Portable pipeline automatic circumferential walking device and pipeline processing method

A kind of walking equipment and portable technology, which is applied in the field of portable pipe automatic circular traveling equipment and pipeline processing, can solve the problems of wheel deviation, easy aggravation, magnetic force reduction, etc., achieve ultra-high walking accuracy, convenient control mode, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

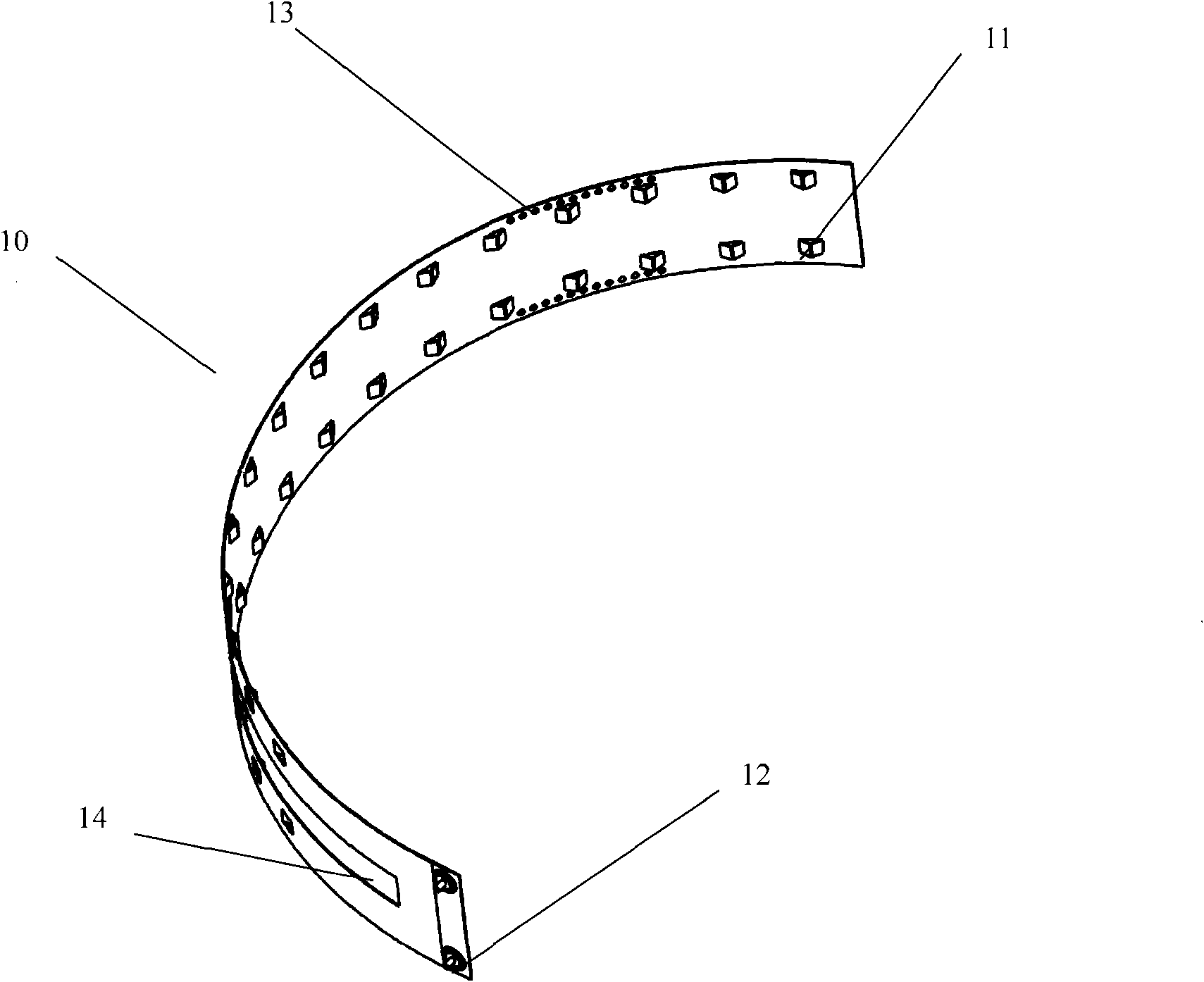

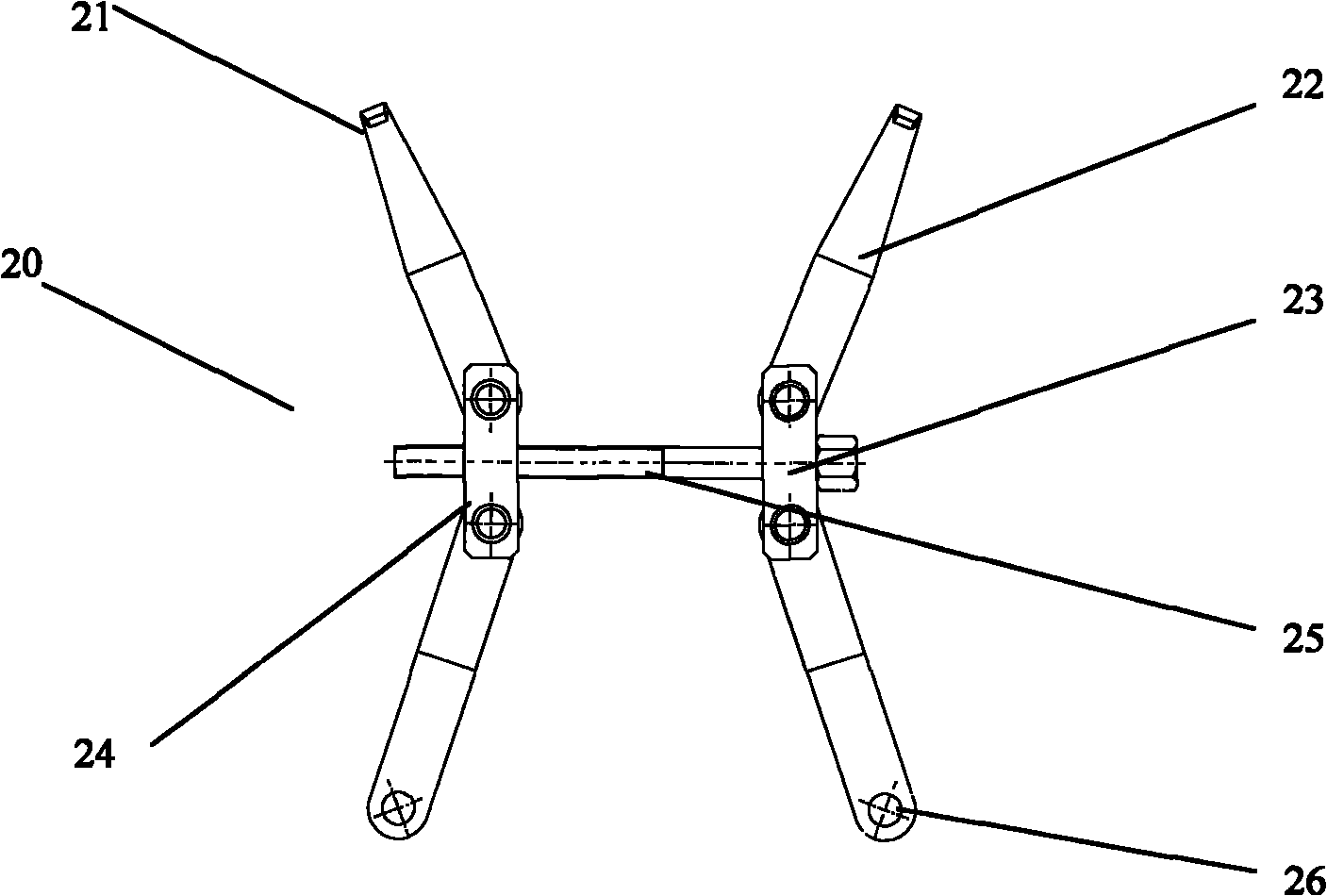

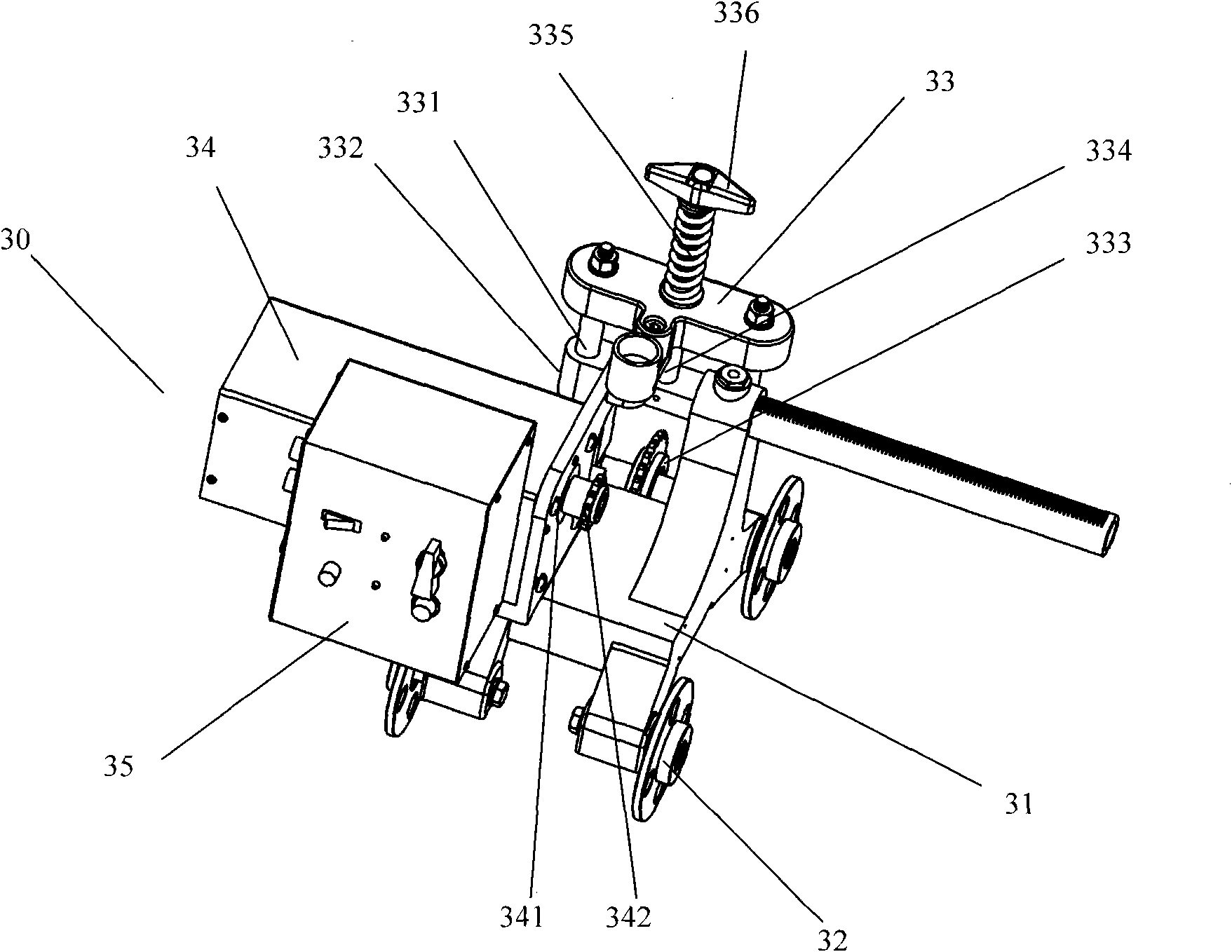

[0018] The present embodiment is made up of circular track part, traveling mechanism part, control part. Wherein the circular track part is composed of track 10 (see figure 1 ), and the claws 20 for the installation track (see figure 2 )composition. The track 10 is made of thin plates of different lengths, and the thin plates have the ability to undergo plastic deformation, and can be bent into different radians as required to adapt to pipes of different diameters. Several grooves 11 are distributed along the length direction of the track. One end of the track 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com