Double-lead-screw loading horizontal movement measuring mechanism

A technology of measuring mechanism and horizontal movement, which is applied in the direction of measuring devices, metal processing, metal processing equipment, etc., which can solve the problems such as difficult to adapt to the volume, and achieve the effects of improving production efficiency, high loading and walking accuracy, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

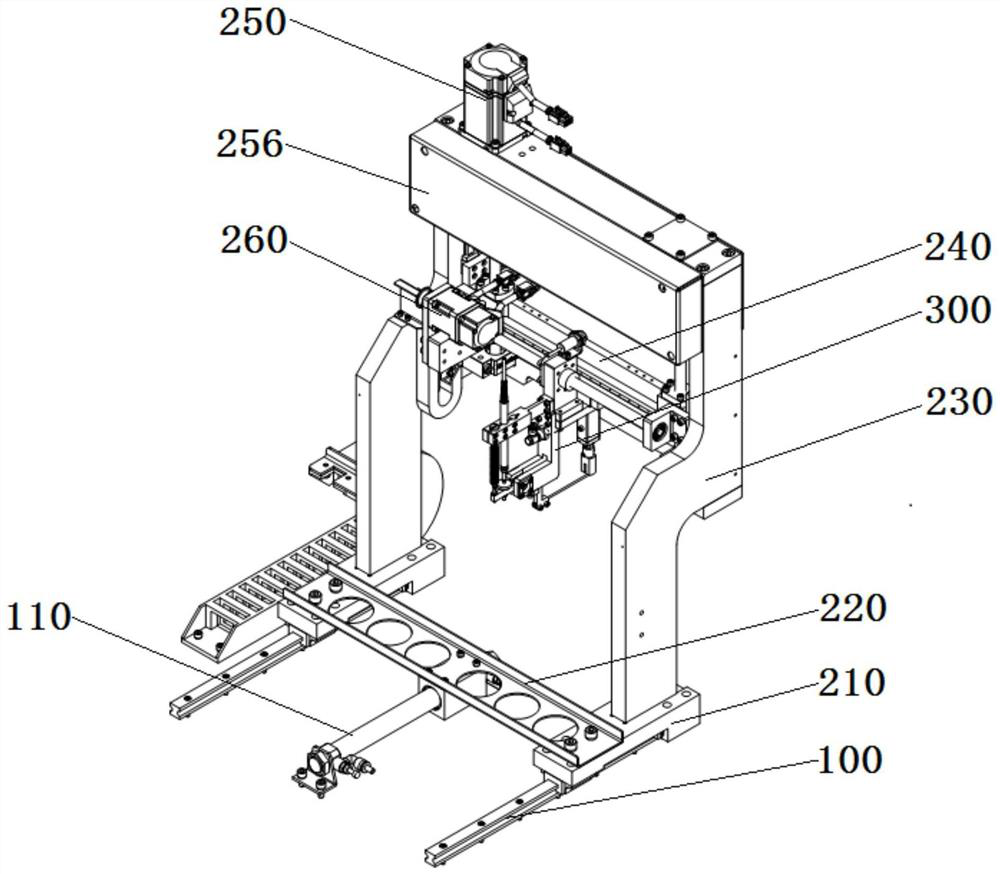

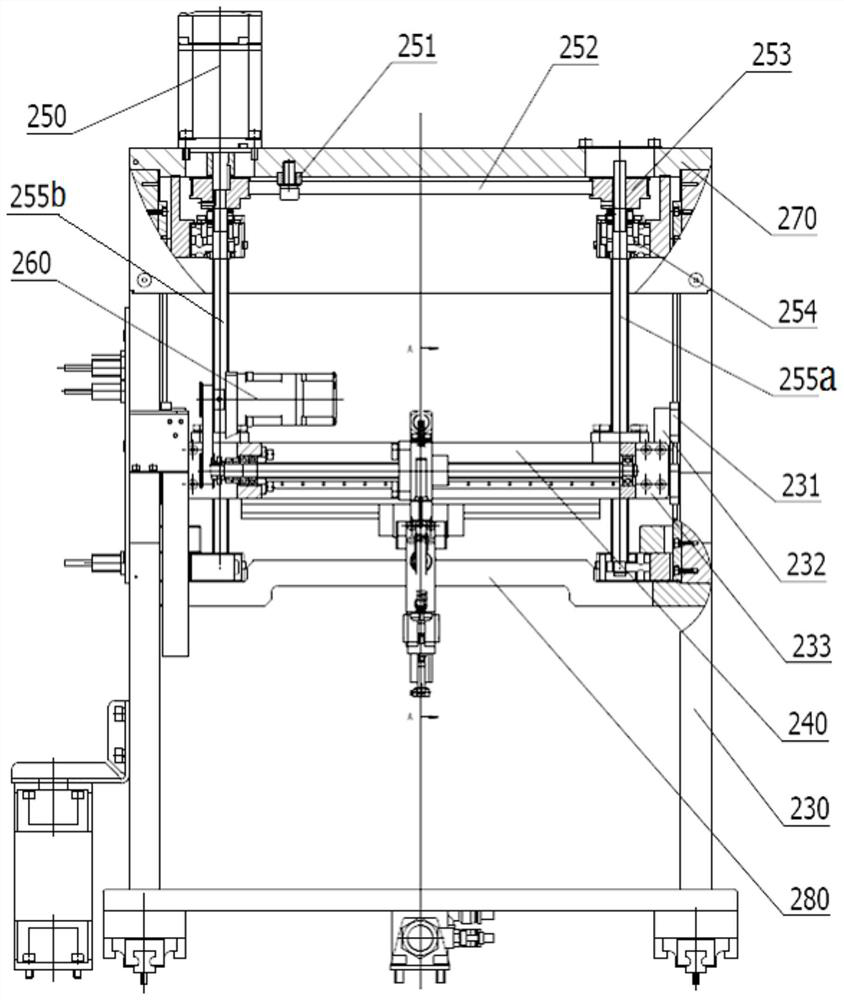

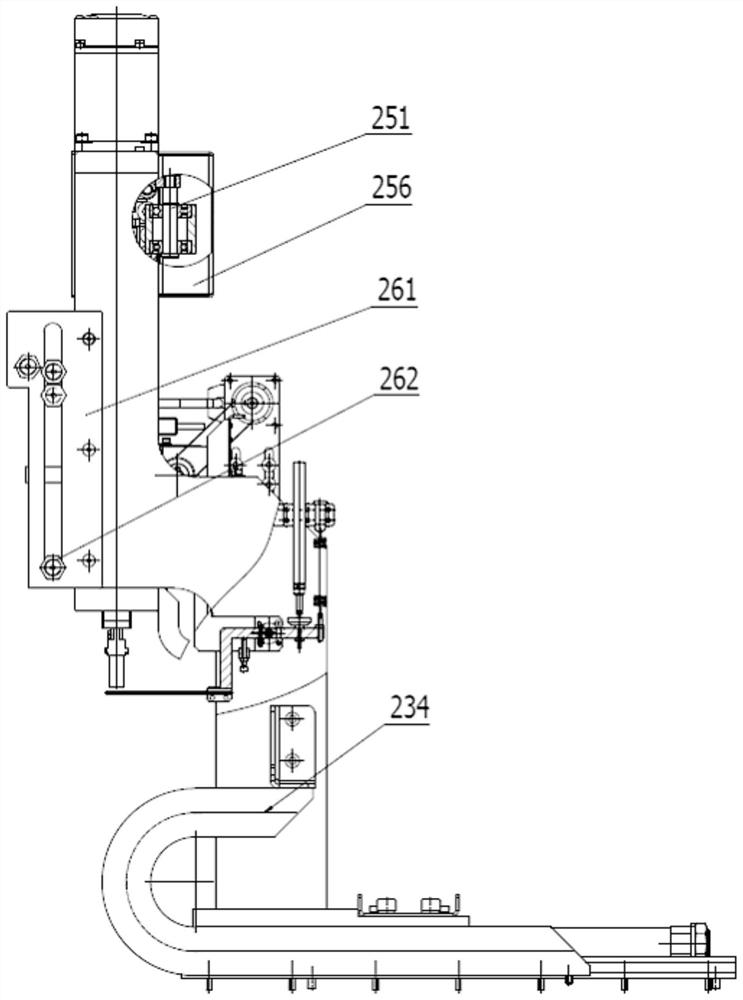

[0060] like Figure 1-5 As shown, the present invention provides a double-screw loading horizontal movement measuring mechanism, including: a first guide rail 100, a cylinder 110, a slider connecting plate 210, a cylinder connecting plate 220, a side vertical plate 230, a loading beam 240, a first drive Motor 250 , second driving motor 260 , top beam 270 , lower beam 280 , and measuring mechanism 300 .

[0061]The double-screw loading horizontal movement measuring mechanism is arranged on the top of the main machine. On the top of the main machine, two first guide rails 100 are arranged. The two first guide rails 100 are arranged along the Y-axis direction. One end of the air cylinder 110 is fixed on the top of the host, and the other end is fixedly connected to the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com