Hot press molding method

A hot-press forming and forming temperature technology, applied in glass forming, glass re-molding, glass manufacturing equipment, etc., can solve the problems of pressing mold printing, X-shaped pattern, dark pattern, etc., and reduce the pressing mold printing. , The effect of improving the molding process and reducing the energy consumption of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

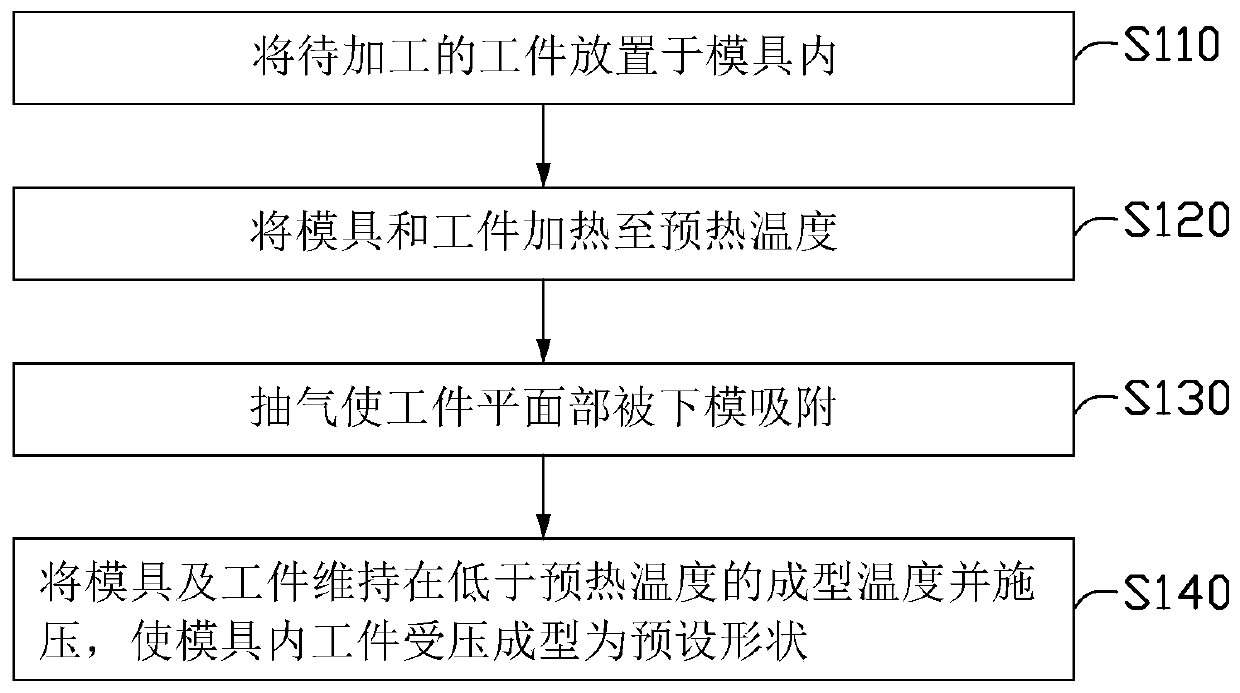

[0109] see figure 1 As shown, the present embodiment provides a method of thermocompression molding, including:

[0110] S110: placing the workpiece to be processed in the mold.

[0111] The workpiece includes a flat part of the workpiece and a part to be bent of the workpiece. When the workpiece is put into the mold, the flat part of the workpiece is in direct contact with the surface of the mold. When the workpiece is a planar workpiece, the part of the workpiece to be bent is the part that will be bent when the mold is pressed together, usually including the entire area of the edge of the workpiece or a part of the edge of the workpiece.

[0112] S120: heating the mold and the workpiece to a preheating temperature.

[0113] Among them, heating the mold and workpiece to the preheating temperature adopts infrared heating and electric heating to supply heat. During the preheating phase, the mold and the workpiece are usually heated together, because it is necessary to ens...

Embodiment 2

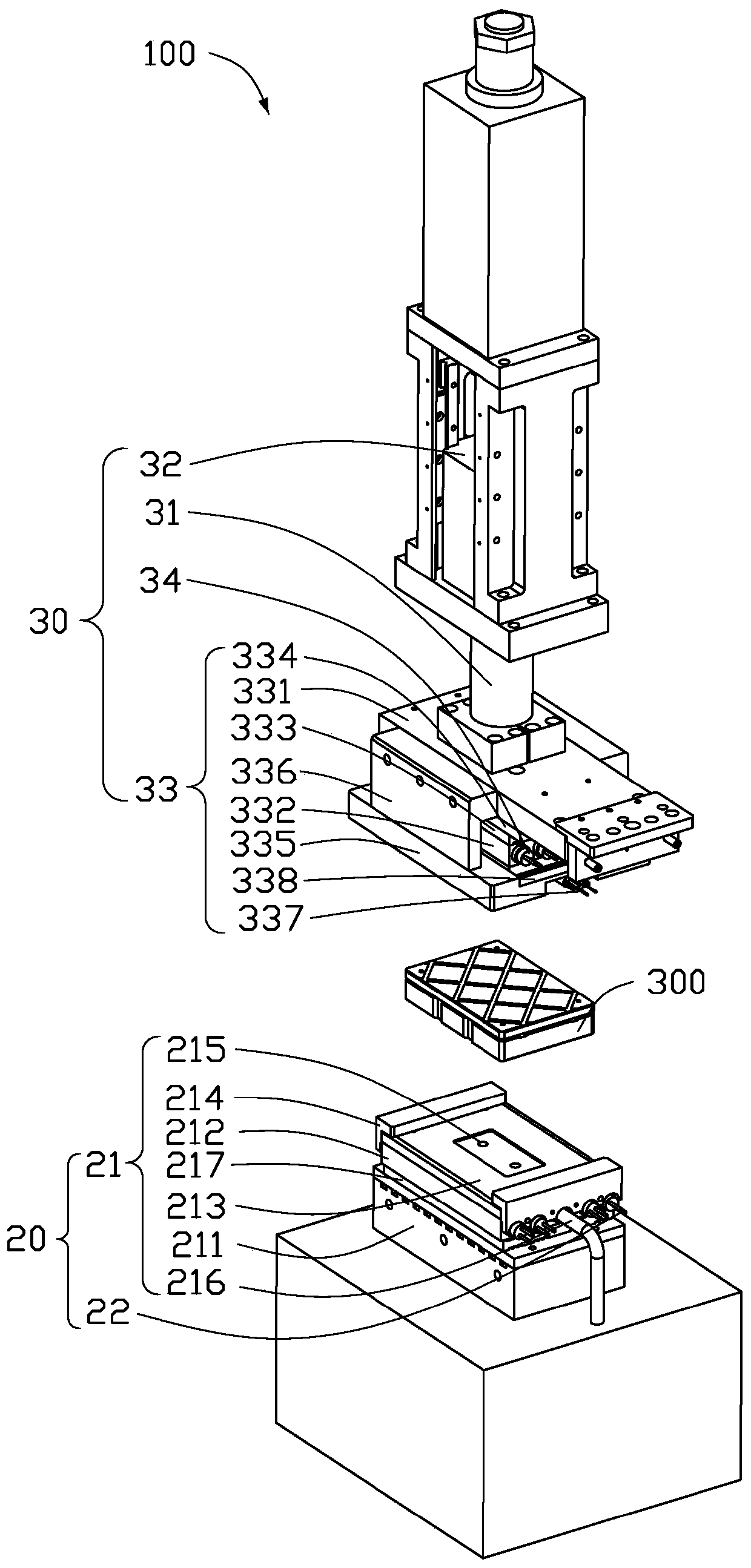

[0132] In another embodiment of the present invention, a kind of thermocompression forming method is provided, comprising the steps of:

[0133] S210: placing the workpiece to be processed in the mold.

[0134] The mold used in this embodiment includes an upper mold and a lower mold. The lower mold is provided with a boss for carrying the flat part of the workpiece, and the upper mold matched with the lower mold is provided with a cavity corresponding to the boss. The workpiece to be processed is placed on the boss of the lower mold in the mould. The workpiece includes a flat part of the workpiece and a part to be bent. The flat part of the workpiece is in direct contact with the upper surface of the boss in the lower mold. A receiving groove is provided in the lower mold, the boss is located in the receiving groove, and the groove formed by the boss and the side of the receiving groove forms a guiding groove for bending the workpiece.

[0135] In this embodiment, the workpie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com