Apparatus for forming pipe material

A tube and forming surface technology, applied in forging/pressing/hammer devices, forming tools, mechanical equipment, etc., can solve the problems of limited shape, large device volume, and uneven force, and achieve uniform forming pressure and reduce process. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

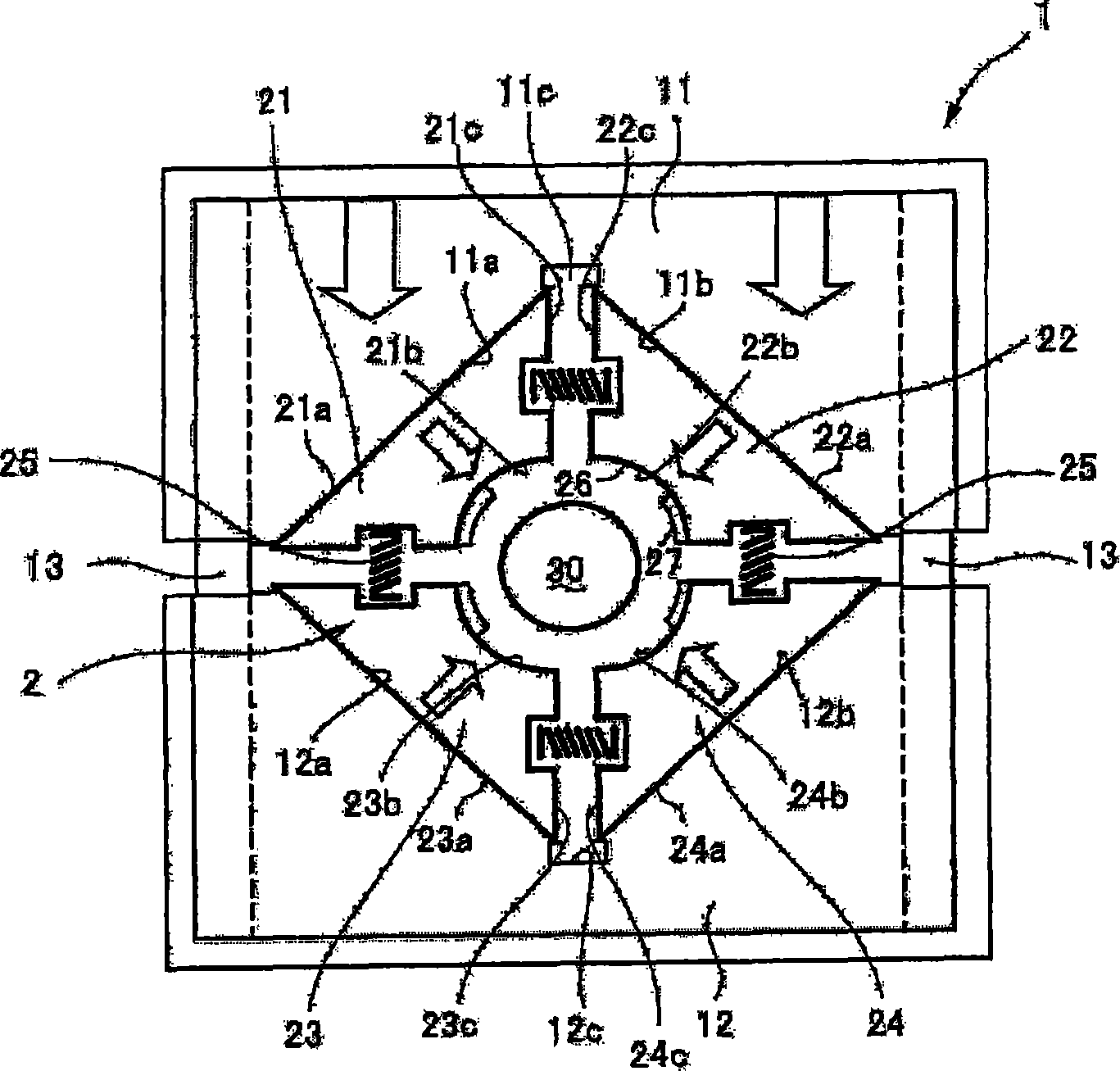

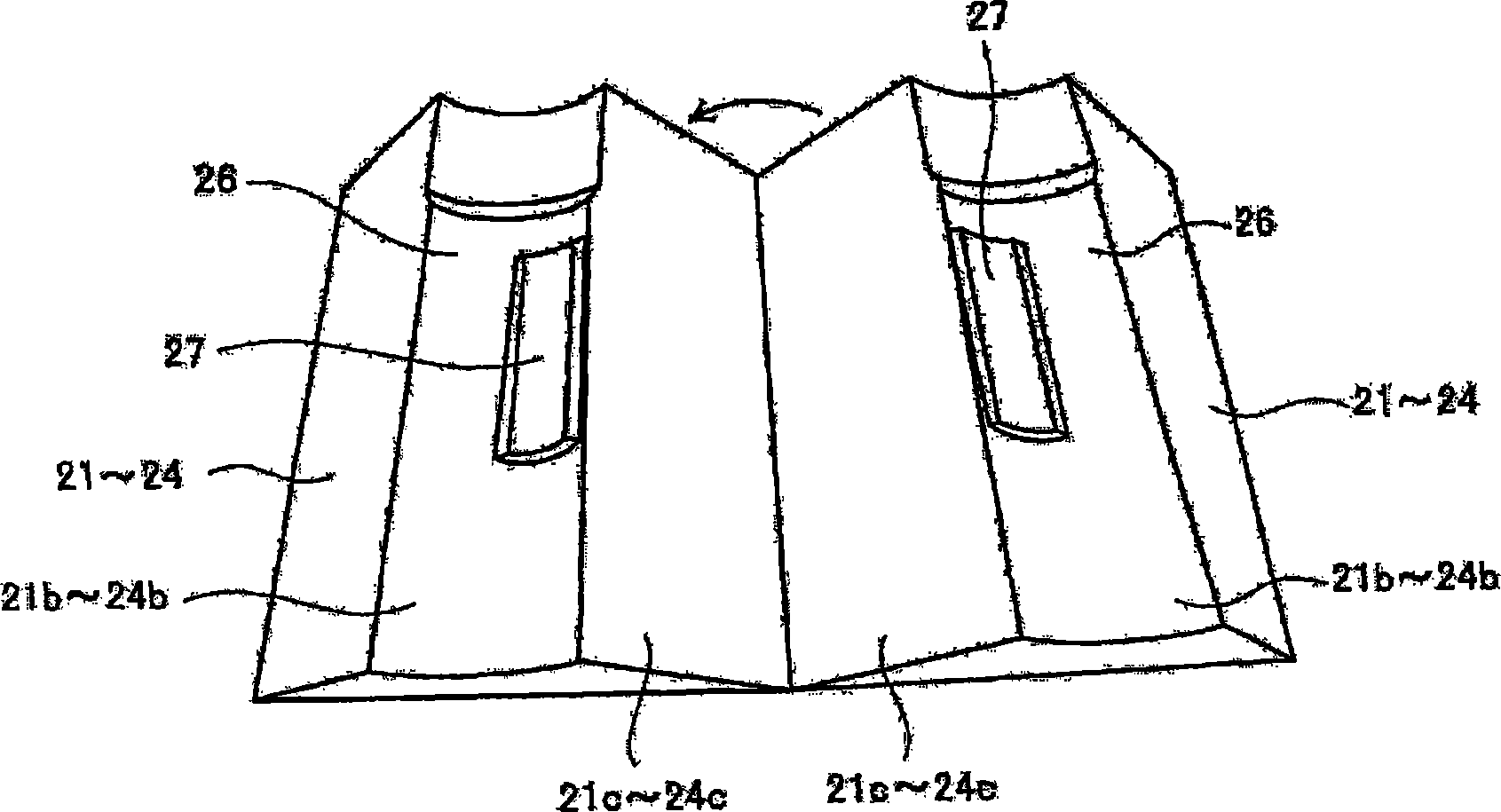

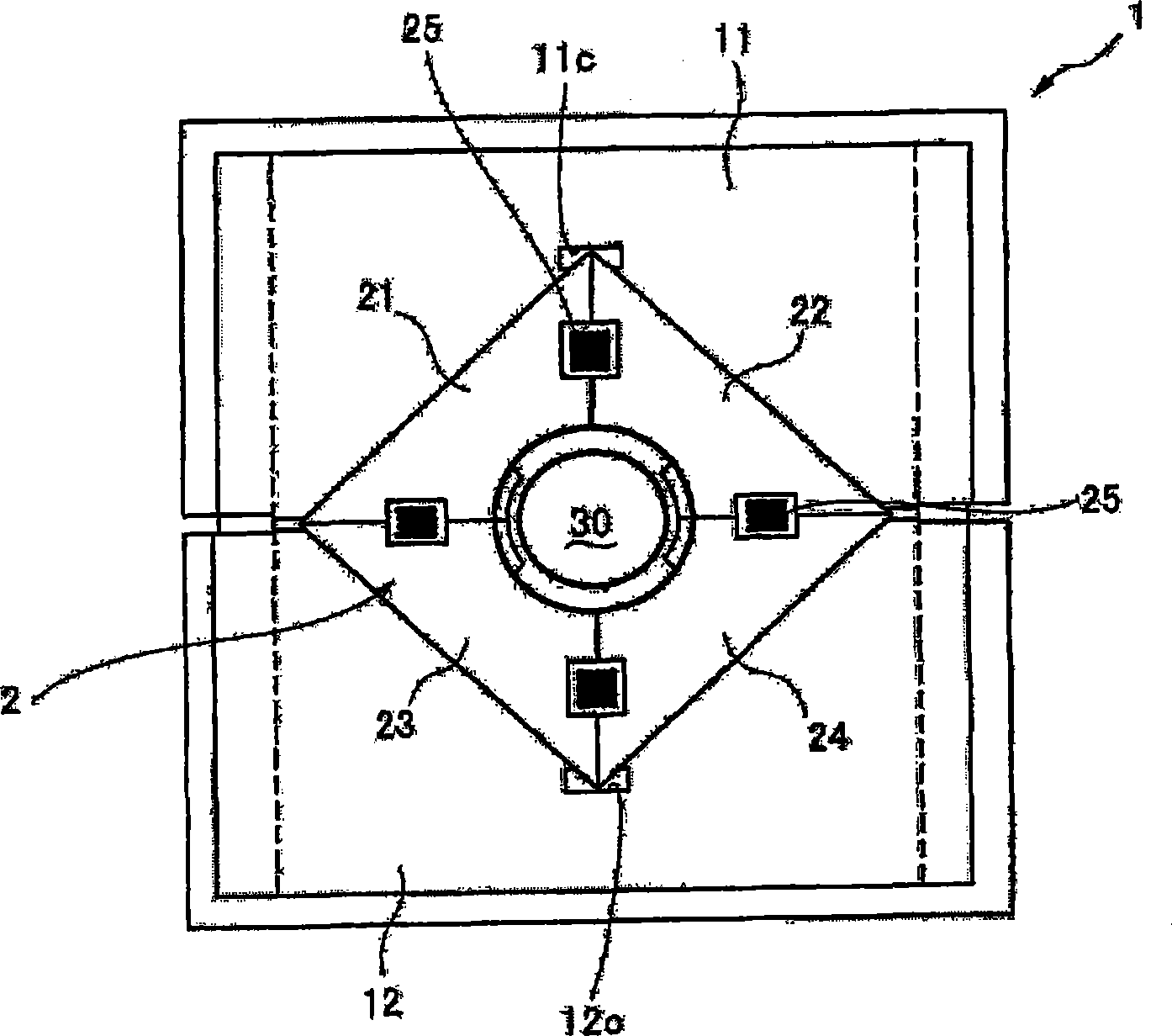

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. here, figure 1 It is a front view of the mold opening state of the forming apparatus of the present invention. figure 2 It is a perspective view of one of the four split molds constituting the inner mold of the molding apparatus. image 3 It is a front view of the mold-opening state of the molding device of the above-mentioned molding device. Figure 4 It is a view showing the end of the exhaust pipe after molding.

[0021] The forming device includes an outer mold 1 and an inner mold 2 . The outer mold 1 is composed of upper and lower split molds 11 and 12. The upper split mold 11 engages with the sliding member 13 and is driven by an unshown hydraulic cylinder or electric motor to move forward and backward relative to the lower split mold 12.

[0022] The smooth sliding surfaces 11a and 11b forming an inverted V-shape are formed und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com