Light guide plate and manufacturing method of light guide plate as well as backlight module and display device

A manufacturing method and a technology of a light guide plate, which are applied to manufacturing tools, lighting devices, fixed lighting devices, etc., can solve the problem of uneven light and shade on the exit surface of the light guide plate, insufficient adjustment of the luminance of the light guide plate, and unclear images on the liquid crystal display and other issues, to achieve the effect of realizing automatic mass production of mold core engraving, increasing and affecting the definition, increasing the brightness of the image and affecting the definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

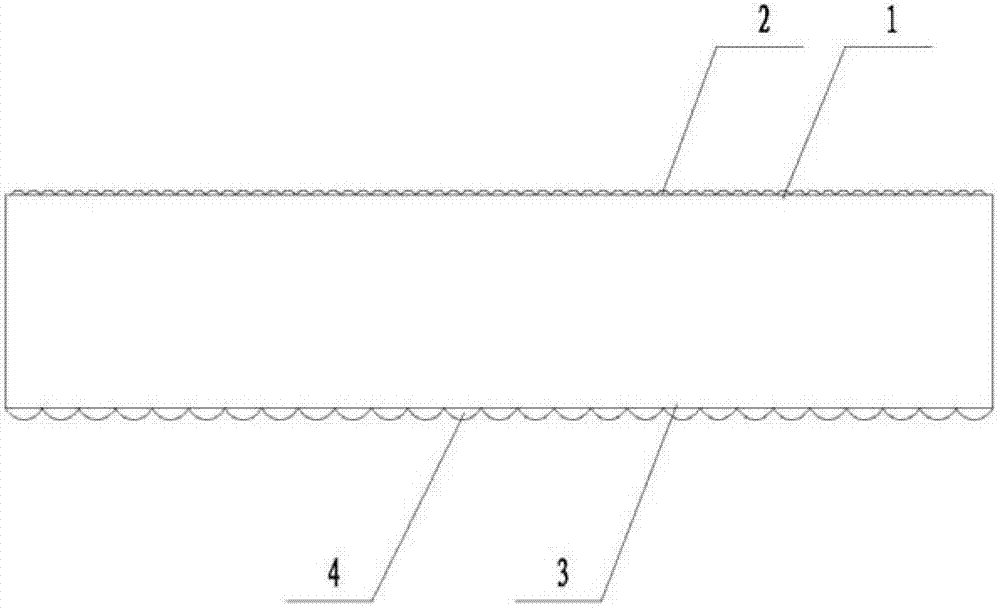

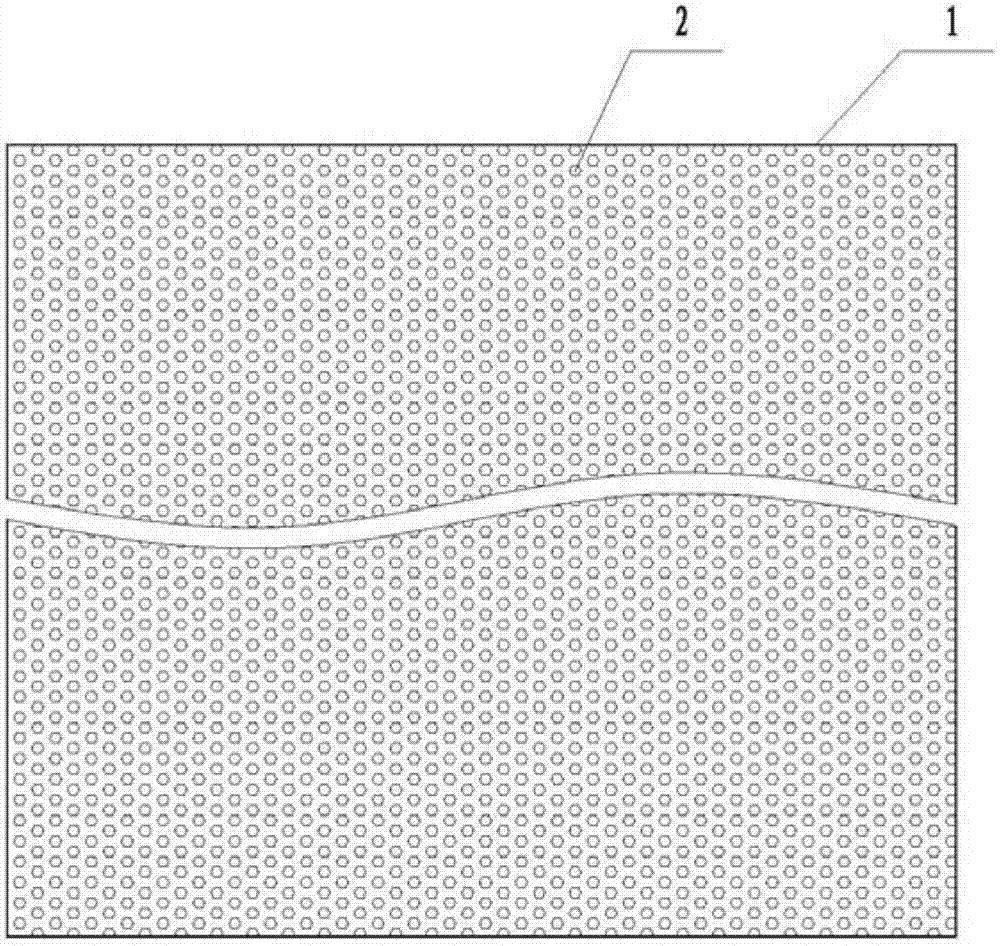

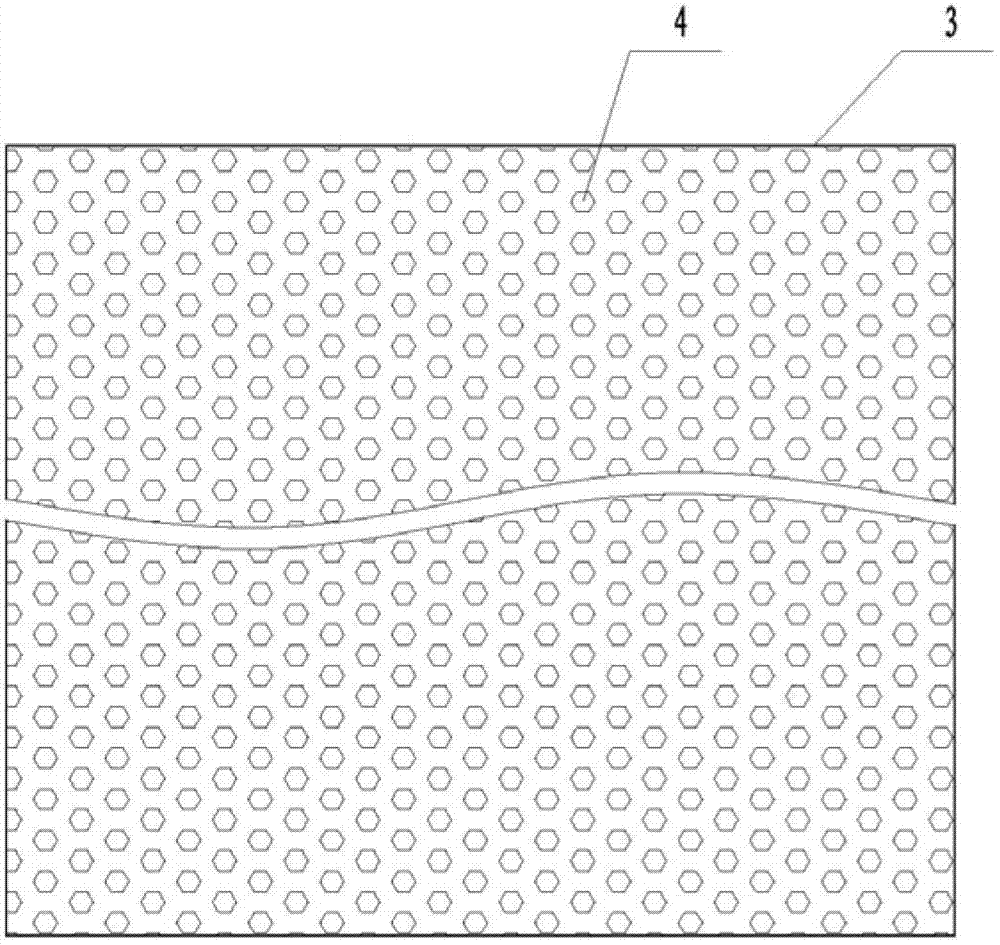

[0037] see figure 1 , figure 2 , image 3 As shown, a light guide plate in this embodiment includes a light guide plate base material, and the light guide plate base material includes an incident surface for receiving light beams, a bottom surface connected to the incident surface, a bottom surface connected to the incident surface and connected to the incident surface. The exit surface opposite to the bottom surface, one side opposite to the incident surface and the remaining opposite sides, the exit surface at the top of the light guide plate is provided with a micro-transmission surface 1; the micro-transmission surface includes a plurality of evenly distributed micro-transmission points 2; The micro-transparency point is provided with an outer convex surface, and the outer convex surface is an arc-shaped mirror surface that can collect light; Adjust to gather the scattered light; increase the display brightness and affect the clarity of the liquid crystal display, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com