Intelligent shuttling trolley applied to stacker

A stacker and trolley technology, which is applied in the field of intelligent shuttle trolleys, can solve the problems of inability to precisely control and remotely monitor the running and lifting dynamics of the shuttle trolley, inability to realize intelligent charging and multiple safety protection, and insufficiently compact structure design. Achieve the effect of improving the efficiency of storage operation and use of the three-dimensional warehouse, reducing the cost of equipment input, and improving the efficiency of operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

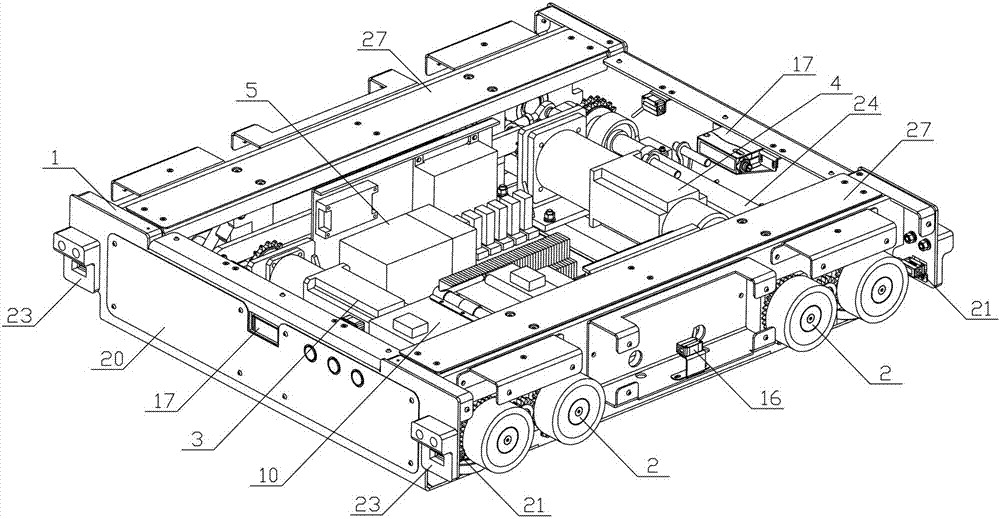

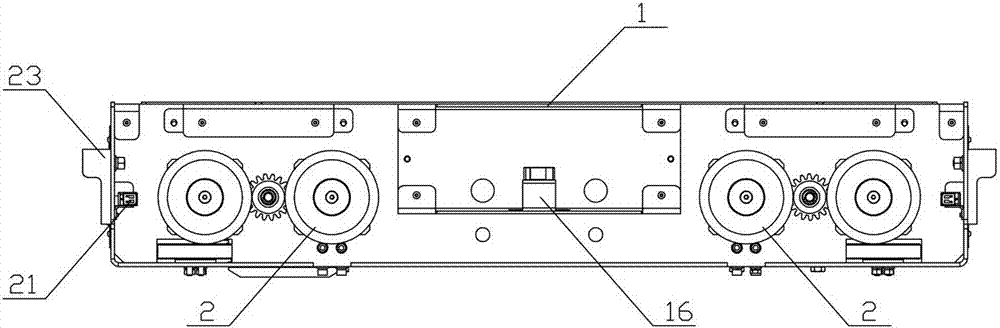

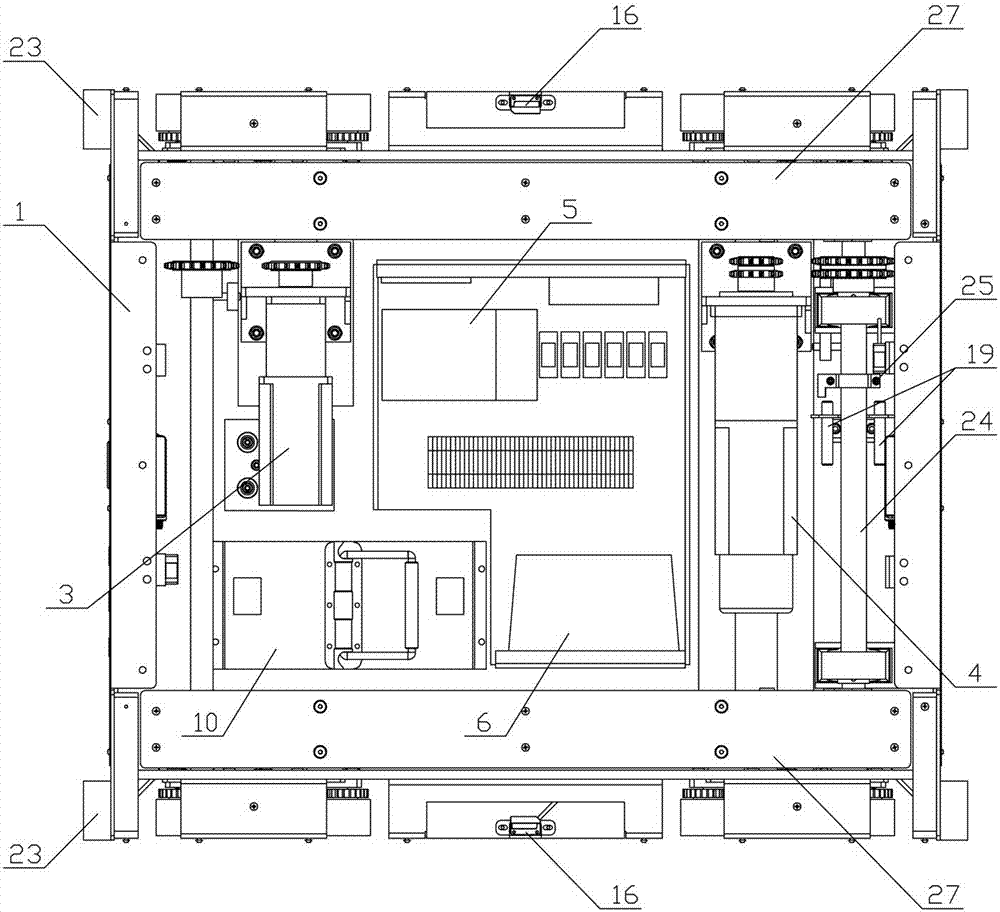

[0032] see Figure 1-5 , an intelligent shuttle trolley applied to a stacker, including a frame 1 and four sets of traveling wheels 2, a traveling motor 3, a lifting motor 4 and a lifting mechanism driven by the lifting motor 4 are installed in the frame 1, and the traveling motor 3 It forms a driving connection with one group of traveling wheels, and anti-collision devices are provided on the front and rear sides of the frame 1; a power distribution unit, a PLC controller 5, a servo driver 6, a wireless communication terminal 7, and a power distribution unit are installed in the frame 1. A wireless remote control terminal 8, and is equipped with a remote monitoring terminal 9 that matches the wireless remote control terminal 8;

[0033]The power distribution unit includes a rechargeable battery 10, a power detection unit 11 for real-time detection of the power of the rechargeable battery 10, a charging brush plate 12 that is arranged at the bottom of the vehicle frame 1 and i...

Embodiment 2

[0042] see Figure 7 , the present embodiment adopts a three-dimensional warehouse of an intelligent shuttle car applied to a stacker described in Embodiment 1, including an upper area 35, a lower area 36, and a stacker horizontally arranged between the upper and lower areas 35, 36 In the roadway 37, several unit shelves 38 arranged in an array are correspondingly arranged in the upper area 35 and the lower area 36, and a pallet 39 is arranged on each unit shelf 38; The stacker track 40 of the stacker 13; the unit shelf of each row in the upper and lower districts 35,36 is provided with the shuttle trolley track 41 for carrying the shuttle trolley 15; the right side of the upper and lower districts 35,36 is provided There is a row of fast lanes 42 for carrying shuttle cars 15 .

[0043] Depend on Figure 7 It can be seen that the stacker 13 is used as a transfer track for the shuttle car 15 to walk from the shuttle car track 41 of the upper area 35 to the corresponding l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com