Filter

A filter and filter element technology, used in filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of dangerous operation, inconvenient exhaust, damage to the filter element before its service life, etc., and achieve reliable assembly. High performance, easy maintenance and construction, and long filter life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

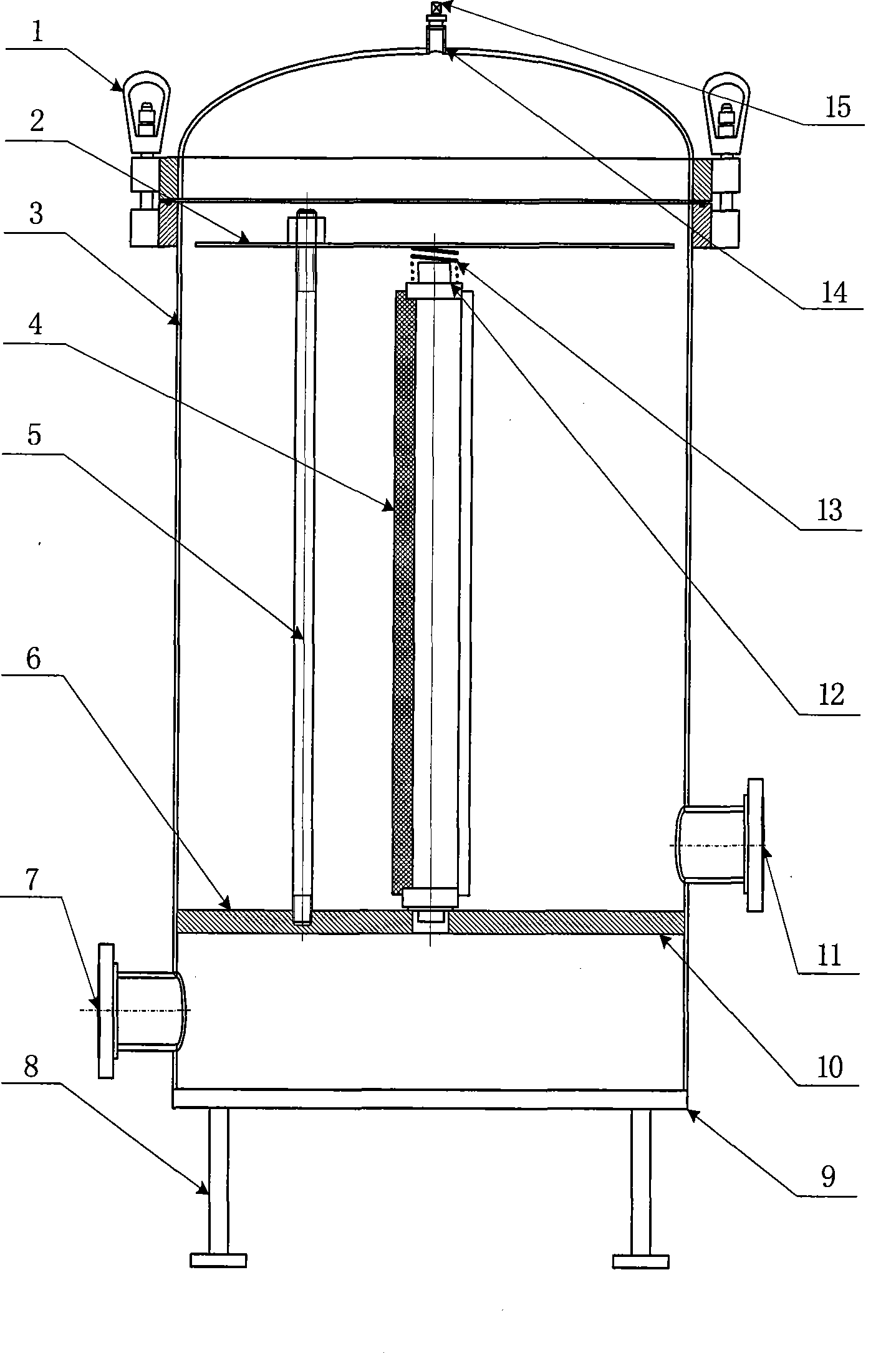

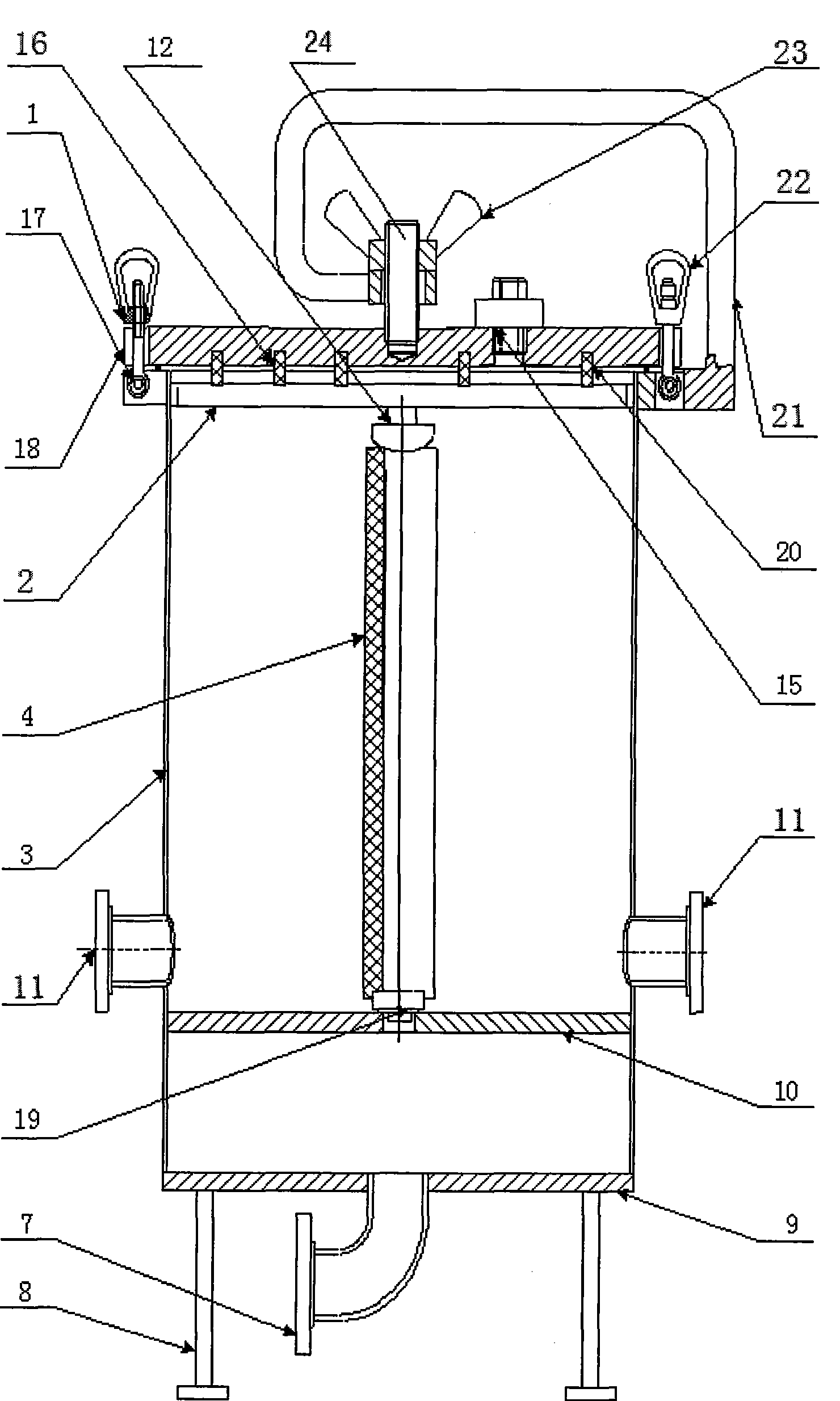

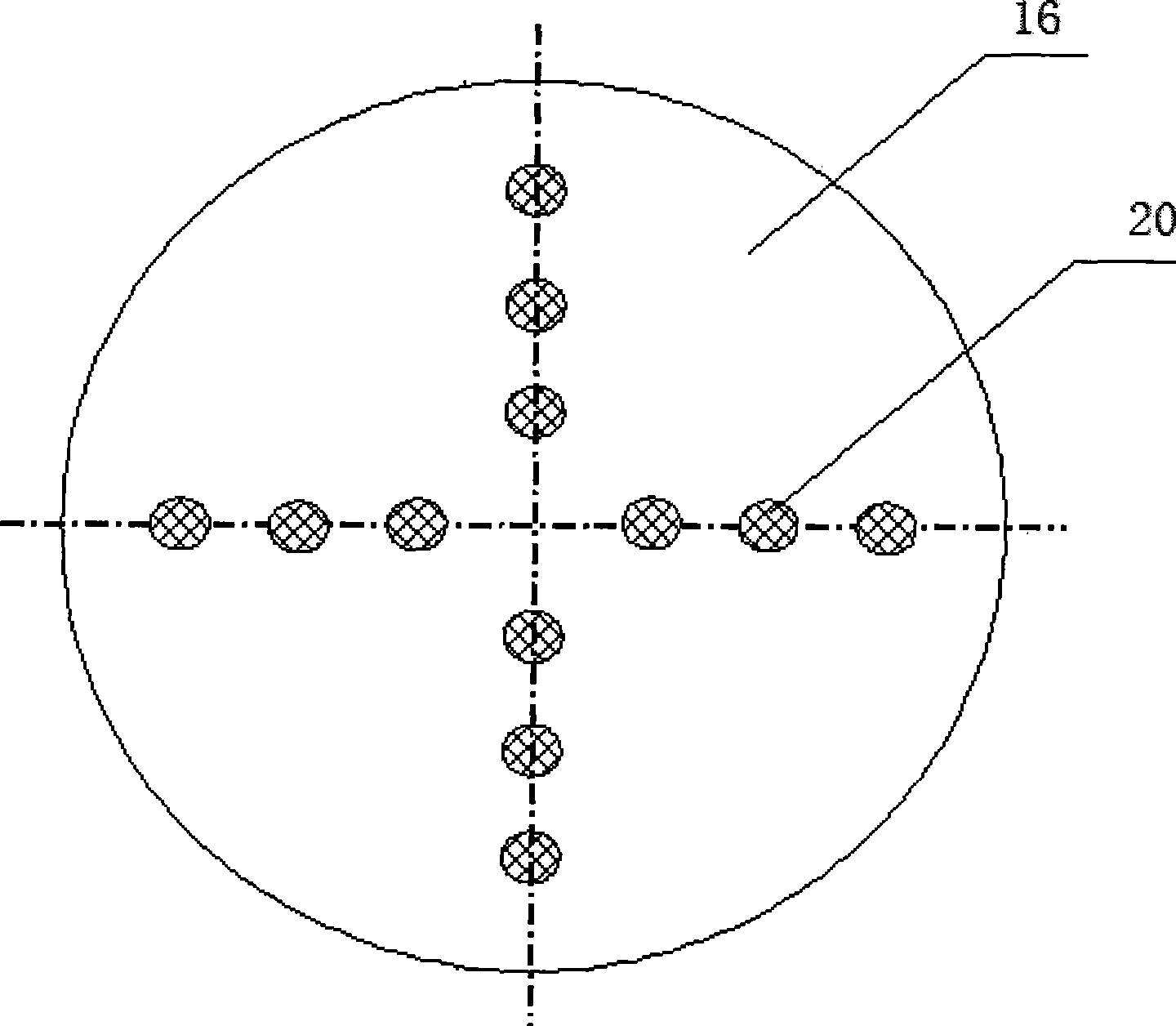

[0020] Such as figure 2 , image 3 As shown, a filter includes a drainage plate 10, which divides the filter cylinder into upper and lower parts, a column filter element 4 is arranged in the middle of the upper cylinder, and the bottom end of the column filter element passes through the bottom of the filter element. The end bracket 19 is connected to the drainage plate 10, and the top is connected to the pressing plate 2 through the filter element plug 12, which is a linear sealing plug, which saves parts such as springs. The lower cylindrical body is connected with the legs 8 through the support plate 9 . Water inlets 11 are respectively provided on both sides of the bottom of the upper cylinder, and the water outlet 7 is arranged in the middle below the support plate 9 of the lower cylinder; there is a flange on the upper edge of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com