Automatic pipeline crack scanning device

A technology for scanning devices and cracks, which is applied to pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of low scanning efficiency and accurate detection results, and achieve simple and convenient operation and overcome the problems of scanning inefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The preferred embodiment of the automatic inspection device for pipeline cracks of the present invention is:

[0016] It includes two adjusting rotating mechanisms, each adjusting rotating mechanism is respectively equipped with an adjusting limit mechanism, and an axial scanning mechanism is installed between the two adjusting rotating mechanisms.

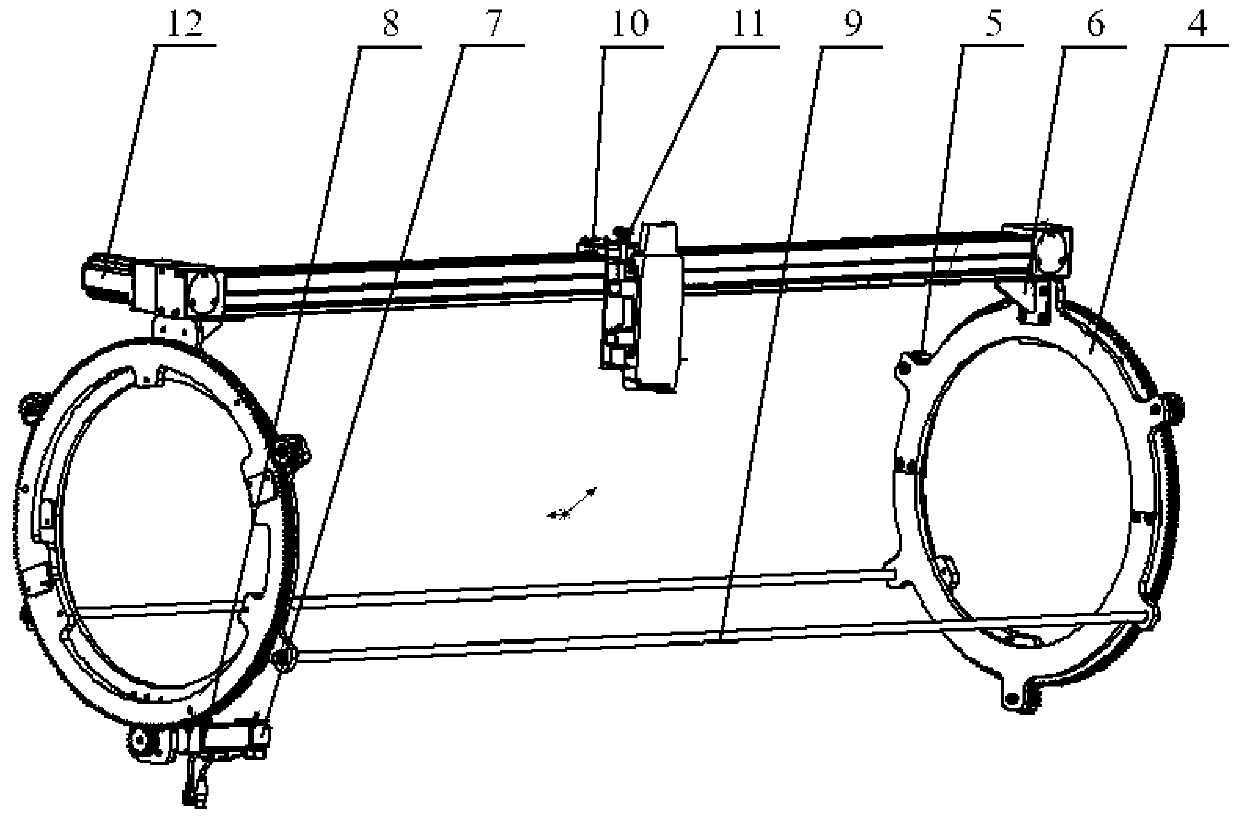

[0017] The axial scanning mechanism includes two symmetrical mounting plates, six pinion gears, three rotating mounting plates, a Delta servo motor, a motor reducer, two connecting shafts, a linear slide sensor mounting frame, and a mounting frame Fine-tuning nut, linear slide motor;

[0018] Three pinion gears are installed on each mounting plate, two of which rotate the mounting plate to fix the linear slide table and the two mounting plates together; the motor reducer and the Delta servo motor are installed on the other rotating mounting plate, and the two are symmetrical The mounting plate is fixed together by two conn...

specific Embodiment

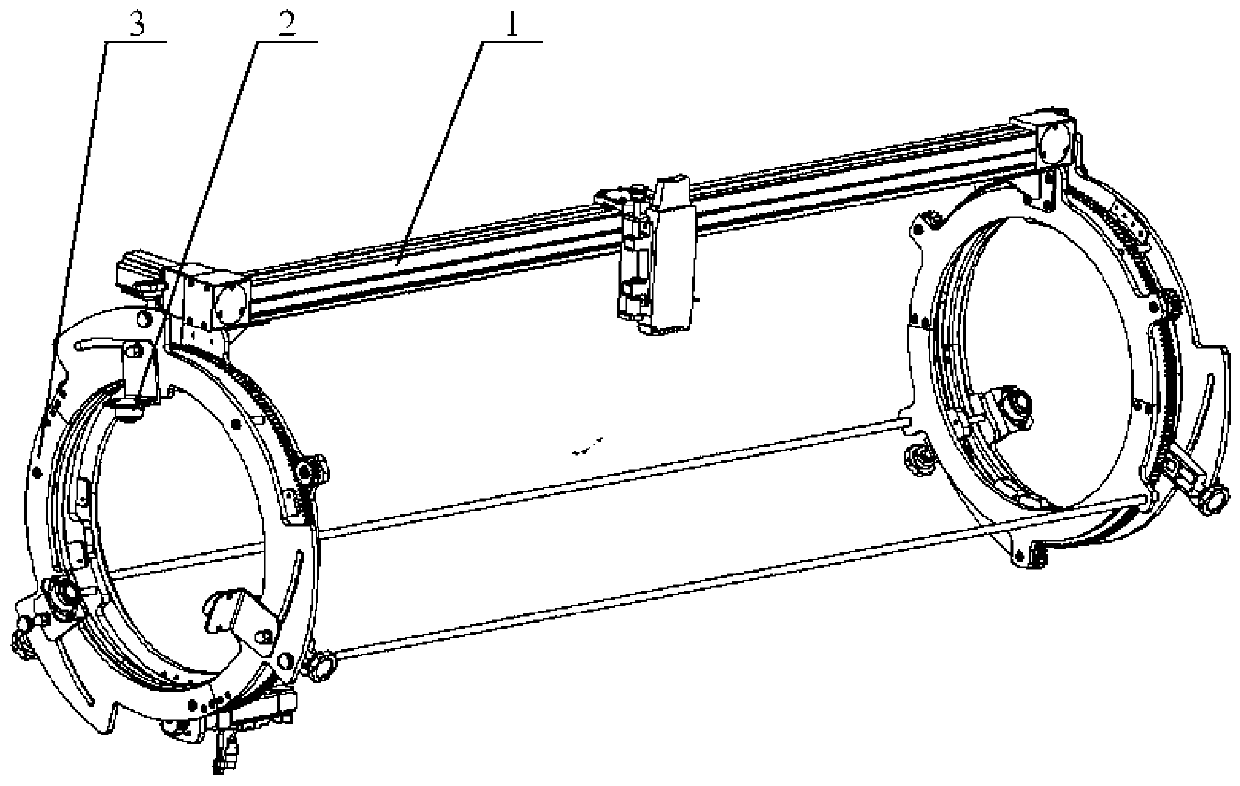

[0031] Such as figure 1 As shown, an automatic inspection device for pipeline cracks is used for automatic inspection of cracks on the outer wall of gas pipelines, including an axial scanning mechanism 1, an adjustment limit mechanism 2, and an adjustment rotation mechanism 3; the adjustment limit mechanism 2 is installed on Adjusting the rotating mechanism 3 allows the automatic crack inspection device for pipelines to be clamped, fixed and axially slid for pipes of different diameters. Scanning for cracks on the outer wall.

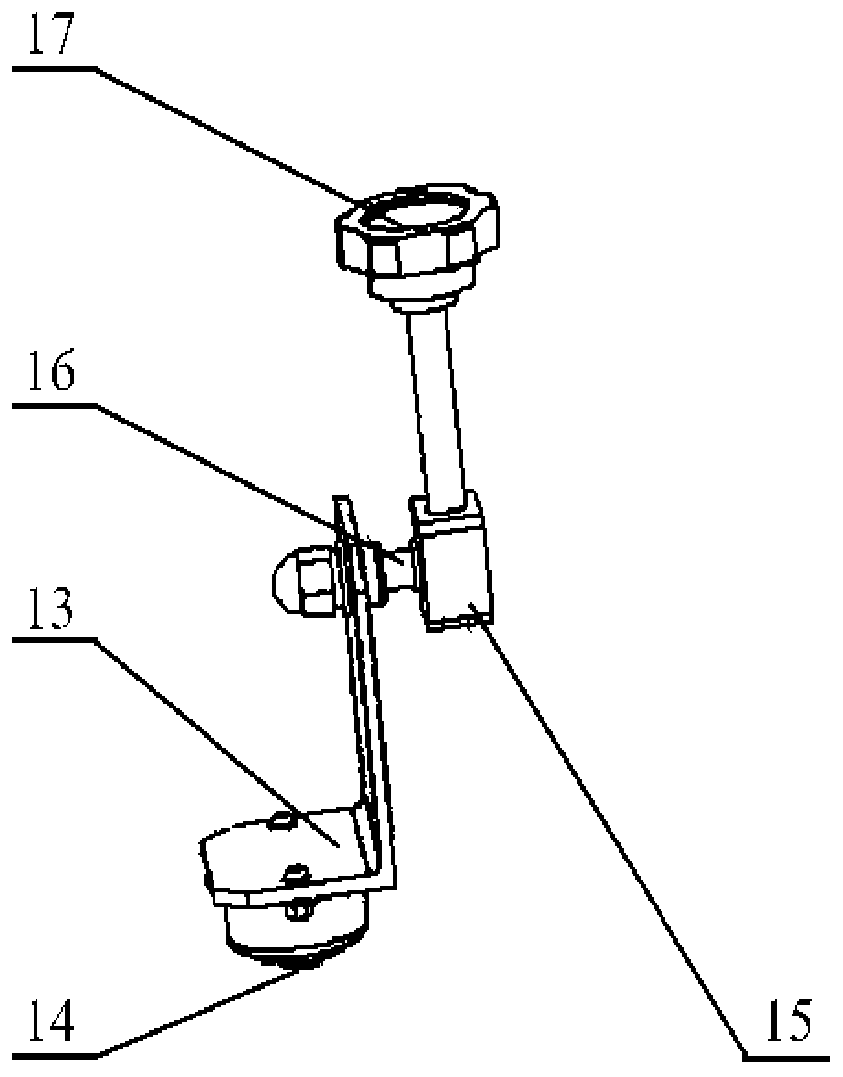

[0032] Such as figure 2 , image 3 and Figure 4 As shown, it includes: two mounting plates 4, six pinion gears 5, three rotating mounting plates 6, Delta servo motor 7, motor reducer 8, two connecting shafts 9, linear slide sensor mounting frame 10, installation Frame fine-tuning nut 11, linear slide motor 12, bulls-eye bearing mounting frame 13, bulls-eye bearing 14, adjustment limit block 15, adjustment connecting shaft 16, fine-tuning knob 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com