Laminated mould of multi-layer circuit board

A technology of circuit boards and molds, applied in multilayer circuit manufacturing, printed circuit, printed circuit manufacturing, etc., can solve the problems of affecting lamination speed, high manufacturing cost of positioning system, and inability to reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described below by taking a four-layer circuit board as an example.

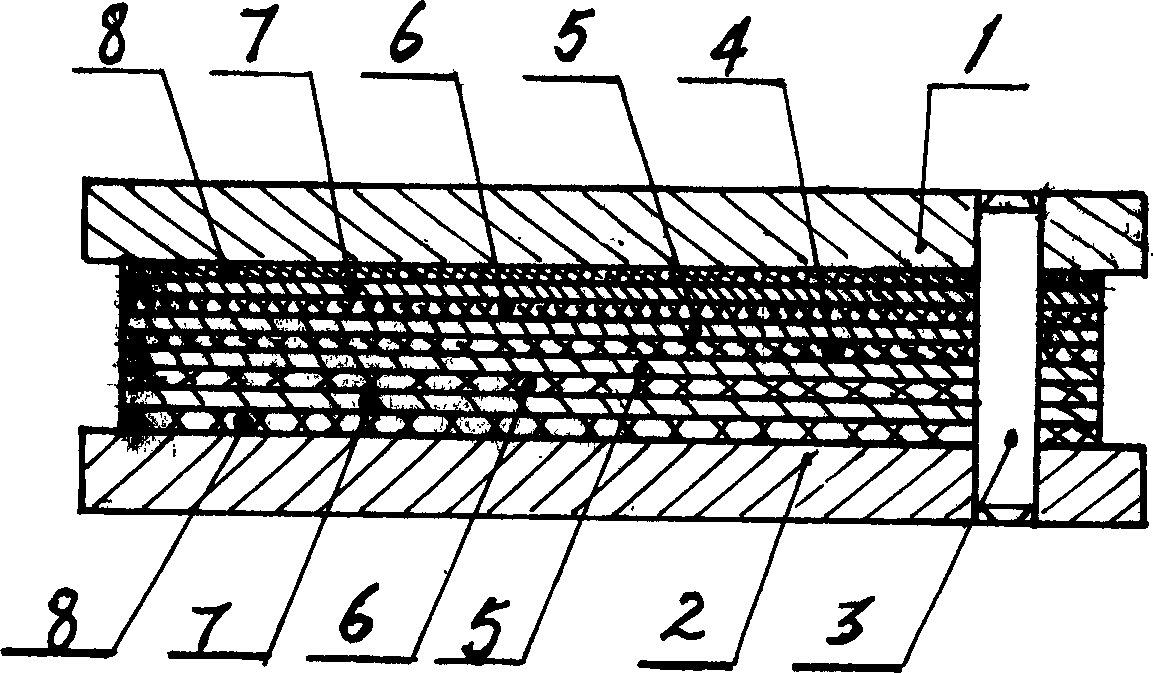

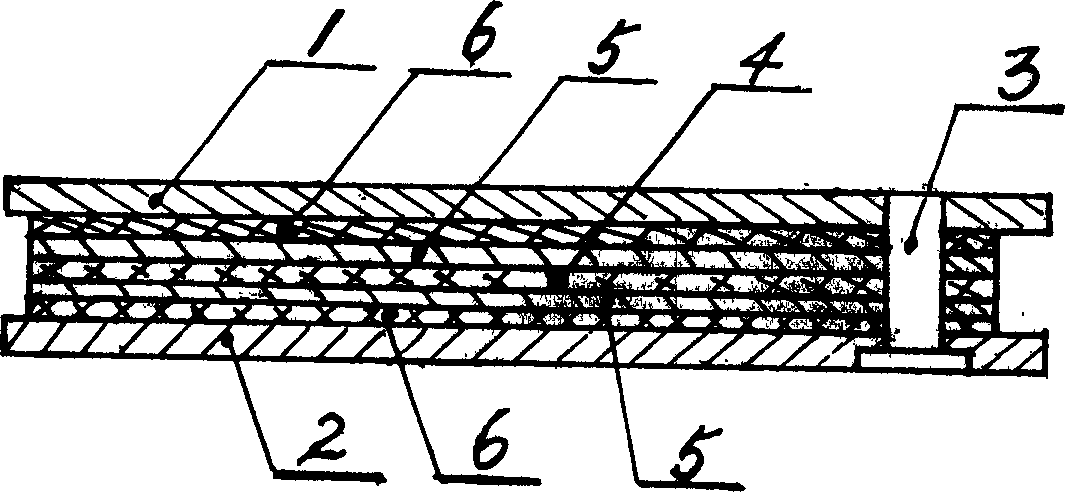

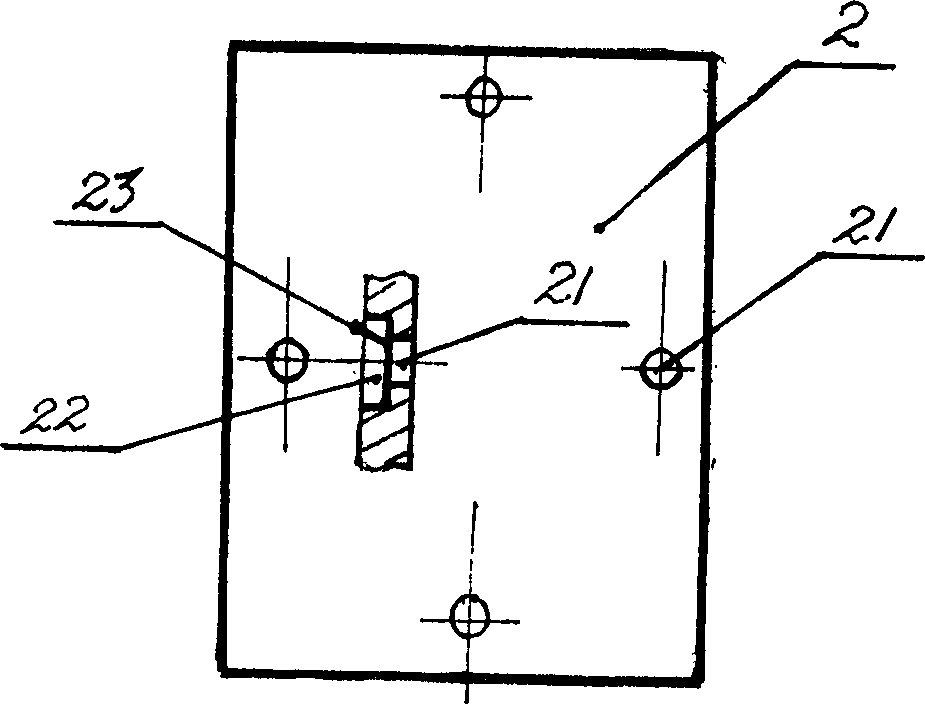

[0018] The lamination mold of multilayer circuit board of the present invention is made up of upper formwork 1, lower formwork 2, positioning pin 3, the thickness of upper formwork 1 and lower formwork 2 are 2 millimeters, and its material is high-quality pressure-resistant mirror stainless steel plate, four circular positioning holes 21 with countersunk holes 22 are arranged on the lower template 2, and the step surface 23 of the counterbore 22 is perpendicular to the axis of the positioning holes 21; four long waist holes are arranged on the upper template 1 11. The centers of the four long waist holes 11 correspond to the centers of the positioning holes 21 on the lower template 2, and the center line of the two long waist holes 11 is perpendicular to the center line of the other two long waist holes 11; The positioning pin 3 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com