Bearing ring automatic machining equipment

A technology for automatic processing and bearing rings, applied in the field of bearing processing, can solve the problems of excessive variation in the inner diameter/outer diameter of a single plane, low qualified rate of semi-finished turning parts, and difficulty in adjusting the clamping force, so as to increase practical performance, Uniform pressure to avoid excessive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

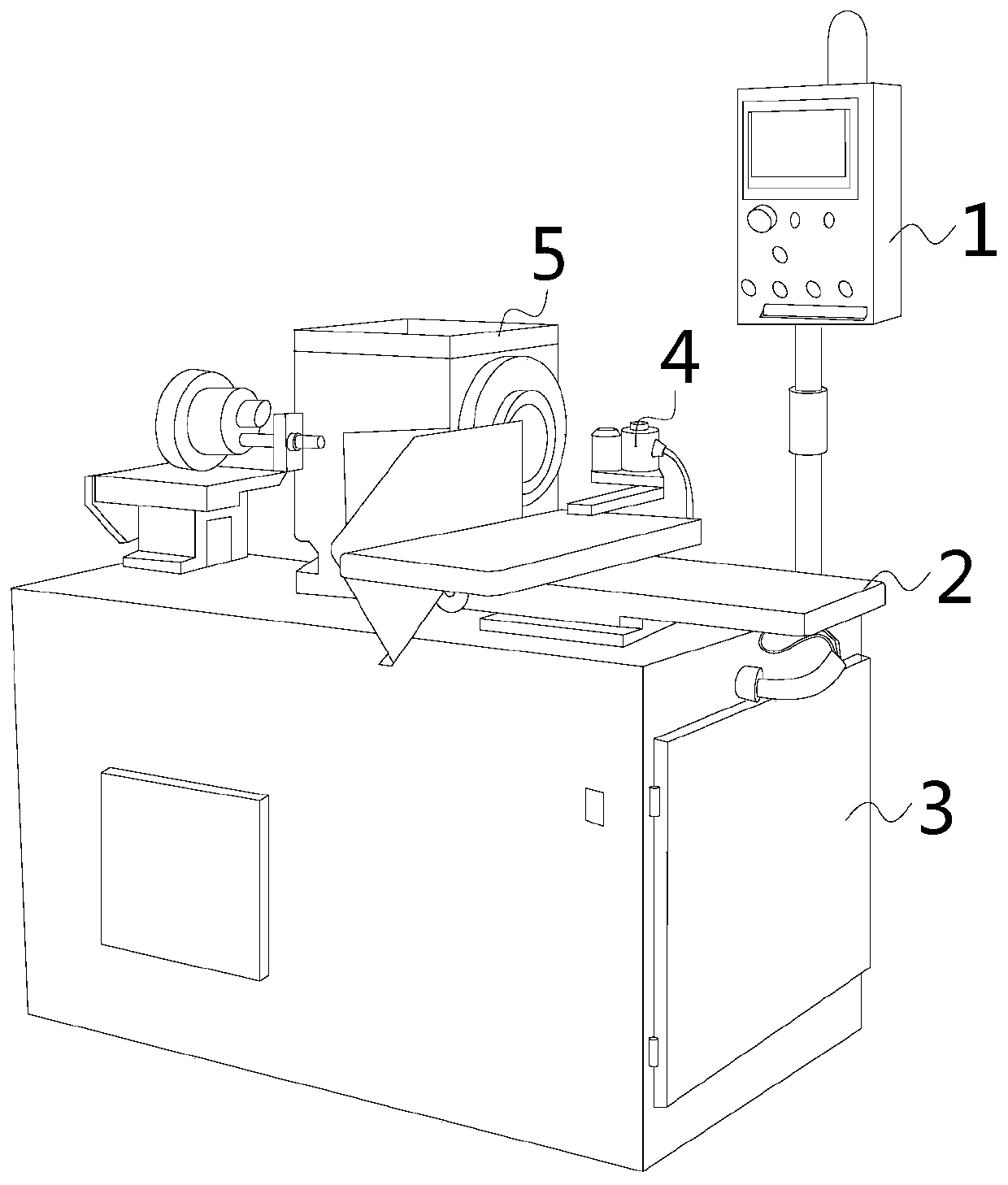

[0027] see Figure 1-Figure 6 , the present invention provides an automatic processing equipment for bearing rings, the structure of which includes a controller 1, an operating table 2, a body 3, a tool 4, a soft claw disk mounting seat 5, and a soft claw disk 6. The top surface of the body 3 is provided with a There is an operation table 2, and the other end is installed with a soft claw disk mounting seat 5, and the soft claw disk mounting seat 5 is movable with a soft claw disk 6, and a controller 1 is installed side by side on the body 3 on one side of the operation table 2 And a cutter 4, the cutter 4 is located between the soft claw plate mounting seat 5 and the controller 1.

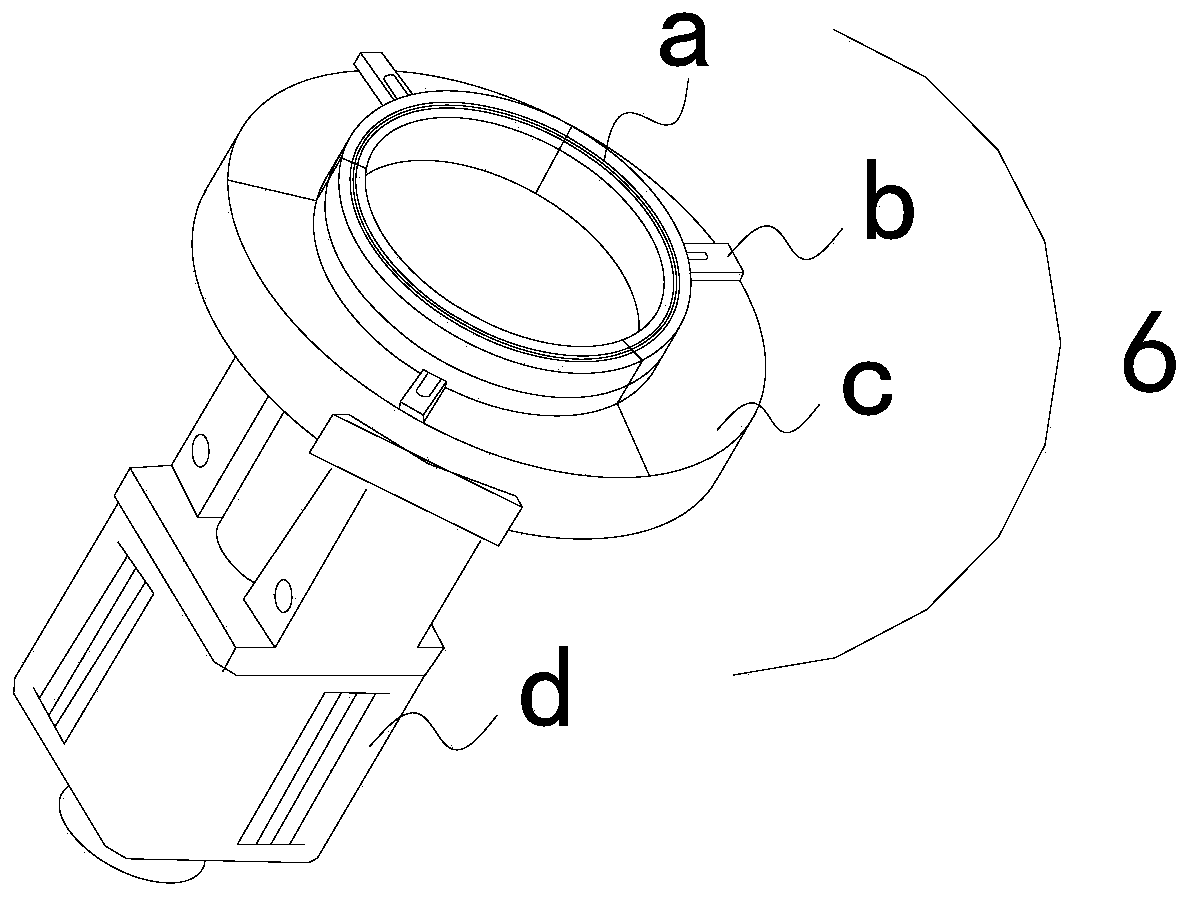

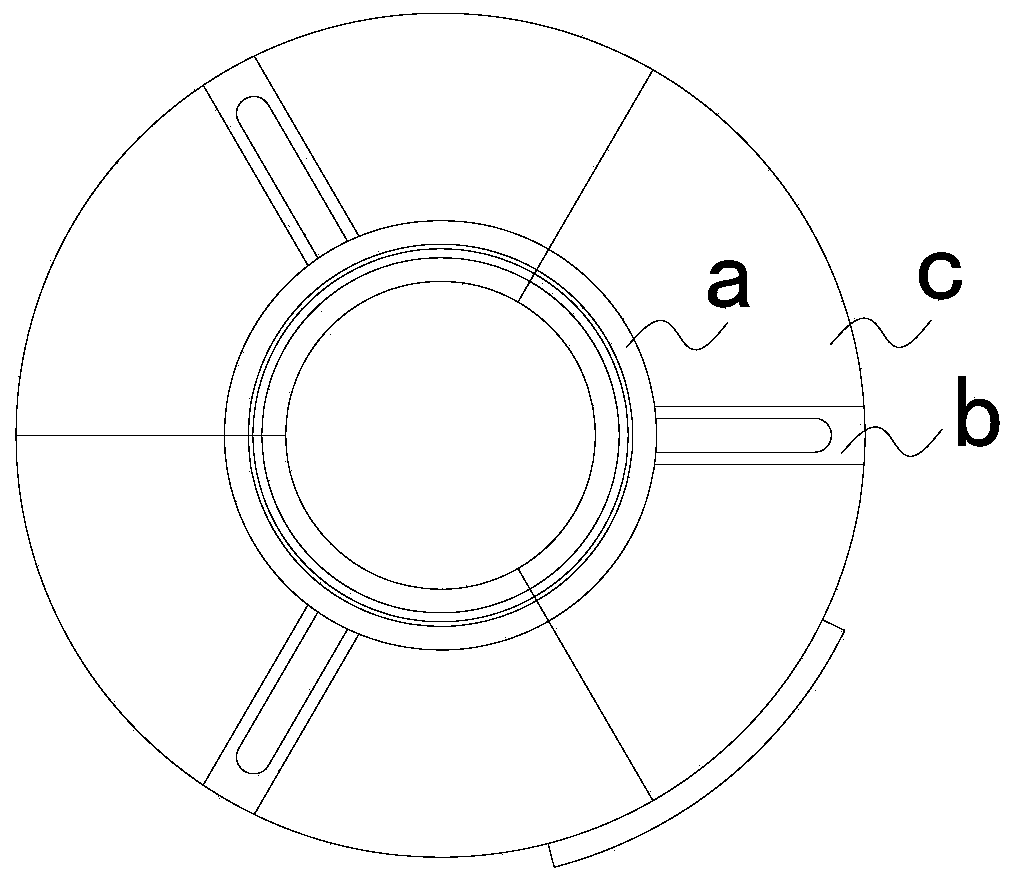

[0028] The soft claw disc 6 is composed of claw a, sliding seat b, claw body c, and motor d. The motor d is located directly below the claw body c. There are three claw bodies c, and the three claw bodies c are adjacent to each other. The two will be joined together to form a complete circle. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com