Flat-clothing machine tool

A technology for covering cover plates and card clothing, which is applied in deburring devices, textiles and papermaking, fiber processing, etc., and can solve problems such as uneven side pressure clamping force of moving plate, fixed moving speed, complex adjustment structure, etc. , to achieve the effects of reducing maintenance and electricity costs, improving efficiency, and adjusting the structure simply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

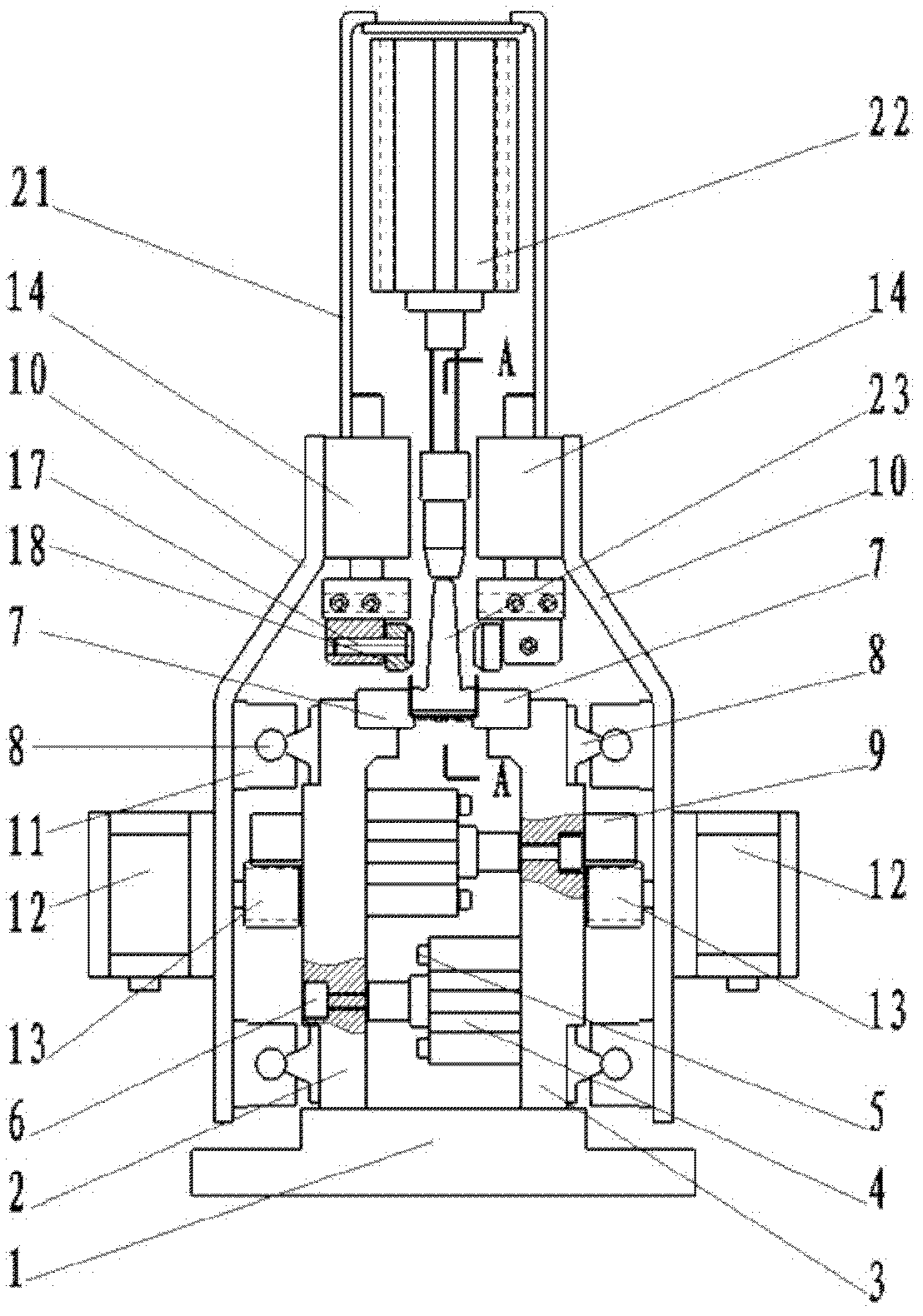

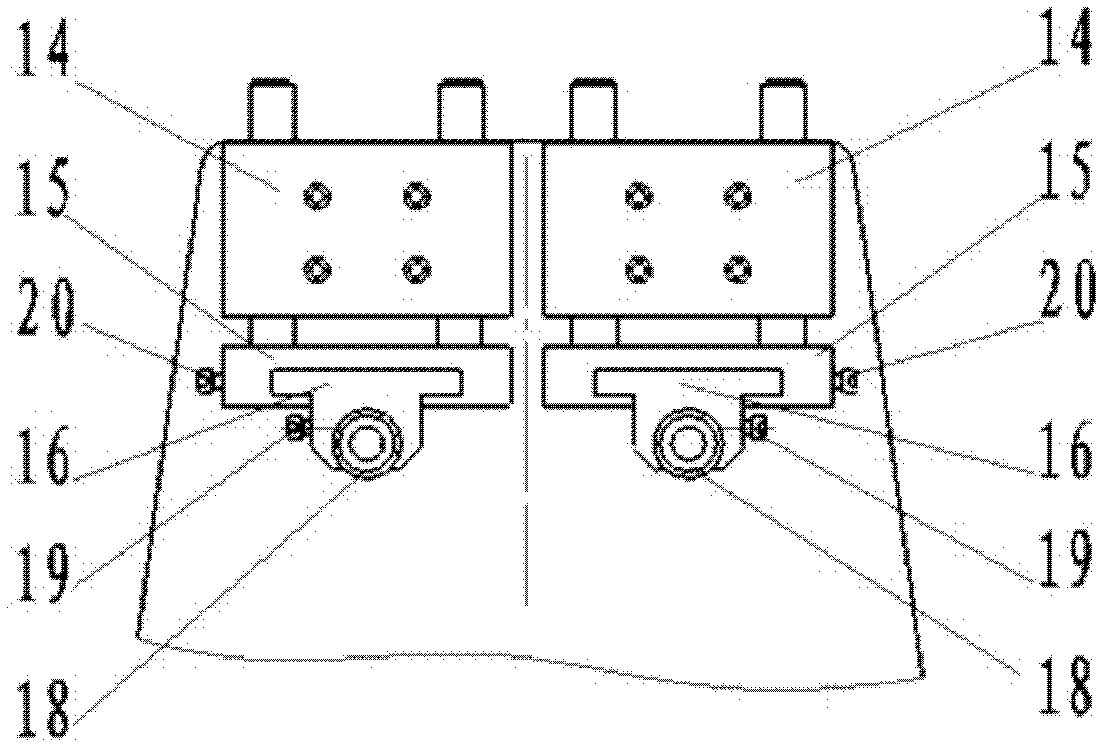

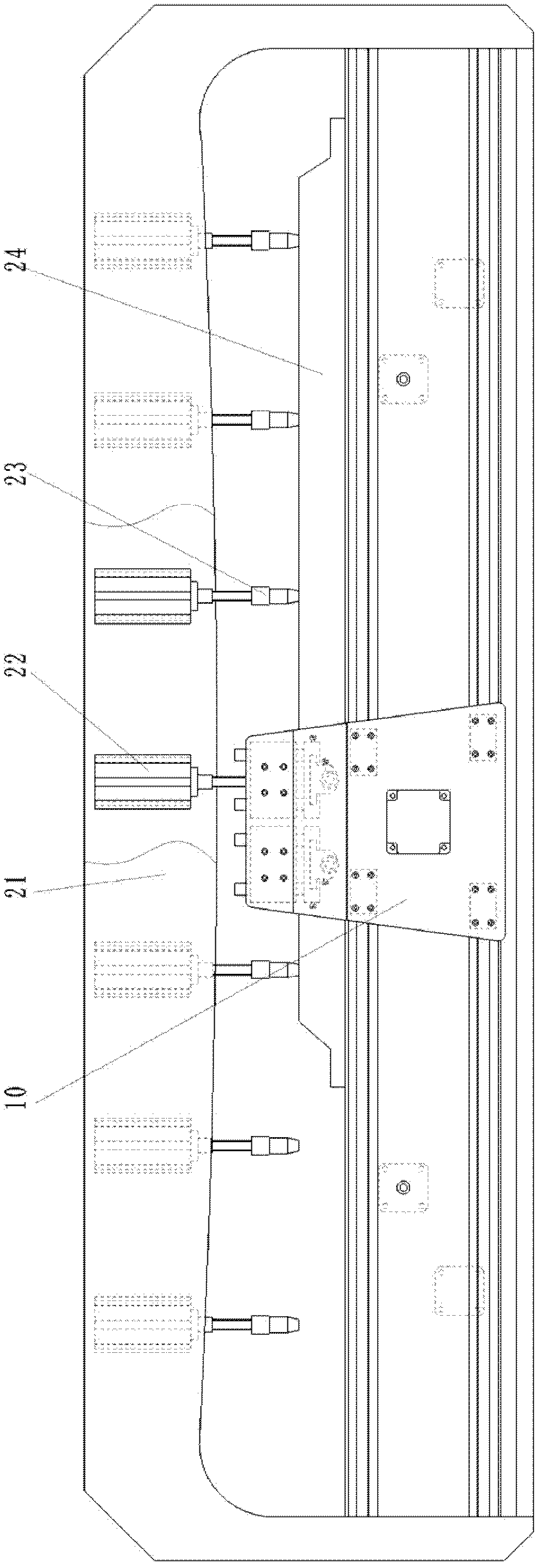

[0038] Such as figure 1 , figure 2 , image 3 As shown, they are respectively the side view of the structure schematic diagram of the flat card clothing machine tool of the present invention, the structure schematic diagram of the A-A plane and the front view.

[0039] A machine tool for covering card clothing, including a side pressing clamping device, a top pressing device, a pressing sliding table device and a pressing movement device, the two sides of the workpiece are clamped and fixed by the side pressing clamping device, and the two sides of the workpiece are fixed by the top pressing device The top of the workpiece is pressed and fixed, and the pressure movement during the process is realized by the pressure sliding table device, and the workpiece is processed by the pressure movement device, wherein, the base plate 1 is fixedly installed with a fixed support beam 2, and the mobile support The beam 3 is parallel to the fixed support beam 2 and can move relative to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com