Multi-piece rotation type equal-indexing machining workpiece overall clamping and rotating machining fixture

A technology of processing workpieces, clamping and rotating, applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems such as difficult to guarantee product processing quality, repeated non-value-added actions, severe vibration of the index plate, etc., to achieve Ensure consistency and speed, improve effective working time, precise processing and operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

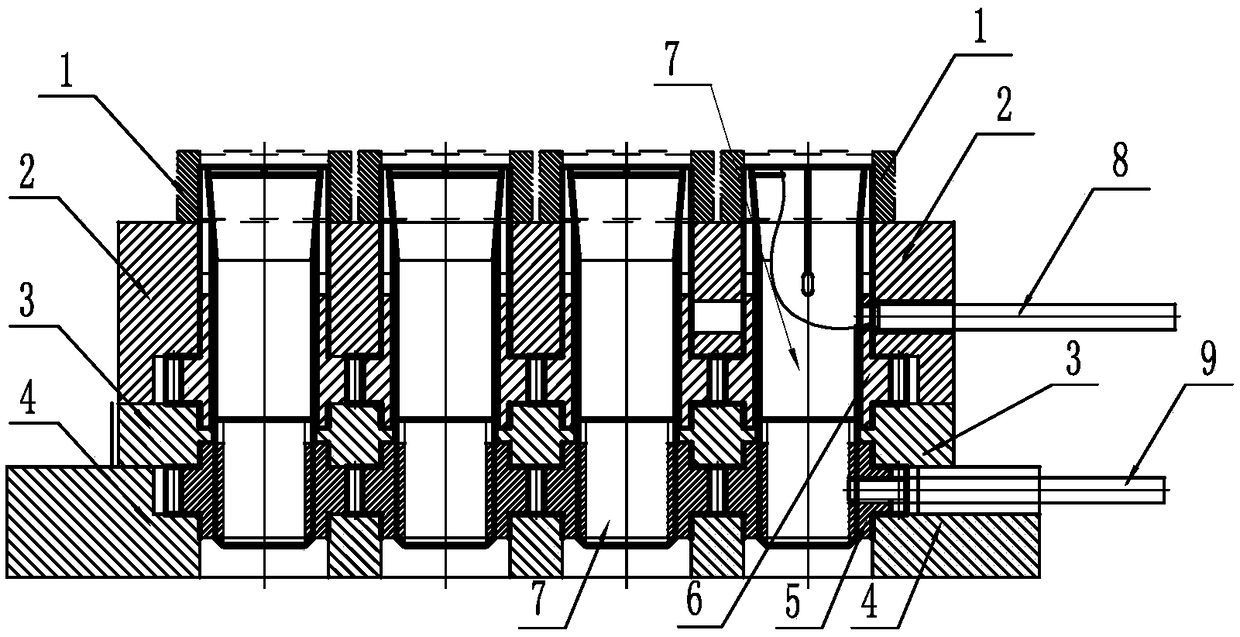

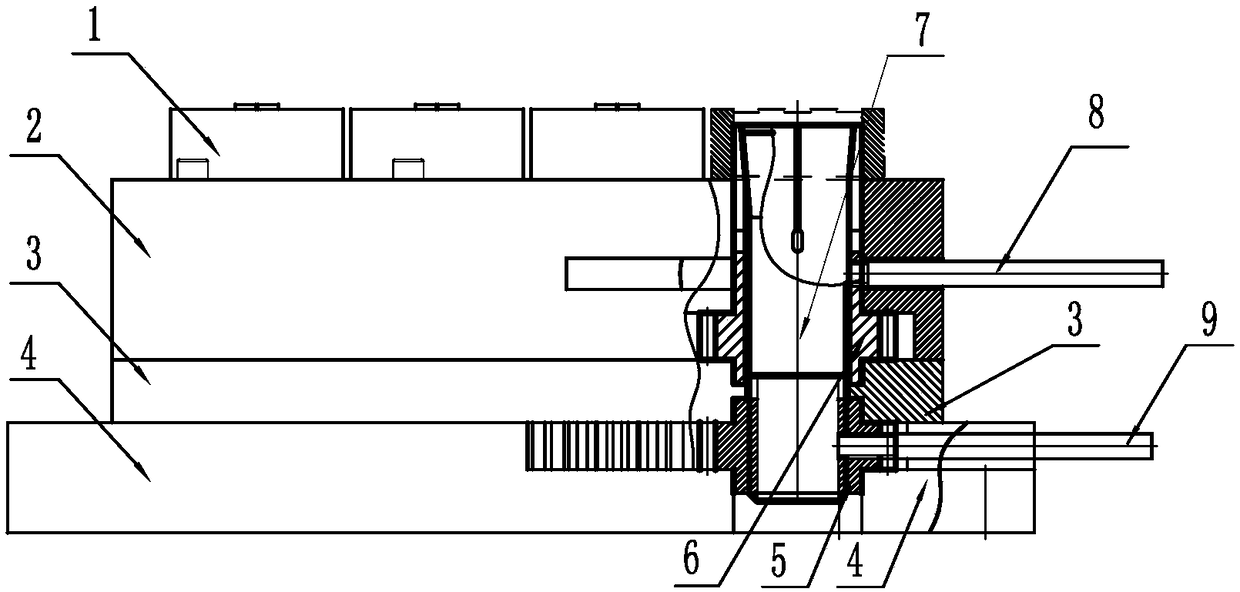

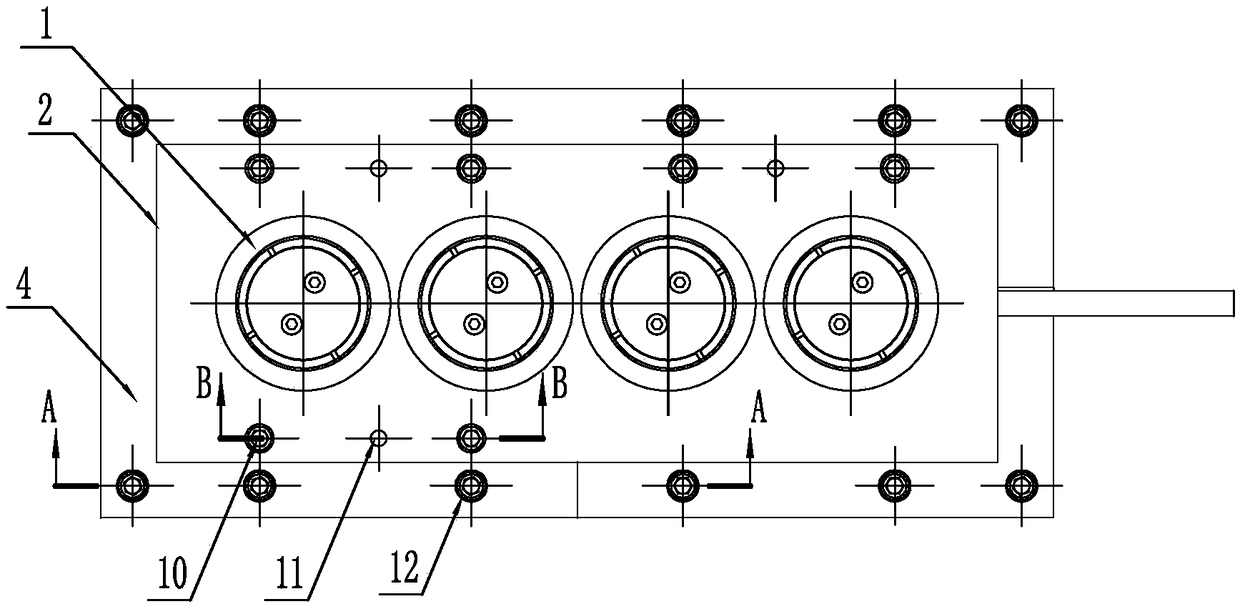

[0039] A multi-piece rotary equal indexing processing workpiece integral clamping rotary processing fixture, the fixture is used for rotary equal indexing processing workpieces that are clamped by geared expansion sleeves or clamped by expansion, including tooling base And the expansion device and steering mechanism installed in the tooling matrix;

[0040] The tooling base includes a bottom tooling body 4, a middle tooling body 3 and an upper tooling body 2 which are sequentially stacked and connected from bottom to top. The tooling base is provided with N mounting holes arranged side by side, and the mounting holes run through The bottom tooling body 4, the middle tooling body 3 and the upper tooling body 2 include the bottom hole, the middle hole and the upper hole. The bottom hole, the middle hole and the upper hole are respectively located in the bottom tooling body and the middle tooling body and upper tooling body;

[0041] The upper tooling body 2 located at the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com