Clamp for shaft parts and clamping device

A technology for shaft parts and clamping devices, applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems of affecting the total processing time, reducing production efficiency, short processing time, etc., and achieving a simple and practical structure. , High production efficiency, firm clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

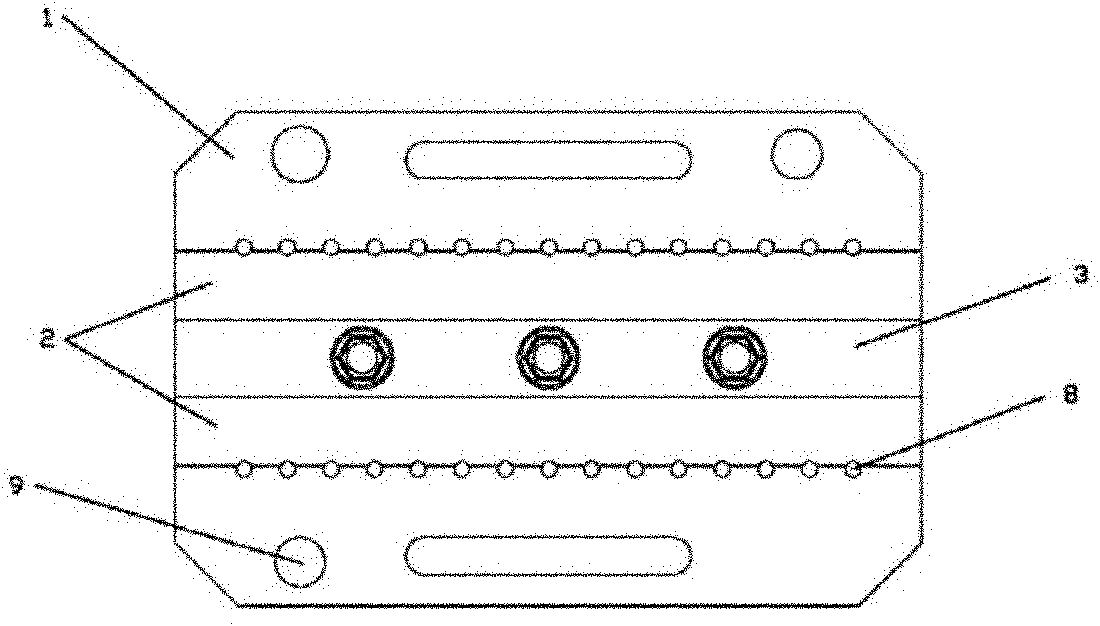

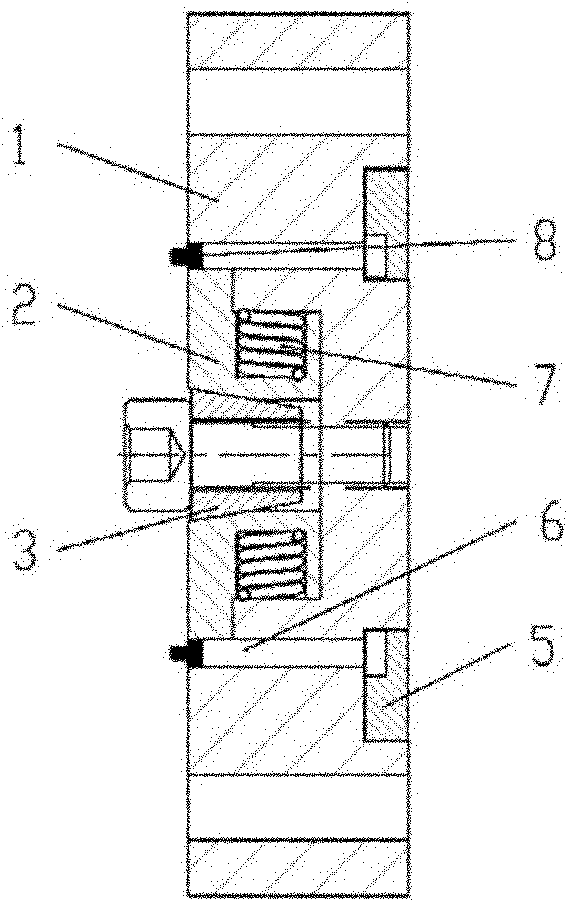

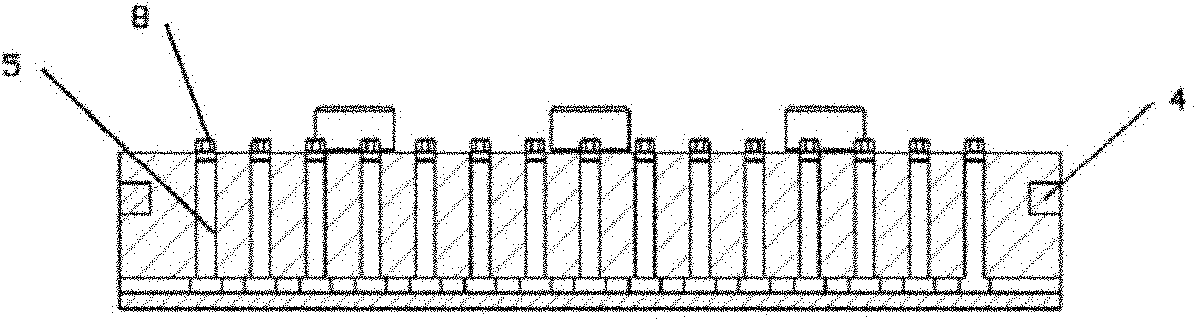

[0026] like figure 1 , 2 Said, a fixture for shaft parts, the fixture includes a positioning plate 1, a slider 2 installed in the chute of the positioning plate 1, a locking block 3 matched with the slider 2, so that The slide block 2 generates the return spring 7 of the reset force, and the workpiece 8 installed on the positioning plate 1 through the positioning pin 6; the slide block 2 is two and symmetrically distributed on the locking block one 3 and the locking block 3 directly or indirectly conflicts with the slider 2; the positioning pin 6 is fixedly installed in the positioning hole of the positioning plate 1 through the pressing block 5 Inside, the positioning pins 6 are multiple and distributed on both sides of the positioning plate 1. In this embodiment, the positioning pins are divided into two rows and evenly distributed on both sides of the positioning plate, and each There are fifteen positioning pins in a row, and the positioning pins are matched with the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com