Workpiece surface treatment method and terminal shell

A technology of workpiece surface and processing method, applied in the direction of electrical digital data processing, surface reaction electrolytic coating, digital data processing parts, etc. Large and other problems, to achieve the effect of avoiding step difference, avoiding knife pick marks, and high engraving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

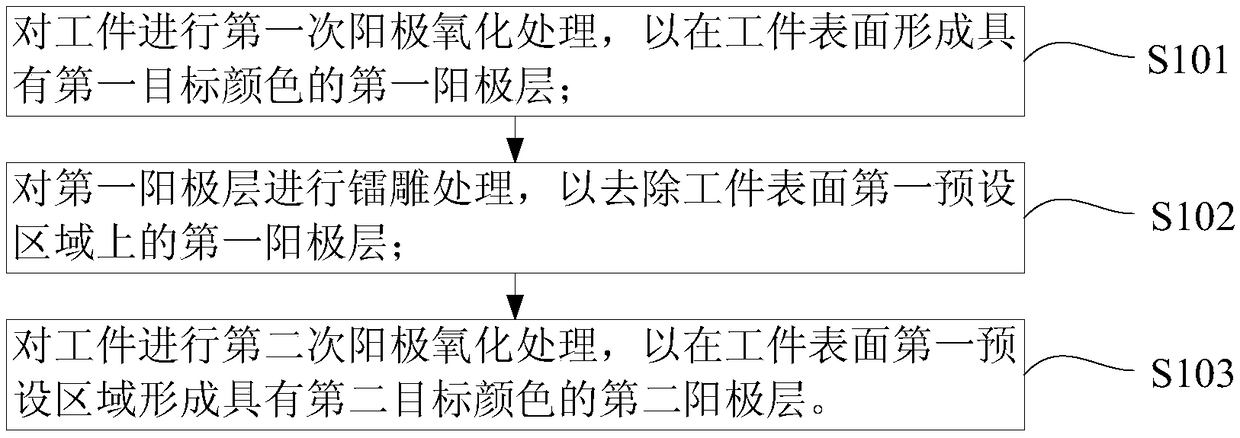

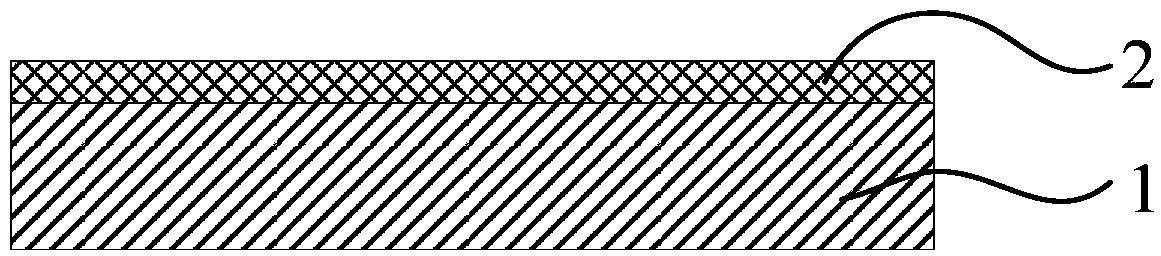

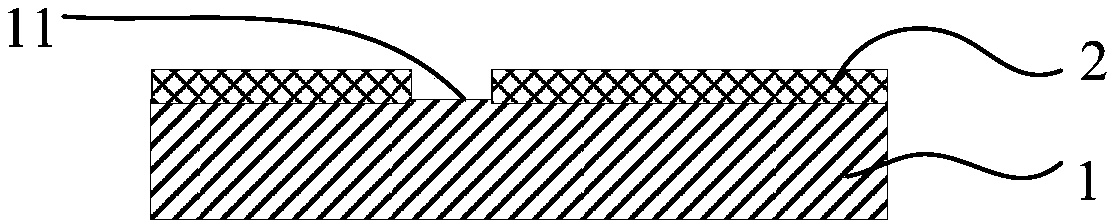

[0042] figure 1 It is a flow chart of a workpiece surface treatment method shown according to an exemplary embodiment; figure 2 is a partial cross-sectional view of the workpiece after the first anodizing treatment shown according to an exemplary embodiment; image 3 is a schematic structural view of a workpiece after laser engraving according to an exemplary embodiment; Figure 4 is a partial cross-sectional view of a workpiece after the second anodizing treatment according to an exemplary embodiment.

[0043] like figure 1 shown, combined with Figure 2-4 , the workpiece surface treatment method comprises the steps of:

[0044] S101, performing a first anodic oxidation treatment on the workpiece to form a first anode layer with a first target color on the surface of the workpiece;

[0045] The workpiece 1 is a semi-finished product that has been formed but not colored, and the finished product formed after the surface treatment method of the workpiece can be the casing...

Embodiment 2

[0110] Figure 9 It is a schematic diagram showing a partial structure of a terminal housing according to an exemplary embodiment.

[0111] like Figure 9 As shown, the embodiment of the present disclosure provides a terminal housing, which is made by using the workpiece surface treatment method provided in Embodiment 1.

[0112] In the embodiment of the present disclosure, the terminal housing is formed from a workpiece that has been formed but not colored, and is formed after the workpiece surface treatment method of the embodiment of the disclosure, which includes: a first anode layer 2 with a first target color, A second anode layer 3 having a second target color and a third anode layer 4 having a third target color.

[0113] In the embodiment of the present disclosure, the terminal casing may be a casing of a terminal such as a smart phone, a tablet, or a notebook, that is, a body, and may be made of metal aluminum or an aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com