Petroleum pipeline weld seam trolley automatic walking method

An automatic walking and oil pipeline technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as complicated installation, low precision, and unstable operation of the walking device, and achieve improved walking accuracy and improved welding Quality, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

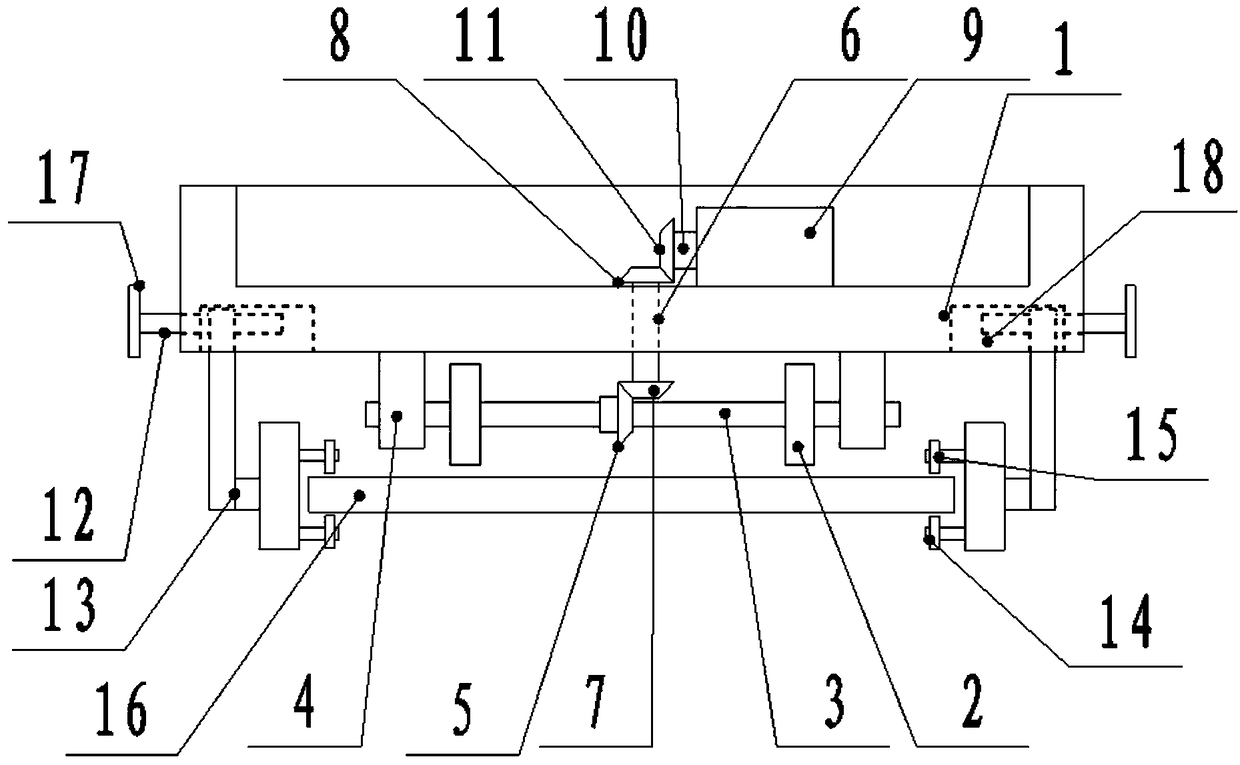

[0035] Such as figure 1 As shown in the present invention, an automatic walking method of a petroleum pipeline welding seam trolley is provided with two driving wheels 2 on the bottom surface of the welding trolley frame 1, and the two driving wheels 2 are connected by a wheel shaft 3, and the wheel shaft 3 is connected by a suspension The frame 4 is installed on the welding trolley frame 1, and the axle bevel gear 5 is arranged on the axle 3, and the welding trolley frame 1 corresponding to the axle bevel gear 5 is provided with a transmission shaft 6 for vertical transmission. The lower end of the shaft 6 is provided with a lower transmission shaft bevel gear 7 meshing with the wheel shaft bevel gear 5, the upper end of the transmission shaft 6 is provided with an upper transmission shaft bevel gear 8, and the welding trolley frame 1 is provided with a drive motor 9, so The rotating shaft 10 of the driving motor 9 is provided with a rotating shaft bevel gear 11, and the rota...

Embodiment 2

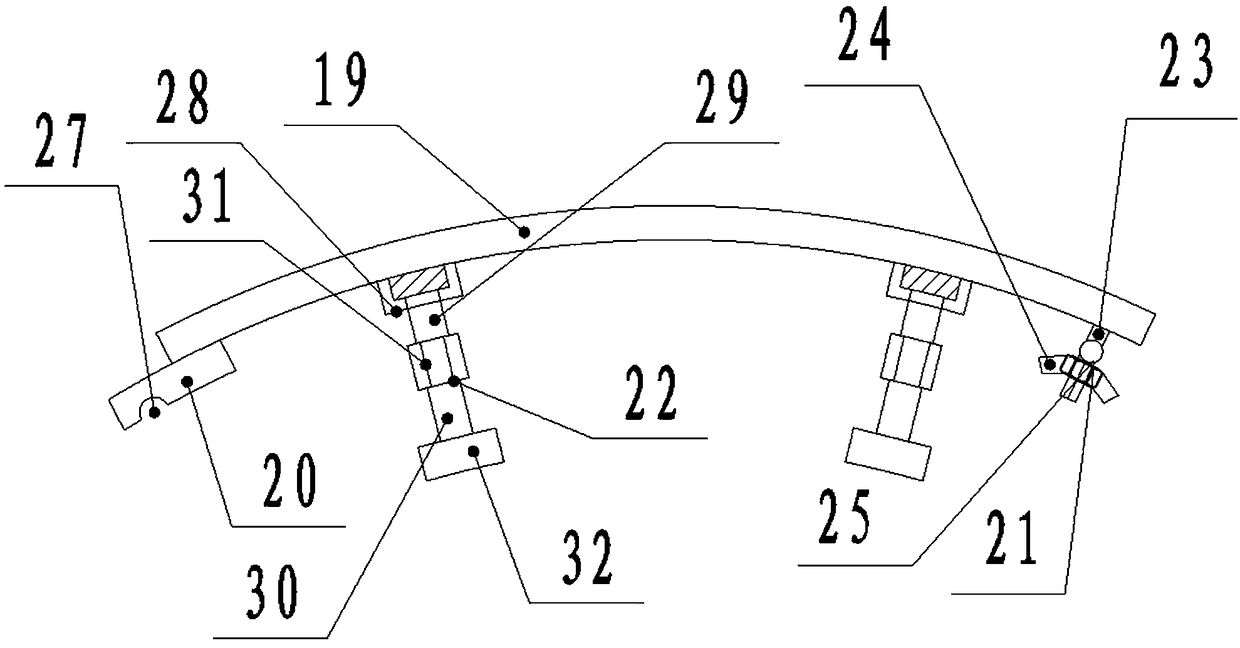

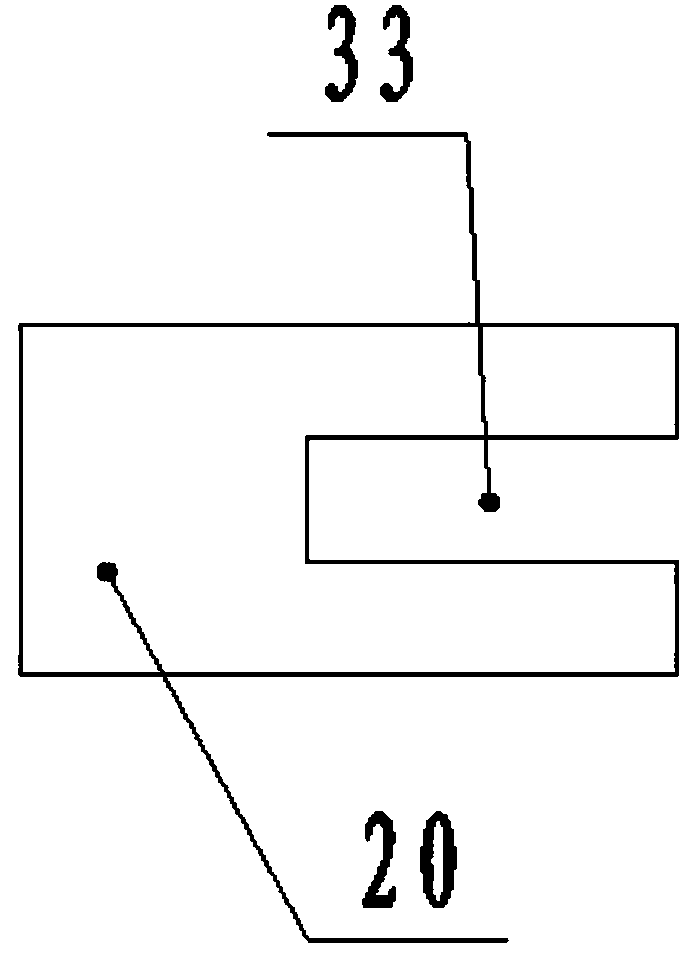

[0041] Such as Figure 2-4 As shown, the present invention is an automatic walking method for a petroleum pipeline weld trolley. On the basis of Embodiment 1, the track 16 includes a plurality of arc-shaped track plates 19 connected end-to-end, and the arc-shaped track plates 19 have certain flexibility. Different pipe diameters change the radian at a small angle. The inner surface of one end of the arc-shaped track plate 19 is provided with a connecting plate 20, the other end of the arc-shaped track plate 19 is provided with a bolt joint 21, and the inner surface of the arc-shaped track plate 19 is evenly arranged. Adjust the support bar 22, and the plurality of arc track plates 19 are connected end to end by connecting plates 20 and bolt joints 21 to form a circular track structure. When in use, a corresponding number of arc-shaped track plates are selected according to the diameter of the welded pipe to form a welding track for the weld of the ring pipe, so that pipes with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com