Independent-tool-setting type numerical control edge carving machine

A side carving machine and knife type technology, which is applied in the direction of processing models, decorative arts, etc., can solve the problems of not having polyhedron carving functions, etc., and achieve the effects of improving walking accuracy and carving accuracy, high work efficiency, and improving walking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

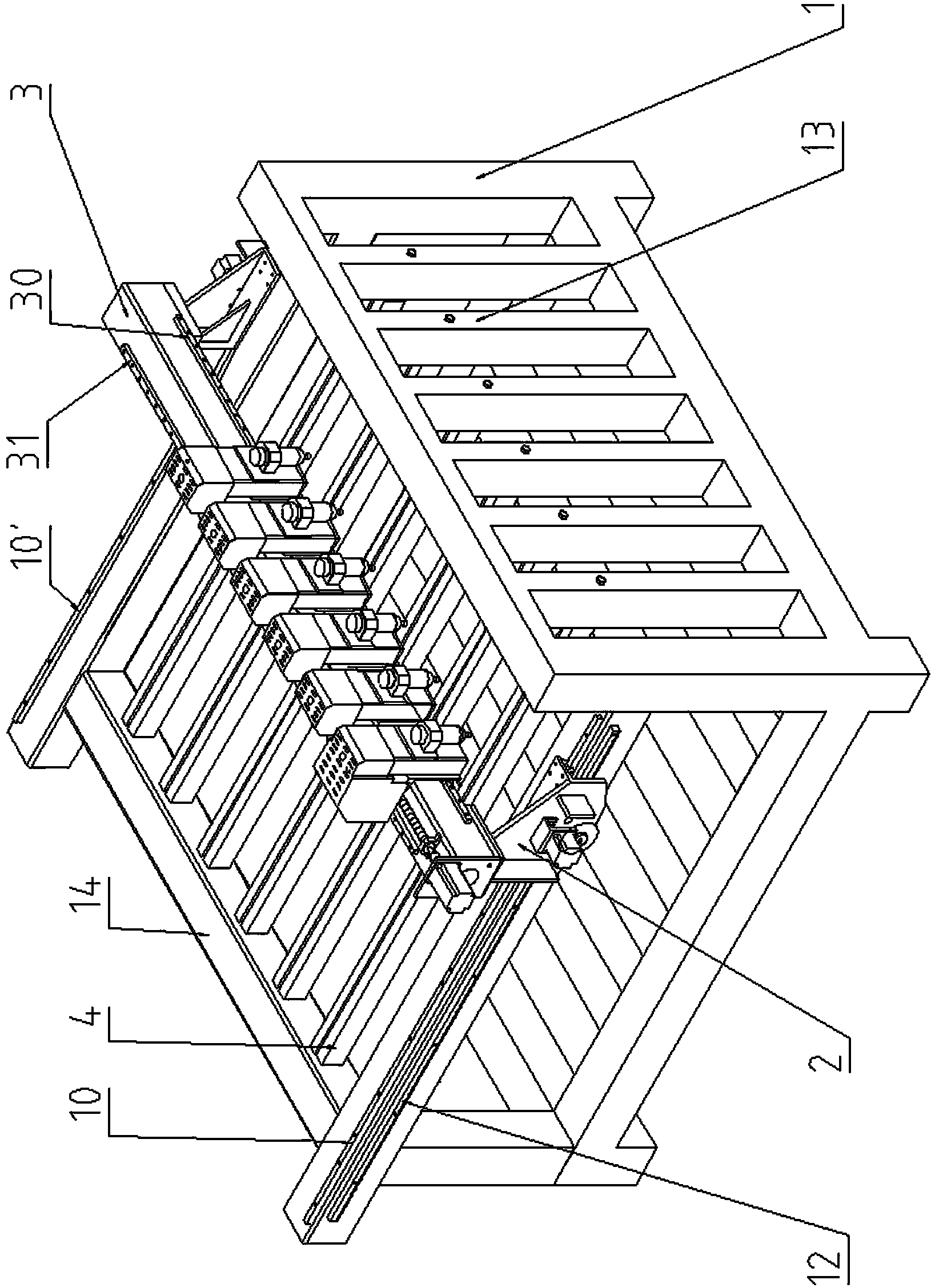

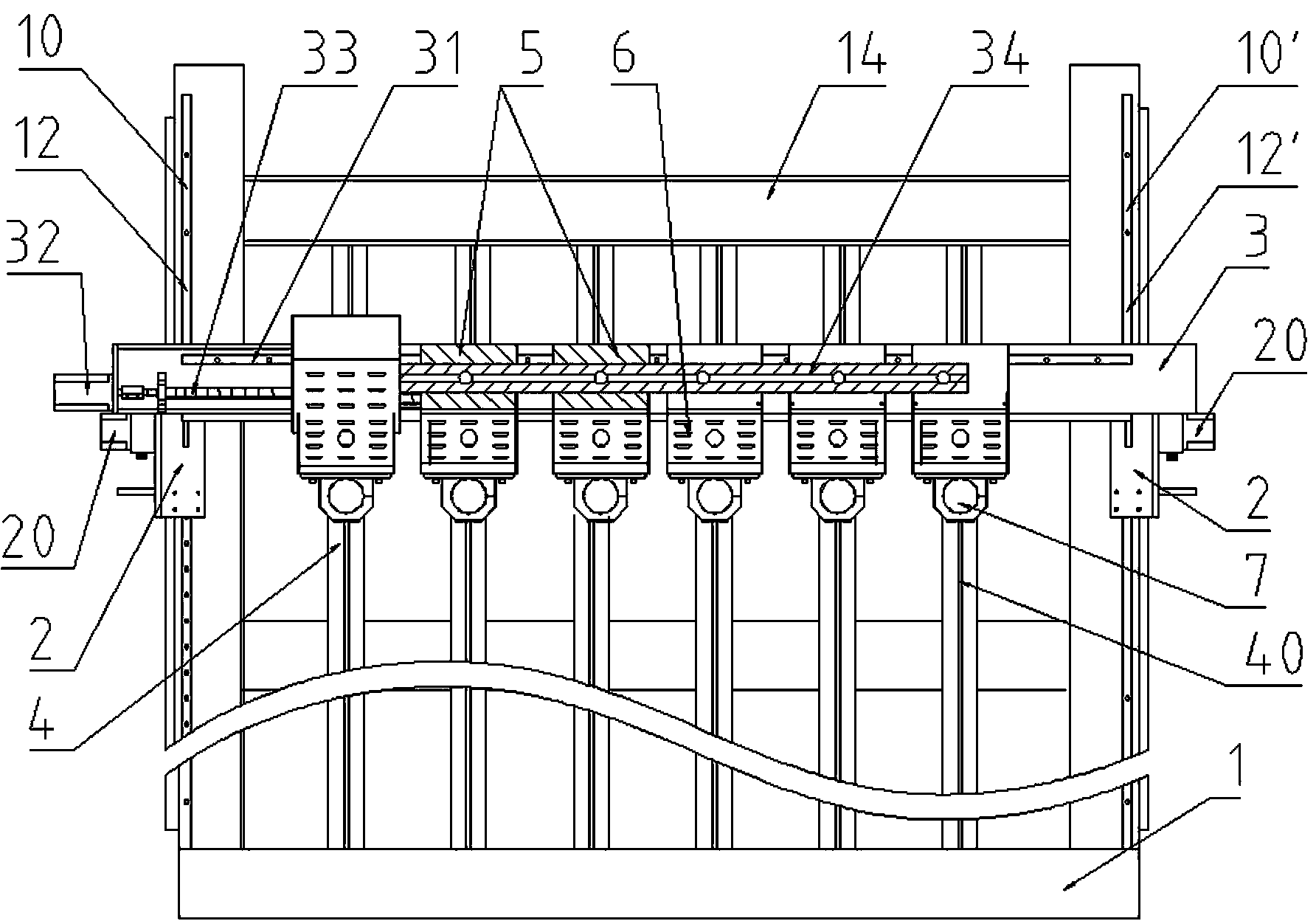

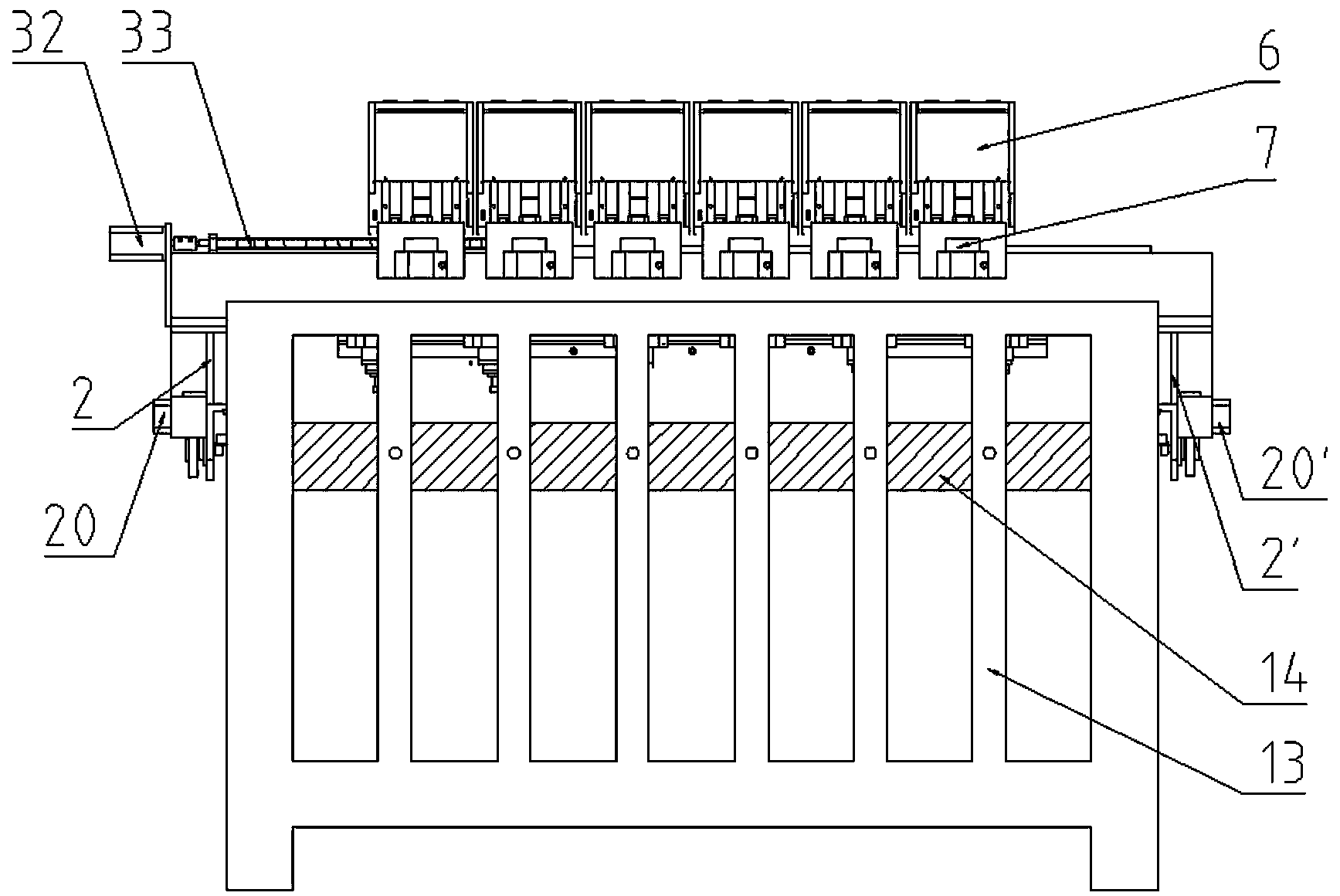

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1 to Figure 5 It can be seen that the independent knife-setting CNC edge carving machine of the present invention includes a bed body 1, and a left column 2 and a right column 2' are movably connected to the bed body 1 through the left guide rail 10 and the right guide rail 10'. There is also a Y-direction driving device between the left column 2, the right column 2' and the bed body 1, a gantry 3 is provided above the left column 2 and the right column 2', and an X-direction drive is provided on the vertical surface of the gantry 3. Vertical guide rail 30, horizontal plane are provided with X to horizontal guide rail 31, on the gantry 3 by X to vertical guide rail 30, X to horizontal guide rail 31 activities, be provided with a plurality of engraving head bases 5, described engraving head base 5 is made of interconnected Composed of a vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com