Welding tractor with steel structure being subjected to gas shielded welding

A gas shielded welding and welding trolley technology, which is applied to welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low control precision, complex structure, inconvenient installation, etc., achieve high walking precision, improve welding precision, and eliminate errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

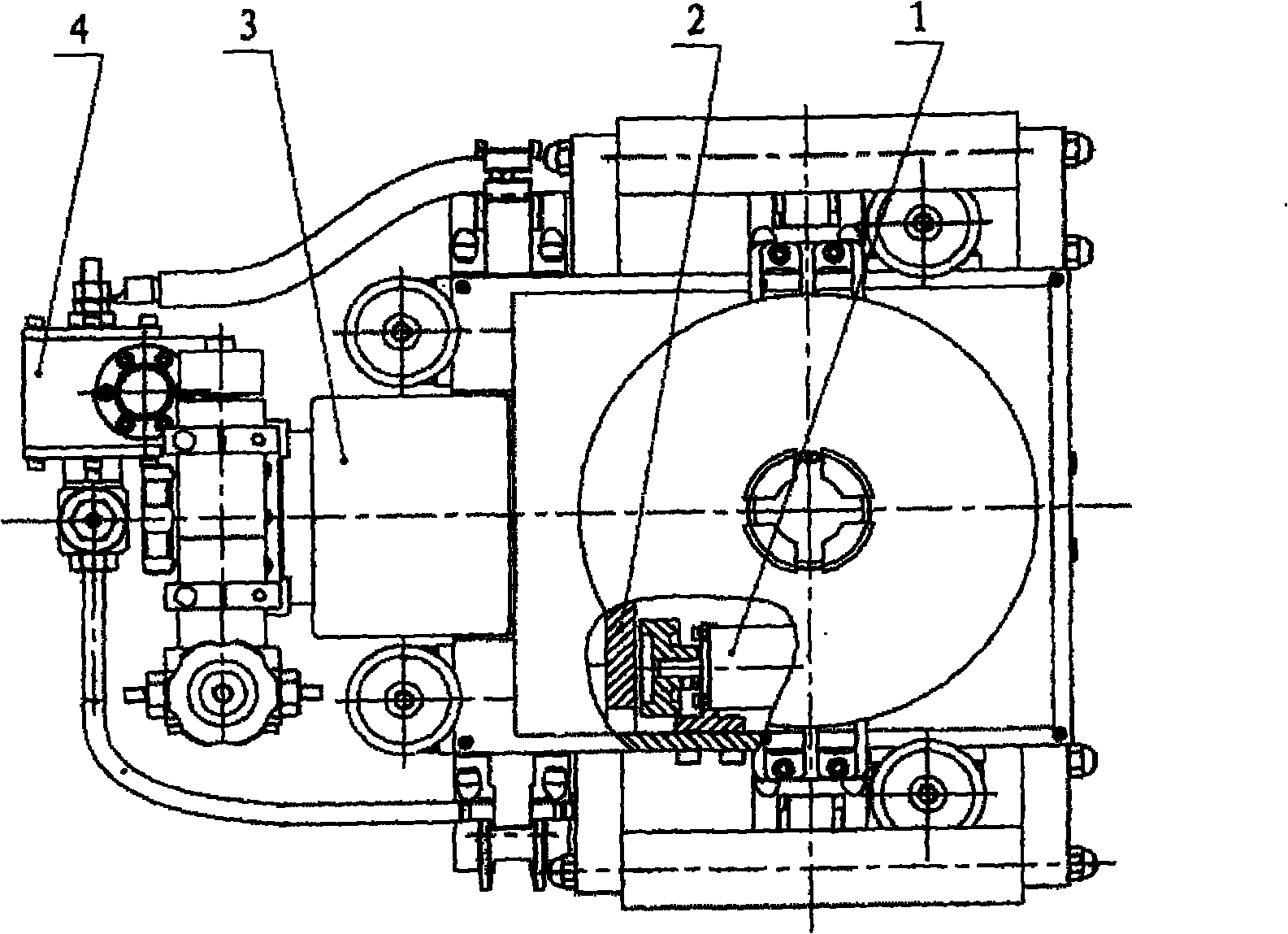

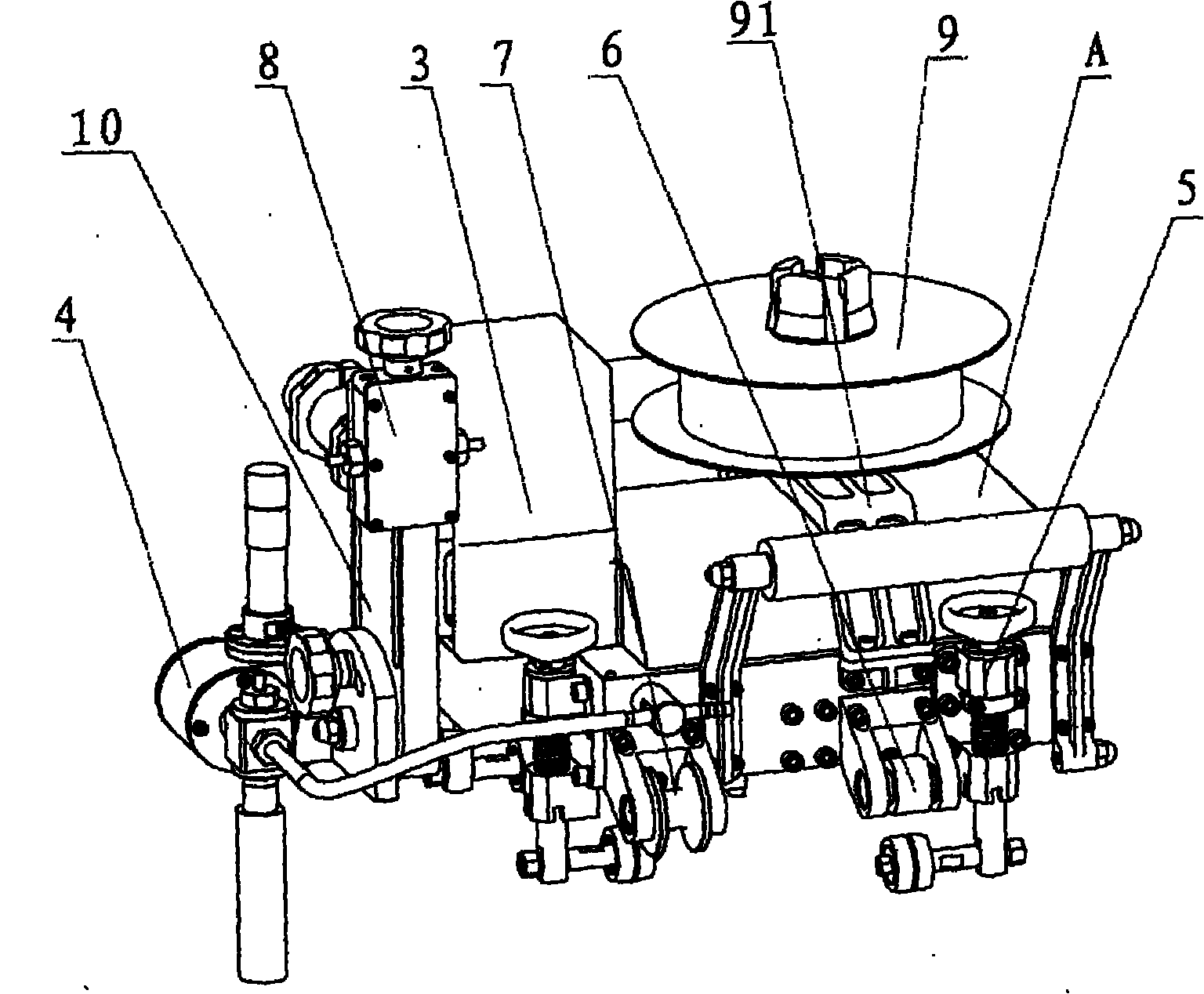

[0036] Such as Figure 1 to Figure 1 As shown in 0, the steel structure gas shielded welding welding trolley of the present invention includes a traveling mechanism 1 and a welding torch axial adjustment mechanism 2 arranged inside the housing A, a welding torch radial adjustment mechanism 3 arranged outside the housing A, and a welding torch clamp Angle swing mechanism 4, suspension locking mechanism 5, guide mechanism, wire feeding mechanism 8 and welding wire reel 9; the walking mechanism 1, welding torch axial adjustment mechanism 2, welding torch radial adjustment mechanism 3, welding torch angle swing mechanism 4 and feeding The wire mechanism 8 is connected with the control mechanism respectively.

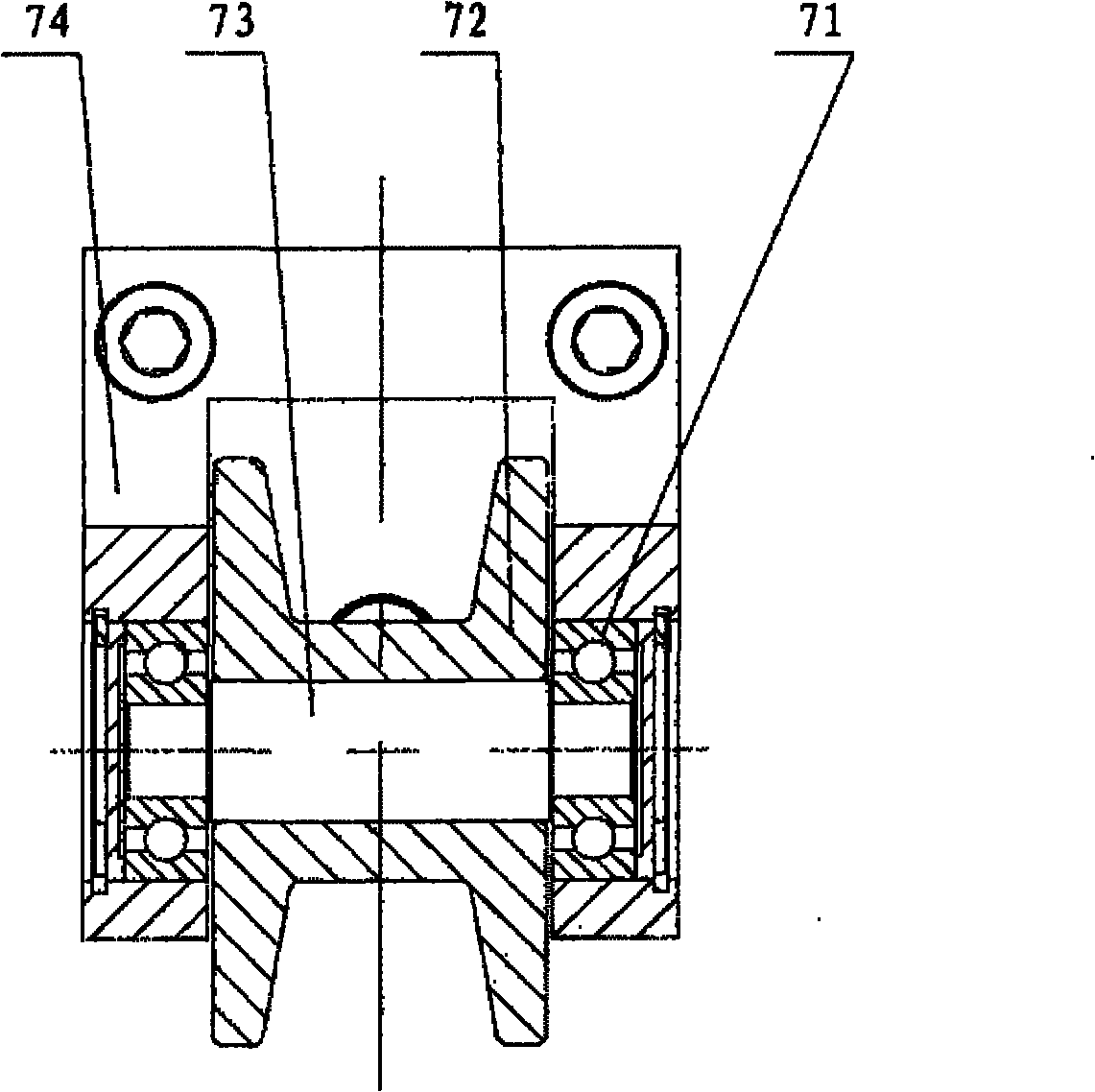

[0037] Such as Figure 5 As shown, the steel structure gas shielded welding welding trolley of the present invention has a traveling mechanism 1 comprising a driving motor 13 and a driving gear 11; the driving motor 13 is fixed on the inner side wall of the housing A throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com