Array magnetic navigation sensor

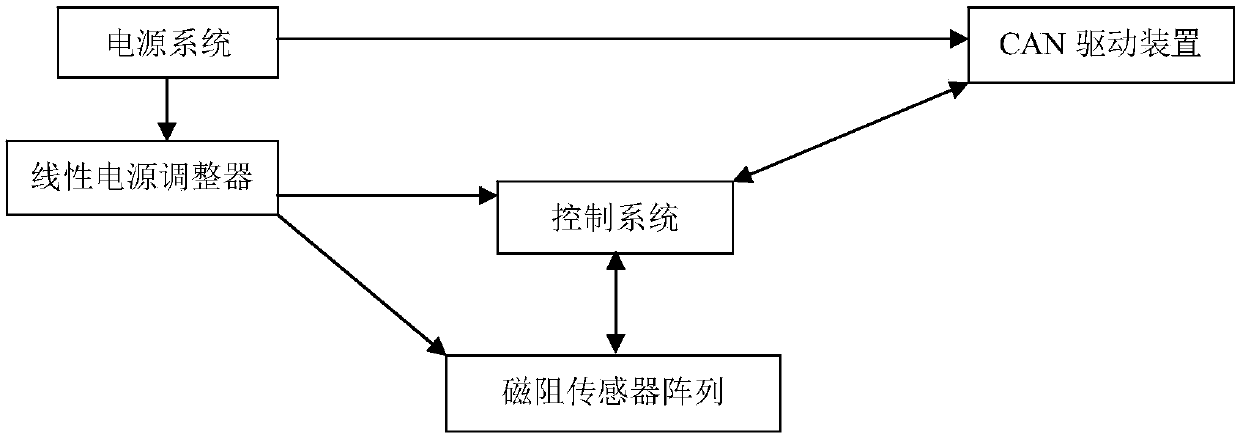

The technology of magnetic navigation sensor and magnetoresistive sensor is applied in the field of array magnetic navigation sensor, which can solve the problems of difficult judgment, unstable signal output, occupation of control system, etc., to achieve flexible and convenient wiring structure, improve walking accuracy and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

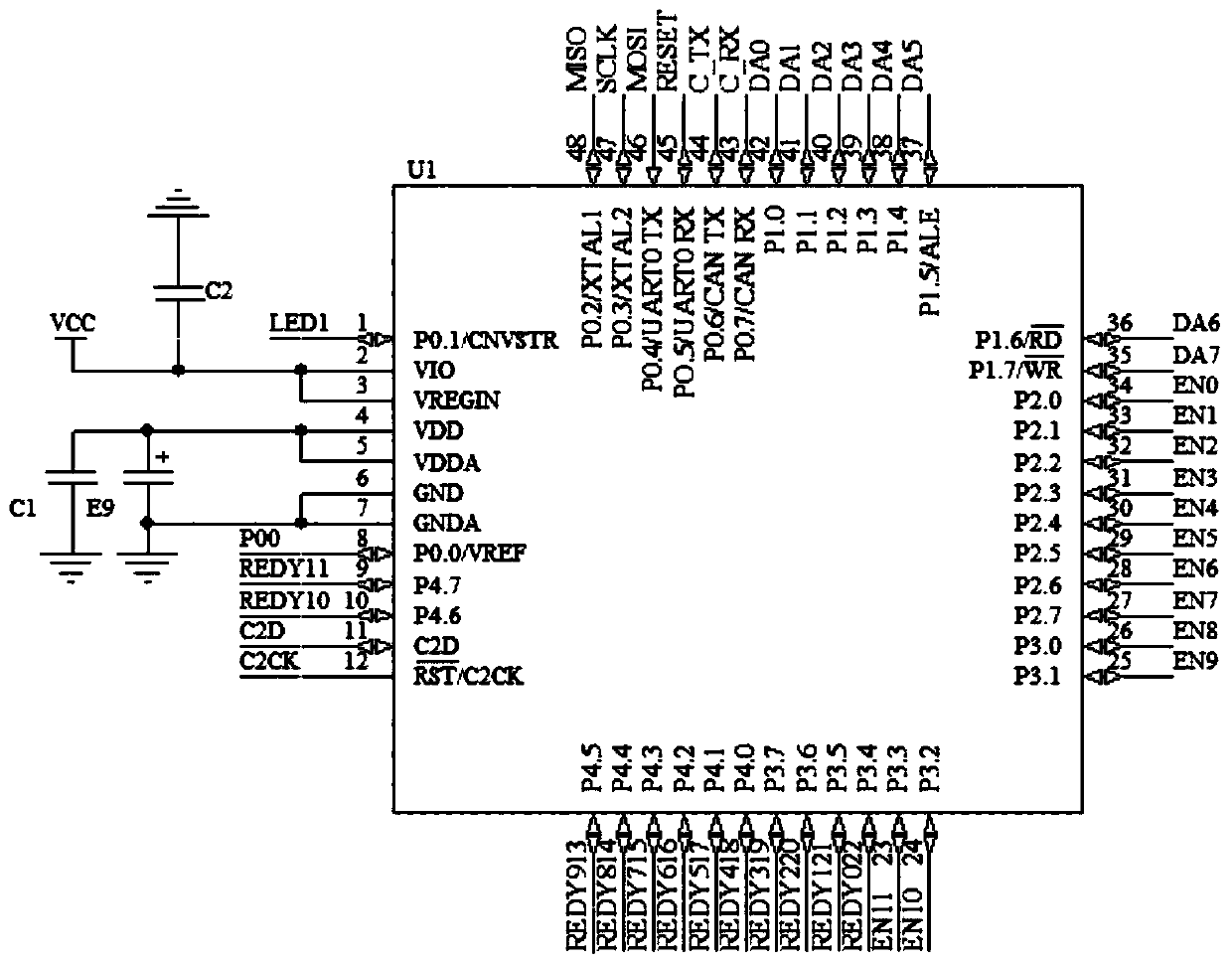

[0025] 45, 46, 47, 48 are SPI function pins, which are connected with the SPI function pins of the magnetic drive chip. The layout of the magnetoresistive sensor array is 10 rows and 20 columns, and a total of 200 points form a matrix. Each point requires two IO signals, chip select and data waiting signals. The controller controls each sensor separately through a logic device. Pins 43 and 44 of C8051F500-IQ are CAN bus communication pins, which are connected with pins 3 and 4 of the CAN driver.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com