Self-levelling machine spraying putty powder for interior wall as well as preparation method and use method of putty powder

A technology of self-leveling and putty powder, which is applied in the direction of filling slurry, etc., can solve the problems of high cost, complex putty powder preparation formula, inability to effectively solve prickly heat, pinholes, honeycomb, etc. Healing performance, effect of improving sag phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

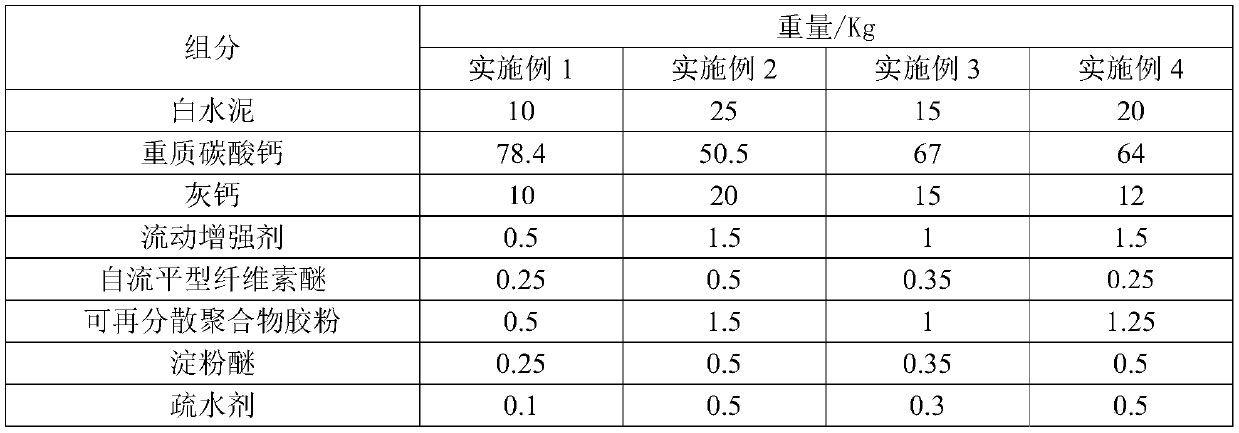

Embodiment 1

[0024] This embodiment provides a method for making putty powder sprayed by a self-leveling interior wall machine, the steps are as follows:

[0025] White cement 10kg, heavy calcium carbonate 78.4kg, gray calcium 10kg, flow enhancer 0.5kg, self-leveling cellulose ether 0.25kg, redispersible polymer rubber powder 0.5kg, starch ether 0.25kg, hydrophobic agent 0.1kg , followed by feeding and mixing, and stirring for 30 minutes to prepare the self-leveling interior wall machine spray putty powder.

[0026] This embodiment provides a method for using a self-leveling interior wall machine to spray putty powder, the steps are as follows:

[0027] (1) Prepare materials; use a kind of self-leveling interior wall machine spray putty powder and clear water prepared by the above method, the mass ratio of clean water and self-leveling interior wall machine spray putty powder is 0.38:1, (2) mix and stir; use an electric mixer Stir the mixed slurry prepared in (1) until it is uniform witho...

Embodiment 2

[0029] This embodiment provides a method for making putty powder sprayed by a self-leveling interior wall machine, the steps are as follows:

[0030] White cement 25kg, heavy calcium carbonate 50.5kg, gray calcium 20kg, flow enhancer 1.5kg, self-leveling cellulose ether 0.5kg, redispersible polymer rubber powder 1.5kg, starch ether 0.5kg, hydrophobic agent 0.5kg , followed by feeding and mixing, and stirring for 30 minutes to prepare the self-leveling interior wall machine spray putty powder.

[0031] This embodiment provides a method for using a self-leveling interior wall machine to spray putty powder, the steps are as follows:

[0032](1) Prepare materials; use a kind of self-leveling interior wall machine spray putty powder and clear water prepared by the above method, the mass ratio of clean water and self-leveling interior wall machine spray putty powder is 0.40:1, (2) mix and stir; use an electric mixer Stir the mixed slurry prepared in (1) until it is uniform without ...

Embodiment 3

[0034] This embodiment provides a method for making putty powder sprayed by a self-leveling interior wall machine, the steps are as follows:

[0035] 15kg of white cement, 67kg of heavy calcium carbonate, 15kg of gray calcium, 1kg of flow enhancer, 0.35kg of self-leveling cellulose ether, 1kg of redispersible polymer rubber powder, 0.35kg of starch ether, and 0.3kg of hydrophobic agent are fed in sequence Mix and stir for 30 minutes to prepare the self-leveling interior wall machine spray putty powder.

[0036] This embodiment provides a method for using a self-leveling interior wall machine to spray putty powder, the steps are as follows:

[0037] (1) Prepare materials; use a kind of self-leveling interior wall machine spray putty powder and clear water prepared by the above method, the mass ratio of clean water and self-leveling interior wall machine spray putty powder is 0.35:1, (2) mix and stir; use an electric mixer Stir the mixed slurry prepared in (1) until it is unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com