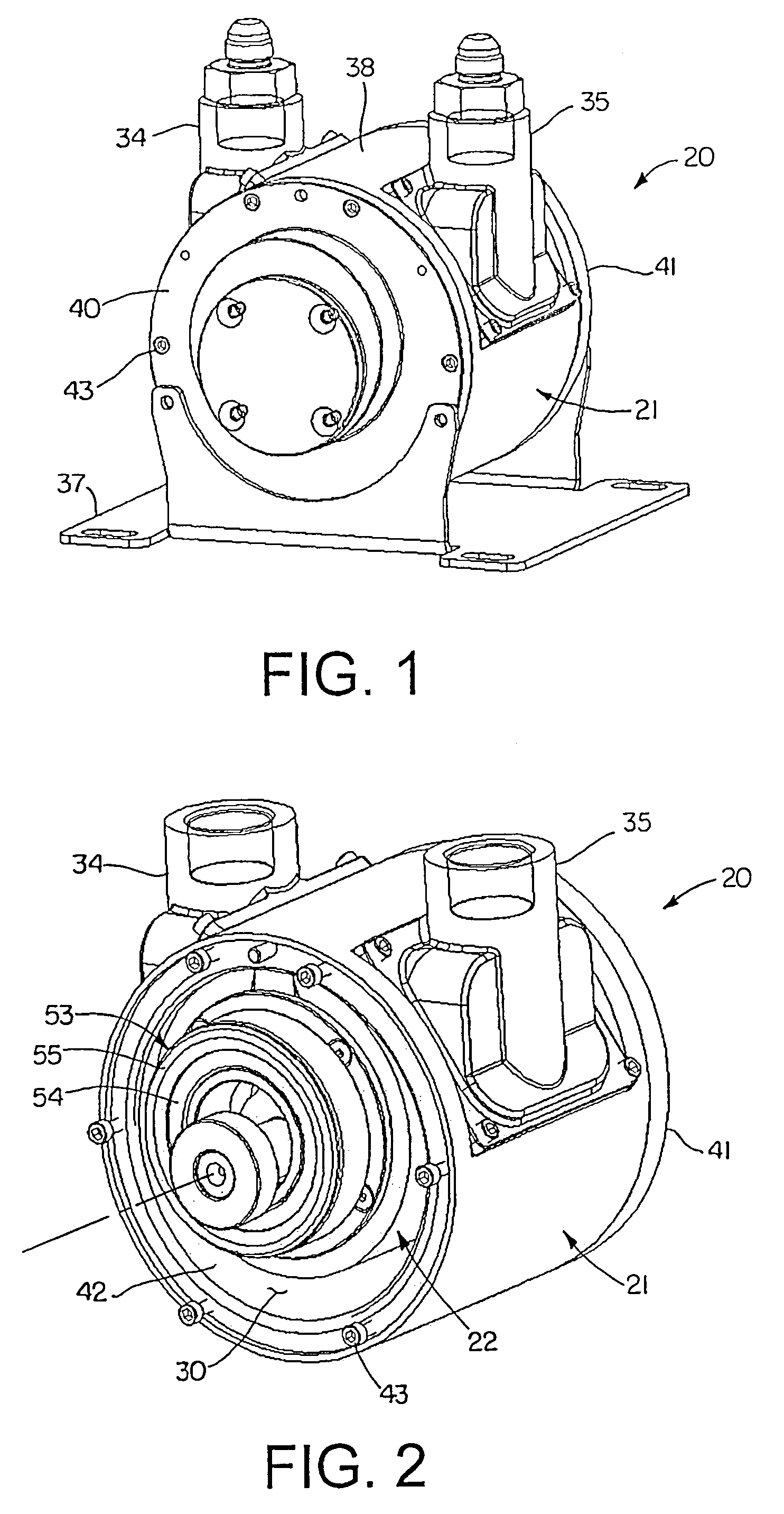

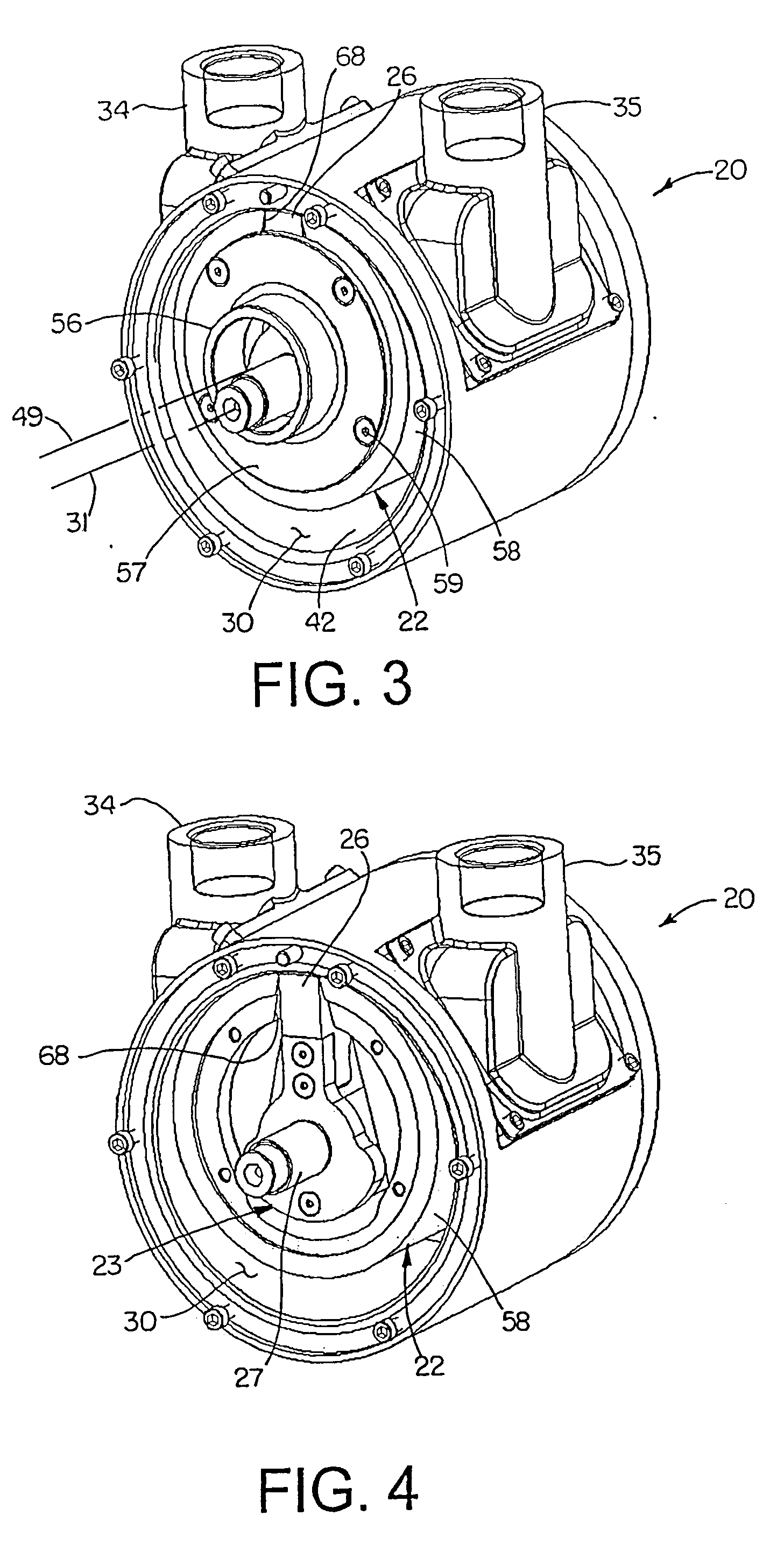

[0027]Referring now to the drawings in detail, and initially to FIGS. 1-5, an exemplary rotary vane device according to the invention is designated generally by reference numeral 20. As shown, the device 20 generally comprises a housing 21, a rotor 22 (FIGS. 3 and 4) and a vane and drive assembly 23 (FIGS. 4 and 6). In the illustrated embodiment, the vane and drive assembly 23, as best seen in FIG. 6, comprises a single vane 26 mounted, or formed integrally with, a vane drive member 27. Although these components will be described below in greater detail, it will be appreciated that such components can vary in various respects without deviating from the basic principles of the present invention. In addition, the illustrated rotary vane device is particularly suited for use as a gas compressor and will be chiefly described in this context. A rotary vane device according to the invention, however, may be adapted for use with other fluids, in particular as a pump for liquids. Additional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com