Intelligent log cutting and sawing machine

A cutting saw and log technology, which is applied in the field of intelligent log sawing machine, can solve the problems of large floor area, low material yield, and large waste of boards, so as to improve the material yield, reduce material selection and stacking procedures , Reduce the effect of occupying the workshop area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

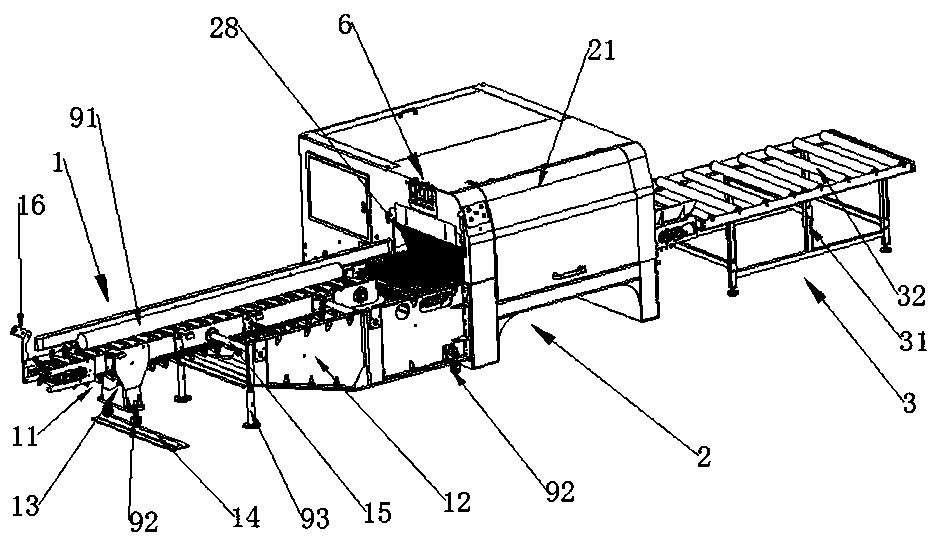

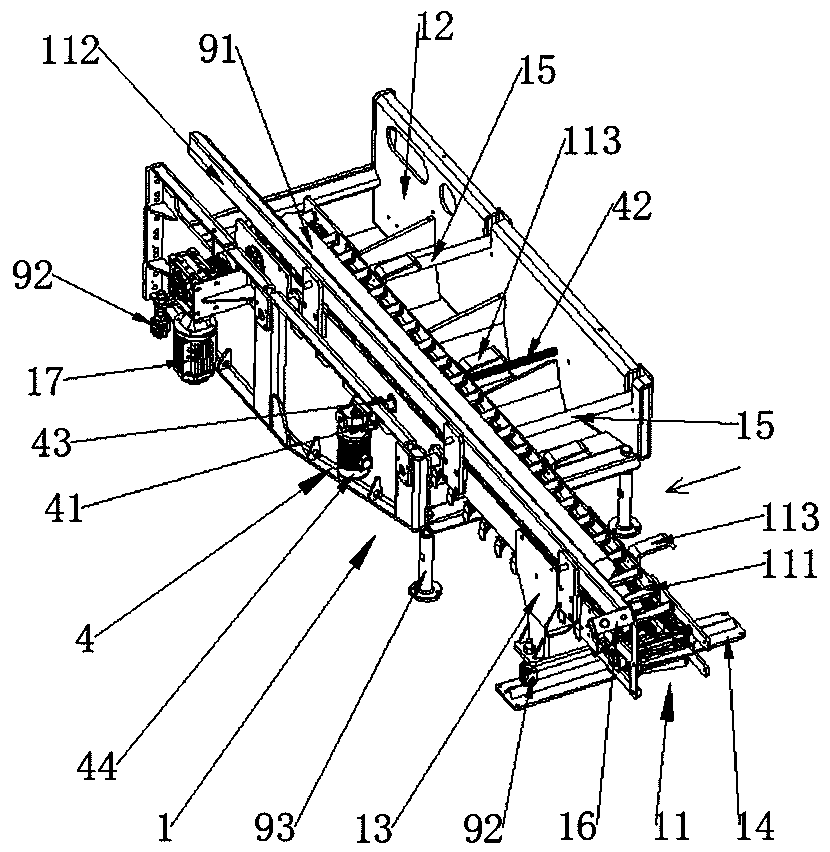

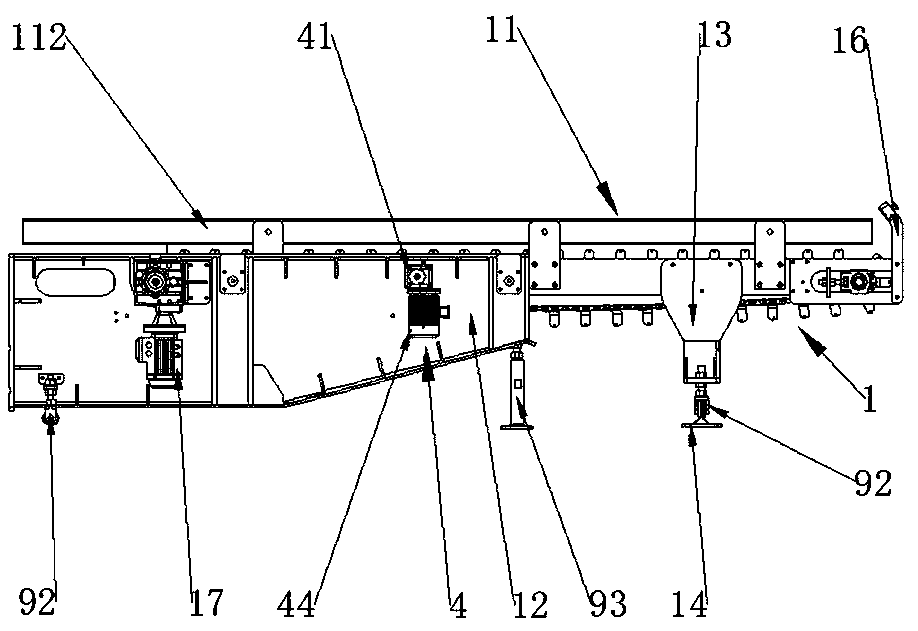

[0040] see Figure 1-16 , an intelligent log cutting saw machine, which includes a feeding and selecting device 1, a cutting machine 2, and a discharging device 3 from front to back; the feeding and selecting device 1 includes a feeding conveyor chain 11, arranged on the feeding The base 12 below the rear part of the material conveyor chain 11 and the feed motor 17 and distance adjustment mechanism 4 fixed on the base 12; the output shaft of the feed motor 17 and the driving sprocket of the feed conveyor chain 11 transmission connection; after a number of support rods 15 pass through the supports on both sides of the feed conveyor chain 11 along the width direction of the feed conveyor chain 11, the two ends are respectively fixed on the base 12; the cutting machine 2 includes a machine tool 21 and the electric control panel 211, feeding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com